Grade 23 Ti 6Al-4V ELI Titanium Alloy Plate Manufacturer - Daxun Alloy

As a leading supplier of titanium in China, Daxun provides high-performance titanium plates to the world.

- Plate Grade:Grade 23 USN R56401

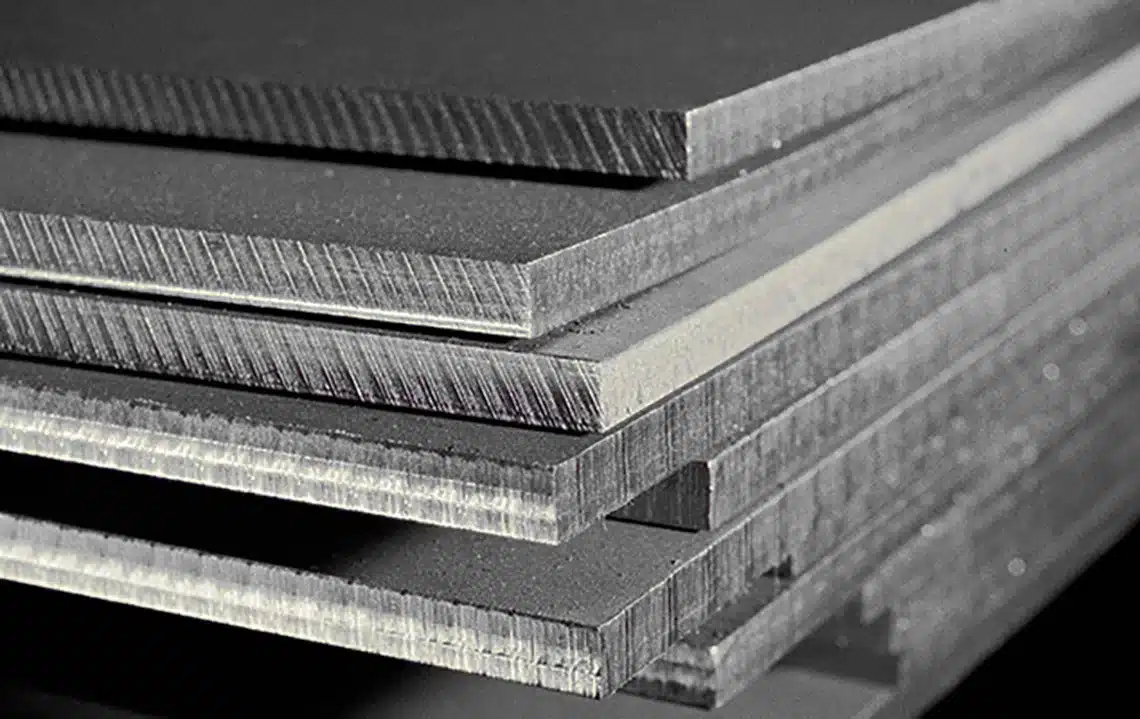

- Plate Production type:cold rolling, hot rolling, forging.

- Standard:ASTM B 265,ASME SB265,AMS491 etc

- Features:High strength, Lightweight, High-temperature resistance

- Surface:bright, polished, pickled, sandblasted, etc.

- Size:0.3mm ≤ 1000mm ≤ 2500mm or as your request

————Daxun produces titanium sheets in China to meet the diverse and ——demanding needs of customers!

Provide High Quality Grade 23 Titanium Plates to Customers Around The World

Grade 23 titanium plate is a commercial grade of Ti-6Al-4V ELI (Extra Low Interstitial). It is an improved alloy that further reduces the content of interstitial elements such as oxygen, iron, and nitrogen (such as oxygen content ≤ 0.13%) based on the classic Ti-6Al-4V (Grade 5). It is characterized by high strength, light weight, strong corrosion resistance, and is very friendly to the human body (high biocompatibility). This material is both strong and durable and can be used in various harsh environments, such as strong acids, strong alkalis, and seawater. It is not easily damaged. Its density is much smaller than that of steel, but its strength is close to that of steel, so it is often used to manufacture products that require both lightness and high durability.

Where is Grade 23 titanium plate used?

