Grade 7 Ti-0.15Pd Alloy Pipe Manufacturer

As a leading supplier of titanium and titanium alloy tubes in China, Daxun provides high-performance titanium tubes to the world.

- Titanium tube Grade:Grade 7 - UNS R52400

- Titanium tube types:Seamless Ti tube, Ti welded tube, forged Ti tube

- Titanium tube density The density of grade 7 titanium is approximately 4.51 g/cm3

- Standards:ASTM B338、ASTM B861、ASTM B862

- Softest Ti,High ductility, Very corrosion resistant, good cold formability

————Daxun produces titanium tubes in China to meet the diverse and ——demanding needs of customers!

Grade 7 Titanium Alloy Pipe Manufacturer - Daxun Alloy

Provide High Quality Grade 7 Titanium Pipe to Customers Around The World

Grade 7 titanium pipe is a palladium-enhanced commercially pure titanium alloy (Ti-0.12Pd), engineered for ultimate corrosion resistance in the most aggressive environments. It combines the inherent formability and weldability of pure titanium with exceptional durability against reducing acids and chlorides. Its density (4.51 g/cm³) is approximately 60% that of steel, while offering unparalleled defense against chemical attack, pitting, and crevice corrosion. The alloy excels in harsh conditions—including hot reducing acids, chloride-rich solutions, and sour gas environments—maintaining integrity where other materials fail.

- Palladium’s electrochemical role: Pd acts as a cathodic catalyst, promoting rapid repassivation of the titanium oxide layer when damaged. This self-healing mechanism prevents localized corrosion (pitting/crevice) in reducing acids like HCl, H₂SO₄, and wet chlorine environments where conventional titanium fails.

- Synergy with titanium matrix: While retaining pure titanium’s inherent ductility and weldability, the Pd dopant creates a barrier against hydrogen embrittlement and stress corrosion cracking (SCC), enabling reliable performance in chemically aggressive media

Where is Grade 7 titanium pipe used?

In chemical processing plants, it’s the material of choice for reactor vessels, heat exchangers, and piping systems handling sulfuric acid, hydrochloric acid, and chlorinated organics due to its inertness. Marine and offshore industries rely on it for critical seawater systems, desalination equipment, and subsea components, leveraging its unmatched resistance to saltwater corrosion and biofouling. Oil and gas operations employ it in downhole tubing, Christmas tree components, and sour gas pipelines where high-pressure H₂S and CO₂ environments cause rapid degradation of standard alloys. Pharmaceutical and biotech facilities use it for ultra-pure water systems and chemical delivery lines, ensuring zero contamination. Additionally, nuclear waste treatment et pollution control systems utilize it for scrubbers and condensers exposed to corrosive flue gases and acidic effluents, combining longevity with absolute reliability.

Key Performance:

Strength-Ductility Balance:

- Tensile Strength: 483 MPa (annealed state) – Matches Grade 2 but with superior corrosion resistance.

- Elongation: ≥20% – Exceptional ductility for cold forming and high fatigue resistance.

- Density: 4.51 g/cm³ – 60% lighter than steel, ideal for weight-sensitive applications.

Corrosion Resistance:

- Palladium-enhanced performance: Resists pitting/crevice corrosion in seawater, chlorides, reducing acids (HCl, H₂SO₄), and sour gas (H₂S).

- Outperforms Grade 2/9: Immune to corrosion in oxidizing media and aggressive chemical environments where stainless steel fails.

- Galvanic compatibility: No risk of galvanic corrosion when paired with dissimilar metals.

Weldability & Processability:

- Welding: Excellent TIG/laser weldability – no post-weld cracking due to Pd stabilization.

- Forming: Superior cold workability vs. Grade 5; easily formed into tubes, sheets, and complex shapes.

- Traitement thermique : Stress-relieved at 480–595°C to optimize corrosion resistance and ductility.

