Grade 9 Ti-3Al-2.5V Titanium Alloy Pipe Manufacturer

As a leading supplier of titanium and titanium alloy tubes in China, Daxun provides high-performance titanium tubes to the world.

- Titanium tube Grade:Grade 9 – UNS R56320

- Titanium tube types:Seamless Ti tube, Ti welded tube, forged Ti tube

- Titanium tube density The density of grade 9 titanium is 4.48 g/cm3

- Standards:ASTM B381、AMS 4920、ASTM B265

- Softest Ti,High ductility, Very corrosion resistant, good cold formability

————Daxun produces titanium tubes in China to meet the diverse and ——demanding needs of customers!

Grade 9 Titanium Alloy Pipe Manufacturer - Daxun Alloy

Provide High Quality Grade 9 Titanium Pipe to Customers Around The World

Grade 9 titanium pipe is a versatile alpha-beta alloy (Ti-3Al-2.5V), offering an optimal balance between pure titanium’s formability and Grade 5’s strength. It features moderate strength, exceptional weldability, and outstanding corrosion resistance in diverse environments. Its density (4.48 g/cm³) is approximately 60% that of steel, yet it delivers strength comparable to some steels, making it ideal for weight-sensitive applications. The alloy excels in durability across harsh conditions, including seawater, chemical processing, and extreme temperatures, while maintaining excellent fracture toughness and fatigue resistance.

Where is Grade 9 titanium pipe used?

In aerospace, it’s used for hydraulic and fuel lines, ducting systems, and airframe components—reducing weight without sacrificing structural integrity. Chemical processing plants rely on it for heat exchangers, reactor tubing, and piping systems handling corrosive acids, alkalis, and chlorides due to its inertness. Marine and offshore industries use it for seawater cooling systems, desalination plants, and subsea equipment, leveraging its unparalleled seawater corrosion resistance. Oil and gas operations employ it in downhole tubing, risers, and Christmas tree components for high-pressure sour gas environments. Additionally, sports equipment manufacturers utilize it for high-performance bicycle frames, golf shafts, and racing components, where its strength-to-weight ratio and fatigue resistance are critical. It also serves in power generation (condenser tubing) and industrial heat transfer systems, combining longevity with thermal efficiency.

Key Performance:

Strength-Ductility Balance:

- Tensile Strength: 620 MPa (annealed state) – Lower than Grade 23 but 30% stronger than pure titanium (Grade 1-4).

- Elongation: ≥15% – Superior ductility vs. Grade 5 (≥10%), enabling complex forming and high fatigue resistance.

- Density: 4.48 g/cm³ – 60% lighter than steel, ideal for weight-sensitive applications.

Corrosion Resistance:

- Resists pitting/crevice corrosion in seawater, chlorides, and acidic/alkaline environments (e.g., HCl, H₂SO₄).

- Outperforms stainless steel in marine/chemical processing, with no galvanic corrosion risk.

Weldability & Processability:

- Welding: Exceptional compatibility with TIG, laser, and electron-beam welding – minimal post-weld cracking risk.

- Forming: Cold-workable into tubes, sheets, and complex shapes; machinability comparable to Grade 5.

- Heat Treatment: Stress-relieved at 480–650°C to optimize mechanical properties.

Application Advantages:

- Aerospace: Hydraulic tubing, ducting – weight reduction without sacrificing fatigue life.

- Marine: Heat exchangers, desalination plants – seawater immunity extends service life.

- Chemical: Reactors, piping systems – handles sour gas (H₂S) and strong acids.

- Industrial: High-pressure cylinders, sports equipment (bike frames, golf shafts) – lightweight durability.

Data

- Parameter

- Physical Properties

- Mechanical Properties

| Element | Composition Range (wt.%) |

|---|---|

| Ti | Balance (>90%) |

| Al | 2.50–3.50% |

| V | 2.00–3.00% |

| Fe | ≤0.25% |

| O | ≤0.13% |

| C | ≤0.08% |

| N | ≤0.03% |

| H | ≤0.015% |

| Other | ≤0.4% (single element) |

Key Characteristics

- Strength-to-Weight Ratio: Higher than pure titanium (Grades 1–4) but lower than Ti-6Al-4V (Grade 5).

- Corrosion Resistance: Excellent in marine, chemical, and chloride environments.

- Biocompatibility: Non-toxic and MRI-compatible, but less commonly used in implants than Grade 23.

- Formability: Superior to Grade 5; suitable for complex forming, welding, and machining.

Typical Applications

- Aerospace: Hydraulic tubing, aircraft fittings, fasteners.

