Daxun is a professional supplier of duplex 2507 stainless steel coils

En tant que principal fournisseur et exportateur de bobines d'acier inoxydable en Chine, Daxun fournit des bobines d'acier inoxydable dans le monde entier.

- Coil grade: SS 2507-S32750

- Extreme resistance to uniform corrosion

- Good resistance to inorganic acids/chlorides

- Works with dilute hydrochloric acid

- Improved machinability and weldability

- High impact strength

Global leader in stainless steel coil fabrication services

Daxun is a full-service 2507 Duplex Steel Coil Supplier in China, offering coil thicknesses ranging from 0.5mm to 3.16mm. 2507 alloy duplex steel plate is a less expensive alloy than 904L or 6% molybdenum super austenitic stainless steel. Alloy 2507 (UNS S32750) is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel. It is intended for demanding applications requiring high strength and corrosion resistance, such as chemical processing, petrochemical, and seawater equipment. The steel is very resistant to chloride stress corrosion cracking, with a high thermal conductivity and a low coefficient of thermal expansion. The high chromium, molybdenum, and nitrogen concentration ensures good resistance to pitting, crevice corrosion, and general corrosion.

Dah Hsun is an ISO 9001:2008 certified firm that is a major supplier and exporter of ASTM A240 Stainless Steel Coils. Stainless steel coils can be cut to your requirements and include a full set of mill test results. Custom lengths and widths are available up to 2000mm. Exporting is our specialty! We can obtain several hard-to-find grades and/or non-standard sizes to satisfy our customers’ specific needs. We have vast experience processing steel coil goods and can divide all stainless steel coils to the desired sizes. Introducing our extensive line of Dah Hsun Stainless Steel goods – the pinnacle of dependability, durability, and performance. We are glad to provide a wide selection of grades and varieties to fulfill the diverse needs of industrial and architectural applications.

Our stainless steel coil goods, which range from the Austenitic series to the Ferritic series and other special categories, are well-known for their high performance and extensive requirements. The austenitic series includes 304/304L/304J1, 321 and 316/316L/317L/316Ti/310/309, which can fulfill varied thickness requirements and give a variety of surface treatments, including 2B, BA, NO.4, 8K, SB, HL, NO.1, and so on.

Our ferrite line, which includes 430, ultra-pure ferrite 443, and 436L/439/444/441, caters to customers looking for unique qualities and applications. These materials can accommodate thicknesses ranging from 0.4mm to 3.0mm and offer a variety of surface treatment options such as 2B, BA, NO.4, 8K, SB, HL, and so on.

By selecting our stainless steel coils, you are investing in a material that ensures long service life, great reliability, and exceptional performance. Don’t compromise on quality; choose our stainless steel solutions and see the impact they can make in your project. Contact Daxun today for additional information or to place an order for the stainless steel coil specs and quantities that you require.

Données

- Paramètres

- Élément

- Propriétés mécaniques

- PROPRIÉTÉS PHYSIQUES

- Tous les équivalents

- 2507 Coil stock

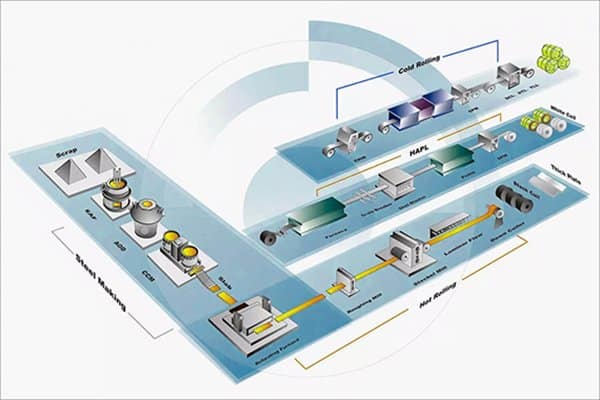

| 2507/S32750 Stainless Steel Coil Manufacturing Process | Hot Rolled (HR) / Cold Rolled (CR) |

| 2507/S32750 Stainless Steel Coil Grades | 201 / 304 / 304L/ 2507/S32750 / 309S / 420 / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. |

| UNS No. – UNS S2507/S32750, UNS S31008, UNS S31600, UNS S31603, UNS S31603, UNS S31600, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| EN No. 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| 2507/S32750 Stainless Steel Coil Thickness | 0.6 MM TO 16 MM THICKNESS |

| 2507/S32750 Stainless Steel Coil Width | 1250 MM / 1500 MM / 2000 MM / 04 Feet / 05 Feet and Custom Cut Width as Per Requirement |

| 2507/S32750 Stainless Steel Coil Length | 2400 MM / 2420 MM / 6000 MM / 08 Feet / 10 Feet / Coil Cut and Custom Cut Length as Per Requirement |

| 2507/S32750 Stainless Steel Coil Surface Finish | 2B, 2D, BA, MATT, MATT PVC, No.4, No.5, SB, HR, No.8, Mirror, Hairline, Brush, Textured, Oil base wet Polished, Both sides Polished available. |

| 2507/S32750 Stainless Steel Coil Coating | PVC coating Normal / Laser, Film: 100 micrometer, Color: black/white. |

| 2507/S32750 Stainless Steel Coil Other Testing | NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, etc. |

| 2507/S32750 Stainless Steel CoilValue Added Services | Gas Cutting / CNC Plasma Cutting / Profiling / Rolling / Bending / Sheet Metal Fabrication / Drill / Punch / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| 2507/S32750 Stainless Steel Coil Packaging | Loose / Carrate / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps |

| 2507/S32750 Stainless Steel Coil Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| 2507/S32750 Stainless Steel Coil Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC |

| Fabricant | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, VDM, Nippon Metal, Outokumpu, Qingshan, Delong. |

| Port d'embarquement | Port de Shanghai/Ningbo/Tianjin/Qindao |

| Grade | Super Duplex 2507 |

| Désignation UNS | S32750 |

| Carbone (C) Max. | 0.03 |

| Manganèse (Mn) Max. | 1.2 |

| Phosphore (P) Max. | 0.035 |

| Soufre (S) Max. | 0.02 |

| Silicium (Si) Max. | 0.8 |

| Chrome (Cr) | 24.0–26.0 |

| Nickel (Ni) | 6.0–8.0 |

| Molybdène (Mo) | 3.0–5.0 |

| Azote (N) | 0.24–0.32 |

| Fer (Fe) | Bal. |

| Copper (Cu) | 0.5 |

| Autres éléments | — |

| Physical Properties of Super Duplex 2507 Alloys in the Annealed Condition at -20°F to +100°F | ||||||||||||||

| Résistance à la traction | Limite d'élasticité | |||||||||||||

| Alloy | Désignation UNS | Spec. | psi | MPa | ksi | psi | MPa | ksi | Elongation in 2 in. (min.) % | Grain Size Req. | Max. Hardness | Modulus of Elasticity (x106 psi) | Mean Coefficient of Thermal Expansion (IN./IN./°F x 10-6) | Thermal Conductivity (BTU-in/ ft2-h-°F) |

