While stainless steel exhausts dominate consumer markets, titanium exhaust pipes deliver measurable performance advantages for high-stakes applications—from professional racing to saltwater marine engines. Yet misconceptions persist: Is titanium just a luxury upgrade? Can it handle extreme heat? Is the cost justified? This guide cuts through marketing hype with metallurgical evidence, revealing exactly where titanium exhaust systems transform performance and where conventional materials still make sense.

The Weight Advantage

Titanium’s density of 4.51 g/cm³—approximately 43% lighter than austenitic stainless steel (7.93 g/cm³)—creates tangible performance improvements when applied to exhaust systems:

- Vehicle Dynamics: Reducing rear-end weight by 8-15 kg improves weight distribution, enhancing cornering stability and reducing understeer in performance vehicles

- Engine Response: Lower rotational mass at the exhaust outlet allows faster engine revving and improved throttle response

- Fuel Efficiency: Every 10% reduction in vehicle weight improves fuel economy by approximately 6-8% under mixed driving conditions

Unlike aluminum alternatives, titanium maintains structural integrity at exhaust operating temperatures while delivering significant weight savings. The optimal balance is achieved using Grade 2 commercially pure titanium for standard applications or Grade 9 (Ti-3Al-2.5V) for high-stress sections requiring enhanced strength.

Why Titanium Outlasts Stainless Steel in Demanding Conditions

Automotive exhaust systems face a uniquely challenging environment combining high temperatures, moisture condensation, acidic combustion byproducts, and thermal cycling. These factors accelerate material degradation through multiple mechanisms:

Failure Modes Comparison:

- 304 Stainless Steel: Forms chromium oxide layer vulnerable to sulfuric acid attack above 500°C. Pitting corrosion initiates at weld zones where chromium carbide precipitation occurs. Typical service life: 3-5 years in aggressive environments.

- 316 Stainless Steel: Molybdenum addition (2-3%) improves pitting resistance but doesn’t prevent intergranular corrosion at sensitized weld areas. Service life extends to 5-8 years.

- Titanium (Grade 2): Develops a stable titanium dioxide (TiO₂) passive film resistant to sulfuric, nitric, and hydrochloric acids across the entire exhaust temperature range. No documented cases of corrosion failure in properly fabricated automotive exhaust systems after 20+ years of field use.

Marine Applications: In saltwater environments, titanium’s immunity to chloride attack becomes decisive. While stainless steel exhaust components typically require replacement every 2-3 years on marine vessels, titanium systems operate continuously for 10+ years without degradation.

Thermal Management: Engineering Efficiency

Titanium’s thermal properties contribute to engine efficiency through two mechanisms:

Heat Dissipation:

With thermal conductivity of 21.9 W/m·K (versus 16.2 W/m·K for 304 stainless steel), titanium pulls heat away from combustion chambers more effectively. This reduces underhood temperatures by 15-20°C, lowering intake air temperature and increasing oxygen density for more complete combustion.

Gas Velocity Maintenance:

Titanium’s lower heat retention keeps exhaust gases hotter through the entire system length. Hotter gases maintain higher velocity, improving scavenging efficiency—particularly in the 4,000-7,000 RPM range where performance engines operate most frequently. Independent dyno testing confirms 2-4% torque improvement across the powerband compared to equivalent stainless steel systems.

Critical Applications for Titanium Exhaust Systems

Racing and Performance Vehicles:

- Circuit racing where weight distribution affects lap times

- Drag racing applications benefiting from reduced rotational mass

- Rally vehicles requiring corrosion resistance in extreme conditions

Marine Applications:

- Saltwater vessels where chloride exposure destroys stainless steel

- High-performance boats where weight reduction improves handling and speed

- Commercial marine operations where downtime costs exceed material premiums

Specialized Industrial Equipment:

- Generator exhaust systems in corrosive environments

- Agricultural equipment operating with high-sulfur fuels

- Emergency response vehicles requiring maximum reliability

FAQ About Titanium Exhaust Pipes

Q: Can titanium exhaust pipes withstand high exhaust temperatures?

A: Grade 2 titanium maintains structural integrity up to 538°C (1000°F)—well above typical exhaust gas temperatures in production vehicles (400-500°C). Only specialized applications like turbocharger housings exceed this limit, where nickel-based superalloys are better suited. Titanium’s real thermal limitation is continuous exposure above 800°C, which no standard automotive exhaust produces. Properly designed titanium systems actually run cooler than stainless steel due to superior heat dissipation.

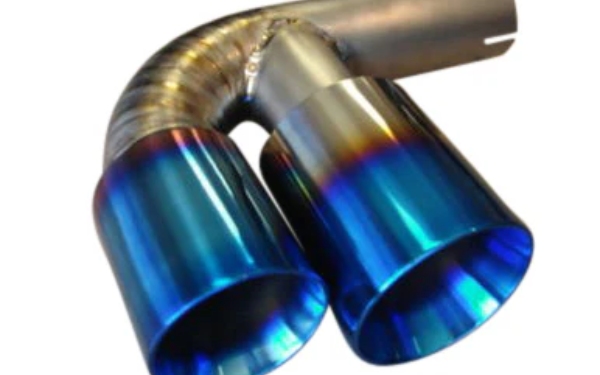

Q: Does blue/purple discoloration on titanium exhaust indicate failure?

A: No—this coloration is purely cosmetic oxidation of the surface oxide layer. Similar to tempering colors on tool steel, heat tinting (straw-yellow to deep blue) occurs when titanium is exposed to 300-600°C. It does not affect structural integrity or corrosion resistance. Many professional racing teams actually prefer this aesthetic as it verifies the system has reached optimal operating temperatures. Properly fabricated titanium exhausts with visible heat tinting have operated 300,000+ miles in demanding applications.

Q: Does titanium exhaust produce a different sound than stainless steel?

A: Yes—titanium’s higher speed of sound (4,170 m/s vs. steel’s 3,200 m/s) and lower internal damping create a distinctive acoustic profile. The exhaust note typically shifts to higher frequencies (240-280 Hz vs. 180-220 Hz for stainless), producing a crisper, more metallic tone that enthusiasts describe as “responsive.” This isn’t merely aesthetic—it provides immediate audible feedback about engine behavior during high-performance driving.

Conclusion

Titanium exhaust pipes deliver genuine engineering advantages—but only when matched to appropriate applications. For high-performance automotive, marine, and racing applications where these conditions exist, titanium provides measurable benefits in weight savings, corrosion resistance, thermal efficiency, and service life. For standard commuter vehicles in mild environments, stainless steel remains the practical choice.

Daxun Alloy Co. Ltd. possesses extensive manufacturing expertise in titanium materials, delivering specialized material solutions based on stringent quality control standards. If your project requires sourcing premium titanium alloy materials, contact us immediately.