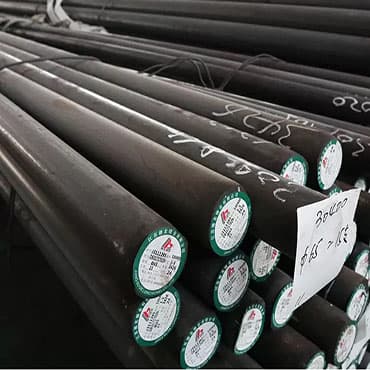

SS 410 stainless steel bars and round bars China supplier

En tant que principal fournisseur et exportateur d'acier inoxydable en Chine, Daxun fournit des barres d'acier inoxydable.(barres rondes) dans le monde entier.

- Grade: AISI 410-12Cr13

- Manufacturing: hot rolled, cold drawn, forged

- Standards: ASTM, ASME, GB, DIN, JIS, ISO

- It is magnetic in both annealed and hardened conditions

- Different heating methods produce various properties

- High corrosion resistance to acids: nitric acid, sulfuric acid

As a well-known industry participant, Daxun manufactures, exports, stocks, and supplies a full range of 410 Stainless Steel Round Bar (SS 410 Round Bar) to domestic and international consumers. We make this 410 Stainless Steel Round Bar (SS 410 Round Bar) from the highest quality materials and adhere to the toughest quality specifications.

Leader mondial des services de fabrication de barres en acier inoxydable et de barres rondes

ASTM A479 AISI 410 Stainless Steel Round Bar, ASTM A479 SS 410 Square Bar, 410 Stainless Steel Flat Bar, Stainless Steel 410 Rod, Extensive range of Stainless Steel 410 Round Bar, SS 410 Round Bar, SS DIN 1.4006 Round Bar manufacturers, Buy Stainless Steel 410 Bright Bar, 410 SS Polished Bar, SS 410 Rod suppliers, China AISI SS 410 Round Bar producers.

410 Stainless Steel Bar is a martensitic stainless steel that offers excellent corrosion resistance, strength, and hardness. This steel is magnetic in both the annealed and hardened states, and a variety of properties can be produced using a variety of heat treatments.

One of the main benefits of 410 Stainless Steel Bar is its high corrosion resistance, making it suitable for a variety of situations. This includes indoor and outdoor applications, as well as situations with severe chemicals, acids, and other corrosive compounds.

410 Stainless Steel Bar is not only corrosion resistant, but also strong and durable. This makes it ideal for use in industries that require strong and durable materials, such as automotive drive shafts and the aerospace industry.

Heat treatment is a critical part of 410 Stainless Steel Bar processing. Different heat treatment procedures can be employed to improve specific qualities of the steel, such as strength, ductility, and hardness. These heat treatment techniques include annealing, quenching, and tempering.

History of 410 Stainless Steel Bar

The American Iron and Steel Institute (AISI) developed 410 stainless steel in the early twentieth century. It is a martensitic stainless steel, which means it contains at least 11.5% chromium. This alloy was designed to improve the corrosion resistance of standard carbon steel through the addition of chromium.

In the early days, 410 stainless steel round bar was mainly used for the manufacture and construction of tools and equipment. Its excellent strength and corrosion resistance made the steel ideal for long-term use.

During World War II, the demand for 410 stainless steel round bar rose as it was used to make military equipment such as tanks and submarines. This strengthened its image as a reliable and durable substance.

In the post-war period, 410 stainless steel found an increasingly wide range of applications, especially in the automotive and aerospace industries. Its excellent strength and corrosion resistance made it ideal for use in harsh environments. In the 1960s and 1970s, 410 stainless steel became increasingly popular in the culinary and medical industries after it was discovered to be a suitable material for the manufacture of cookware, surgical instruments, and food processing equipment.