| Super Duplex 2507 | S32950 | A789, A790 | 100,000 | 690 | 100 | 70,000 | 485 | 70 | 20 | — | 30.5 Rc | — | — | — |

| Super Duplex 2507 | S32750 | A789, A790 | 116,000 | 800 | 116 | 80,000 | 550 | 80 | 15 | — | 32 Rc | 27.5 | 7.2 | 98 |

| Density, lb/in3 | 0.28 |

| Modulus of Elasticity, psi | 29.0x 106 |

| Coefficient of Thermal Expansion, 68-212˚F, /˚F | 7.5 x 10-6 |

| Thermal Conductivity, Btu/ft hr ˚F | 8 |

| Specific Heat, Btu/lb ˚F | 0.12 |

| Electrical Resistivity, Microhm-in | 31.5 |

| Super Duplex 2507 Product Range | |||

| Alloy | Désignation UNS | Werkstoff NR. | Specifications* |

| Super Duplex 2507 | S32750 | 1.441 | A/SA789, A/SA790 |

| • Tisco Stainless Steel 2507 coil | • 2507 Stainless Steel B. Q. Profile coil |

| • SS 2507 Perforated coil | • Best selling 4’x8′ mirror finished ss 2507 coil |

| • Stainless Steel 2507 UNS S31635 coil | • Decorative hairline inox cold rolled ss 2507 coil |

| • A 240 Chequered 2507 coil | • Hair Line Finish SS 2507 coil |

| • Aperam Stainless Steel 2507 coil | • Laser cutting ss 2507 coil |

| • Stainless Steel 2507 coil | • Tisco Supplier 3mm Thickness Stainless Steel 2507 coil |

| • A 240 2507 coil | • Decorative Stainless Steel 2507 coil |

| • SS 2507 Embossed coil | • Scotch Brite SS 2507 coil |

| • Outokumpu SS 2507 coil | • Baosteel Stainless Steel 2507 coil |

| • SA 240 2507 stainless steel coil | • Stainless Steel Cladding 2507 coil |

| • Bright Hammered Pattern Decorative SS 2507 coil | • Black SS 2507 coil 4mm Thick |

| • Stainless Steel 2507 coil | • Bright-pickled Stainless Steel 2507 coil |

| • SS DIN 1.4571 coil | • Cold rolled, heat treated 2507 coil |

| • ThyssenKrupp Stainless Steel 2507 coil | • 3mm Cold Rolled AISI SS 2507 coil |

| • ASTM A240 Stainless Steel 2507 coil | • Mill Supply SS 2507 coil |

| • Surface Polishing SS 2507 coil | • Grade Prime SS 2507 coil |

| • 2507 Stainless Steel HR coil | • Carpenter Custom 450 Stainless Steel 2507 coil |

| • 2507 Stainless Steel Chequered coil | • Cut to Size Stainless Steel 2507 coil |

| • 2507 Stainless Steel Golden Laser Pattern coil | • Non Magnetic Polishing Stainless Steel 2507 coil |

| • Super thin-Mirror surface BA ss 2507 coil | • ASME SA240 2507 coil |

| • Super Austenitic SS 2507 coil | • 2507 Stainless Steel Blank coil |

| • ASTM A240 2507 coil | • 2507 Stainless Steel Perforated coil |

| • JMSS cold rolled ss 2507 coil | • Embossed ss 2507 coil |

| • Cold Rolled No.1 Finish SS 2507 coil | • Cheap cold rolled ss 2507 coil with best price |

| • SEW 400 Stainless Steel 2507 coil | • Brush finish ss 2507 coil price list |

| • Hot Rolled Stainless Steel 2507 coil | • SS URANUS B6 2507 coil |

| • Sales Promotion SS 2507 coil | • 2B SUS SS 2507 coil |

| • Cr Stainless Steel 2507 coil | • Food Grade Stainless Steel 2507 coil |

| • SS 2507 Mill Test Certificate coil | • No. 4 PVC Coated SS 2507 coil |

| • ASTM A240 2507 coil | • SS 2507 coil Blasted Tin-Gold Rose |

| • Cold rolled, bright annealed 2507 coil | • 2mm ASTM SS 2507 coil |

| • Ground Stainless Steel 2507 coil | • Stainless Steel Corrugated 2507 coil |

| • Hot Selling AISI SS 2507 coil | • ASTM B625 2507 coil |

| • SS 2507 Rose Golden coil | • Brushed or dull polished Stainless Steel 2507 coil |

| • Surface coated Stainless Steel 2507 coil | • Cold rolled, heat treated, pickled 2507 coil |

| • Satin finish Stainless Steel 2507 coil | • 10K Mirror Finish Surface SS 2507 coil |

| • AISI stainless steel 2507 armor coil | • Gold Etched SS 2507 coil |

| • Satin finish Stainless Steel 2507 coil | • 18 Gauge SS 2507 coil |

| • Mirror Finish SS 2507 coil | • Patterned Stainless Steel 2507 coil |

| • SS 2507 coil Gold Brush Finish | • #4 Finish Stainless Steel 2507 coil |

| • 2507 Stainless Steel CR coil | • Patterned Stainless Steel 2507 coil |

| • 2507 Stainless Steel 2B coil | • Passenger Elevator Cabin SS 2507 coil |

Choisissez Daxun et faites en sorte que vos clients soient satisfaits.

Quick response 2507 Stainless Steel coil

Nous assurons une livraison rapide et en temps voulu des produits en acier inoxydable pour les clients ayant des besoins urgents. Cette rapidité s'explique par le soutien du système, du flux d'informations à la logistique et au flux de capitaux. Par exemple, en termes de flux d'informations, les données des commandes de Daxun sont transmises au système logistique en temps réel et les données sont connectées de manière transparente ; en termes de logistique, le centre de traitement est proche des autoroutes, des rivières et des mers, avec une programmation raisonnable, une réponse rapide, un stockage et un lien de transport, et un chargement efficace, ce qui garantit que la tâche est accomplie dans les délais prévus.

Avantages de Daxun

Quality is belief, and integrity is a business card. Daxun pioneered the concept of “performance excellence management” and implemented the “PDCA+Lean” management model. The company’s business card says “Daxun = assured quality”. Daxun Stainless Steel achieves full traceability of each steel plate from the ERP system, including variety, specification, and origin, and advocates and encourages industry anti-counterfeiting. Daxun Stainless Steel relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strict monitoring during sales, and provides worry-free service guarantees after sales.

