Grade 12 (Ti-0.3Mo-0.8Ni) Titanium Alloy Plate Manufacturer - Daxun Alloy

As a leading supplier of titanium in China, Daxun provides high-performance titanium plates to the world.

- Plate Grade:Grade 12 UNS R53400

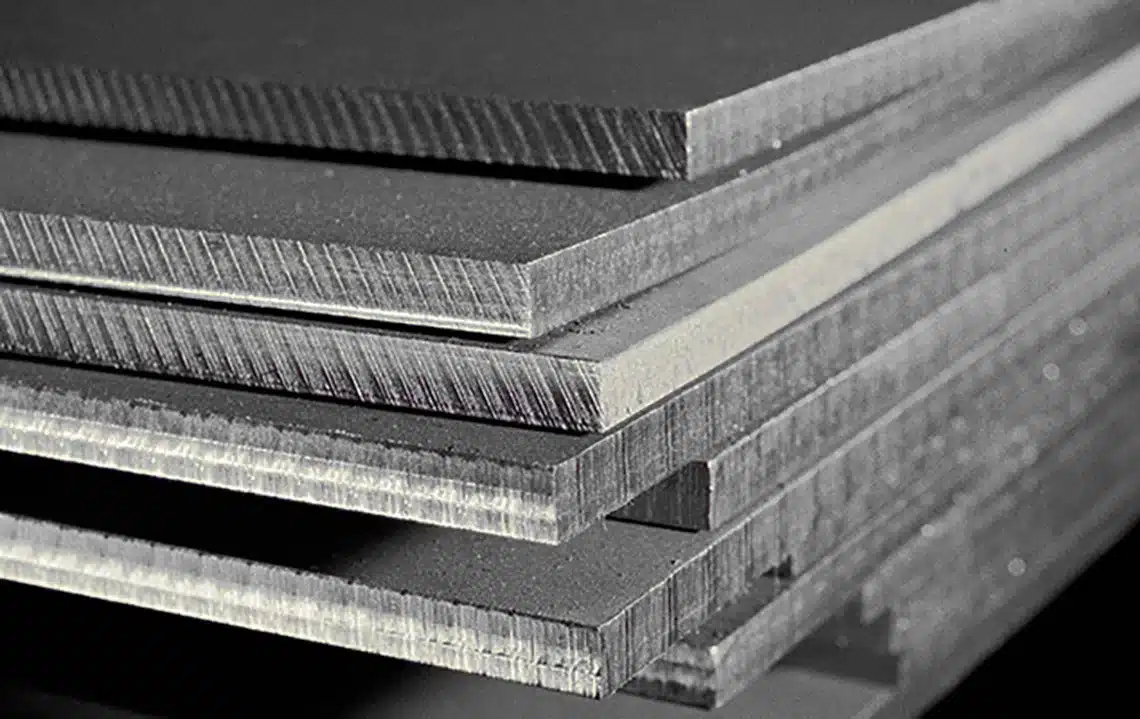

- Plate Production type:cold rolling, hot rolling, forging.

- Standard:ASTM B861

- Features:High strength, Lightweight, High-temperature resistance

- Surface:bright, polished, pickled, sandblasted, etc.

- Size:0.3mm ≤ 1000mm ≤ 2500mm or as your request

————Daxun produces titanium sheets in China to meet the diverse and ——demanding needs of customers!

Providing High-quality Grade 12 Titanium Plate to Serve Customers Worldwide

Grade 12 titanium (Ti Grade 12 / UNS R53400) is a nickel-molybdenum-enhanced, commercially pure (CP) titanium alloy specifically engineered for superior corrosion resistance in moderately aggressive environments. It consists of titanium (≥99%) with strategic additions of 0.6–0.9% nickel (Ni) and 0.2–0.4% molybdenum (Mo), which significantly improves its corrosion performance. This nickel-molybdenum modification enhances resistance to reducing acids (e.g., sulfuric, hydrochloric), chloride solutions, and crevice corrosion—conditions where standard CP grades like Grade 2 would show limited performance. While maintaining the inherent advantages of titanium—low density (~4.5 g/cm³), high strength-to-weight ratio, excellent weldability, and biocompatibility—Grade 12 offers improved strength and better corrosion resistance at elevated temperatures (up to ~315°C/600°F) compared to other CP grades. Its passive oxide layer, reinforced by the nickel-molybdenum addition, provides robust protection against chemical attack, making it an excellent choice for applications requiring enhanced corrosion performance without the premium cost of palladium-containing alloys.

