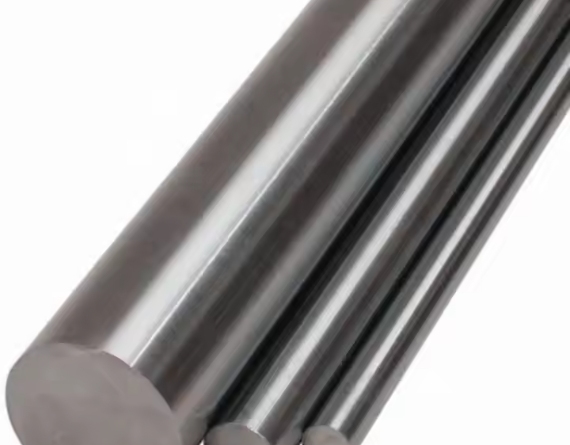

Daxun is an excellent manufacturer of grade 9 (Ti-3Al-2.5V) titanium rods and bars.

As China’s leading supplier of titanium and titanium alloy rods, Daxun provides high-performance titanium rods to the world.

- Titanium bar grade: Grade 9 UNS R56320

- Titanium bar types: rolled bars, drawn bars, forged titanium bars

- Titanium bar density The density of Grade 9 titanium is 4.48 g/cm3

- Main standards: ASTM ASME GB GJB EN JIS DIN ISO ATP BS, etc.

- High strength, high temperature resistance, corrosion resistance, light

- weight, excellent comprehensive performance.

————Daxun produces titanium rods in China to meet the diverse and ——demanding needs of customers!

The global leader in commercially pure titanium rod manufacturing services

Grade 9 Titanium Alloy Rod Manufacturer – Daxun Alloy

Providing High-Quality Grade 9 Titanium Rods to Customers Worldwide

Grade 9 titanium rod is a versatile alpha-beta alloy (Ti-3Al-2.5V), offering an optimal balance between pure titanium’s formability and Grade 5’s strength. It features moderate strength, exceptional weldability, and outstanding corrosion resistance in diverse environments. Its density (4.48 g/cm³) is approximately 60% that of steel, yet it delivers strength comparable to some steels, making it ideal for weight-sensitive applications. The alloy excels in aerospace components, fasteners, and structural parts due to its high strength-to-weight ratio and fatigue resistance.

Key Applications:

Aerospace & Defense: Used in hydraulic systems, fasteners, and airframe structures where lightweight durability is critical.

Industrial Machinery: Employed in high-strength fasteners (e.g., Grade 9 nuts) for heavy equipment like earth-moving machinery, offering 20% higher strength than standard steel fasteners.

Marine & Chemical: Resists seawater and chemical corrosion in pump shafts, valve components, and subsea hardware.

Medical & Sports: Utilized in biocompatible implants and high-performance sports equipment (e.g., bicycle components) for its fatigue resistance and low density.

Energy Sector: Applied in downhole tools and heat exchangers for oil/gas operations, combining corrosion resistance with mechanical stability.

Manufactured under ASTM B348 standards, Grade 9 titanium rods are available in custom sizes to meet global industrial demands.

Daxun is your trusted titanium alloy rod production company. Daxun produces all grades of titanium alloys, including commercially pure titanium series CP, titanium alloy series, titanium nickel alloy, etc. They have reliable performance and provide high performance for your critical applications. In various industries and applications, you can rely on Daxun titanium alloy rods for high strength, high temperature and corrosive environments. For decades, Daxun Metals has been committed to producing highly engineered titanium alloy solutions to meet the most severe challenges.

Data

- Parameter

- Ingredient

- Mechanical Properties

- Physical Properties

| Specification | Details |

|---|---|

| Material | Titanium rod and bar Grade 9 (UNS R56320) |

| Standard | ASTM B348, ASTM SB348, AMS 4921, AMS 4902 |

| Dimensions | EN, ASTM, JIS, ASME, BS, AISI, GB, GJB, DIN |

| Diameter Range | 0.125″ – 14″ (3.175mm – 355.6mm), custom |

| Length Range | Up to 240″ (6096mm), custom |

| Finish | Cold (bright) drawn, centerless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centerless Ground & Black |

| Surface Finish | Cold drawn, Centerless Ground, Polished, Or Rough Turned, Black, NO.4 Finish, BA Finish, Matt Finish, etc. |

