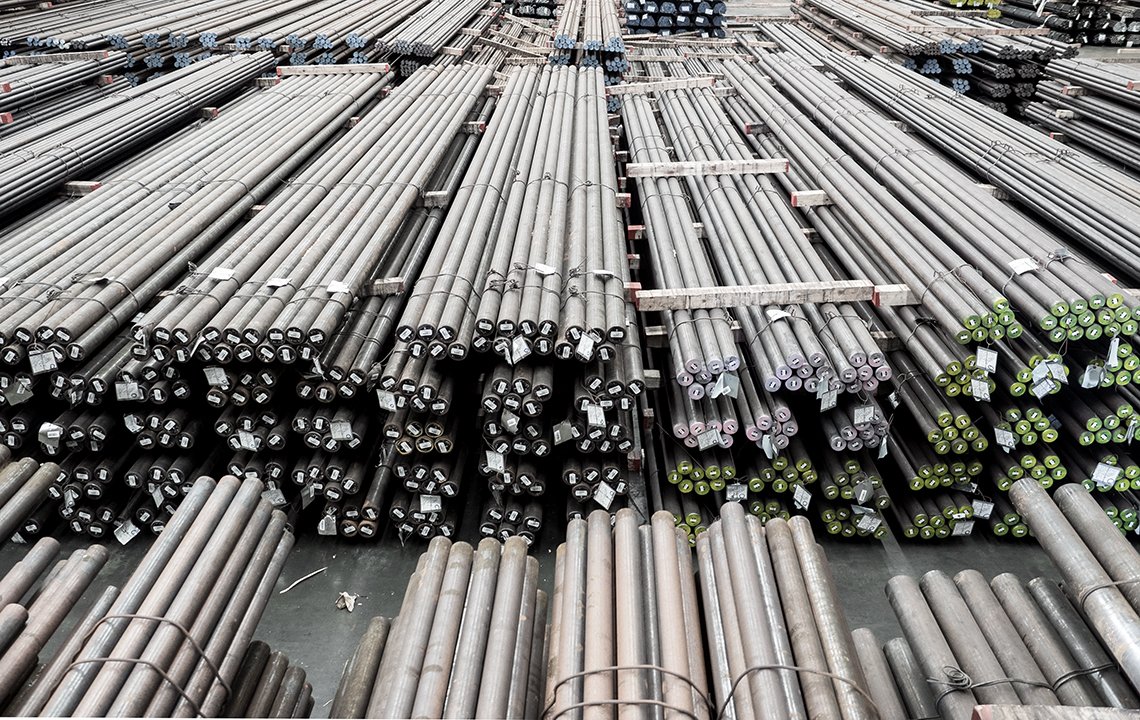

Daxun is an excellent manufacturer of CP Grade 3 titanium rods and bars.

- Titanium bar grade: R50550 / CP TI50A

- Titanium bar types: rolled bars, drawn bars, forged titanium bars

- Main standards: ASTM ASME GB GJB EN JIS DIN ISO ATP BS, etc.

- High corrosion resistance, excellent weldability, superior strength, lightweight, and outstanding performance in aggressive environments.

The global leader in commercially titanium alloy rod manufacturing services

Daxun, specializing in the production of alloy titanium rods for extreme environments

As the strongest of the CP grades, Grade 3 offers an outstanding combination of high tensile strength, excellent corrosion resistance, and good formability. This makes it an ideal material for demanding industrial applications where both durability and fabricability are paramount.This titanium grade provides superior strength compared to CP Grade 2, making it perfect for components that must withstand higher mechanical stresses. Its exceptional corrosion resistance ensures longevity in harsh environments, including seawater, chlorides, and oxidizing acids. The material features excellent weldability using standard techniques, allowing for easy fabrication and assembly, while maintaining good formability for bending and machining into complex shapes. Despite its strength, it retains titanium’s characteristic lightweight properties, contributing to overall weight reduction in final assemblies.

Common Applications:

CP Grade 3 titanium bar finds extensive use across critical industries. In chemical processing, it’s trusted for heat exchangers, pressure vessels, and piping systems. The aerospace sector relies on it for airframe and jet engine components, fasteners, and brackets. Marine engineering applications include desalination plant components, propeller shafts, and offshore hardware. Power generation facilities utilize it for condenser and heat exchanger tubing, while the medical industry values it for surgical implants and instruments where high strength is essential.

Key Properties & Advantages:

- Superior Strength: Significantly stronger than CP Grade 2, making it suitable for components that must withstand higher mechanical stresses.

- Exceptional Corrosion Resistance: Highly resistant to corrosion in a wide range of environments, including seawater, chlorides, and oxidizing acids.