2507 Stainless Steel coil Packaging

Daxun Alloy garantit la meilleure qualité d'emballage, car celui-ci joue un rôle important dans le fret international, où les marchandises passent par différents canaux avant d'atteindre leur destination finale ; nous accordons donc une attention particulière à l'emballage. Nous emballons nos marchandises de différentes manières, en fonction du produit. Nous emballons nos produits de différentes manières, notamment :

- Boîtes et caisses

- Emballage rétractable

- Palettes en bois

- Boîtes en bois

Qualité, livraison, inspection

- Daxun effectue également plusieurs tests d'assurance qualité. Ces tests comprennent le test d'aplatissement, le test de piqûre et de résistance, le test mécanique, le test de dureté, l'identification positive du matériau, le test d'expansion, etc. Tous ces tests garantissent que le matériau est adapté à l'application requise.

- Au cours du processus de production, nous mesurons le diamètre, l'épaisseur et la surface du produit. Notre délai de livraison standard est de 7 à 15 jours, sauf pour certains produits de taille spéciale, pour lesquels le délai de livraison peut atteindre 20 jours.

Nos délais de livraison sont strictement conformes au contrat. - Aider les agences tierces des clients à se rendre à l'usine pour l'inspection

- Fournir des échantillons gratuits aux clients pour qu'ils les testent

- Soutien à l'inspection sur site ou à l'inspection vidéo en usine

2507 Stainless Steel coil Ordering Information

Les bons de commande doivent indiquer la quantité, le grade, le type ou la catégorie, la référence API5L, l'épaisseur, la largeur, la longueur et toutes les pièces jointes ou exigences supplémentaires relatives à la composition chimique, aux propriétés mécaniques, au traitement thermique, aux essais supplémentaires, au processus de fabrication, au revêtement de surface ou à la finition. Contactez Daxun dès maintenant, nous répondrons à votre email dans les plus brefs délais.

Support technique

Si vous avez besoin d'une assistance technique supplémentaire, notre métallurgiste résident et notre personnel compétent se feront un plaisir de vous aider. En outre, Daxun dispose d'un laboratoire d'essai certifié, une première dans l'industrie des stocks multimétaux et plastiques. Ceci, à notre avis, démontre notre dévouement inébranlable à la qualité et notre philosophie en tant que fournisseur de services complets.

2507 Stainless Steel Coil Features

Daxun Alloy Permettez à votre marque de s'améliorer rapidement

- Galerie

- Série de produits

- Equipement principal

| Grade | Type | Épaisseur | Surface |

| Austénitique | 304/304H/304L/304J1 | 0,25-150 mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80 mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0.3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferrite | 430 | 0,4-3,0 mm | 2B/BA/NO.4/8K/SB/HL |

| Ferrite ultra pure | 443 | 0,4-2,0 mm | 2B |

| 436L/439/444/441 | 0,5-3,0 mm | 2B、2D | |

| 409L | 0,4-2,5 mm | 2B、2D | |

| Acier super austénitique | N08904 | 0,6-50 mm | SWE / JPN / CHN |

| S31254 | 0,5-50 mm | SWE / JPN / CHN | |

| N08926 | 0,5-50 mm | SWE / JPN / CHN | |

| N08367 | 0,5-50 mm | SWE / JPN / CHN | |

| Alliage base nickel | N08031 | 1.0-50mm | US / JPN / GER |

| N08810/N08800 | 0,8-50 mm | US / JPN / CHN | |

| N08028 | 1.0-20mm | US / GER / JPN | |

| N08020 | 1.0-20mm | US / GER / JPN | |

| N08825 | 0,8-40 mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50 mm | US / GER / JPN | |

| N06022 | 1.0-50mm | US / GER / JPN | |

| N06625 | 0,8-20 mm | US / GER / CHN | |

| N04400 | 1.0-20mm | US / GER / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20 mm | US / JPN | |

| Titane | TA1/Gr1 | 0,5-50 mm | JPN / CHN |

| TA2/Gr2 | 0,5-50 mm | JPN / CHN | |

| Matériel de soudage | ERNiCrMo-13 | 1.2、2.4mm | GER |

| ERNiCrMo-3 | 2,4 mm | GER | |

| ERNiCrMo-4 | 2,4 mm | ÉTATS-UNIS |

| Filiale | Principaux équipements | Qté | Capacité annuelle |

| Daxun Stainless steel co.(JiangSu) | Machine à refendre | 1 | Feuilles décoratives : 60 000 tonnes |

| Machine à découper | 1 | ||

| Machine à polir No.4 et Hairline Sheet to Sheet | 1 | ||

| Machines de polissage de bobine à bobine No.4/Hairline | 1 | ||

| Machines à polir 8K/Super Mirror Sheet to Sheet | 2 | ||

| Machines de polissage 8K/Super Mirror Coil to Coil | 3 | ||

| Machines de revêtement couleur PVD | 4 | ||

| Machines de revêtement chimique liquide | 2 | ||

| Machines anti-dactyloscopiques | 2 | ||

| Machines Auto Pick and Place | 16 | ||

| Plate Washing Machine | 1 | ||

| Daxun Stainless steel co.(Shanghai) | Machine de laminage à froid | 3 | Bobines 2B : 100 000 tonnes |

| Ligne de recuit et de décapage | 2 | Feuilles décoratives;30 000 tonnes | |

| Machine à refendre | 1 | ||

| Machine de coupe à longueur | 1 | ||

| Machine à polir No.4/HL (feuille à feuille) | 3 | ||

| Machine à polir 8K (feuille à feuille) | 13 | ||

| Machine de revêtement PVD du titane | 4 | ||

| Machines de revêtement chimique liquide | 1 | ||

| Daxun Stainless steel co.(Shandong) | Machine de laminage à froid | 3 | Bobines 2B et BA : 220 000 tonnes |

| Ligne de recuit et de décapage (2B & BA) | 2 | Feuilles décoratives : 60 000 tonnes | |

| Levée de tension et passage de la peau | 1 | ||

| Machine à refendre | 1 | ||

| Machine de coupe à longueur | 1 | ||

| Machine à polir No.4/HL (feuille à feuille) | 1 | ||

| Machine à polir 8K (feuille à feuille) | 11 | ||

| Machine automatique à revêtir le cuivre | 1 | ||

| Machine d'impression numérique | 1 | ||

| Machine de revêtement PVD du titane | 3 | ||

| Machines de revêtement chimique liquide | 1 | ||

| Machine anti-doigts | 1 | ||

| Daxun Stainless steel co.(Sichuan) | Machine à refendre | 1 | Bobines 2B et BA : 180 000 tonnes |

| Machine à découper | 1 | Feuilles décoratives : 50 000 tonnes | |

| Machine à polir No.4 et Hairline Sheet to Sheet | 1 | ||

| Machines de polissage de bobine à bobine No.4/Hairline | 1 | ||

| Machines à polir 8K/Super Mirror Sheet to Sheet | 1 | ||

| Machines de polissage 8K/Super Mirror Coil to Coil | 1 | ||

| Machines de revêtement couleur PVD | 1 | ||

| Machines de revêtement chimique liquide | 1 | ||

| Machines anti-dactyloscopiques | 1 |

SS 2507 Surface Types of Stainless Steel Coils (6)

Informations disponibles pour référence et téléchargement

Daxun est un fabricant de bobines d'acier inoxydable digne de confiance.