Application Advantages:

- Traitement chimique : Reactors, piping, heat exchangers – handles hot reducing acids, chlorides, and sour gas.

- Marine: Desalination plants, seawater cooling systems – lifetime immunity to saltwater corrosion.

- Aerospace: Hydraulic fluid lines – lightweight durability in corrosive fuel/hydraulic environments.

- Industrial: Pollution control scrubbers, geothermal systems – withstands high-temperature acidic vapors.

- Medical: Implant components – biocompatible with enhanced corrosion resistance in bodily fluids.

Données

- Paramètres

- Physical Properties

- Propriétés mécaniques

| Élément | Symbol | Composition Range (wt.%) |

|---|---|---|

| Titane | Ti | Balance (>99%) |

| Palladium | Pd | 0.12–0.25% |

| Iron | Fe | ≤0.30% |

| Oxygen | O | ≤0.25% |

| Carbone | C | ≤0.08% |

| Azote | N | ≤0.03% |

| Hydrogen | H | ≤0.015% |

| Autres éléments | Each | ≤0.40% (single element) |

Key Characteristics

- Strength-to-Weight Ratio: Comparable to pure titanium (Grades 1–4) but lower than Ti-6Al-4V (Grade 5) or Ti-3Al-2.5V (Grade 9). Optimized for corrosion resistance over mechanical strength.

- Corrosion Resistance: Unmatched in reducing acids (e.g., HCl, H₂SO₄), chlorides, and crevice corrosion environments. Outperforms all commercially pure grades (1–4) and Grade 5/9 in aggressive chemical media due to palladium (Pd) stabilization.

- Biocompatibility: Fully non-toxic and MRI-compatible. Suitable for surgical instruments and chemical processing equipment, though not used for permanent implants (Grade 23 preferred).

- Formability: Retains excellent cold formability, weldability, and machinability of pure titanium. Significantly easier to fabricate than Grade 5/9, enabling complex geometries without specialized tooling.

| Propriété | Value (Imperial) | Value (Metric) |

|---|---|---|

| Densité | 0.163 lb/in³ | 4.51 g/cm³ |

| Melting Point | 3,000–3,050°F | 1,650–1,680°C |

| Conductivité thermique | 9.5 Btu/(hr·ft·°F) | 16.4 W/(m·K) |

| Coefficient of Thermal Expansion | 4.8 × 10⁻⁶/°F | 8.6 × 10⁻⁶/K |

| Résistivité électrique | 1.78 × 10⁻⁶ Ω·cm | 1.78 μΩ·m |

| Propriété | Value (Imperial) | Value (Metric) |

|---|---|---|

| Résistance à la traction | 50,000–65,000 psi | 345–450 MPa |

| Limite d'élasticité | 30,000–45,000 psi | 207–310 MPa |

| Elongation | 20–30% | 20–30% |

| Dureté (Brinell) | 120–160 HB | 120–160 HB |

| Module d'élasticité | 14.9–16.0 × 10⁶ psi | 103–110 GPa |

Choose Daxun to help your project take off.

Advanced Production:Titanium seamless pipe

- Titanium seamless tubes are hot rolled or hot extruded, straightened, processed with inner and outer diameters, and surface etched. Tubes can be supplied in heat-treated or non-heat-treated forms. Daxun has 100% ultrasonic testing capabilities. Hot rolled tube/hot extruded titanium seamless tube: outer diameter 1.0 mm to 325 mm, wall thickness 0.3 mm to 50 mm, length up to 12000 mm. Cold rolled titanium seamless tube: cold processed tubes are supplied after heat treatment, surface etching, hydrostatic test or ultrasonic inspection according to the requirements of the manufacturing specification. Outer diameter 6 mm to 102 mm, wall thickness 0.5 mm to 20 mm, length up to 9000 mm.

- (The above is agreed upon by the manufacturer and the customer based on the specific situation)

Grade 7 Titanium Tube Features

Grade 7 Titanium Tube is the softest form of titanium and has the highest ductility. It has good cold forming characteristics and offers excellent corrosion resistance. It also has excellent welding properties and high impact toughness.

