Grade 7 (Ti-0.15Pd) Titanium Alloy Plate Manufacturer - Daxun Alloy

As a leading supplier of titanium in China, Daxun provides high-performance titanium plates to the world.

- Plate Grade:پایه هفتم UNS R52400

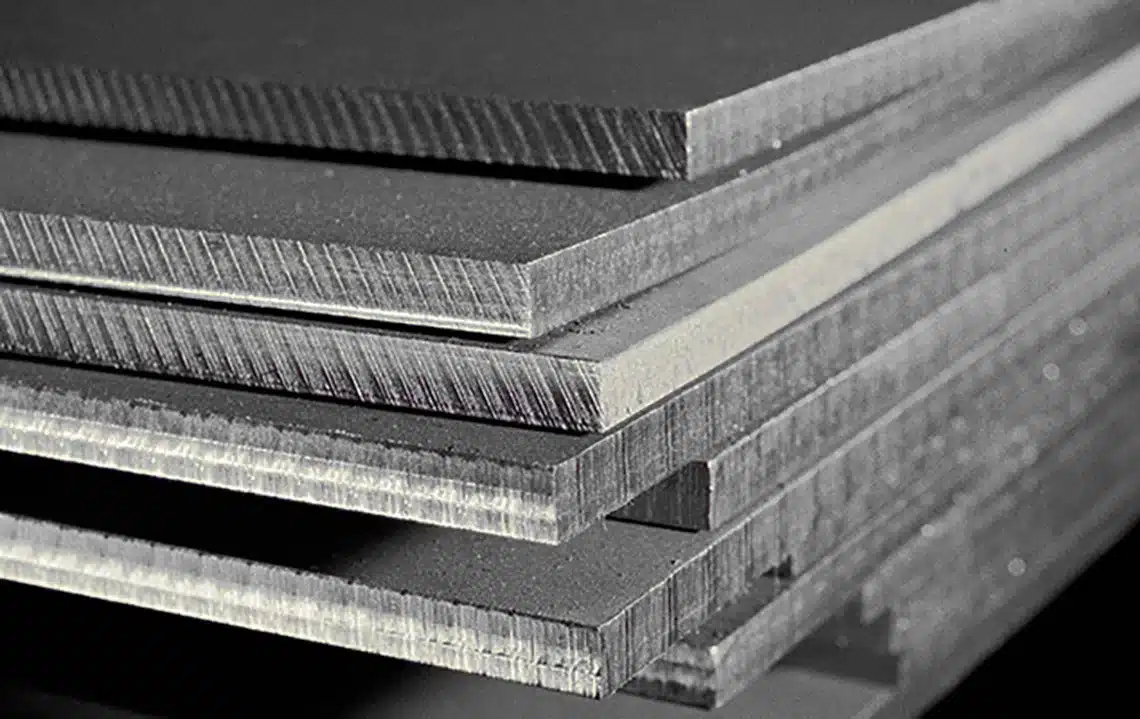

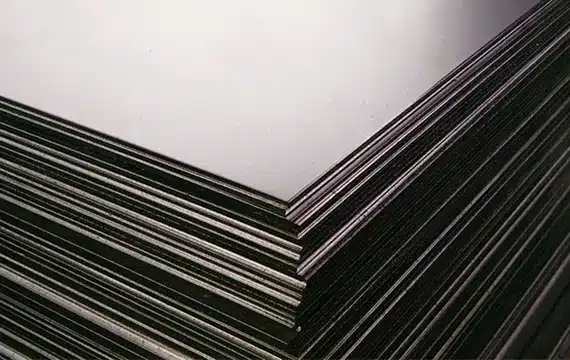

- Plate Production type:cold rolling, hot rolling, forging.

- Standard:ASTM B 265,ASME SB265,AMS491 etc

- Features:High strength, Lightweight, High-temperature resistance

- Surface:bright, polished, pickled, sandblasted, etc.

- Size:0.3mm ≤ 1000mm ≤ 2500mm or as your request

————Daxun produces titanium sheets in China to meet the diverse and ——نیازهای سختگیرانه مشتریان!