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless steels are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the stainless steel plates have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

Projets et produits récents

Produits apparentés (10)

Principaux fournisseurs de bobines d'acier inoxydable en Chine

Daxun est engagée dans le commerce international depuis plus de dix ans. En 2023, son chiffre d'affaires à l'exportation a dépassé les 100 millions de dollars américains et son volume d'exportation s'est classé parmi les principaux fabricants chinois d'acier inoxydable. Daxun continue d'améliorer ses compétences en matière de services. Afin de servir le marché mondial, nous avons établi trois installations de services d'exportation en Chine et coopéré avec des entreprises d'ingénierie, des aciéries et des sociétés de commerce international. Daxun fournit des services de chaîne d'acier inoxydable et a établi des relations de coopération à long terme avec des dizaines d'aciéries de renom dans le monde entier. Son stock comprend 50 000 tonnes de bobines d'acier inoxydable conventionnel et 20 000 tonnes d'acier duplex, d'alliages à base de nickel, d'acier résistant à la chaleur et d'autres métaux. Les matériaux en acier inoxydable de Daxun sont de qualité constante. Les types, les spécifications et les poids de livraison sont strictement conformes aux normes.

What Is Duplex 2507 Stainless Steel?

Duplex 2507 stainless steel is a super duplex steel with low carbon content (up to 0.03%), chromium (~25%), nickel (~7%), and molybdenum (~4%). Duplex 2507 stainless steel is designed to satisfy the high demands of applications requiring great strength and corrosion resistance. These applications include chemical process equipment, the petrochemical industry, and seawater equipment. This steel is very resistant to chloride-induced stress corrosion cracking. Because of its high chromium, molybdenum, and nitrogen content, it provides excellent resistance to pitting, crevice, and general corrosion.

How Is Duplex 2507 Stainless Steel Made?

- Duplex 2507 stainless steel is normally manufactured in the same manner as other current high-alloy steels. An electric arc furnace is used to melt scrap steel and add the desired alloys. Once the steel is molten, it is moved to an AOD (argon oxygen decarburization) converter, where numerous important processes occur, including decarburization, sulfur refinement, and the elimination of dissolved gases.

- Nitrogen is generally added to the steel during the AOD process. The steel is then sent to the ladle furnace, where the inclusions are adjusted.

- Following these preliminary procedures, the molten steel is transferred to the casting operation, which can produce solitary ingots (huge metal blocks) or continuously produced blooms. These solid steel blooms or ingots are further refined by being reheated and then forged or rolled to the desired thickness. To achieve homogeneous internal structure, a heat treatment known as solution annealing is used, followed by a water quenching procedure.

- Duplex 2507 coil materials can be fabricated using either hot or cold forming processes. For hot forming, the temperature should be set between 1024 °C and 1232 °C. Following the hot forming step, a solution annealing process should be performed at a minimum temperature of 1052-1125 °C, followed by a fast water quench. Cold forming, which includes bending, deep drawing, extruding, and pressing, requires a following heat treatment that includes solution annealing and quenching.

How Does Duplex 2507 Stainless Steel Differ From Duplex Steel?

- Duplex 2507 stainless steel is considered a super duplex stainless steel. Duplex stainless steels are a type of stainless steel having a microstructure that contains both ferrite and austenite in roughly equal amounts. They integrate some of the most valuable features from each of these phases. This unique mix provides duplex stainless steel with high corrosion resistance as well as strong mechanical strength. However, different duplex steel grades provide differing levels of corrosion resistance. While they have good resistance to localized corrosion including pitting, crevice corrosion, and stress corrosion cracking, the exact level of resistance varies depending on the grade and alloy composition. Duplex stainless steels are split into four categories based on their PREN (Pitting Resistance Equivalent Number) range. Among these groups, super duplex stainless steel has a PREN number ranging from 38 to 45.

What Are the Uses of Duplex 2507 Stainless Steel?

Some common applications of Duplex 2507 stainless steel include:

- Dessalement.

- Oil and gas industry equipment, including offshore platforms, pipelines, and well casings.

- Chemical processing equipment, especially for handling corrosive chemicals.

- Pulp and paper industry, particularly bleaching process equipment.

- Petrochemical industry applications, including PVC strippers.

- Installations de dessalement de l'eau.

- Power industry equipment, such as flue gas desulfurization (FGD) systems.

- Marine components, including ship propellers and shafts.

- Pollution control equipment such as scrubbers.

- Fittings are crucial components for connecting and controlling the flow of fluids in pipelines and systems. This includes elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples, among others.

What Are the Advantages of Using Duplex 2507 Stainless Steel?

The advantages of using Duplex 2507 stainless steel include:

- It is very resistant to pitting corrosion, having a PREN of up to 43. This means it has better corrosion resistance than stainless steel grades such as 254SMO. Duplex 2507 is also highly resistant to other types of corrosion, such as Stress Corrosion Cracking (SCC), crevice corrosion, and general corrosion. These combined corrosion-resistant qualities make Duplex 2507 an adaptable and dependable alternative for a wide range of applications in harsh environments.

- 2507 provides twice the yield strength of 300 class stainless steel. This strength advantage allows for thinner steel sections and lower material costs for equipment operating under the same load levels.

- It has double the yield and tensile strength of standard stainless steel. This leads to greatly better wear resistance.

Standards

- ASTM/ASME ………. A240 – UNS S32750

EURONORM………… 1.4410 – X2 Cr Ni MoN 25.7.4

AFNOR……………….. Z3 CN 25.06 Az

CORROSION RESISTANCE

General corrosion

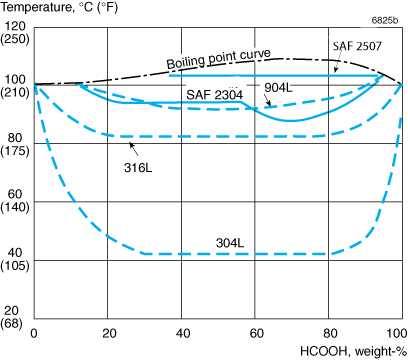

- SAF 2507™ is highly resistant to corrosion by organic acids, e.g. experience less than 0.05 mm/year in 10% formic and 50% acetic acid where ASTM 316L has corrosion rate higher than 0.2 mm/year. Pure formic acid see Figure 4. Also in contaminated acid SAF 2507™ remains resistant.