| Condition | Annealed |

| Tolerance | Diameter tolerance: +/- 0.005″ (0.127mm), length tolerance: +/- 0.125″ (3.175mm) |

| Form | Titanium square bars, titanium ingots, titanium round bars, rectangular titanium bars, triangular titanium bars, forged titanium bars, titanium hexagonal bars, etc. |

| Physical Properties | Density: 0.161 lb/in³ (4.48 g/cm³), Melting Point: 3,020°F (1,660°C), Elongation: 10-15%, Modulus of Elasticity: 16.5 x 10⁶ psi (114 GPa) |

| Chemical Composition | Titanium (balance), Aluminum: 2.5-3.5%, Vanadium: 2.0-3.0%, Oxygen (max): 0.20%, Iron (max): 0.25%, Carbon (max): 0.08%, Nitrogen (max): 0.03%, Hydrogen (max): 0.015% |

| Element |

Composition Range (wt.%)

|

| Ti |

Balance (>90%)

|

| Al | 2.50–3.50% |

| V | 2.00–3.00% |

| Fe | ≤0.25% |

| O | ≤0.13% |

| C | ≤0.08% |

| N | ≤0.03% |

| H | ≤0.015% |

| Other |

≤0.4% (single element)

|

| Property | Value (Imperial) | Value (Metric) |

| Tensile Strength | 130–140 ksi | 895–965 MPa |

| Yield Strength (0.2% offset) | 120–125 ksi | 825–860 MPa |

| Elongation | 10–15% | 10–15% |

| Reduction in Area | 25–30% | 25–30% |

| Hardness (Brinell) | 280–320 HB | 290–330 HBW |

| Modulus of Elasticity | 16.5 × 10⁶ psi | 114 GPa |

|

High-Temperature Performance

|

||

| Temperature (°F) | Tensile Strength (ksi) |

Yield Strength (ksi)

|

| 400°F (200°C) | 115–125 | 105–110 |

| 600°F (315°C) | 100–110 | 90–95 |

| 800°F (425°C) | 85–95 | 75–80 |

| Property | Value (Imperial) | Value (Metric) |

| Density | 0.160 lb/in³ | 4.43 g/cm³ |

| Melting Point | 3,000–3,050°F | 1,650–1,680°C |

| Thermal Conductivity | 6.5 Btu/(hr·ft·°F) | 11.2 W/(m·K) |

| Coefficient of Thermal Expansion | 5.3 × 10⁻⁶/°F | 9.5 × 10⁻⁶/K |

| Electrical Resistivity | 120 µΩ·cm | 120 nΩ·m |

Choose Daxun to help your project take off.

DAXUN® Grade 9 Titanium Rod Features

DAXUN® Ti Grade 5 is a titanium alloy bar (6al-4v) featuring:

- Good hot formability and weldability;

- Tensile strength can reach 1000MPa;

- Dimensional work at high temperature

- Insensitive to seawater or seawater;

- Not affected by various corrosive media;

- High strength and good toughness;

- Resist crack initiation and crack propagation.

Daxun Factory Advantages

Daxun’s “Performance Excellence Management” concept promotes the “PDCA + Lean” management model. The company’s business card says “Daxun = Reliable Quality”. Daxun uses the ERP system to achieve full traceability of the variety, specification, and origin of each titanium rod, and advocates and encourages industry anti-counterfeiting. Daxun relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

