Daxun is a 310S stainless steel sheet supplier from China

As China’s leading stainless steel plate supplier and exporter, Daxun provides 310S stainless steel plates to the world.

- Grade: AISI 310-310S-S31008

- Fabrication : tôles laminées à froid, tôles laminées à chaud, tôles forgées

- Norme : ASTM, ASME, GB, DIN, JIS, ISO, EN, BS

- Type : tôles minces laminées à froid, tôles épaisses laminées à chaud

- Surface : 2B, NO.1, NO.4, HL, BA, 8K, etc.

- Longueur : 2438mm3048mm6000mm peut être personnalisé

- Origine : TISCO, Baosteel, Pohang, Tsingshan, Delong

The global leader in stainless steel sheet fabrication services

S31008 (310S) Sheet and Plate, Austenitic stainless steel alloy 310S (UNS S31008) is designed for applications requiring high-temperature corrosion resistance. The alloy resists oxidation up to 2010°F (1100°C) with room temperature cycling. Alloy 310 can be used in moderate carburizing environments and is resistant to sulfidation due to its high chromium content and moderate nickel content. More severe carburizing environments in heat-treating equipment typically require a nickel alloy such as 330 (UNS N08330). Alloy 310S can be used in bonding, nitriding, mild oxidation, and thermal cycling processes; however, a reduced maximum service temperature is required. Alloy 310 can also be used in cryogenic applications because it has low magnetic permeability and remains strong down to -450°F (-268°C). When heated to 1202–1742, the alloy precipitates the sigma phase (650–950°C). Hardness is partially restored by solution annealing at 2012–2102°F (1100–1150°C). This alloy is also available as a low-carbon alloy, 310S (UNS S31008). It is easily fabricated. A high carbon modification, 310H (UNS S31009), is designed to improve creep resistance. In most cases, the grain size and carbon content of the plate can meet both 310S and 310H standards. Standard shop fabrication procedures can be used to easily weld and process alloy 310.

Stainless Steel 310S Plate has trace amounts of silicon, sulfur, phosphorus, manganese, and up to 24% chromium, 19% nickel, and up to 0.08% carbon. Heat resistance, corrosion resistance, strength, and even high-temperature oxidation resistance are just a few of the many benefits of this popular stainless steel alloy. It can be utilized in many different applications, including burners, oil burners, and evaporator pipes and tubes. Because of its affordability, it’s perfect for a range of applications requiring low-cost maintenance supplies.

Because of its exceptional resilience to high temperatures, the 310S stainless steel plate is a great option for a wide range of industries, including petrochemical and chemical production, food processing, power plants, dairy farms, sugar mills, breweries, and energy generation. 310S Stainless Steel Plate is capable of withstanding oxidizing environments up to 2100°F (1149°C) due to its high chromium concentration. Its ductility, toughness, and weldability are all excellent. Its exceptional low-temperature performance, even down to -20°F (-29°C), combined with its resistance to heat and corrosion make it the perfect material for cryogenic applications. In conclusion, it is an excellent option for high-temperature industrial applications due to its strong resistance to oxidation and ability to prevent scaling at temperatures as high as 2000°F (1093°C).

Données techniques

- Paramètres

- Élément

- Propriétés mécaniques

- Standard

| Product Parameters: 310(UNS S31008) Stainless Steel Sheet/Plate | |||

| Largeur | 10mm~2500mm | ||

| Épaisseur | 0,2mm~100mm | Tolérance d'épaisseur | +/-0,03 mm |

| Standard | ASTM/ASME 240/480,JIS 4305,DIN EN 10088-2 | ||

| Surface | 2B,BA,8K,NO.1,NO.4,NO.3,hairline,damier,or ,noir ,or rose,etc. | ||

| spécification | 1000*2000/L,1219*2438/L,1250*2500/L,1500*3000/L1500*6000/L,1800*6000/L,2000*6000/L2200*6000L | ||

| Origine du moulin | TISCO, ZPSS, BAOSTEEL, JISCO, ZSESS, ATI, SMC, HAYNES, VDM, ArcelorMittal, Outokumpu, etc. | ||