- Marine: Heat exchangers, seawater components, propeller shafts.

- Medical: Surgical instruments, non-implantable devices.

- Industrial: Chemical processing equipment, pressure vessels.

| Property | Value (Imperial) | Value (Metric) |

|---|---|---|

| Density | 0.160 lb/in³ | 4.43 g/cm³ |

| Melting Point | 3,000–3,050°F | 1,650–1,680°C |

| Thermal Conductivity | 6.5 Btu/(hr·ft·°F) | 11.2 W/(m·K) |

| Coefficient of Thermal Expansion | 5.3 × 10⁻⁶/°F | 9.5 × 10⁻⁶/K |

| Electrical Resistivity | 120 µΩ·cm | 120 nΩ·m |

Room Temperature Properties (Annealed Condition)

| Property | Value (Imperial) | Value (Metric) |

|---|---|---|

| Tensile Strength | 130–140 ksi | 895–965 MPa |

| Yield Strength (0.2% offset) | 120–125 ksi | 825–860 MPa |

| Elongation | 10–15% | 10–15% |

| Reduction in Area | 25–30% | 25–30% |

| Hardness (Brinell) | 280–320 HB | 290–330 HBW |

| Modulus of Elasticity | 16.5 × 10⁶ psi | 114 GPa |

High-Temperature Performance

| Temperature (°F) | Tensile Strength (ksi) | Yield Strength (ksi) |

|---|---|---|

| 400°F (200°C) | 115–125 | 105–110 |

| 600°F (315°C) | 100–110 | 90–95 |

| 800°F (425°C) | 85–95 | 75–80 |

Choose Daxun to help your project take off.

Advanced Production:Titanium seamless pipe

Titanium seamless tubes are hot rolled or hot extruded, straightened, processed with inner and outer diameters, and surface etched. Tubes can be supplied in heat-treated or non-heat-treated forms. Daxun has 100% ultrasonic testing capabilities. Hot rolled tube/hot extruded titanium seamless tube: outer diameter 1.0 mm to 325 mm, wall thickness 0.3 mm to 50 mm, length up to 12000 mm. Cold rolled titanium seamless tube: cold processed tubes are supplied after heat treatment, surface etching, hydrostatic test or ultrasonic inspection according to the requirements of the manufacturing specification. Outer diameter 6 mm to 102 mm, wall thickness 0.5 mm to 20 mm, length up to 9000 mm.

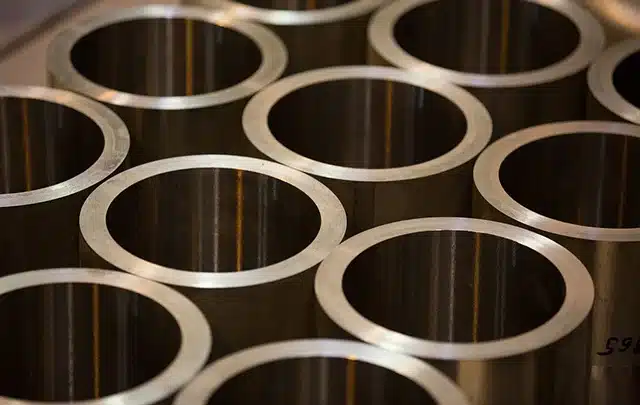

Advanced Production: Titanium Welded Tube

Titanium Welded Tube: Diameter ranges from 6.0mm to 1219mm, wall thickness ranges from 0.3mm to 30mm (depending on diameter), length up to 25000mm, made from Gr1 titanium tube. Welded tubes are made from flat rolled billets (tube blanks) on electric tube welding machines using automatic tungsten inert gas (argon) welding, and heat treated on the mill line. Mechanical tests, geometric measurements, 100% ultrasonic and eddy current testing, pneumatic or hydrostatic testing are performed before the finished titanium welded tubes are packaged according to customer specifications. Manufacturing technology as well as inspection and testing equipment ensure that thin wall welded tubes meet ASTM B 338 and ASME SB 338 specifications.

Test Reports

Our Grade 9 titanium tubing comes with an extensive range of certification and testing documentation tailored to meet your specific project requirements. We supply detailed material traceability records, comprehensive chemical composition analysis, and mechanical property certifications that demonstrate the exceptional performance characteristics of our titanium products. Each tube shipment includes quality assurance documentation covering dimensional verification, surface inspection reports, and welding procedure specifications when applicable.