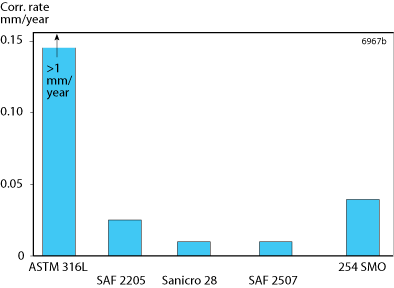

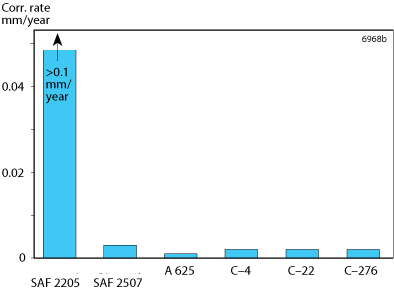

- Figure 5 and Figure 6 show results from tests of SAF™ 2507 and various stainless steels and nickel alloys in acetic acid contaminated with chlorides which in practice are frequently present in processes.

Figure 4. Isocorrosion diagram in formic acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in stagnant test solution.

Figure 5. Corrosion rate of various alloys in 80% acetic acid with 2000 ppm chloride ions at 90°C.

Figure 6. Corrosion rate of various alloys in concentrated acetic acid with 200 ppm chloride ions.

Practical experience with SAF™ 2507 in organic acids, e.g. in terephthalic acid plants, has shown that this alloy is highly resistant to this type of environment. The alloy is therefore a competitive alternative to high alloyed austenitics and nickel alloys in applications where standard austenitic stainless steels corrode at a high rate.

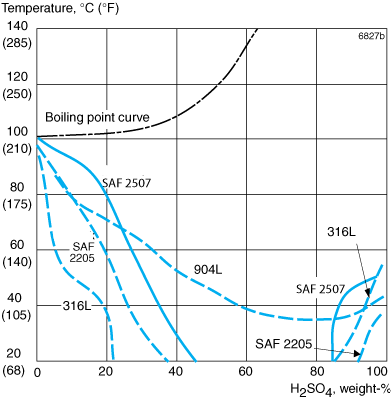

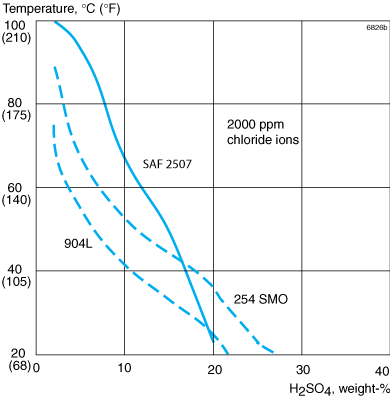

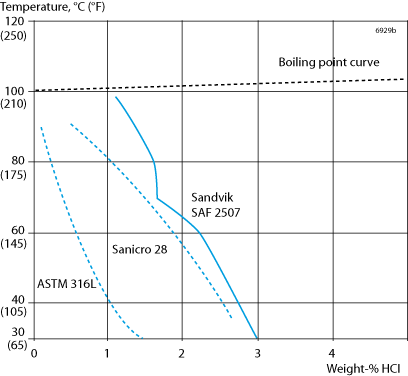

Resistance to inorganic acids is comparable to, or even better than that of high alloy austenitic stainless steels in certain concentration ranges. Figures 7 to 9 show isocorrosion diagrams for sulfuric acid, sulfuric acid contaminated with 2000 ppm chloride ions, and hydrochloric acid, respectively.

Figure 7. Isocorrosion diagram in naturally aerated sulfuric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in a stagnant test solution.

Figure 8. Isocorrosion diagram, 0.1 mm/year (4 mpy) in a naturally aerated sulfuric acid containing 2000 ppm chloride ions.

Figure 9. Isocorrosion diagram in hydrochloric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in stagnant test solution.

Pitting and crevice corrosion

The pitting and crevice corrosion resistance of stainless steel is primarily determined by the content of chromium, molybdenum and nitrogen. The manufacturing and fabrication practices, e.g. welding, are also of vital importance for the actual performance in service.

A parameter for comparing the resistance to pitting in chloride environments is the PRE number (Pitting Resistance Equivalent).

The PRE is defined as, in weight-%

PRE = %Cr + 3.3 x %Mo + 16 x %N

For duplex stainless steels the pitting corrosion resistance is dependent on the PRE value in both the ferrite phase and the austenite phase, so that the phase with the lowest PRE value will be limiting for the actual pitting corrosion resistance. In SAF™ 2507 the PRE value is equal in both phases, which has been achieved by a careful balance of the elements.

The minimum PRE value for SAF™ 2507 seamless tubes is 42.5. This is significantly higher than e.g. the PRE values for other duplex stainless steels of the 25Cr type which are not super-duplex. As an example, UNS S31260 25Cr3Mo0.2N has a minimum PRE-value of 33.

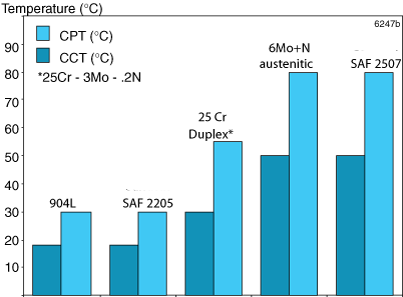

One of the most severe pitting and crevice corrosion tests applied to stainless steel is ASTM G48, i.e. exposure to 6% FeCI3 with and without crevices (method A and B respectively). In a modified version of the ASTM G48 A test, the sample is exposed for periods of 24 hours. When pits are detected together with a substantial weight loss (>5 mg), the test is interrupted. Otherwise, the temperature is increased by 5 °C (9 °F) and the test is continued with the same sample. Figure 11 shows critical pitting and crevice temperatures (CPT and CCT) from the test.

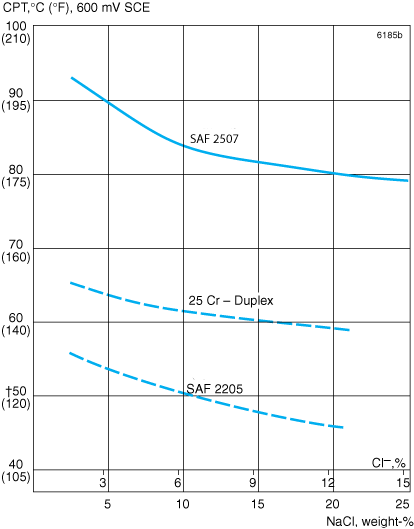

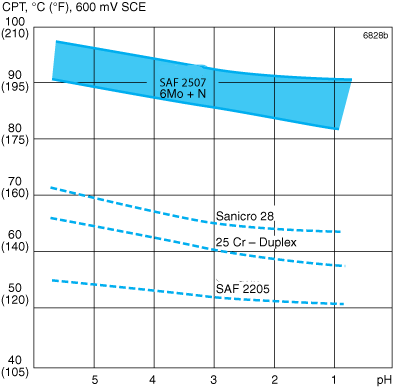

Potentiostatic tests in solutions with different chloride contents are presented in Figure 11. Figure 12 shows the effect of increased acidity. In both cases the applied potential is 600 mV vs SCE, a very high value compared with that normally associated with natural unchlorinated seawater, thus resulting in lower critical temperatures compared with most practical service conditions.