- Excellent Weldability: Can be readily welded using standard techniques, ensuring ease of fabrication and assembly.

- Good Formability: Offers better ductility than many titanium alloys, allowing for bending, forming, and machining into complex shapes.

- Lightweight: Retains the characteristic low density of titanium, contributing to overall weight reduction in final assemblies.

| Spécifications | Details |

|---|---|

| Matériau | CP Grade 3 Titanium Bar |

| Standard | ASTM B348, AMS 4921 |

| Dimensions | EN, ASTM, JIS, ASME, BS, AISI, GB, GJB, DIN |

| Diameter Range | 0.125″ – 14″ (3.175mm – 355.6mm), custom |

| Length Range | Up to 240″ (6096mm), custom |

| Formulaire | Round Bar, Square Bar, Hexagonal Bar |

| Finition de la surface | Cold drawn, Centerless Ground, Polished, Or Rough Turned, Black, NO.4 Finish, BA Finish, Matt Finish, etc. |

| Condition | Hardened & tempered, annealed |

| Tolérance | Diameter tolerance: +/- 0.005″ (0.127mm), length tolerance: +/- 0.125″ (3.175mm) |

| Formulaire | Titanium square bars, titanium ingots, titanium round bars, rectangular titanium bars, triangular titanium bars, forged titanium bars, titanium hexagonal bars, etc. |

Daxun Alloy supply CP Grade 3 titanium bar sourced from premier mills, ensuring every piece meets stringent international standards for quality and consistency. Our material is fully certified and available in a wide range of sizes, with custom cutting services to meet your exact project specifications. Contact our expert team today for a competitive quote and personalized service for your titanium requirements.

Données

- Paramètres

- Propriétés mécaniques

- Physical Properties

| Élément | Content (%) |

| Titane (Ti) |

Balance (~99.1%)

|

| Oxygène (O) | 0.10 – 0.27 |

| Fer (Fe) | ≤ 0.30 |

| Carbon © | ≤ 0.10 |

| Azote (N) | ≤ 0.05 |

| Hydrogène (H) | ≤ 0.015 |

| Propriété | Valeur |

| Résistance à la traction |

~450–485 MPa

|

| Limite d'élasticité |

~380–415 MPa

|

| Elongation | ~20–30% |

| Dureté (Brinell) |

~200–240 HB

|

| Propriété | Valeur |

| Densité | ~4.51 g/cm³ |

| Melting Point |

~1660–1670 °C

|

| Module d'élasticité |

~103–107 GPa

|

| Conductivité thermique |

~21.9 W/m·K (at 25°C)

|

| Résistivité électrique | ~420 nΩ·m |

Choose Daxun to help your project take off.

Daxun Factory Advantages

Daxun’s “Performance Excellence Management” concept promotes the “PDCA + Lean” management model. The company’s business card says “Daxun = Reliable Quality”. Daxun uses the ERP system to achieve full traceability of the variety, specification, and origin of each titanium rod, and advocates and encourages industry anti-counterfeiting. Daxun relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

CP Grade 3 Titanium Rod Production Method

Daxun produces high-quality titanium bars with high performance, and can also manufacture according to customer’s agreement:

- Titanium ingots need to go through heat treatment and machining, immersion ultrasonic testing, mechanical properties testing, macroscopic and microscopic structural inspection and other processes. Production process: hot-rolled titanium bars – high efficiency, stable performance, forged titanium bars – flexible size, multi-fire forging, improve the comprehensive performance of titanium bars, cold-drawn titanium bars – usually small-sized high-precision titanium bars; the above titanium bars are all delivered with bright surface.

Qualité, livraison, inspection

Daxun performs several quality assurance tests, these tests include mechanical tests like area tensile, chemical analysis, material positive identification – PMI test, micro and macro testing, intergranular corrosion (IGC) test, ultrasonic flaw detection test, pitting and resistance test, hardness test, material positive identification, expansion test etc. All these tests ensure that the CP Grade 3 Titanium Rod and CP Grade 3 Titanium Round Bar material is suitable for the required application. During the production process, we measure the diameter, thickness and surface of the product.

- Nos délais de livraison sont strictement conformes au contrat.