| Certification | ISO, SGS, BV, TUV, CE, etc. | ||

| Élément | % Présent (sous forme de produit) | |

| C, H, P, L | TW* / TS* | |

| Carbone (C) | ≤0.10 | ≤0.15 |

| Silicium (Si) | ≤1.50 | ≤0.75 |

| Manganèse (Mn) | ≤2.00 | ≤2.00 |

| Phosphore (P) | ≤0.045 | ≤0.045 |

| Soufre (S) | ≤0.015 | ≤0.030 |

| Chrome (Cr) | 24.00 – 26.00 | 24.00 – 26.00 |

| Nickel (Ni) | 19.00 – 22.00 | 19.00 – 22.00 |

| Azote (N) | ≤0.11 | - |

| Fer (Fe) | Équilibre | Équilibre |

| Forme du produit | |||||

| C, H, P | L | TW* / TS* | |||

| Thickness a or diamter d (mm) | a ≤ 12 | d ≤ 25 | - | ||

| Hardness HB max. 1) 2) 3) | 192 | 192 | - | ||

| Proof Strength3) | Rp0.2 N/mm2 | 210 | 210 | 230 | |

| Rp1.0 N/mm2 | 230 | 230 | 270 | ||

| Résistance à la traction | Rm N/mm2 | 500 – 700 | 500 – 700 | min. 500 | |

| Allongement min. en % | Long Products | 351) | 351) | 334) / 355) | |

| Flat Products | 0.5 ≤ a/d < 3 | 334)5) | 334)5) | 354)5)6) | |

| 3 ≤ a/d | 354)5) | 354)5) | 354)5)6) | ||

| 310 | 310S | 310H |

|---|---|---|

| UNS S31000 | UNS S31008 | UNS S31009 |

| ASTM A240 | ASTM A240 | ASTM A240 |

| ASTM A480 | ASTM A480 | ASTM A480 |

| ASME SA240 | ASME SA240 | ASME SA240 |

| AMS 5521 | AMS 5521 | AMS 5521 |

Choisissez Daxun et faites en sorte que vos clients soient satisfaits.

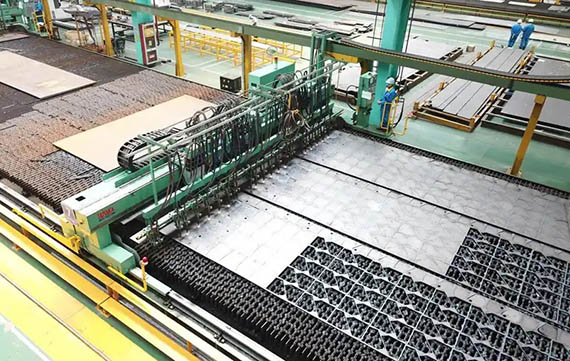

Livraison rapide

We provide timely and fast delivery of 310S stainless steel plate products for customers with urgent needs. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real-time, and the data is seamlessly connected; in terms of logistics, the processing center is close to highways and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on time.

Benefits of Stainless Steel 310S Plates :

- Corrosion resistance: The main benefit of 310S stainless steel plates is their excellent corrosion resistance. They resist corrosion from a wide range of environments, including acidic and alkaline solutions, making them suitable for a wide range of applications.

- High-temperature strength: 310S stainless steel plates exhibit excellent strength at elevated temperatures. This property is critical in applications that are frequently exposed to high temperatures, ensuring structural integrity and performance in demanding conditions.

- Durability and lifespan: The durability of 310S stainless steel plates gives them a long service life, making them an affordable choice for many applications. The material is resistant to wear and tear, minimizing the need for frequent replacement.

Benefits of Stainless Steel 310S Plates :

310S/2520 Plate Features:

- High-temperature resistance

- Excellent oxidation resistance

- Improved creep/rupture properties

- Excellent corrosion resistance

- Not susceptible to thermal fatigue and cyclic heating

- Good strength at temperatures up to 2100°F

Qualité, livraison, inspection

- Daxun contrôle strictement la qualité des produits. Avant de passer commande, nous vous enverrons la garantie du produit. Si vous avez besoin d'échantillons pour les tester, nous pouvons également vous les envoyer gratuitement.

- During the production process, we carefully measure the diameter, thickness, and surface quality of each product to ensure it meets exacting standards. Our standard delivery time is typically 7 to 15 days. However, for special-sized products, the delivery time may be extended to 20 days to accommodate the additional customization and processing required.

Nos délais de livraison sont strictement conformes au contrat. - Aider les agences tierces des clients à se rendre à l'usine pour l'inspection

- Fournir des échantillons gratuits aux clients pour qu'ils les testent

- Soutien à l'inspection sur site ou à l'inspection vidéo en usine

Applications

- Cryogenic Components: Designed to withstand extremely low temperatures, ensuring optimal performance in critical applications.

- Food Processing: Reliable materials and components tailored for hygienic and efficient food production systems.

- Furnaces: Durable solutions for burners, doors, fans, ducting, and liners, supporting high-temperature industrial processes.