Figure 10. Critical pitting and crevice temperatures in 6% FeCl3, 24h (similar to ASTM G48).

The scatter band for SAF™ 2507 and 6Mo+N illustrates the fact that both alloys have similar resistance to pitting, and CPT-values are within the range shown in the figure.

Tests were performed in natural seawater to determine the critical crevice corrosion temperature of samples with an applied potential of 150 mV vs SCE. The temperature was raised by 4°C (7oF) steps every 24 hours until crevice corrosion occurred. The results are shown in the table below.

| Alloy | CCT (°C) |

|---|---|

| SAF 2507 | 64 |

| 6Mo+N | 61 |

In these tests the propagation rates of initiated crevice corrosion attacks, at 15-50°C (59-122°F) and an applied potential of 150 mV vs SCE were also determined. These were found to be around ten times lower for SAF™ 2507 than for the 6Mo+N alloy.

Figure 11. Critical pitting temperatures (CPT) at varying concentrations of sodium chloride, from 3 to 25% (potentiostatic determination at +600 mV SCE with surface ground with 600 grit paper).

Figure 12. Critical pitting temperatures (CPT) in 3% NaCl with varying pH (potentiostatic determination at +600 mV SCE with surface ground with 600 grit paper).

The corrosion resistance of SAF™ 2507 in oxidizing chloride solutions is illustrated by critical pitting temperatures (CPT) determined in a ‘Green death’ -solution (1% FeCI3 + 1% CuCl2 +11% H2SO4 + 1.2% HCI) and in a ‘Yellow death’ -solution (0.1 % Fe2(SO4)3 + 4% NaCl + 0.01 M HCI). The table below shows CPT-values for different alloys in these solutions. It is clear that the values for SAF™ 2507 are on the same level as those for the nickel alloy UNS N06625. The tests demonstrate a good correlation with the ranking of alloys for use as reheater tubes in flue gas desulfurization systems.

Critical pitting temperature (CPT) determined in different test solutions.

| Alloy | Critical pitting temperature (CPT), °C ‘Green death’ |

‘Yellow death’ |

|---|---|---|

| SAF™ 2507 | 72.5 | >90 |

| 6Mo+N | 70 | >90 |

| UNS N06625 | 67.5 | >90 |

| ASTM 316 | <25 | 20 |

Stress corrosion cracking

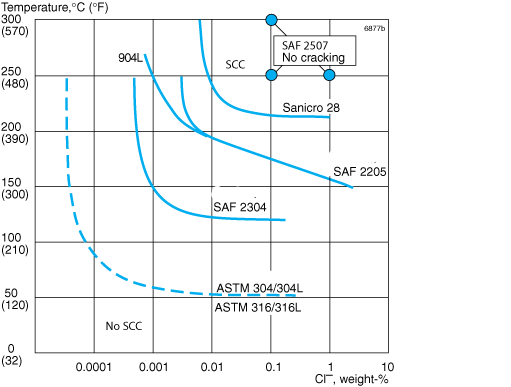

SAF™ 2507 has excellent resistance to chloride induced stress corrosion cracking (SCC).

The SCC resistance of SAF™ 2507 in chloride solutions at high temperatures is illustrated in Figure 13. There were no signs of SCC up to 1000 ppm Cl–/300°C and 10000 ppm Cl–/250°C.

SAF™ 2507 U-bend specimens exposed for 1000 hours in hot brine (108°C, 226°F, 25% NaCl) showed no cracking.

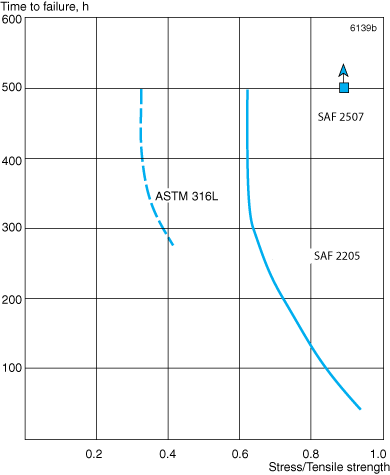

The threshold stress for SAF 2507® in 40% CaCl2 at 100 °C (210 °F) and pH = 6.5 is above 90% of the tensile strength for both parent metal and welded joints (TIG-welded with Alleima® 25.10.4.L or MMA-welded with Alleima® 25.10.4.LR).

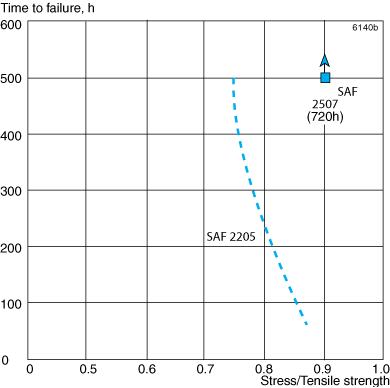

Figure 14 shows the result of testing in 40% CaCl2 at 100 °C (210 °F) acidified to pH = 1.5. Acidifying of the standard test solution to pH = 1.5 lowers the threshold stress for SAF™ 2205, but not for SAF™ 2507. This applies to both parent metal and welded joints.

The threshold stress for both parent metal and welded joints of SAF™ 2507 in boiling 45% MgCl2 , 155°C (311°F) (ASTM G36), is approximately 50% of the proof strength.

Figure 13. SCC resistance in oxygen-bearing (abt. 8 ppm) neutral chloride solutions. Testing time 1000 hours. Applied stress equal to proof strength at testing temperature.

Figure 14. Results of SCC tests with constant load in 40% CaCl2, pH=1.5, at 100 °C (210°F) with aerated test solution.

Figure 15. Constant load SCC tests in NACE solution at room temperature (NACE TM 0177).

Figure 15 shows the results of SCC tests at room temperature in NACE TM0177 Test solution A (5% sodium chloride and 0.5% acetic acid saturated with hydrogen sulfide). No cracking occurred on SAF™ 2507, irrespective of the applied stress.

In aqueous solutions containing hydrogen sulfide and chlorides, stress corrosion cracking can also occur on stainless steels at temperatures below 60 °C (140 °F). The corrosivity of such solutions is affected by acidity and chloride content. In direct contrast to the case with ordinary chloride-induced stress corrosion cracking, ferritic stainless steels are more sensitive to this type of stress corrosion cracking than austenitic steels.

In accordance with ISO 15156/NACE MR 0175 solution annealed and rapid cooled wrought SAF™ 2507 is suitable for use at temperatures up to 450 °F (232 °C) in sour environments in oil and gas production, if the partial pressure of hydrogen sulphide does not exceed 3 psi (0.20 bar).

SAF™ 2507, with a maximum hardness of 32 HRC, solution annealed and rapidly cooled, according to NACE MR0103, is suitable for use in sour petroleum refining.