- Softest Titanium

- Highest Ductility

- Excellent Corrosion Resistance

- Good Cold Formability

Advanced Production: Titanium Welded Tube

Titanium Welded Tube: Diameter ranges from 6.0mm to 1219mm, wall thickness ranges from 0.3mm to 30mm (depending on diameter), length up to 25000mm, made from Gr1 titanium tube. Welded tubes are made from flat rolled billets (tube blanks) on electric tube welding machines using automatic tungsten inert gas (argon) welding, and heat treated on the mill line. Mechanical tests, geometric measurements, 100% ultrasonic and eddy current testing, pneumatic or hydrostatic testing are performed before the finished titanium welded tubes are packaged according to customer specifications. Manufacturing technology as well as inspection and testing equipment ensure that thin wall welded tubes meet ASTM B 338 and ASME SB 338 specifications.

Test Reports

The test reports we provide include: Factory test certificate for Grade 7 titanium welded pipe and Grade 7 titanium seamless pipe, EN 10204 3.1, Chemical report, Mechanical report, PMI test report, Visual inspection report, Third-party inspection report, NABL approved laboratory report, Destructive test report, Non-destructive test report. (Daxun will provide according to customer’s requirements)

Applications and standards

Titanium Grade 7 Pipes and Tubing are extensively applied in extremely corrosive conditions in the below Industries:

- Chemical processing parts such as heat exchangers, reaction vessels, evaporators and delivery pipelines, automotive exhaust, oil and gas industry, petrochemical plants, chemical plants, industrial machinery, power industry, paper and pulp industry, food processing industry, refineries, pharmaceutical and food processing equipment, etc.

- Specifications : ASTM B861, B862, B338 / ASME SB861, SB862, SB338

Standard : ASTM, ASME and API

Qualité, livraison, inspection

Daxun performs several quality assurance tests, these tests include flattening test, flaring test, ultrasonic flaw detection test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the Grade 7 Titanium Welded Pipe and Grade 7 Titanium Seamless Pipe materials are suitable for the required application. During the production process, we measure the diameter, thickness and surface of the products. Our standard delivery time is 5-7 days and the delivery time for special size products is 15-20 days.

- Nos délais de livraison sont strictement conformes au contrat.

- Aider les agences tierces des clients à se rendre à l'usine pour l'inspection

- Support free samples for customer testing

- Soutien à l'inspection sur site ou à l'inspection vidéo en usine

Emballage

Daxun Alloy garantit la meilleure qualité d'emballage, car celui-ci joue un rôle important dans le fret international, où les marchandises passent par différents canaux avant d'atteindre leur destination finale ; nous accordons donc une attention particulière à l'emballage. Nous emballons nos marchandises de différentes manières, en fonction du produit. Nous emballons nos produits de différentes manières, notamment :

- Boîtes et caisses

- Emballage rétractable

- Palettes en bois

- Boîtes en bois

Support technique

Si vous avez besoin d'une assistance technique supplémentaire, notre métallurgiste résident et notre personnel compétent se feront un plaisir de vous aider. En outre, Daxun dispose d'un laboratoire d'essai certifié, une première dans l'industrie des stocks multimétaux et plastiques. Ceci, à notre avis, démontre notre dévouement inébranlable à la qualité et notre philosophie en tant que fournisseur de services complets.

