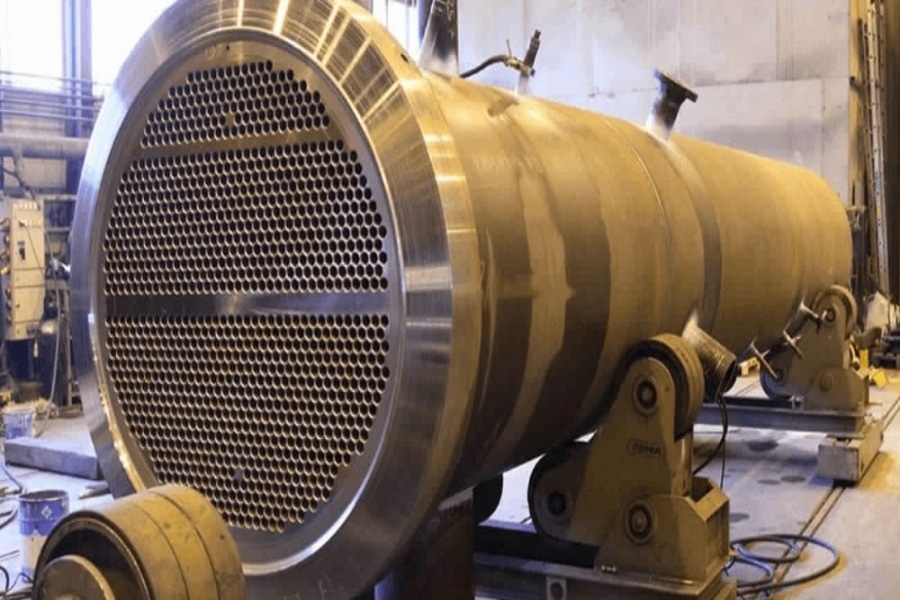

Titanium Shell and Tube Heat Exchanger

High quality titanium heat exchanger produced in China

- Titanium Grade: TA1、TA2、TA10、Gr.1、Gr.2

- Shell Diameter Range:DN50 – DN1200(2″ – 48″)

- Heat Transfer Area:0.5 – 500 m²

- Tube Length:0.5 – 6 m

- Design Pressure:0.6 – 4.0 MPa

- Design Temperature:-20℃ ~ 250℃

- Heat Transfer Coefficient:2000 – 5000 W/(m²·℃)

——Daxun produces titanium heat exchanger in China to meet the diverse and demanding needs of customers!

Basic Introduction of Titanium Heat Exchanger

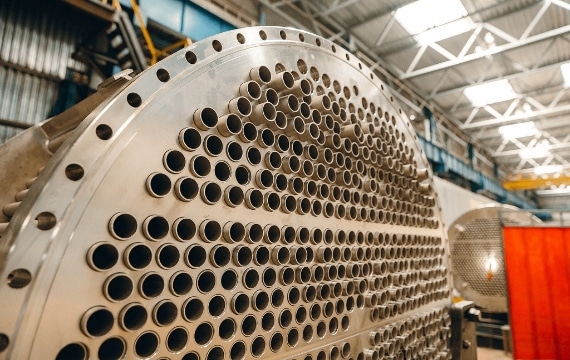

Titanium heat exchanger is a high-efficiency heat exchange equipment made of high-quality titanium tubes. It is a device that transfers heat from one heat carrier medium to another. It is usually composed of tube bundles, shells, tube sheets and heads. The tube bundle is made of titanium metal and is used to guide fluid flow and exchange heat; the shell wraps the tube bundle to provide structural support and protection for the heat exchanger; the tube sheet is used to fix the tube bundle and separate the fluid channels to ensure that the fluid flows in an orderly manner in the heat exchanger; some heat exchangers are also equipped with baffles, which are set in the shell to change the flow direction of the fluid and enhance the heat exchange effect.

Working Principle

Based on the basic principle of heat transfer, two fluids of different temperatures flow in the internal channel of the titanium heat exchanger. The hot fluid flows through the tube bundle or channel of the titanium heat exchanger, transferring heat to the titanium alloy wall; the cold fluid flows through the channel on the other side, absorbing the heat transferred by the titanium alloy wall, thereby achieving heat exchange. Although the thermal conductivity of titanium is lower than that of traditional materials such as copper, the heat exchange efficiency can be improved by optimizing the arrangement of the tube bundle and adding baffles. Under high temperature conditions, titanium can maintain stable physical properties without deformation or failure, ensuring the efficient operation of the heat exchanger.