- Fluidized Bed Furnaces: Robust components including coal burners, grates, ducting, and bellows for enhanced operational efficiency.

- Ore Processing and Steel Mills: High-performance equipment for smelting, steelmaking, and continuous casting operations.

- Petroleum Refining: Specialized systems such as catalytic recovery units, flares, heat exchangers, and tube hangers for maximum efficiency in refining processes.

- Production d'électricité : Precision-engineered components like gas furnace internals, pulverized coal burners, and tube hangers to support energy production.

- Sintering and Cement Plants: Reliable burners, burner hoods, feed and discharge systems, and bellows for seamless operation in harsh environments.

- Heat Treating: Advanced solutions, including annealing covers and boxes, burner grates, doors, fans, muffle furnaces, retorts, heat exchangers, and walking beams for consistent performance in thermal processing.

SS 310S Plate Surface Treatment

1D: The surface is matte with a discontinuous particle shape.

2D : Blanc avec un ton argenté.

2B: Silver gray with better gloss and flatness than the 2D surface.

Ba : Surface proche d'un miroir avec une brillance et une réflectivité excellentes.

No.3 : Bonne brillance et surface rugueuse.

No.4 : La surface présente des lignes fines et une bonne brillance.

HL : Gris argenté avec des cheveux dorés.

8K : Surface miroir.

310 plate stainless steel Features

Daxun Permettez à votre marque de s'améliorer rapidement

- Galerie

- Tolérance

- État de livraison

- Autres séries de produits

| Tolérance pour la tôle 2B | |||

| Taille | Rang de tolérance | ||

| Groupe 1 | Groupe 2 | Groupe 3 | |

| 0.4 | 0.3 ~ 0.32 | 0.33 ~ 0.37 | 0.37 ~ 0.39 |

| 0.5 | 0.4 ~ 0.42 | 0.43 ~ 0.47 | 0.47 ~ 0.49 |

| 0.6 | 0.5 ~ 0.52 | 0.53 ~ 0.56 | 0.57 ~ 0.59 |

| 0.7 | 0.6 ~ 0.62 | 0.63 ~ 0.67 | 0.67 ~ 0.69 |

| 0.8 | 0.7 ~ 0.72 | 0.73 ~ 0.77 | 0.74 ~ 0.79 |

| 0.9 | 0.8 ~ 0.82 | 0.83 ~ 0.87 | 0.87 ~ 0.89 |

| 1 | 0.89 ~ 0.9 | 0.91 ~ 0.94 | 0.94 ~ 0.99 |

| 1.2 | 1.02 ~ 1.08 | 1.09 ~ 1.15 | 1.16 ~ 1.18 |

| 1.5 | 1.32 ~ 1.38 | 1.39 ~ 1.45 | 1.46 ~ 1.48 |

| 2 | 1.72 ~ 1.79 | 1.8 ~ 1.86 | 1.87 ~ 1.9 |

| 2.5 | 2.23 ~ 2.36 | 2.32 ~ 2.42 | 1.42 ~ 1.47 |

| 3 | 2.7 ~ 2.77 | 2.78 ~ 2.82 | 2.85 ~ 2.9 |

| Tolérance pour la tôle laminée à chaud n° 1 | |||

| Taille | Rang de tolérance | ||

| Groupe 1 | Groupe 2 | Groupe 3 | |

| 3 | 2.6 ~ 2.75 | 2.75 ~ 2.85 | 2.86 ~ 2.9 |

| 4 | 3.5 ~ 3.6 | 3.6 ~ 3.75 | 3.76 ~ 3.95 |

| 5 | 4.5 ~ 4.6 | 4.6 ~ 4.75 | 4.75 ~ 4.95 |

| 6 | 5.4 ~ 5.6 | 5.6 ~ 5.75 | 5.75 ~ 5.85 |

| 8 | 7.3 ~ 7.5 | 7.5 ~ 7.65 | 7.65 ~ 7.85 |

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9.6 ~ 9.85 |

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11.6 ~ 11.85 |

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13.6 ~ 13.85 |

| 16 | 15.2~ 15.5 | 15.5~ 15.7 | 15.7~ 16.1 |

| 18 | 17.2~ 17.5 | 17.5~ 17.7 | 17.7~ 18.1 |

| 20 | 19.2~ 19.5 | 19.5~ 19.7 | 19.7~ 20.1 |

| 30 | 29.2~ 29.5 | 29.5~ 29.7 | 29.7-30.1 |

| 40 | 39.2~ 39.5 | 39.5~ 39.7 | 39.7~ 40.1 |

| 50 | 49.2~ 49.5 | 49.5~ 49.7 | 49.7~ 50.1 |

| 60 | 59.2~ 59.5 | 59.5~ 59.7 | 59.7~ 60.1 |

| Choix de l'État de livraison | État de surface |

| Laminés à froid | 2B |

| 2D | |

| BA | |

| Ligne de démarcation des cheveux | |

| N° 3 | |

| N°4 | |

| 6K | |

| 8K | |

| Remarque : | |

| 1. Si vous avez besoin d'un autre pays de livraison que ceux mentionnés ci-dessus, veuillez nous le confirmer. | |