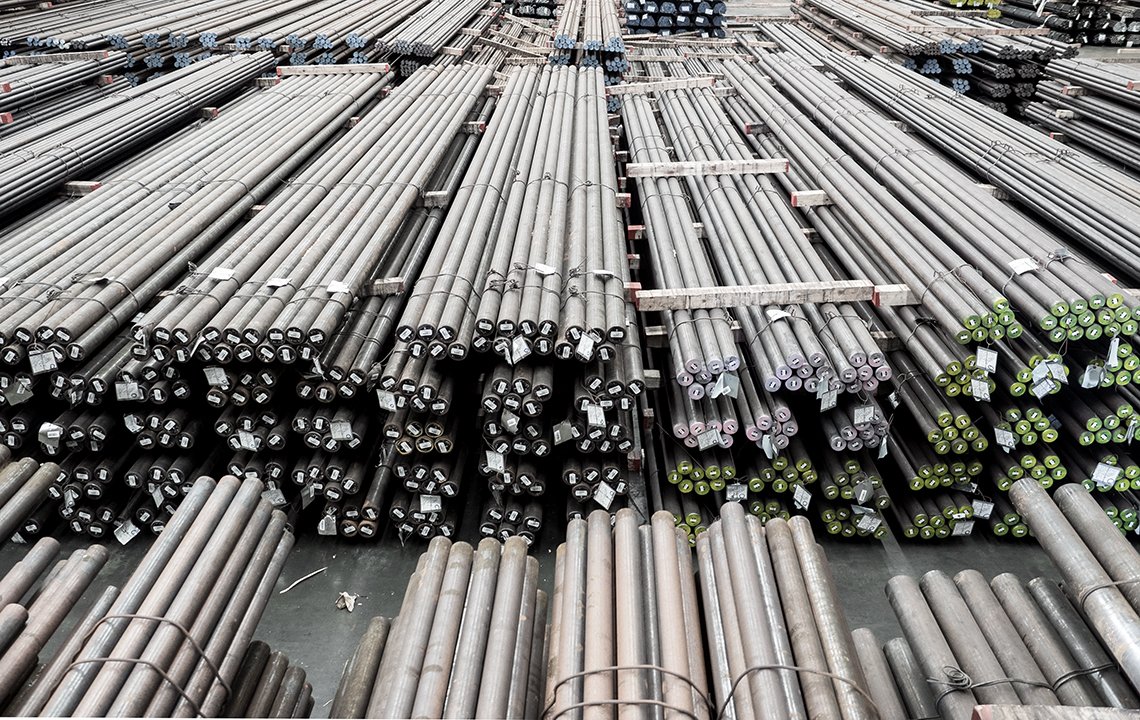

Grade 9 Titanium Rod Production Method

Daxun produces high-quality titanium bars with high performance, and can also manufacture according to customer’s agreement:

- Titanium ingots need to go through heat treatment and machining, immersion ultrasonic testing, mechanical properties testing, macroscopic and microscopic structural inspection and other processes. Production process: hot-rolled titanium bars – high efficiency, stable performance, forged titanium bars – flexible size, multi-fire forging, improve the comprehensive performance of titanium bars, cold-drawn titanium bars – usually small-sized high-precision titanium bars; the above titanium bars are all delivered with bright surface.

Test Reports

The test reports we provide include: Grade 2 Titanium Rod and Grade 2 Titanium Round Bar Factory Test Certificate, EN 10204 3.1, Chemical Report, Mechanical Report, PMI Test Report, Visual Inspection Report, Third Party Inspection Report, NABL Approved Laboratory Report, Destructive Test Report, Non-destructive Testing Report. (Daxun will provide according to customer requirements)

Grade 9 Rods Applications and Standards

Grade 9 Titanium Rods are widely used in the following industries under extreme corrosive conditions:

- Aerospace, shipbuilding, oil and gas industry, marine engineering, chemical plants, industrial machinery, power industry, paper and pulp industry, food processing industry, refineries, military industry, pharmaceutical and food processing equipment, etc.

- Specifications: AMS 4928,AMS 4967,AMS 4965 ,AMS 6931 ,ASTM B 348

- Standards: ASTM, ASME, EN, JIS, DIN, GB, GJB, API

Quality, delivery, inspection

Daxun performs several quality assurance tests, these tests include mechanical tests like area tensile, chemical analysis, material positive identification – PMI test, micro and macro testing, intergranular corrosion (IGC) test, ultrasonic flaw detection test, pitting and resistance test, hardness test, material positive identification, expansion test etc. All these tests ensure that the Grade 2 Titanium Rod and Grade 2 Titanium Round Bar material is suitable for the required application. During the production process, we measure the diameter, thickness and surface of the product.

- Our delivery time is strictly in accordance with the contract.

- Support customer third-party agencies to go to the factory for inspection

- Support free samples for customer testing

- Support on-site or video factory inspection

Packaging

Daxun Alloy ensures the best quality of packaging as it plays an important role in international freight where goods go through various channels to reach the final destination, so we pay special attention to packaging. We pack our goods in many ways depending on the product. We pack our products in many ways such as:

• Boxes and crates

• Shrink wrap

• Wooden pallets

• Wooden boxes

Technical Support

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry. This, in our opinion, demonstrates our unwavering dedication to quality and our philosophy as a full-service supplier.