Providing High-quality Grade 7 Titanium Plate to Serve Customers Worldwide

Grade 7 titanium plate (Ti Grade 7 / UNS R52400) is a palladium-enhanced, commercially pure (CP) titanium alloy specifically engineered for supreme corrosion resistance in aggressive environments. It consists of titanium (≥99%) with a critical addition of 0.12–0.25% palladium (Pd), which fundamentally alters its electrochemical behavior. This palladium modification dramatically improves resistance to reducing acids (e.g., sulfuric, hydrochloric, phosphoric), chloride solutions (including seawater and brines), and crevice/pitting corrosion—scenarios where standard CP grades like Grade 2 would rapidly degrade. While retaining the inherent advantages of titanium—low density (~4.5 g/cm³), high strength-to-weight ratio, excellent weldability, and biocompatibility—Grade 7 exhibits superior performance at elevated temperatures (up to ~400°C/750°F) and in highly oxidizing or acidic conditions. Its passive oxide layer, stabilized by palladium, provides unparalleled protection against chemical attack, making it one of the most corrosion-resistant metallic materials available.

Where is Grade 7 titanium plate used?

Grade 7 titanium plate is extensively used in chemical processing for critical components like reactor vessels, heat exchangers, piping systems, and agitators handling acids, chlorides, or organic solvents. In marine and offshore engineering, it serves in seawater desalination plants, heat rejection systems, and subsea equipment exposed to high-salinity environments. The alloy also excels in pollution control systems (e.g., flue-gas desulfurization scrubbers), pharmaceutical manufacturing, and medical implants (e.g., orthopedic devices) due to its inertness and longevity. Despite its higher initial cost—driven by palladium content—Grade 7 delivers exceptional lifecycle value by minimizing downtime, maintenance, and replacement costs in corrosive service. Its reliability in preventing catastrophic failures ensures safety and efficiency in applications ranging from nuclear waste containment to aerospace fluid systems, justifying its selection as a premium solution for the most demanding corrosion challenges.

دادهها

- پارامتر

- خواص فیزیکی

- خواص مکانیکی

| عنصر | نماد | Composition Range (wt.%) |

|---|---|---|

| تیتانیوم | تیتانیوم | Balance (>99%) |

| Palladium | Pd | 0.12–0.25% |

| آهن | آهن | ≤0.30% |

| اکسیژن | O | ≤0.25% |

| کربن | C | ≤0.08% |

| نیتروژن | N | ≤0.03% |

| هیدروژن | H | ≤0.015% |

| عناصر دیگر | Each | ≤0.40% (single element) |

Key Characteristics

- Strength-to-Weight Ratio: Comparable to pure titanium (Grades 1–4) but lower than Ti-6Al-4V (Grade 5) or Ti-3Al-2.5V (Grade 9). Optimized for corrosion resistance over mechanical strength.

- Corrosion Resistance: Unmatched in reducing acids (e.g., HCl, H₂SO₄), chlorides, and crevice corrosion environments. Outperforms all commercially pure grades (1–4) and Grade 5/9 in aggressive chemical media due to palladium (Pd) stabilization.

- Biocompatibility: Fully non-toxic and MRI-compatible. Suitable for surgical instruments and chemical processing equipment, though not used for permanent implants (Grade 23 preferred).

- Formability: Retains excellent cold formability, weldability, and machinability of pure titanium. Significantly easier to fabricate than Grade 5/9, enabling complex geometries without specialized tooling.

| مالکیت | Value (Imperial) | Value (Metric) |

|---|---|---|

| تراکم | 0.163 lb/in³ | 4.51 g/cm³ |

| نقطه ذوب | 3,000–3,050°F | 1,650–1,680°C |

| هدایت حرارتی | 9.5 Btu/(hr·ft·°F) | 16.4 W/(m·K) |

| Coefficient of Thermal Expansion | 4.8 × 10⁻⁶/°F | 8.6 × 10⁻⁶/K |

| مقاومت الکتریکی | 1.78 × 10⁻⁶ Ω·cm | 1.78 μΩ·m |

| مالکیت | Value (Imperial) | Value (Metric) |

|---|---|---|

| مقاومت کششی | 50,000–65,000 psi | 345–450 MPa |

| مقاومت تسلیم | 30,000–45,000 psi | 207–310 MPa |

| Elongation | 20–30% | 20–30% |

| سختی (برینل) | 120–160 HB | 120–160 HB |

| ماژول ارتجاعی | 14.9–16.0 × 10⁶ psi | 103–110 GPa |

داکسون را انتخاب کنید تا به پروژهتان کمک کند اوج بگیرد.