- Aider les agences tierces des clients à se rendre à l'usine pour l'inspection

- Support free samples for customer testing

- Soutien à l'inspection sur site ou à l'inspection vidéo en usine

Emballage

Daxun Alloy garantit la meilleure qualité d'emballage, car celui-ci joue un rôle important dans le fret international, où les marchandises passent par différents canaux avant d'atteindre leur destination finale ; nous accordons donc une attention particulière à l'emballage. Nous emballons nos marchandises de différentes manières, en fonction du produit. Nous emballons nos produits de différentes manières, notamment :

- Boîtes et caisses

- Emballage rétractable

- Palettes en bois

- Boîtes en bois

Support technique

Si vous avez besoin d'une assistance technique supplémentaire, notre métallurgiste résident et notre personnel compétent se feront un plaisir de vous aider. En outre, Daxun dispose d'un laboratoire d'essai certifié, une première dans l'industrie des stocks multimétaux et plastiques. Ceci, à notre avis, démontre notre dévouement inébranlable à la qualité et notre philosophie en tant que fournisseur de services complets.

Daxun CP Grade 3 Titanium Rods help your brand improve quickly

- Tolerances for CP Grade 3 Titanium Round Bars

|

NOMINAL SIZE

|

h5

|

h6

|

h7

|

h8

|

h9

|

H10

|

H11

|

h12

|

|

DIAMETER mm

|

||||||||

| ~ to 3 | +0.004/0 | +0.006/0 | +0.01/0 | +0.014/0 | +0.025/0 | +0.04/0 | +0.06/0 | +0.1/0 |

| over 3 to 6 | +0.005/0 | +0.008/0 | +0.012/0 | +0.018/0 | +0.03/0 | +0.048/0 | +0.075/0 | +0.12/0 |

| over 6 to 10 | +0.006/0 | +0.009/0 | +0.015/0 | +0.022/0 | +0.036/0 | +0.058/0 | +0.09/0 | +0.15/0 |

| over 10 to 18 | +0.008/0 | +0.011/0 | +0.018/0 | +0.027/0 | +0.043/0 | +0.07/0 | +0.11/0 | +0.18/0 |

| over 18 to 30 | +0.009/0 | +0.013/0 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 | +0.13/0 | +0.21/0 |

| over 30 to 50 | +0.011/0 | +0.016/0 | +0.025/0 | +0.039/0 | +0.062/0 | +0.1/0 | +0.16/0 | +0.25/0 |

| over 50 to 80 | +0.013/0 | +0.019/0 | +0.03/0 | +0.046/0 | +0.074/0 | +0.12/0 | +0.19/0 | +0.3/0 |

| over 80 to 120 | +0.015/0 | +0.022/0 | +0.035/0 | +0.054/0 | +0.087/0 | +0.14/0 | +0.22/0 | +0.35/0 |

| over 120 to 180 | +0.018/0 | +0.025/0 | +0.04/0 | +0.063/0 | +0.1/0 | +0.16/0 | +0.25/0 | +0.4/0 |

| over 180 to 250 | +0.02/0 | +0.029/0 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 | +0.29/0 | +0.46/0 |

Types of CP Grade 3 Titanium Rods (3)

Tige en titane

Projets et produits récents

Produits apparentés (8)

CP Grade 3 is the strongest of the commercially pure titanium grades, offering approximately 20-30% higher tensile strength than Grade 2. You should choose Grade 3 when your application demands higher mechanical strength and pressure resistance. However, CP Grade 2 is slightly more formable, weldable, and typically more cost-effective. The simple rule is: Choose Grade 3 for strength, and Grade 2 for better formability and value.

Machining CP Grade 3 requires following standard practices for titanium. It demands slower cutting speeds, higher feed rates, and ample coolant compared to steel. Using sharp carbide tools and maintaining a constant cut to avoid work hardening is key. While it machines slower than steel, it can be precisely fabricated into complex shapes with the right equipment and techniques.

Its corrosion resistance is exceptional, particularly in oxidizing environments like seawater, salt spray, and chloride solutions. It forms a stable, passive oxide film that protects it from most forms of corrosion, including pitting and crevice corrosion, making it a premier choice for the chemical processing and marine industries.

Absolutely. All our CP Grade 3 titanium bars comply with international standards such as ASTM B348 et AMS 4921. Every shipment is accompanied by a full Material Test Report (MTR) / mill certification, verifying its chemical composition and mechanical properties for your complete peace of mind.

Please fill in the form on the “Contact Us” page, or call our sales manager at “+86 13382898899”, we will contact you as soon as possible. Our WhatsApp is online, and email ([email protected]) will be checked within 6 hours. Every inquiry or message will be responded to promptly. In addition, we share market information with our customers every week

We can provide titanium rod samples for you to check the quality. Sample is free and you just pay the freight.

Nous avons exporté vers plus de 42 pays, tels que le Canada, le Chili, le Koweït, l'Allemagne, la Corée du Sud, l'Arabie saoudite, Singapour, etc.

Les commandes d'essai peuvent être livrées dans un délai d'une semaine. Pour les commandes régulières, il faut compter environ deux semaines.