In the medical field, it is used to make artificial joints, bone fixation plates and dental implants because it is harmless to the human body and can be used for a long time without being easily damaged. It is also used to make key parts on aircraft and spacecraft, such as landing gear and engine parts, which can reduce weight and ensure strength. Chemical plants use it to make corrosion-resistant pipes and reactors, which can also be used for a long time in strong acid and alkali environments. In shipbuilding and marine engineering, it is used to make ship parts and seawater treatment equipment, and is not afraid of seawater corrosion. In addition, this material is also used in some parts of high-end sports equipment and nuclear power plants because it is both light and durable and can adapt to various extreme environments.

Data

- Parameter

| Element | Ti | Al | V | O | Fe | C | N | H | Other elements |

| Composition Range (wt.%) | >89% | 5.50 – 6.75% | 3.50 – 4.50% | ≤ 0.13% | ≤ 0.25% | ≤ 0.08% | ≤ 0.05% | ≤ 0.0125% | ≤ 0.4% |

Key Notes:

ELI (Extra Low Interstitial): Grade 23 has stricter limits on oxygen, nitrogen, hydrogen, and carbon compared to standard Grade 5 (Ti-6Al-4V) to enhance ductility and biocompatibility.

Primary alloying elements: Aluminum (Al) and vanadium (V) contribute to strength and phase stability.

Impurity control: Low iron, carbon, nitrogen, and hydrogen ensure superior corrosion resistance and fatigue performance.

Key performance:

High strength + high toughness: tensile strength can reach 895-930 MPa (annealed state), elongation ≥10%, better than ordinary Grade 5, suitable for scenes with dynamic loads.

Excellent corrosion resistance: acid resistance (such as hydrochloric acid, sulfuric acid), alkali resistance, seawater resistance, outstanding performance in medical implants and chemical equipment.

Biocompatibility: non-magnetic, non-toxic, excellent compatibility with human tissue, is the preferred material for orthopedic implants.

Processability: can be formed by forging, rolling, machining, welding performance is better than ordinary titanium alloy.

Choose Daxun to help your project take off.

Key Features

Grade 23 titanium alloy plate is the most commercially available of all titanium alloys. It combines high strength and toughness. Grade 23 can be cold drawn and extruded, but this process is generally limited to smaller industrial facilities and is more commonly applied to commercially pure grades.

Ti-6Al-4V ELI Grade 23 titanium alloy has good comprehensive properties:

- High strength

- Creep resistance

- Fatigue resistance

- Heat treatable

- Good ductility

- Good plasticity

- Good weldability

- Suitable for service temperatures -196°C-450°C

Common applications

Ti-6AL-4V ELI titanium plates and sheets are primarily used for components that demand superior corrosion resistance, high strength at elevated temperatures (400-450°C), as well as good ductility and lateral strength.

1. Applications include jet engine compressor blades, disks, and rings, fuselage components like wings and doors, turbine disks, bulkheads, military aircraft parts, engine nozzles, landing gear doors, and fuselage superplastic forming components.

2. Military applications include armor, guidance, shell casings, etc.

3. Spacecraft components, including rocket engines and heat shields, etc.

4. Medical and surgical instruments.

5. Sports equipment, including bicycle frames and golf clubs.

Custom Cutting

Daxun Alloy provides customers with customized cutting solutions of various sizes to help you control the size loss of titanium plates, thereby saving your processing costs and time. Our cutting methods include:

- Water jet cutting

- Laser cutting

- Plasma cutting

- Wire cutting

- Bending

- Slitting

- Sawing

Packaging

We pay special attention to packaging. We pack our goods in many ways depending on the product. We pack our products in many ways such as:

• Boxes and crates

• Shrinkwrap

• Wooden pallets

• Wooden boxes

Technical Support

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry.