Applications and standards

Titanium Grade 9 Pipes and Tubing are extensively applied in extremely corrosive conditions in the below Industries:

- Chemical processing parts such as heat exchangers, reaction vessels, evaporators and delivery pipelines, automotive exhaust, oil and gas industry, petrochemical plants, chemical plants, industrial machinery, power industry, paper and pulp industry, food processing industry, refineries, pharmaceutical and food processing equipment, etc.

- Specifications : ASTM B861, B862, B338 / ASME SB861, SB862, SB338

Standard : ASTM, ASME and API

Quality, delivery, inspection

Daxun performs several quality assurance tests, these tests include flattening test, flaring test, ultrasonic flaw detection test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the Grade 9 Titanium Welded Pipe and Grade 9 Titanium Seamless Pipe materials are suitable for the required application. During the production process, we measure the diameter, thickness and surface of the products. Our standard delivery time is 5-7 days and the delivery time for special size products is 15-20 days.

- Our delivery time is strictly in accordance with the contract.

- Support customer third-party agencies to go to the factory for inspection

- Support free samples for customer testing

- Support on-site or video factory inspection

Packaging

Daxun Alloy ensures the best quality of packaging as it plays an important role in international freight where goods go through various channels to reach the final destination, so we pay special attention to packaging. We pack our goods in many ways depending on the product. We pack our products in many ways such as:

• Boxes and crates

• Shrink wrap

• Wooden pallets

• Wooden boxes

Technical Support

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry. This, in our opinion, demonstrates our unwavering dedication to quality and our philosophy as a full-service supplier.

Daxun Grade 9 Titanium TUBE Let your brand improve rapidly

- Gallery

Grade 9 titanium tube form (4)

Recent hot case projects and products

Related Products (5)

While Grade 5 titanium offers higher strength, Grade 9 provides better formability, weldability, and corrosion resistance. Grade 9 is often preferred for tubing applications due to its excellent balance of properties and easier fabrication characteristics.

We offer Grade 9 titanium tubes in a wide range of outside diameters from 6mm to 120mm, with wall thicknesses from 0.5mm to 10mm. We can supply both seamless and welded tubes, with lengths up to 6 meters or as specified by customer requirements.

Yes, we can produce Grade 9 titanium tubes to your specific requirements including custom dimensions, special tolerances, unique tempers, and specific surface finishes. Please provide your technical specifications, and our engineering team will work with you to meet your exact needs.

All our Grade 9 titanium tubes undergo comprehensive quality control including dimensional checks, surface inspection, and mechanical testing. We provide complete material traceability and full documentation including chemical analysis, mechanical properties, and conformity certificates with every shipment.

At DAXUN, we offer a wide range of titanium alloy grades from grade 1 to grade 12.

Grades 1-4 are pure titanium, while higher grades are alloys.

Alloy grades are popular for their high strength-to-weight ratio.

The most commonly used titanium alloy grade we find is grade 5. While still high in titanium, this grade is one of the most reliable because it can withstand temperatures up to 600°F and withstand extreme conditions.

Higher grades are favored by industries such as aerospace and marine industries for their wear and corrosion resistance.

Conversely, lower grades are primarily used for welding due to their lower strength.

To learn more about the differences between different grades of titanium alloy, call +86 13382898899 today to speak directly with our experts.

While the grade of titanium does increase the cost slightly, the total cost is primarily determined by the shape and form of titanium you require.

At DAXUN, we offer a wide range of titanium products, including tubes, tubes, coils and bars. The length, width and quantity of each item you require will affect the amount you pay at checkout.

Unfortunately, it is difficult to come up with a price online without knowing much about your project and what the titanium will be used for.

Fortunately, our team of experts are always here to help and advise you on your titanium needs. By sending an email to [email protected], we will be able to get back to you with some advice and an accurate quote.

Make sure to include as much information as possible about the grade, shape and quantity of titanium you require to get a better understanding of your needs.

The team at DAXUN is experienced, knowledgeable, and friendly. With years of experience in the industry, they know all about titanium, including its uses, benefits, and grades.

For regular updates on titanium, its uses, and its applications across industries, be sure to check out our blog. Our experts have written easy-to-follow guides that you can always refer to when you have questions.

If you’re still having trouble, feel free to contact us; we’ll be happy to help.

By sending an email to [email protected], you’ll receive a quick response. Make sure to include as much detail as possible in your question so we can recommend a suitable solution.

We can provide stainless steel sheet samples for you to check the quality. Sample is free and you just pay the freight.

We’ve exported to more than 42 countries, such as Canada, Chile, Kuwait, Germany, South Korea, Saudi Arabia, Singapore etc.

Trial orders can be delivered within a week. For regular orders, it takes two weeks roughly.