Titanium Heat Exchanger Parameter Table

| Material Specifications | Titanium Grade | TA1、TA2、TA10、Gr.1、Gr.2 |

| Shell Thickness | 3 – 10 mm | |

| Tube Specification | Φ10×0.5 – Φ38×2 mm | |

| Geometric Dimensions | Shell Diameter Range | DN50 – DN1200(2″ – 48″) |

| Heat Transfer Area | 0.5 – 500 m² | |

| Tube Length | 0.5 – 6 m | |

| Performance Parameters | Design Pressure | 0.6 – 4.0 MPa |

| Design Temperature | -20℃ ~ 250℃ | |

| Heat Transfer Coefficient | 2000 – 5000 W/(m²·℃) | |

| Pressure Drop | Tube side: 0.01 – 0.1 MPaShell side: 0.005 – 0.05 MPa | |

| Manufacturing Standards | GB 151, GB/T 14976,ASME VIII, EN 13445 | |

| Cleaning Interval | 6 – 24 months | |

| Service Life | 10 – 20 years |

Characteristics of Titanium Heat Exchanger

Strong corrosion resistance

Titanium exhibits good corrosion resistance in a variety of industrial solutions. Industrial pure titanium can be widely used in organic compounds, alkaline solutions, and salt solutions, and is not easy to react with them. For example, in highly corrosive environments such as sulfuric acid production and chlor-alkali industry, as well as marine environments (seawater desalination, marine platform cooling, etc.), it can effectively resist corrosion and reduce equipment damage and maintenance costs caused by corrosion.

High heat transfer efficiency

Although the thermal conductivity of titanium is lower than that of traditional heat exchanger materials such as copper, titanium heat exchangers can achieve excellent heat conduction effects through reasonable design (such as optimizing tube bundle arrangement, adding baffles, etc.) and efficient production processes. Its heat transfer coefficient is 30% to 50% higher than that of tubular heat exchangers, and the heat recovery rate can reach 90%. Especially under high temperature conditions, titanium can maintain stable physical properties without deformation or failure, which greatly improves the safety and service life of the heat exchanger.

Compact structure

The density of titanium is about 60% of that of steel, which makes the titanium heat exchanger have low density and high strength. While ensuring strength, it reduces the weight and volume of the equipment, occupies a small area, and is easy to install and maintain. Compared with other types of heat exchangers, it has a smaller volume and lighter weight under the same heat exchange area.

Low maintenance cost

The titanium surface is not easy to scale, which reduces the frequency of cleaning and maintenance. In addition, some types of titanium heat exchangers (such as detachable ones) are easy to clean and maintain, reducing the time and cost of downtime for maintenance. At the same time, due to the strong corrosion resistance of titanium, the service life of the equipment is long, and the maintenance cost during use is relatively low.

Non-magnetic characteristics

Metal ions are not easily lost, and this non-magnetic characteristic can be fully utilized to be used as a heat exchanger for pharmaceutical and food purposes, meeting the strict requirements of these industries for equipment material safety and hygiene.

Application of Titanium Heat Exchanger

- With the various excellent properties of industrial pure titanium, titanium heat exchangers are widely used in the following industries and fields:

1. Chemical industry: It can be used for heat exchange processes in highly corrosive environments, such as sulfuric acid production, chlor-alkali industry, etc. It can also be used for high-temperature and high-pressure chemical media processing to ensure the stability and safety of the production process.

2. Oil and gas industry: It provides reliable heat exchange solutions in processes such as oil refining, oil and gas separation, oil field water injection, seawater desalination, pipeline distillation, etc., and can also resist seawater corrosion in offshore oil production.

3. Marine engineering field: It is used in the heat exchange process in seawater desalination equipment, as well as the cooling system and heat exchange process in offshore platform equipment to resist seawater corrosion and the attachment of marine organisms.

4. Food processing industry: It is used in processes such as fruit juice sterilization and cooling, animal and vegetable oil heating and cooling, etc., to maintain the sanitary quality of food, avoid pollution and odor, and meet the sanitary standards of food processing.