| 2. En cas de demande ou de commande, veuillez nous faire part de toute exigence supplémentaire non indiquée ici. | |

| État de livraison | |

| Choix de l'État de livraison | État de surface |

| Laminés à chaud | N°1 |

| N° 3 | |

| N°4 | |

| 6K | |

| 8K | |

| Mariné | |

| Remarque : | |

| 1. Si vous avez besoin d'un autre pays de livraison que ceux mentionnés ci-dessus, veuillez nous le confirmer. | |

| 2. En cas de demande ou de commande, veuillez nous faire part de toute exigence supplémentaire non indiquée ici. | |

| Grade | Type | Épaisseur | Surface |

| Austénitique | 304/304H/304L/304J1 | 0,25-150 mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80 mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0.3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferrite | 430 | 0,4-3,0 mm | 2B/BA/NO.4/8K/SB/HL |

| Ferrite ultra pure | 443 | 0,4-2,0 mm | 2B |

| 436L/439/444/441 | 0,5-3,0 mm | 2B、2D | |

| 409L | 0,4-2,5 mm | 2B、2D | |

| Grade | Type | Épaisseur | Original |

| Acier résistant à la chaleur | 309S | 0,5-40 mm | CHN |

| 310S | 0,5-40 mm | CHN | |

| Acier duplex | 2101 | 1,5-50 mm | CHN |

| 2304 | 3.0-50mm | CHN | |

| 2205 | 0,5-60 mm | CHN | |

| 2507 | 1.0-60mm | SWE / JPN / CHN | |

| Acier super austénitique | N08904 | 0,6-50 mm | SWE / JPN / CHN |

| S31254 | 0,5-50 mm | SWE / JPN / CHN | |

| N08926 | 0,5-50 mm | SWE / JPN / CHN | |

| N08367 | 0,5-50 mm | SWE / JPN / CHN | |

| Alliage base nickel | N08031 | 1.0-50mm | US / JPN / GER |

| N08810/N08800 | 0,8-50 mm | US / JPN / CHN | |

| N08028 | 1.0-20mm | US / GER / JPN | |

| N08020 | 1.0-20mm | US / GER / JPN | |

| N08825 | 0,8-40 mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50 mm | US / GER / JPN | |

| N06022 | 1.0-50mm | US / GER / JPN | |

| N06625 | 0,8-20 mm | US / GER / CHN | |

| N04400 | 1.0-20mm | US / GER / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20 mm | US / JPN | |

| Titane | TA1/Gr1 | 0,5-50 mm | JPN / CHN |

| TA2/Gr2 | 0,5-50 mm | JPN / CHN | |

| Matériel de soudage | ERNiCrMo-13 | 1.2、2.4mm | GER |

| ERNiCrMo-3 | 2,4 mm | GER | |

| ERNiCrMo-4 | 2,4 mm | ÉTATS-UNIS |

The surface and shape of 310S stainless steel plate (7)

Informations disponibles pour référence et téléchargement

Daxun est un fabricant de plaques d'acier inoxydable digne de confiance.

En tant que fabricant professionnel, Daxun s'assure que tous les produits qu'il fabrique sont de haute qualité. Par conséquent, nous veillons à ce que toutes les plaques d'acier inoxydable soient certifiées ISO9001, SGS, CE, OQC et autres normes de qualité internationales. Chez Daxun, vous avez l'assurance que tous les produits sont durables, de haute qualité et très performants.

Projets et produits récents

Produits apparentés (13)

Nous pouvons vous fournir des échantillons de tôles d'acier inoxydable pour vous permettre de vérifier la qualité. L'échantillon est gratuit et vous ne payez que les frais de transport.

Nous avons exporté vers plus de 42 pays, tels que le Canada, le Chili, le Koweït, l'Allemagne, la Corée du Sud, l'Arabie saoudite, Singapour, etc.

Notre MOQ est de 1 tonne pour les tôles d'acier inoxydable.

Les commandes d'essai peuvent être livrées dans un délai d'une semaine. Pour les commandes régulières, il faut compter environ deux semaines.