Where is Grade 12 titanium used?

Grade 12 titanium is widely utilized in chemical processing for components such as heat exchangers, piping systems, and vessels handling chlorides, organic acids, and reducing media. In marine and offshore applications, it serves in seawater cooling systems, heat rejection equipment, and components exposed to brackish water. The alloy also performs exceptionally well in oil and gas production, particularly in downhole equipment and sour gas environments where hydrogen sulfide resistance is critical. Additionally, Grade 12 finds applications in pollution control systems, pulp and paper processing, and heat management systems. Its cost-effective balance between corrosion resistance and mechanical properties—offering performance superior to standard CP grades but at a lower cost than palladium-enhanced alloys—provides excellent lifecycle value by reducing maintenance requirements and extending service life in corrosive environments. This combination of performance and economics makes Grade 12 titanium a preferred material for demanding applications where both reliability and cost-effectiveness are essential considerations.

Data

- Parameter

- Physical Properties

- Mechanical Properties

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Titanium (Ti) | Balance | Balance |

| Molybdenum (Mo) | 0.25 | 0.40 |

| Nickel (Ni) | 0.60 | 0.90 |

| Iron (Fe) | — | 0.30 |

| Oxygen (O) | — | 0.25 |

| Carbon © | — | 0.08 |

| Nitrogen (N) | — | 0.03 |

| Hydrogen (H) | — | 0.015 |

| Other Elements | — | 0.40 (total) |

| Property | Value/Range | Unit |

|---|---|---|

| Density | 4.48 | g/cm³ |

| Melting Point | 1650 ± 20 | °C |

| Thermal Conductivity | 7.2 (at 25°C) | W/m·K |

| Specific Heat | 560 (at 25°C) | J/kg·K |

| Electrical Resistivity | 1.7 | μΩ·m |

| Magnetic Susceptibility | Paramagnetic | — |

| Property | Minimum Requirement | Typical Value | Unit | Test Method |

|---|---|---|---|---|

| Tensile Strength | 483 | 520–620 | MPa | ASTM E8/E8M |

| Yield Strength (0.2% offset) | 345 | 380–480 | MPa | ASTM E8/E8M |

| Elongation | 18 | 22–30 | % | ASTM E8/E8M |

| Hardness | ≤ 200 (HV) | 150–180 (HV) | Vickers | ASTM E10 |

| Impact Toughness | Not specified | 40–60 | J | ASTM E23 |

Elevated Temperature Performance

| Temperature (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 100 | 450–500 | 320–370 | 20–25 |

| 200 | 400–450 | 280–330 | 18–23 |

| 300 | 350–400 | 240–290 | 15–20 |

Choose Daxun to help your project take off.

Common applications

Grade 12 titanium plates and sheets are primarily used in applications that require excellent corrosion resistance in reducing environments, combined with higher strength than pure titanium grades and good weldability.

- Applications include chemical processing equipment such as heat exchangers, pressure vessels, and piping systems that handle hot chlorides and acids.

- Industrial applications include components for pulp and paper manufacturing, where resistance to corrosive chemicals and high temperatures is essential.

- Marine and offshore equipment, including seawater cooling systems, heat exchangers, and components exposed to brackish water environments.

- Oil and gas industry components, particularly for equipment used in sour gas environments containing hydrogen sulfide.

- Power generation equipment, including condenser tubing and other components that operate in corrosive high-temperature environments.

Fast delivery

Daxun provides customers with timely and fast delivery of grade 12 titanium plate products. Behind the speed is the system support from professional production capacity, and information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real-time, and the data is seamlessly connected.

Custom Cutting

Daxun Alloy provides customers with customized cutting solutions of various sizes to help you control the size loss of titanium plates, thereby saving your processing costs and time. Our cutting methods include:

- Water jet cutting

- Laser cutting

- Plasma cutting

- Wire cutting

- Bending

- Slitting

- Sawing

Packaging

We pay special attention to packaging. We pack our goods in many ways depending on the product. We pack our products in many ways such as:

• Boxes and crates

• Shrinkwrap

• Wooden pallets

• Wooden boxes

Technical Support

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry.