Common applications

Grade 7 titanium plates and sheets are primarily utilized in applications requiring exceptional corrosion resistance, particularly in aggressive chemical environments, combined with moderate strength and excellent weldability.

- Applications include chemical processing equipment such as heat exchangers, reactor vessels, and piping systems that handle chlorides, acids, and other corrosive substances.

- Industrial applications include marine components, offshore oil and gas equipment, and desalination plants where exposure to saltwater and harsh chemicals is common.

- Pharmaceutical and food processing equipment that demands high purity standards and resistance to corrosive cleaning agents.

- Laboratory equipment and analytical instruments that require superior chemical resistance for accurate testing and processing.

- Pollution control systems, including scrubbers and ductwork in power plants and industrial facilities that handle corrosive exhaust gases.

تحویل سریع

Daxun provides customers with timely and fast delivery of grade 7 titanium plate products. Behind the speed is the system support from professional production capacity, and information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real-time, and the data is seamlessly connected.

Custom Cutting

Daxun Alloy provides customers with customized cutting solutions of various sizes to help you control the size loss of titanium plates, thereby saving your processing costs and time. Our cutting methods include:

- Water jet cutting

- Laser cutting

- Plasma cutting

- Wire cutting

- Bending

- برش شیاری

- ارّهکاری

بستهبندی

We pay special attention to packaging. We pack our goods in many ways depending on the product. We pack our products in many ways such as:

• جعبهها و صندوقها

• Shrinkwrap

• پالتهای چوبی

• جعبههای چوبی

پشتیبانی فنی

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry.

Daxun Grade 7 Titanium sheet Let your brand improve rapidly

- Other Titanium Plate Grades

| به جز محصولات فهرستشده در زیر، سایر محصولات فلزی موجود در اینجا ذکر نشدهاند. سایر محصولات فلزی که DAXUN میتواند تولید و عرضه کند شامل تانتال، نیوبیوم، زیرکونیوم، هافنیوم، نیکل، مس و غیره هستند که عمدتاً به شکل ورق، شمش و لوله عرضه میشوند. | |

| محصولات/استاندارد فرآوری | رتبه/اندازه |

| Titanium Plate, Sheet, Coil— ASME SB265, AMS 4911, AMS 4919, AMS 4914,ASTM F67, ASTM F136 | GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR12, GR16, GR17, GR23, Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3 (ضخامت: (0.0197”-6”)حداکثر عرض: ۱۲ فوت، حداکثر طول: ۵۰ فوت) |