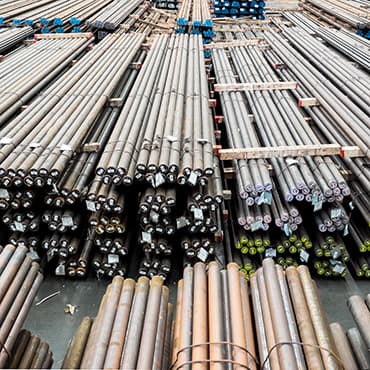

Notre réseau de centres de service stocke des produits en barres d'acier inoxydable pour un approvisionnement rapide en barres de tailles et d'alliages courants.Nous produisons également des barres d'acier inoxydable de taille personnalisée et pouvons organiser des programmes d'inventaire pour une rotation rapide si les quantités sont inférieures aux minimums de l'usine.Daxun Alloys stocke des barres rondes en acier inoxydable avec des diamètres allant de 1/16″ à 26″. Les barres rondes sont disponibles dans presque toutes les nuances d'acier inoxydable, y compris 302, 303, 304/L, 309/S, 310/S, 316/L, 317/L, 321, 321/H, 347, 347H, 410, 416, 420, 440C, 17-4PH, Duplex 2205, et Alloy 20. Les barres rondes en acier inoxydable traitées thermiquement sont proposées en 17-4PH, H900 (sur demande), H1025, H1150, Double H1150 et H1150M. D'autres températures de traitement thermique peuvent être fabriquées sur demande. Nous stockons les aciers inoxydables de la série 400 suivants : 410, 430 et 416. Nous avons également en stock des barres rondes en acier inoxydable de précision et de qualité roulement 303, 304 et 316/L. La majeure partie de notre stock est constituée de nos barres usinées uniques : des barres rondes en acier inoxydable qui sont fondues selon des normes cohérentes afin d'augmenter leur usinabilité et de réduire le coût total par composant. Nos machines de traitement des barres en acier inoxydable permettent à Daxun Alloys de produire selon les spécifications exactes de nos clients.

Données

- Paramètres

- Ingrédients

- Propriétés mécaniques

- PROPRIÉTÉS PHYSIQUES

- Tous les équivalents

- Les types

| ASTM A479 410 Round Bar Specification | ASTM A479 / ASTM A479 /ASTM A182 / ASME SA479 / ASME SA479 / ASME SA182 |

| ASTM A479 410 Round Bar Manufacturing Process | Hot Rolled / Cold Rolled / Hot Forging / Rolling / Machining |

| ASTM A479 410 Round Bar Other Grades | 202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. |

| UNS No. – UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| DIN / EN No. – 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| AFNOR: Z2 CN 18.10, Z 6 CND 17-11, Z 2 CND 17-12,Z3 CrNi 22.05 AZ | |

| EURONORM: FeMi35Cr20Cu4Mo2, FeMi35Cr20Cu4Mo2, X1CrNiMo17 12 2, X3CrNiMo17 12 2, FeMi35Cr20Cu4Mo2, X2CrNiMoN 22.5.3 | |

| ASTM A479 410 Round Bar Dimension | Round Bars : Outside Diameter in the range of 4mm to 500mm |

| Bright Bars : Outside Diameter in the range of 4mm to 200mm | |

| Hex Bars : 18mm to 57mm (11/16″ to 2-3/4″) | |

| Square Bars : 18mm to 57mm (11/16″ to 2-3/4″) | |

| Flat Bars : 1/2″to 10″in thickness range of 2mm to 150mm, Custom Size Stainless Steel Flats available | |

| ASTM A479 410 Round Bar Length | 2 meters to 7.5 meters ( 8 feet to 24 feet), or Custom Length as per Requirement |

| ASTM A479 410 Round Bar Forms and Shape | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, HRAP, Bright, Shaft, Forging Etc. |