Daxun Grade 9 Titanium Rods help your brand improve quickly

- Tolerances for Grade 9 Titanium Round Bars (BS EN ISO 286-2)

| NOMINAL SIZE | h5 | h6 | h7 | h8 | h9 | H10 | H11 | h12 |

|---|---|---|---|---|---|---|---|---|

| DIAMETER mm | ||||||||

| ~ to 3 | +0.004/0 | +0.006/0 | +0.01/0 | +0.014/0 | +0.025/0 | +0.04/0 | +0.06/0 | +0.1/0 |

| over 3 to 6 | +0.005/0 | +0.008/0 | +0.012/0 | +0.018/0 | +0.03/0 | +0.048/0 | +0.075/0 | +0.12/0 |

| over 6 to 10 | +0.006/0 | +0.009/0 | +0.015/0 | +0.022/0 | +0.036/0 | +0.058/0 | +0.09/0 | +0.15/0 |

| over 10 to 18 | +0.008/0 | +0.011/0 | +0.018/0 | +0.027/0 | +0.043/0 | +0.07/0 | +0.11/0 | +0.18/0 |

| over 18 to 30 | +0.009/0 | +0.013/0 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 | +0.13/0 | +0.21/0 |

| over 30 to 50 | +0.011/0 | +0.016/0 | +0.025/0 | +0.039/0 | +0.062/0 | +0.1/0 | +0.16/0 | +0.25/0 |

| over 50 to 80 | +0.013/0 | +0.019/0 | +0.03/0 | +0.046/0 | +0.074/0 | +0.12/0 | +0.19/0 | +0.3/0 |

| over 80 to 120 | +0.015/0 | +0.022/0 | +0.035/0 | +0.054/0 | +0.087/0 | +0.14/0 | +0.22/0 | +0.35/0 |

| over 120 to 180 | +0.018/0 | +0.025/0 | +0.04/0 | +0.063/0 | +0.1/0 | +0.16/0 | +0.25/0 | +0.4/0 |

| over 180 to 250 | +0.02/0 | +0.029/0 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 | +0.29/0 | +0.46/0 |

Types of Ti-3AL-2.5V Grade 9 Titanium Rods (3)

Titanium rod

Recent hot case projects and products

Related Products (8)

Daxun Grade 9 Titanium Bar Production & Specifications

Daxun operates an advanced production facility in China manufacturing high-precision Grade 9 titanium bars (Ti-3Al-2.5V). With superior surface finish, dimensional tolerance, straightness and material purity, we ensure technological leadership and consistent production processes. These advantages extend across a wide diameter range and material variants. Our comprehensive service center inventory enables just-in-time delivery globally.

SPECIFICATIONS

- AMS 4911 – Bars, Forgings, and Forging Stock (Annealed)

- ASTM B348 – Standard Specification for Titanium and Titanium Alloy Bars and Billets

HEAT TREATMENT

For enhanced hardness, tensile strength, and fatigue resistance:

- Annealing: 1,300-1,450°F (704-788°C), 1-2 hours, air/furnace cool

- Stress Relief: 1,000-1,200°F (538-649°C), 1-4 hours, air cool

HARDNESS

- Annealed condition: Rockwell C 25-30

- Solution treated & aged: Rockwell C 30-35

Forgeability / Formability

Grade 9 titanium bars are forged at 1,650-1,750°F (899-954°C) with final forging temperature ≥1,400°F (760°C). Minimum 30% reduction recommended for optimal properties. Unlike Grade 23, Grade 9 exhibits excellent cold formability in annealed condition, enabling bending/stretching at room temperature. Hot forming is feasible at 800-1,200°F (427-649°C) without compromising mechanical properties.

Machinability

Machinable using austenitic stainless steel methods with:

- Low cutting speeds

- High feed rates

- Rigid tooling

- Non-chlorinated cutting fluids

Weldability

Grade 9 titanium rods are readily weldable in annealed condition. Requires inert gas shielding (argon/helium) to prevent oxygen/nitrogen/hydrogen contamination. Post-weld stress relief at 1,000-1,200°F (538-649°C) is recommended.