Daxun Grade 7 Titanium TUBE Let your brand improve rapidly

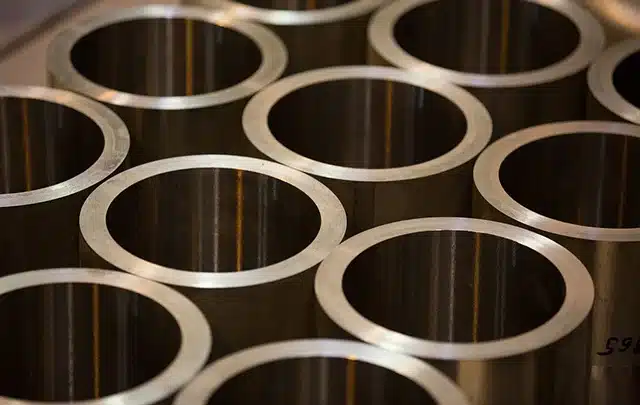

- Galerie

Grade 7 titanium tube form (4)

Projets et produits récents

Produits apparentés (8)

The grade of titanium alloy you need depends on the project you are working on, as each grade has different benefits.

All grades of titanium alloy are extremely strong and corrosion resistant, which means they will continue to work well in the harshest conditions.

The higher grades of titanium alloy (5-12) are alloys designed for specific benefits. For example, grade 12 titanium alloy has excellent heat resistance, making it a perfect choice for shell and tube heat exchangers, hydraulic piping, and chemical industry equipment.

Grades 1-4 are pure titanium alloys, and they are a perfect choice if you need a weldable, ductile material for piping systems and tubing. You will find lower grades used in the marine and industrial industries.

If you are starting a project and are unsure which grade of titanium alloy is best for you, contact us today; we are more than happy to help you.

At DAXUN, we offer a wide range of titanium alloy grades from grade 1 to grade 12.

Grades 1-4 are pure titanium, while higher grades are alloys.

Alloy grades are popular for their high strength-to-weight ratio.

The most commonly used titanium alloy grade we find is grade 5. While still high in titanium, this grade is one of the most reliable because it can withstand temperatures up to 600°F and withstand extreme conditions.

Higher grades are favored by industries such as aerospace and marine industries for their wear and corrosion resistance.

Conversely, lower grades are primarily used for welding due to their lower strength.

To learn more about the differences between different grades of titanium alloy, call +86 13382898899 today to speak directly with our experts.

While the grade of titanium does increase the cost slightly, the total cost is primarily determined by the shape and form of titanium you require.

At DAXUN, we offer a wide range of titanium products, including tubes, tubes, coils and bars. The length, width and quantity of each item you require will affect the amount you pay at checkout.

Unfortunately, it is difficult to come up with a price online without knowing much about your project and what the titanium will be used for.

Fortunately, our team of experts are always here to help and advise you on your titanium needs. By sending an email to [email protected], we will be able to get back to you with some advice and an accurate quote.

Make sure to include as much information as possible about the grade, shape and quantity of titanium you require to get a better understanding of your needs.

The team at DAXUN is experienced, knowledgeable, and friendly. With years of experience in the industry, they know all about titanium, including its uses, benefits, and grades.

For regular updates on titanium, its uses, and its applications across industries, be sure to check out our blog. Our experts have written easy-to-follow guides that you can always refer to when you have questions.

If you’re still having trouble, feel free to contact us; we’ll be happy to help.

By sending an email to [email protected], you’ll receive a quick response. Make sure to include as much detail as possible in your question so we can recommend a suitable solution.

Please fill in the form on the “Contact Us” page, or call our sales manager at “+86 13382898899”, we will contact you as soon as possible. Our WhatsApp is online, and email ([email protected]) will be checked within 6 hours. Every inquiry or message will be responded to promptly. In addition, we share market information with our customers every week

Nous pouvons vous fournir des échantillons de tôles d'acier inoxydable pour vous permettre de vérifier la qualité. L'échantillon est gratuit et vous ne payez que les frais de transport.

Nous avons exporté vers plus de 42 pays, tels que le Canada, le Chili, le Koweït, l'Allemagne, la Corée du Sud, l'Arabie saoudite, Singapour, etc.

Notre MOQ est de 1 tonne pour les tôles d'acier inoxydable.

Les commandes d'essai peuvent être livrées dans un délai d'une semaine. Pour les commandes régulières, il faut compter environ deux semaines.