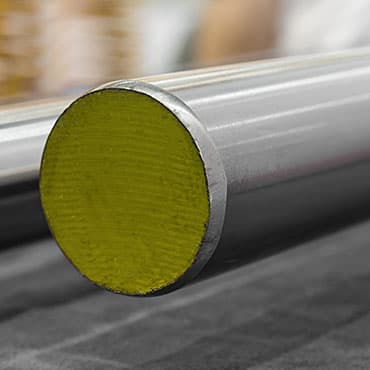

| ASTM A479 410 Round Bar Finish | Noir, poli brillant, brut de décolletage, finition NO.4, finition mate, finition BA |

| ASTM A479 410 Round Bar Dimension Standard | ASTM A 484 / ISO h11 / ISO K12 Tolerances F8 / h8, h9, h10, h11, h12, k12, k13, A-484, EN-10060, DIN-1013 etc. |

| ASTM A479 410 Round Bar Heat Treatment | Condition A in which the bars are Annealed |

| Condition H in which the bars are Hardened and Tempered at a relative Temperature | |

| Condition T in which the bars are Hardened and Tempered at a relatively High Temperature | |

| Condition S in which the bars are Strain Hardened or relatively Light Cold Worked | |

| Condition B in which the bars are Relatively severe Cold worked. | |

| Solution Annealed, Aging and Double Aging | |

| ASTM A479 410 Round Bar Surface Finish | Centreless Ground & Belt Polished, up to Ra value = 0.2 um (12 RMS), and Grit Polished of up to 180 to 600 |

| ASTM A479 410 Round Bar Chamfering | Available in 30°, 45° & 60° through fully automatic, both-end chamfering machine |

| ASTM A479 410 Round Bar Other Testing | NACE MR0175, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, Magnetic Particle Inspection (MPI), 100% tested thru Digital Ultrasonic Flaw Detector, as per ASTM A-388, EN 10308 (class 1to4),API 6A/ISO 10423:2003-PSL3,SEP 1920:1984 ( class A,B,C), MIL STD 2154 etc. |

| ASTM A479 410 Round Bar Value Added Services | Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Polishing |

| ASTM A479 410 Round Bar Packaging | Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps |

| ASTM A479 410 Round Bar Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| ASTM A479 410 Round Bar Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of CHINA Standards BIS Approved ETC |

| ASTM A479 410 Round Bar Documentation | Commercial Invoice which includes HS Code / Packing List including net weight and gross weight, number of boxes, Marks and Numbers / Certificate of Origin legalized/attested by Chamber of Commerce or Embassy / Fumigation Certificates / Raw Material Test Reports / Material Traceability Records / Quality Assurance Plan (QAP) / Heat Treatment Charts / Test Certificates certifying NACE MR0103, NACE MR0175 / Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 / Guarantee Letter / NABL approved Laboratory Test Reports / Welding Procedure Specification/Procedure Qualification Record, WPS/PQR / Form A for the purposes of the Generalized System of Preferences (GSP) |

| UNS No | S41000 |

| FR | 1.4006 |

| AISI | 410 |

| Carbone (C) | 0.08/0.15 |

| Silicium (Si) | 1 |

| Manganèse (Mn) | 1 |

| Phosphorus (P) | 0.04 |

| Soufre (S) | 0.03 |

| Chrome (Cr) | 11.5/13.5 |

| Molybdène (Mo) | |

| Nickel (Ni) | 0.75 |

| Propriété | Valeur |

| Densité | 7.8 g/cc |

| Limite d'élasticité | 1,225 MPa at a strain of 0.2% |

| Résistance ultime à la traction | 1,525 MPa |

| Dureté | 126–192 Brinell hardness (annealed condition) 201–255 Brinell hardness (when hardened and tempered) |

| Bulk Modulus | 200 GPa |

| Melting Point | 1,480–1,530 °C |

| Résistance à la corrosion | Good corrosion resistance in mild atmospheric environments, water, and some mild chemical environments. It shows pitting corrosion and brown staining in salt water conditions and offers lower resistance to acidic environments than the austenitic stainless steel alternatives. |