Size Range

- Diameter: Ø 0.8 – 350 mm (drawn/ground/hot-rolled)

- Tolerances: h9–h6 (ISO 286-2)

- Lengths: Up to 6,000 mm (custom lengths negotiable)

Availability & Processing

Processing options include:

- Drawing, straightening, grinding, polishing

- Annealing (stress-relieved or full)

- Custom end machining (chamfering, centering, facing)

- Surface Finish: Defect-free (Level 4 per eddy current testing)

Delivery Standards

ASTM, AMS, ASME, GB, GJB, ISO, DIN, EN, NACE, API

Material Services

As an ISO-certified service center, we provide:

- 100% non-destructive testing (ultrasonic/eddy current)

- Third-party certification (TÜV, DNV)

- Long-term supply agreements with fixed pricing

- Global logistics support since 2003

Ordering Information

Purchase orders must specify:

- Quantity, grade (Ti-3Al-2.5V), diameter, length

- Tolerance class (e.g., h6)

- Surface treatment (polished/ground)

- Applicable standards (ASTM B348/AMS 4911)

- Additional testing requirements

Contact Daxun for technical consultation and rapid quotation.

The grade of titanium alloy you need depends on the project you are working on, as each grade has different benefits.

All grades of titanium alloy are extremely strong and corrosion resistant, which means they will continue to work well in the harshest conditions.

The higher grades of titanium alloy (5-12) are alloys designed for specific benefits. For example, grade 12 titanium alloy has excellent heat resistance, making it a perfect choice for shell and tube heat exchangers, hydraulic piping, and chemical industry equipment.

Grades 1-4 are pure titanium alloys, and they are a perfect choice if you need a weldable, ductile material for piping systems and tubing. You will find lower grades used in the marine and industrial industries.

If you are starting a project and are unsure which grade of titanium alloy is best for you, contact us today; we are more than happy to help you.

At DAXUN, we offer a wide range of titanium alloy grades from grade 1 to grade 12.

Grades 1-4 are pure titanium, while higher grades are alloys.

Alloy grades are popular for their high strength-to-weight ratio.

The most commonly used titanium alloy grade we find is grade 5. While still high in titanium, this grade is one of the most reliable because it can withstand temperatures up to 600°F and withstand extreme conditions.

Higher grades are favored by industries such as aerospace and marine industries for their wear and corrosion resistance.

Conversely, lower grades are primarily used for welding due to their lower strength.

To learn more about the differences between different grades of titanium alloy, call +86 13382898899 today to speak directly with our experts.

While the grade of titanium does increase the cost slightly, the total cost is primarily determined by the shape and form of titanium you require.

At DAXUN, we offer a wide range of titanium products, including plates, tubes, coils and bars. The length, width and quantity of each item you require will affect the amount you pay at checkout.

Unfortunately, it is difficult to come up with a price online without knowing much about your project and what the titanium will be used for.

Fortunately, our team of experts are always here to help and advise you on your titanium needs. By sending an email to [email protected], we will be able to get back to you with some advice and an accurate quote.

Make sure to include as much information as possible about the grade, shape and quantity of titanium you require to get a better understanding of your needs.

The team at DAXUN is experienced, knowledgeable, and friendly. With years of experience in the industry, they know all about titanium, including its uses, benefits, and grades.

For regular updates on titanium, its uses, and its applications across industries, be sure to check out our blog. Our experts have written easy-to-follow guides that you can always refer to when you have questions.

If you’re still having trouble, feel free to contact us; we’ll be happy to help.

By sending an email to [email protected], you’ll receive a quick response. Make sure to include as much detail as possible in your question so we can recommend a suitable solution.

Please fill in the form on the “Contact Us” page, or call our sales manager at “+86 13382898899”, we will contact you as soon as possible. Our WhatsApp is online, and email ([email protected]) will be checked within 6 hours. Every inquiry or message will be responded to promptly. In addition, we share market information with our customers every week

We can provide titanium rod samples for you to check the quality. Sample is free and you just pay the freight.

We’ve exported to more than 42 countries, such as Canada, Chile, Kuwait, Germany, South Korea, Saudi Arabia, Singapore etc.

Our MOQ is 300 Kg for titanium rod.

Trial orders can be delivered within a week. For regular orders, it takes two weeks roughly.