Daxun Grade 12 Titanium sheet Let your brand improve rapidly

- Other Titanium Plate Grades

| Apart from the products listed below, other available metal products are not listed here. Other metal products DAXUN can manufacture and supply include Tantalum, Niobium, Zirconium, Hafnium, Nickel, Copper etc., which are mainly in the form of Plate, Bar and Tube. | |

| Products/Processing Standard | Grade/Size |

| Titanium Plate, Sheet, Coil— ASME SB265, AMS 4911, AMS 4919, AMS 4914,ASTM F67, ASTM F136 | GR1, GR2, GR3, GR4, GR5, GR7,GR9, GR12, GR16, GR17, GR23,Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3(Thickness:( 0.0197”-6”)Max Width: 12 feet,Max Length: 50 feet) |

| AMS-T-9046 | |

| Titanium and Titanium alloy sheet, plate | |

| Commercially pure titanium (CP) | |

| Code designation | Yield strength |

| minimum, ksi 1 / | |

| CP-1 Gr1 | 70 |

| CP-2 Gr2 | 55 |

| CP-3 Gr3 | 40 |

| CP-4 Gr4 | 25 |

| Alpha titanium alloys(A) | |

| Code designation | Composition |

| A-1 | 5A1-2.5Sn |

| A-2 | 5A1-2.5Sn(ELI) 2 / |

| A-3 | 6A1-2Cb-1Ta-0.8Mo |

| A-4 | 8A1-1Mo-1V |

| Alpha-beta titanium alloys(AB) | |

| Code designation | Composition |

| AB-1 Gr5 | 6A1-4V |

| AB-2 Gr5 | 6A1-4V(ELI) |

| AB-3 | 6A1-6V-2Sn |

| AB-4 | 6A1-2Sn-4Zr-2Mo |

| AB-5 | 3A1-2.5V |

| AB-6 | 8Mn |

| Beta titanium alloys(B) | |

| Code designation | Composition |

| B-1 | 13V-11Cr-3A1 |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3A1-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3A1 |

| Processing: | |

| Hot Rolling | Cold Rolling |

| Available Grades: | |

| CP Grade 1 | Grade 6Al-2Sn-4Zr-2Mo (6-2-4-2) |

| CP Grade 2 | Grade 6Al-4V ELI (Formerly Grade 23) |

| Grade 7 | Grade 6Al-6V-2Sn (6-62) |

| Grade 19 | Grade 8Al-1Mo-1V (8-1-1) |

| Grade 5 (6Al-4V) | Grade 9 (3Al-2.5V) |

| Grade 6 (5Al-2.5Sn) | CP Grade 3 |

| Application | |

| Chemical Industry | Desalination Of Sea Water |

| Petrochemical Industry | Aerospace |

| Machining Field, Automobile Field | Mobile Phone Component Field. |

Recent hot case projects and products

Related Products (7)

Grade 12 titanium is a titanium alloy containing 0.3% molybdenum and 0.8% nickel, which provides enhanced strength and superior corrosion resistance compared to commercially pure titanium grades. This combination offers excellent weldability, formability, and stability at elevated temperatures while maintaining good ductility.

While Grade 12 titanium has a higher initial cost than stainless steels, it offers a lower total cost of ownership in corrosive applications due to its extended service life and reduced maintenance requirements. Compared to other titanium grades, Grade 12 is typically priced between Grade 2 and Grade 7 titanium.

Grade 12 titanium maintains its properties at temperatures up to approximately 425°C (800°F). Beyond this temperature, the material may begin to experience reduced mechanical properties, though it still performs better than many competing alloys in high-temperature corrosive environments.

All our Grade 12 titanium plates are supplied with full material test certificates including chemical analysis, mechanical properties, and dimensional verification. We comply with ASTM B265, AMS 4901, and other international standards as required by our customers.

We supply Grade 12 titanium plates in thicknesses ranging from 0.5mm to 100mm, with standard plate dimensions of 1m x 2m or 1.5m x 3m. Custom sizes and thicknesses can be produced to meet specific project requirements.

Please fill in the form on the “Contact Us” page, or call our sales manager at “+86 13382898899”, we will contact you as soon as possible. Our WhatsApp is online, and email ([email protected]) will be checked within 6 hours. Every inquiry or message will be responded to promptly. In addition, we share market information with our customers every week

We can provide titanium sheet samples for you to check the quality. Sample is free and you just pay the freight.

We’ve exported to more than 42 countries, such as Canada, Chile, Kuwait, Germany, South Korea, Saudi Arabia, Singapore etc.

Our MOQ is 1 ton for titanium sheet.

Trial orders can be delivered within a week. For regular orders, it takes two weeks roughly.