Hydrogen Induced Stress Cracking (HISC)

Hydrogen Induced Stress Cracking (HISC) is an embrittlement phenomenon that may occur in cathodically protected subsea steel constructions in the presence of high tensile stresses. When connected to cathodically protected carbon steels, super duplex stainless steels will also be cathodically protected even though this is not necessary. At the prevalent low electrochemical potentials, atomic hydrogen will be generated on the steel surfaces by the reduction of sea water. Embrittlement due to HISC may occur when hydrogen diffuses into the metal.

Hydrogen diffuses much faster in the ferrite phase than in the austenite phase. Therefore, ferritic steels and ferrite containing steels, e.g. super duplex stainless steels, are more susceptible to HISC than austenitic stainless steels. A high mechanical stress increases the risk of HISC by increasing the hydrogen diffusion rate, crack initiation and propagation in the material.

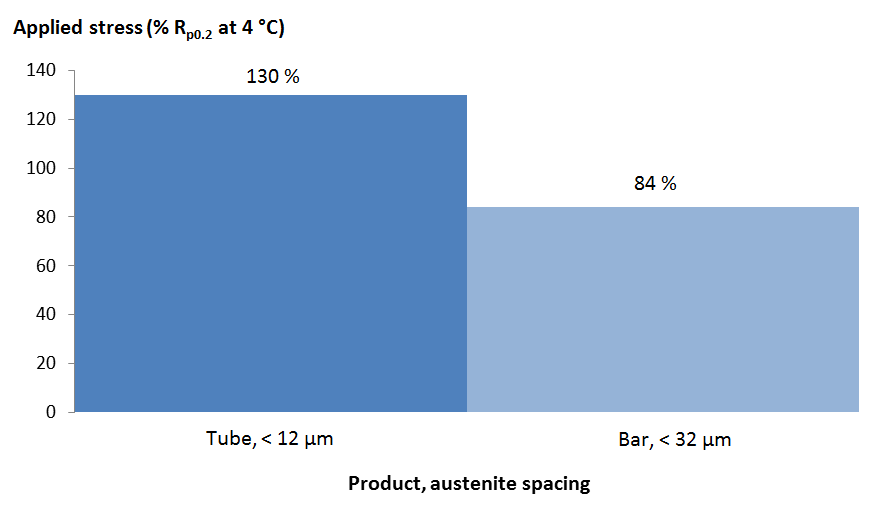

In super duplex stainless steels, cracks tend to propagate in the embrittled ferrite phase and arrest at ferrite-austenite phase boundaries. Susceptibility to HISC significantly increases with increasing austenite spacing. Coarse-grained microstructures are therefore more susceptible. A testing program performed at Alleima Materials Technology has confirmed that tendency to HISC is reduced when austenite spacing is less than 30 μm, as recommended by DNV RP-F112. Cold pilgered and solution annealed tubes with austenite spacing between 5-15 μm have shown very good resistance to HISC under applied stress up to 130% of the yield strength without cracking.

The acceptable stress without HISC occurring for products with different austenite spacing is illustrated in figure 16.

Figure 16. Tolerable stress as a percentage of the actual yield strength at 4°C without HISC occurring is schematically shown for tube and bar products with different austenite spacing. SAF™ 2507 (UNS S32750) has been tested on hydrogen pre-charged tensile specimens, using constant load with a dead weight, with an applied potential of -1050 mV/SCE in a electrochemical cell with 3% NaCl solution at 4°C, 500 hours. [NACE paper no. 07498]

Intergranular corrosion

SAF™ 2507 is a member of the family of modern duplex stainless steels whose chemical composition is balanced to give quick reformation of austenite in the high temperature heat affected zone of a weld. This results in a microstructure that provides the material with good resistance to intergranular corrosion. SAF™ 2507 passes testing to ASTM A262 Practice E (Strauss test) without reservation.

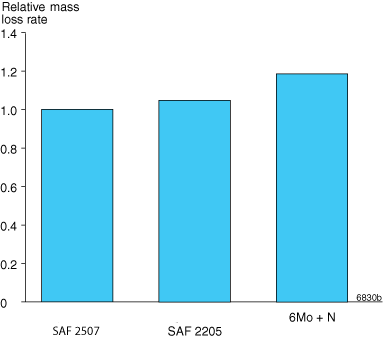

Erosion corrosion

The mechanical properties combined with corrosion resistance give SAF™ 2507 a good resistance to erosion corrosion. Testing in sand containing media has shown that SAF™ 2507 has an erosion corrosion resistance better than corresponding austenitic stainless steels. Figure 17 below shows the relative mass loss rate of the duplex SAF™ 2507, SAF™ 2205 and an austenitic 6Mo+N type steel after exposure to synthetic seawater (ASTM D-1141) containing 0.025-0.25% silica sand at a velocity of 8.9-29.3 m/s (average of all tests is shown).

Figure 17. Relative mass loss rate after testing of the resistance against erosion corrosion.

Corrosion fatigue

Duplex stainless steels which have a high tensile strength usually have a high fatigue limit and high resistance to both fatigue and corrosion fatigue.

The high fatigue strength of SAF™ 2507 can be explained by its good mechanical properties, while its high resistance to corrosion fatigue has been proven by fatigue testing in corrosive media.

TRAITEMENT

Hot Forming

2507 can be hot formed at temperatures ranging from 1875°F to 2250°F. This should be followed by a solution anneal at a minimum temperature of 1925°F, followed by a rapid air or water quench.

Cold Forming

Cold working 2507 can be accomplished using most typical stainless steel forming processes. Because the alloy has a higher yield strength than austenitic steels, but lower ductility, fabricators may need to use higher forming forces, larger bend radii, and springback allowances. Deep drawing, stretching, and other similar processes are more difficult for 2507 than for austenitic stainless steels. Solution annealing and quenching are recommended when the forming process requires more than 10% cold deformation.

Heat Treatment

Heat treatment for 2507 consists of solution annealing and quenching after hot or cold forming. Solution annealing should be performed at a minimum temperature of 1925°F. Annealing should be followed immediately by a rapid air or water quench. Heat treated items that are pickled and rinsed have excellent corrosion resistance.

Welding

2507 is weldable and can be joined to other materials using SMAW, GTAW, PAW, FCW, or SAW. When welding 2507, a 2507/P100 filler metal is recommended to ensure proper duplex weld construction.

2507 does not require preheating except to prevent condensation on cold metal. Interpass welding temperatures should not exceed 300°F or weld integrity will be compromised. To maximize corrosion resistance, root protection should be applied using either argon or 90% N2/10% H2 purge gas. The latter provides higher corrosion resistance.

Quelles sont les surfaces couramment utilisées pour les bobines d'acier inoxydable ?