| Magnetism | Permeability 700–1,000. Highly responsive to magnetic fields, act as a strong magnetic flux carrier due to its martensitic structure. |

| Densité (lb./ in^2) @ RT | 0.28 | |

| Module d'élasticité en traction (psi x 10^6) | 29 | |

| Chaleur spécifique (BTU/o F/lb.) | 32 à 212 oF | 0.11 |

| Conductivité thermique (BTU/hr/ft^2/ft) | 212oF | 14.4 |

| 932oF | 16.6 | |

| Coefficient moyen de dilatation thermique (po x 10^-6 par o F) | 32 à 212oF | 5.5 |

| 32 to 1,200oF | 6.5 | |

| Résistivité électrique (micro ohms - cm) | à 70oF | 22.5 |

| STANDARD | WERKSTOFF NR. | UNS | BS | FR | JIS |

| SS 410 | 1.4006 | S41000 | 410S21 | X12Cr13 | SUS 410 |

| Stainless Steel 410 Rods | 410 SS Threaded Bars Stockiest in India |

| Stainless Steel 410 Round Bars | Stainless Steel 410 Cold Drawn & Polished Square Bars |

| ASTM A479 Stainless Steel 410 Bars | Austenitic ASTM Bright 410 Stainless Steel Bar |

| SS UNS S41000 Round Bars | SS WERKSTOFF NR. 1.4845 Round Bars |

| ASTM A479 410 Stainless Steel Rods Manufacturer | 410 Stainless Steel Hexagon Bars Dealers |

| A479 410 Steel Polish Bars Manufacturer | Stainless Steel 410 Cold Drawn Bars Stockholder |

| SUS 410 Stainless Steel Black Bars Distributors | High Speed Steel Stainless Steel 410 Hollow Bar Suppliers |

| Top Quality Stainless Steel 410 Spring Steel Bars | ASME, ASTM, EN, BS, GB, Stainless Steel 410 Flat Bars |

| Stainless Steel 410 Bright Bar Exporter | AISI ASTM Stainless Steel 410 Round Bar |

| AISI 410 Stainless Steel Forged Round Bars | Cold Rolled Stainless Steel 410 Rods |

Choisissez Daxun et faites en sorte que vos clients soient satisfaits.

Quick response-410 Stainless Steel Rod

We provide customers with timely and fast delivery of 410 stainless steel bar products. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real time, and the data is seamlessly connected; in terms of logistics, the processing center is close to ports and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on time.

Avantages de Daxun

- Variétés : Nous proposons une large gamme de tailles et de qualités, y compris les séries 300, 400, 600, etc.

- Flexibilité : Que vous ayez besoin de barres laminées à chaud ou étirées à froid, nos longueurs de barres en acier inoxydable sont conçues pour répondre aux exigences spécifiques de votre projet.

- Quality Standards: 410 Stainless Steel Rod meet strict ASTM, ISO9001, GB, NSF/ANSI standards to ensure reliability and performance.

- Commandes personnalisées : Vous recherchez des barres en acier inoxydable de dimensions spéciales ? Nous offrons une variété d'options de personnalisation de barres en acier inoxydable à des prix compétitifs et une commande en ligne pratique.

410 Stainless Steel Rod packaging

We pay attention to every process of 416 round bars to ensure quality. The packaging we usually adopt is to pack the stainless steel round bars with environmentally friendly plastic bags and then put them into fumigation-free wooden boxes or wooden pallets. Customized packaging, such as OEM, can also be negotiated. We provide almost everything to meet your round bar packaging requirements. We attach great importance to packaging. The round bars are packed in wooden corrugated boxes, wrapped with plastic packaging and bubble film on the outside.

Qualité, livraison, inspection

- Daxun effectue également plusieurs tests d'assurance qualité. Ces tests comprennent le test d'aplatissement, le test de piqûre et de résistance, le test mécanique, le test de dureté, l'identification positive du matériau, le test d'expansion, etc. Tous ces tests garantissent que le matériau est adapté à l'application requise.