| AMS-T-9046 | |

| Titanium and Titanium alloy sheet, plate | |

| تیتانیوم خالص تجاری (CP) | |

| نشانهگذاری کد | مقاومت تسلیم |

| حداقل، ksi ۱ / | |

| CP-1 Gr1 | 70 |

| CP-2 Gr2 | 55 |

| CP-3 Gr3 | 40 |

| CP-4 Gr4 | 25 |

| آلیاژهای تیتانیوم آلفا (الف) | |

| نشانهگذاری کد | ترکیب |

| الف-۱ | ۵A۱-۲.۵Sn |

| الف-۲ | ۵A۱-۲.۵Sn(ELI) ۲ / |

| الف-۳ | ۶A۱-۲Cb-۱Ta-۰.۸Mo |

| الف-۴ | ۸A۱-۱Mo-۱V |

| آلیاژهای تیتانیوم آلفا-بتا (AB) | |

| نشانهگذاری کد | ترکیب |

| AB-1 Gr5 | ۶A۱-۴V |

| AB-2 Gr5 | ۶A۱-۴V(ELI) |

| AB-3 | ۶A۱-۶V-۲Sn |

| AB-4 | ۶آی۱-۲اسان-۴زیر-۲موی |

| AB-5 | ۳A۱-۲.۵V |

| AB-6 | ۸ منگنز |

| آلیاژهای تیتانیوم بتا (B) | |

| نشانهگذاری کد | ترکیب |

| بی-یک | ۱۳V-۱۱Cr-۳A1 |

| بی-۲ | ۱۱.۵ مولیبروم-۶ زِیرکونیم-۴.۵ قلع |

| بی-۳ | ۳A۱-۸V-۶Cr-۴Mo-۴Zr |

| بی-۴ | ۸ منگنز-۸ تیتانیوم-۲ آهن-۳ آلومینیوم |

| پردازش: | |

| نورد گرم | نورد سرد |

| مراحل در دسترس: | |

| رتبه ۱ CP | Grade 6Al-2Sn-4Zr-2Mo (6-2-4-2) |

| رتبهٔ ۲ CP | Grade 6Al-4V ELI (پیشتر Grade 23) |

| پایه هفتم | Grade 6Al-6V-2Sn (6-62) |

| کلاس نوزدهم | پایه ۸، ال-۱ مو-۱ وی (۸-۱-۱) |

| کلاس پنجم (۶آلومینیوم-۴ونادیوم) | کلاس ۹ (۳ آل-۲.۵ ولت) |

| کلاس ۶ (۵آلومینیوم-۲.۵ قلع) | CP درجه ۳ |

| کاربرد | |

| صنعت شیمیایی | شیرینسازی آب دریا |

| صنعت پتروشیمی | هوافضا |

| حوزه ماشینکاری، حوزه خودروسازی | میدان قطعه تلفن همراه. |

پروژهها و محصولات داغ اخیر

محصولات مرتبط (7)

Grade 7 titanium plate is a commercially pure titanium alloy with the addition of 0.12-0.25% palladium, which significantly enhances its corrosion resistance. This combination maintains the excellent formability and weldability of pure titanium while providing superior resistance to reducing acids and other highly corrosive environments.

Grade 7 titanium plates offer good strength with a minimum yield strength of 275 MPa and minimum tensile strength of 485 MPa. They maintain excellent ductility with approximately 20% elongation, allowing for good formability during fabrication processes.

Yes, Grade 7 titanium plates can be welded using standard titanium welding procedures including TIG, MIG, and plasma arc welding. However, proper shielding with inert gas is essential to prevent contamination during welding. The palladium addition does not significantly affect weldability compared to other commercially pure titanium grades.

We offer Grade 7 titanium plates in various surface finishes including hot-rolled, pickled, sandblasted, and polished finishes. Custom surface treatments can also be provided based on specific application requirements.

Our Grade 7 titanium plates undergo strict quality control including chemical composition analysis, mechanical property testing, and ultrasonic inspection. We provide full material traceability and certification with each order, ensuring compliance with applicable standards such as ASTM B265 and AMS 4902.

Standard lead times for Grade 7 titanium plates typically range from 2-4 weeks depending on size, thickness, and quantity requirements. We also maintain a stock of commonly used dimensions for immediate delivery and can accommodate urgent requests when possible.

لطفاً فرم صفحه “تماس با ما” را پر کنید یا با مدیر فروش ما به شماره +86 13382898899 تماس بگیرید. ما در اسرع وقت با شما تماس خواهیم گرفت. واتساپ ما آنلاین است و ایمیل ([email protected]) ظرف ۶ ساعت بررسی میشود. به هر پرسش یا پیام بهسرعت پاسخ داده خواهد شد. علاوه بر این، ما هر هفته اطلاعات بازار را با مشتریان خود به اشتراک میگذاریم.

We can provide titanium sheet samples for you to check the quality. Sample is free and you just pay the freight.

ما به بیش از ۴۲ کشور مانند کانادا، شیلی، کویت، آلمان، کرهٔ جنوبی، عربستان سعودی، سنگاپور و غیره صادرات داشتهایم.