L'état de surface des bobines d'acier inoxydable 201 peut varier en fonction des méthodes de traitement de laminage à froid utilisées et du traitement de surface appliqué après le laminage. Les traitements de surface des bobines d'acier inoxydable comprennent les traitements NO.1, 2B, 4, HL, 6, 8, BA, TR hard, heavy rolling bright 2H, polished bright, et d'autres traitements de surface :

- NO.1 : Surface obtenue après le laminage à chaud, le traitement thermique et le décapage de bandes d'acier inoxydable. Il est utilisé pour éliminer la couche d'oxyde noir formée par le décapage ou des procédés similaires pendant le laminage à chaud et le traitement thermique. Elle occupe la première place dans le traitement de surface. La surface n° 1 est blanche argentée et mate. Elle est généralement utilisée dans les industries résistantes à la chaleur et à la corrosion qui n'ont pas besoin d'une grande brillance de surface, comme l'industrie de l'alcool, l'industrie chimique, les grands conteneurs, etc.

- 2B : Contrairement à la surface 2D, la surface 2B est lissée par un rouleau léger, et la surface est plus brillante. La valeur de rugosité de surface Ra mesurée par l'équipement est comprise entre 0,1 et 0,5μm, ce qui est une valeur typique pour la plupart des types de traitement. Cette surface de bande d'acier inoxydable présente la plus forte adaptabilité et convient aux industries telles que la chimie, la papeterie, le pétrole, la médecine et un large éventail de domaines tels que les murs-rideaux des bâtiments.

- Surface dure TR : TR stainless steel is also called hard steel. Its characteristic steel grades include 304 and 301, which are used for items that require high strength and hardness, such as railway vehicles, conveyor belts, springs and washers. The idea is to use the work hardening characteristics of austenitic stainless steel to improve the strength and hardness of steel plates through cold working methods such as rolling. In order to replace the gentle flatness of the 2B base surface, the hard material is gently rolled by a few percent to tens of percent, and no annealing is performed after rolling. Therefore, the TR hard surface of the hard material is the rolled surface after the cold rolling process.

- Relance brillante 2H : Après l'opération de laminage, la bande d'acier inoxydable est soumise à un recuit brillant. Une ligne de recuit continu peut être utilisée pour refroidir rapidement la bande. La bande d'acier inoxydable se déplace le long de la ligne à une vitesse de 60 à 80 m/min. Après ce processus, la finition de la surface sera un laminage brillant 2H.

- N° 4 : The No. 4 surface has a good polishing effect and is brighter than No. 3. It can also be obtained by polishing the cold-rolled stainless steel plate with a 2D or 2B surface, and then polishing the processed surface with a sanding belt with a particle size of 150-180#. The tool measures the surface roughness (Ra) between 0.2 and 1.5μm. The No. 4 surface is widely used in restaurants and cooking equipment, medical equipment, architectural decoration, containers and other applications.

- HL : La surface HL est souvent appelée finition capillaire. La norme japonaise JIS spécifie une surface abrasive capillaire continue obtenue par polissage avec une bande abrasive 150-240#. Les restrictions imposées par la norme chinoise GB3280 ne sont pas claires. La finition de surface HL est couramment utilisée pour la décoration architecturale, notamment pour les ascenseurs, les escaliers roulants et les murs extérieurs.

- N° 6 : La surface n° 6 est ensuite polie sur la base de la surface n° 4 à l'aide d'une brosse Tampico ou d'un matériau abrasif de grain W63 spécifié dans la norme GB2477. La surface présente un bon éclat métallique, une grande douceur, une faible réflexion et aucune image. En raison de ses bonnes performances, elle convient parfaitement aux murs-rideaux, à la décoration des glands et aux articles de cuisine.

- BA : Le BA est une surface qui subit un traitement thermique brillant après le laminage à froid. Le traitement thermique brillant consiste en un recuit dans une atmosphère protectrice pour s'assurer que la surface n'est pas oxydée et conserve la brillance de la surface laminée à froid, puis elle est polie à l'aide d'un rouleau lisse de haute précision pour améliorer la brillance de la surface. L'instrument évalue la rugosité de la surface à 0,05-0,1μm, ce qui indique que la surface est proche d'une surface miroir. Les surfaces BA peuvent être utilisées dans une variété d'applications, y compris les ustensiles alimentaires, les appareils ménagers, l'équipement médical, les pièces automobiles et les décorations.

- N° 8 : Surface miroir, réflectivité maximale, pas de particules abrasives. L'industrie du traitement en profondeur de l'acier inoxydable fait également référence au panneau 8K. Le matériau BA est souvent utilisé comme matière première pour le traitement des miroirs. Il suffit de le polir. La surface est belle après le traitement du miroir et est souvent utilisée dans les entrées de bâtiments et la décoration intérieure.

What is the standard sea packaging of 2507 stainless steel coil?

- Emballage maritime standard pour l'exportation :

Enroulement de papier imperméable+film PVC+courroie de cerclage+palette en bois ou caisse en bois ; - Emballage personnalisé selon votre demande (le logo ou d'autres contenus peuvent être imprimés sur l'emballage) ;

- D'autres emballages spéciaux seront conçus à la demande du client ;

L'œil au mur et l'œil au ciel sont tous deux disponibles ; - Par courrier express international : DHL/UPS/FEDEX/EMS et notre propre ligne express ;

- Par voie aérienne, maritime ou terrestre ;

- Port d'expédition : Shanghai, Ningbo, Qingdao, Tianjin ou selon votre demande.

Contactez vos fournisseurs de bobines d'acier inoxydable

- Vous pouvez facilement commander en ligne des bobines d'acier inoxydable dans n'importe quelle taille et quantité.

Par ailleurs, notre sympathique équipe de vente se fera un plaisir de prendre votre commande. Il vous suffit d'appeler le +86 13382898899 ou d'envoyer un courriel à Daxunhejin@gmail et nous vous répondrons dans les plus brefs délais.

Veuillez remplir le formulaire de la page “Contactez-nous” ou appeler notre responsable des ventes au “+86 13382898899”, nous vous contacterons dans les plus brefs délais. Notre WhatsApp est en ligne, et l'email ([email protected]) sera vérifié dans les 6 heures. Chaque demande ou message recevra une réponse rapide. En outre, nous partageons chaque semaine des informations sur le marché avec nos clients

Des échantillons peuvent être fournis gratuitement, mais les frais de transport sont à la charge du client et seront remboursés après coopération.

Nous avons exporté vers plus de 42 pays, tels que le Canada, le Chili, le Koweït, l'Allemagne, la Corée du Sud, l'Arabie saoudite, Singapour, etc.

Our MOQ is 1 ton for stainless steel coil.

Nous disposons d'une organisation complète allant de l'achat des matières premières au traitement et à l'organisation de l'expédition. Tout au long de la chaîne, le personnel documentaire et le service de contrôle de la qualité vérifient et contrôlent les produits en fonction d'exigences précises.

Les commandes d'essai peuvent être livrées dans un délai d'une semaine. Pour les commandes régulières, il faut compter environ deux semaines.