Daxun Grade 23 Titanium sheet Let your brand improve rapidly

- Other Titanium Plate Grades

| Apart from the products listed below, other available metal products are not listed here. Other metal products DAXUN can manufacture and supply include Tantalum, Niobium, Zirconium, Hafnium, Nickel, Copper etc., which are mainly in the form of Plate, Bar and Tube. | |

| Products/Processing Standard | Grade/Size |

| Titanium Plate, Sheet, Coil— ASME SB265, AMS 4911, AMS 4919, AMS 4914,ASTM F67, ASTM F136 | GR1, GR2, GR3, GR4, GR5, GR7,GR9, GR12, GR16, GR17, GR23,Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3(Thickness:( 0.0197”-6”)Max Width: 12 feet,Max Length: 50 feet) |

| AMS-T-9046 | |

| Titanium and Titanium alloy sheet, plate | |

| Commercially pure titanium (CP) | |

| Code designation | Yield strength |

| minimum, ksi 1 / | |

| CP-1 Gr1 | 70 |

| CP-2 Gr2 | 55 |

| CP-3 Gr3 | 40 |

| CP-4 Gr4 | 25 |

| Alpha titanium alloys(A) | |

| Code designation | Composition |

| A-1 | 5A1-2.5Sn |

| A-2 | 5A1-2.5Sn(ELI) 2 / |

| A-3 | 6A1-2Cb-1Ta-0.8Mo |

| A-4 | 8A1-1Mo-1V |

| Alpha-beta titanium alloys(AB) | |

| Code designation | Composition |

| AB-1 Gr5 | 6A1-4V |

| AB-2 Gr5 | 6A1-4V(ELI) |

| AB-3 | 6A1-6V-2Sn |

| AB-4 | 6A1-2Sn-4Zr-2Mo |

| AB-5 | 3A1-2.5V |

| AB-6 | 8Mn |

| Beta titanium alloys(B) | |

| Code designation | Composition |

| B-1 | 13V-11Cr-3A1 |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3A1-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3A1 |

| Processing: | |

| Hot Rolling | Cold Rolling |

| Available Grades: | |

| CP Grade 1 | Grade 6Al-2Sn-4Zr-2Mo (6-2-4-2) |

| CP Grade 2 | Grade 6Al-4V ELI (Formerly Grade 23) |

| Grade 7 | Grade 6Al-6V-2Sn (6-62) |

| Grade 19 | Grade 8Al-1Mo-1V (8-1-1) |

| Grade 5 (6Al-4V) | Grade 9 (3Al-2.5V) |

| Grade 6 (5Al-2.5Sn) | CP Grade 3 |

| Application | |

| Chemical Industry | Desalination Of Sea Water |

| Petrochemical Industry | Aerospace |

| Machining Field, Automobile Field | Mobile Phone Component Field. |

Recent hot case projects and products

Related Products (6)

Grade 23 titanium (Ti-6Al-4V ELI) is an extra low interstitial version of the popular Grade 5 titanium alloy. It contains reduced levels of oxygen, nitrogen, carbon, and iron, which enhances its ductility and fracture toughness while maintaining excellent strength. This makes it particularly suitable for critical applications where reliability is paramount.

We supply Grade 23 titanium plates in thicknesses ranging from 0.5mm to 100mm, with standard widths of 1000mm, 1500mm, and 2000mm. Custom dimensions can be accommodated based on your specific project requirements. All our plates come with full material certification and traceability documentation.

Yes, all our Grade 23 titanium plates come with full material certification including chemical composition analysis, mechanical properties testing, and traceability to the original mill.

Our Grade 23 titanium plates undergo rigorous quality control including incoming material inspection, in-process monitoring, and final testing. We verify chemical composition, mechanical properties, surface quality, and dimensional accuracy. Additionally, we maintain comprehensive quality records and can accommodate third-party inspection if required by our customers.

Please fill in the form on the “Contact Us” page, or call our sales manager at “+86 13382898899”, we will contact you as soon as possible. Our WhatsApp is online, and email ([email protected]) will be checked within 6 hours. Every inquiry or message will be responded to promptly. In addition, we share market information with our customers every week

We can provide titanium sheet samples for you to check the quality. Sample is free and you just pay the freight.

We’ve exported to more than 42 countries, such as Canada, Chile, Kuwait, Germany, South Korea, Saudi Arabia, Singapore etc.

Trial orders can be delivered within a week. For regular orders, it takes two weeks roughly.