Precision Sawing - Tailored Metal Cutting Solutions

- Express Manufacturing Starting From 2 Days

- High-precision saw cutting services

- Stainless Steel plate, Titanium Alloy plate, Carbon Steel plate, Nickel Alloy plate, etc.

- Certifications & inspection reports

What is Sawing?

Sawing is a metalworking process that involves cutting and separating metal materials using a toothed tool (saw blade or saw band). This processing method is widely used in the steel manufacturing and metal fabrication industries, particularly suitable for cutting various types of metal bars, tubes, plates, and structural shapes.

The main characteristics of sawing include:

- High precision: Modern sawing equipment can achieve precise dimensional control, ensuring flat cutting surfaces with small tolerances.

- Wide material applicability: It can process various metal materials including stainless steel, carbon steel, titanium alloys, nickel alloys, and more.

- High efficiency: Compared to other cutting methods, sawing typically offers faster processing speeds, making it especially suitable for mass production.

- Minimal material waste: The narrow kerf of sawing maximizes material utilization and reduces material loss.

- Good surface quality: High-quality sawing produces relatively smooth cutting surfaces, reducing the need for subsequent processing.

In the metalworking industry, common sawing methods include band sawing, circular sawing, and hacksawing, each with its specific applications and advantages. For Daxun Alloy, providing professional sawing services can meet customers’ needs for precise and efficient metal cutting.

The choice of sawing blade is critical to achieving optimal results. Different blade materials, tooth configurations, and coatings are available to suit specific materials and cutting requirements. For instance, bi-metal blades with cobalt or carbide tips offer superior durability when cutting hard alloys, while specialized tooth geometries can reduce vibration and improve surface finish when cutting thin-walled tubes or profiles.

For Daxun Alloy, investing in state-of-the-art sawing technology represents a commitment to providing customers with the highest quality cut components. The combination of advanced equipment, skilled operators, and rigorous quality control processes ensures that each cut piece meets the precise requirements of industries ranging from aerospace and automotive to construction and manufacturing.

The main types of sawing

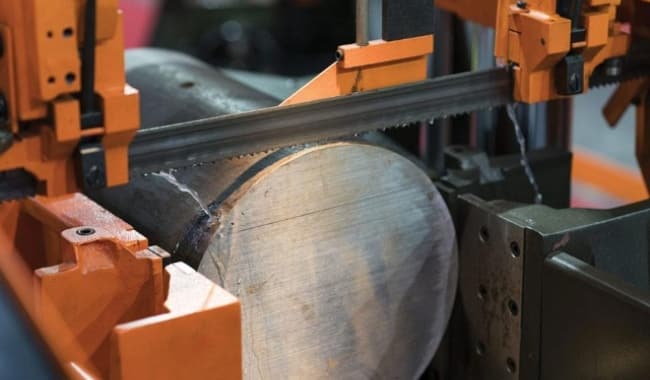

- Band Sawing: Uses a continuous metal band with teeth to cut through various materials. Ideal for straight cuts, irregular shapes, and large stock materials. Offers versatility and good material utilization.

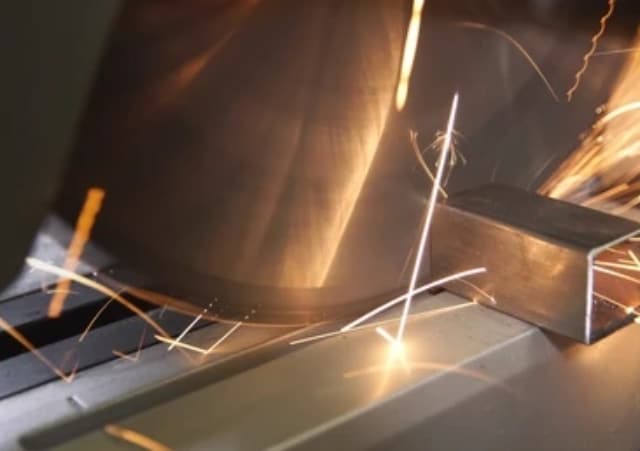

- Circular Sawing: Employs a rotating circular blade to make straight cuts. Known for its speed and precision, making it suitable for high-volume production of tubes, pipes, and solid bars.

- Cold Sawing: Utilizes a toothed blade that transfers heat to the chips rather than the workpiece. Produces clean, burr-free cuts with minimal heat-affected zones, preserving material properties.

- Hacksawing: A basic method using a reciprocating blade. While slower than other methods, it’s cost-effective for simple cutting tasks and smaller workshops.

The main advantages of sawing

- Precision: Sawing techniques deliver highly accurate cuts with tight tolerances, ensuring components meet exact specifications for your projects.

- Material Efficiency: Advanced sawing methods minimize material waste through narrow kerf widths and optimized cutting paths, reducing overall production costs.

- Versatility: Sawing can handle a wide range of materials including stainless steel, carbon steel, titanium, and various alloys that Daxun Alloy specializes in.

- Speed: Modern sawing equipment provides rapid cutting capabilities, significantly reducing production time and improving project turnaround.

- Surface Quality: Sawing produces clean, smooth cuts with minimal burrs, often eliminating the need for additional finishing processes.

- Heat Control: Cold sawing and other advanced techniques generate minimal heat, preserving the material’s original properties and preventing thermal distortion.

- Cost-Effectiveness: Sawing operations typically require less energy and maintenance compared to other cutting methods, offering excellent value for metal fabrication projects.

Sawing services can handle a wide range of metals including stainless steel, carbon steel, titanium, aluminum, and various specialized alloys that Daxun Alloy offers.

The maximum thickness depends on the specific sawing equipment used, but industrial sawing machines can typically handle materials from thin sheets up to 24 inches thick, depending on the material type.

While laser cutting offers extremely fine precision, modern sawing techniques provide excellent accuracy with tight tolerances suitable for most industrial applications, often at a lower cost per part.

Cold sawing produces virtually no heat-affected zone, maintains material integrity, creates minimal burrs, and delivers extremely clean cuts without altering the material’s properties.

To provide an accurate quote, we typically need the material type and grade, dimensions, thickness, required tolerances, quantity needed, and any specific finishing requirements.

Turnaround time varies based on project complexity, volume, and material specifications, but most standard sawing projects at Daxun Alloy are completed within 3-5 business days.

Yes, sawing is versatile enough to be cost-effective for both one-off prototypes and high-volume production runs, making it ideal for projects at any scale.