- Au cours du processus de production, nous mesurons le diamètre, l'épaisseur et la surface du produit. Notre délai de livraison standard est de 7 à 15 jours, sauf pour certains produits de taille spéciale, pour lesquels le délai de livraison peut atteindre 20 jours.

Nos délais de livraison sont strictement conformes au contrat. - Aider les agences tierces des clients à se rendre à l'usine pour l'inspection

- Fournir des échantillons gratuits aux clients pour qu'ils les testent

- Soutien à l'inspection sur site ou à l'inspection vidéo en usine

Support technique

Si vous avez besoin d'une assistance technique supplémentaire, notre métallurgiste résident et notre personnel compétent se feront un plaisir de vous aider. En outre, Daxun dispose d'un laboratoire d'essai certifié, une première dans l'industrie des stocks multimétaux et plastiques. Ceci, à notre avis, démontre notre dévouement inébranlable à la qualité et notre philosophie en tant que fournisseur de services complets.

410 Stainless Steel Rod Ordering Information

410 Round Bar Purchase orders shall include quantity, PSL grade, type or category, API5L reference, diameter, surface finish, length, and any applicable attachments or additional requirements related to chemical composition, mechanical properties, heat treatment, additional testing, manufacturing process, surface finish, or end treatment. Bars are solution bright annealed.

SS410 Stainless Steel Rod Features

Daxun Alloy Permettez à votre marque de s'améliorer rapidement

- Galerie

- État de livraison

- Durcissement par l'âge

| Choix de l'État de livraison | État de surface |

| Forgé | Noir |

| Poli | |

| Laminés à chaud | Noir |

| Poli | |

| Lumineux | |

| Mariné | |

| Etiré à froid | Poli |

| Lumineux | |

| Remarque : | |

| 1. Si vous avez besoin d'un autre pays de livraison que ceux mentionnés ci-dessus, veuillez nous le confirmer. | |

| 2. En cas de demande ou de commande, veuillez nous faire part de toute exigence supplémentaire non indiquée ici. | |

| Les matériaux recuits par mise en solution peuvent être durcis par vieillissement comme suit:-*Dénote un double surstockage | ||||||||||||

| Condition | H900 (H480) | H925 (H495) | H1025 (H550) | H1075 (H580) | H1100 (H595) | H1150 (H620) | H1150M (H620M)* | Plus | H1150D (H620D)* | Plus | ||

| Chauffer jusqu'à | ±15oF | 900oF | 925 oF | 1025oF | 1075oF | 1100oF | 1150oF | 1400oF | 1150oF | 1150oF | 1150oF | |

| ±9oC | 480oC | 495oC | 550oC | 580oC | 595oC | 620oC | 760oC | 620oC | 620oC | 620oC | ||

| Tenir pendant des heures | 1 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | ||

| Frais jusqu'en dessous | Air | Air | Air | Air | Air | Air | Air | Air | Air | Air | ||

| 90oF (32oC) | ||||||||||||

Types of SS 410 Stainless Steel Rods (6)

Informations disponibles pour référence et téléchargement

Production de barres en acier inoxydable

Daxun est un fabricant fiable de barres en acier inoxydable.

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless steel bars are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the 410 Stainless Steel Rod have less defects. At Daxun, rest assured that all products are durable, premium, and high-performance.

Projets et produits récents

Produits apparentés (12)

We can provide 410 Stainless Steel Rod samples for you to check the quality. Sample is free and you just pay the freight.

Nous avons exporté vers plus de 42 pays, tels que le Canada, le Chili, le Koweït, l'Allemagne, la Corée du Sud, l'Arabie saoudite, Singapour, etc.

Our MOQ is 1 ton for stainless steel 410 Stainless Steel Rod.

Les commandes d'essai peuvent être livrées dans un délai d'une semaine. Pour les commandes régulières, il faut compter environ deux semaines.