5. Pharmaceutical industry: It is used in heat exchange and cooling processes in the production of drugs. Its corrosion resistance and easy cleaning can ensure the purity and safety of drugs.

6. Metallurgical industry: In the process of heating or cooling aluminate mother liquor, cooling steelmaking process, etc., it can withstand high temperature and corrosive environment to ensure the stable operation of metallurgical process.

7. Refrigeration industry: It can be used as condenser and evaporator in refrigeration system to realize the condensation and evaporation process of refrigerant.

8. Light industry, electroplating, salt making, paper making, ultrasonic, electronic communication, central heating and other industries: In these fields, titanium heat exchanger provides strong support for the production of enterprises with its excellent performance.

Related Products (3)

Daxun is a trustworthy titanium products manufacturer in the titanium industry

Daxun is a professional manufacturer committed to high-quality products. We ensure all our titanium plates meet international standards. This includes certifications from ISO9001, SGS, CE, and OQC. Our strict quality control process minimizes defects.

When you choose Daxun, you’re guaranteed durable products. Our titanium plates offer excellent performance. You can trust in the quality of everything we produce.

The grade of titanium alloy you need depends on the project you are working on, as each grade has different benefits.

All grades of titanium alloy are extremely strong and corrosion-resistant, which means they will continue to work well even in the harshest conditions.

The higher grades of titanium alloy (5-12) are alloys designed for specific benefits. It also knows as beta alloyes for different usage like metal support in human body. For example, grade 12 titanium alloy has excellent heat resistance, making it a perfect choice for shell and tube heat exchangers, hydraulic piping, and chemical industry equipment.

Grades 1-4 are pure titanium grades, and they are a perfect choice if you need a weldable, ductile material for piping systems and tubing.

When considerding titanium grades, the common physcial properties are heat treatment, fracture toughness, thermal conductivity, mechanical properties, tensile strength and yield strength. Also, we need to understand application to help you to archive your goal.

If you are starting a project and are unsure which grade is best for you, contact us now; we are more than happy to help you.

Titanium Gerades as known as commercially pure titanium and titanium alloys grade level.

At DAXUN, we offer a wide range of titanium alloy grades from grade 1 to grade 18.

Grades 1-4 are pure titanium, while higher grades are alloys. Alloy grades are popular for their high strength-to-weight ratio.

The most commonly used titanium alloy grades is grade 5 (ti 6al 4v). From grade 5, it combines with different metals together, like aluminum and iron. These excellent combination extends the excellent weldability and high temperature creep strength.

Higher grades are favored by industries such as aerospace and marine industries for their wear and corrosion resistance.

To learn more about the differences between different grades of titanium alloy, call +86 13382898899 today to speak directly with our experts.

The team at DAXUN is experienced, knowledgeable, and friendly. With years of experience in the industry, they know all about titanium, including its uses, benefits, and grades.

For regular updates on titanium, its uses, and its applications across industries, be sure to check out our blog. Our experts have written easy-to-follow posts that you can always refer to.

By sending an email to [email protected], you’ll receive a quick response.

Please fill in the form on the “Contact Us” page, or call our sales manager at “+86 13382898899”, we will contact you as soon as possible. Our WhatsApp is online, and email ([email protected]) will be checked within 6 hours. Every inquiry or message will be responded to promptly. In addition, we share market information with our customers every week.

Titanium alloys are a blend of titanium and other chemical elements, designed to offer exceptional tensile strength and toughness, even under extreme temperatures. These alloys are lightweight, exhibit extraordinary corrosion resistance, and can endure high temperatures, making them indispensable in various industries. From aerospace and aircraft to medical devices and jewelry, titanium alloys are integral to many high-stress applications.

Commercially pure titanium, known for its acceptable mechanical properties, is often used in orthopedic and dental implants. The most common titanium alloy, Ti 6Al 4V, includes small amounts of aluminum and vanadium (6% and 4% by weight, respectively). This combination allows for precipitation strengthening, enhancing the alloy’s mechanical properties. Whether in the form of alpha alloys, beta alloys, or alpha-beta alloys, titanium alloys continue to be a cornerstone in industries requiring materials that offer both strength and corrosion resistance.