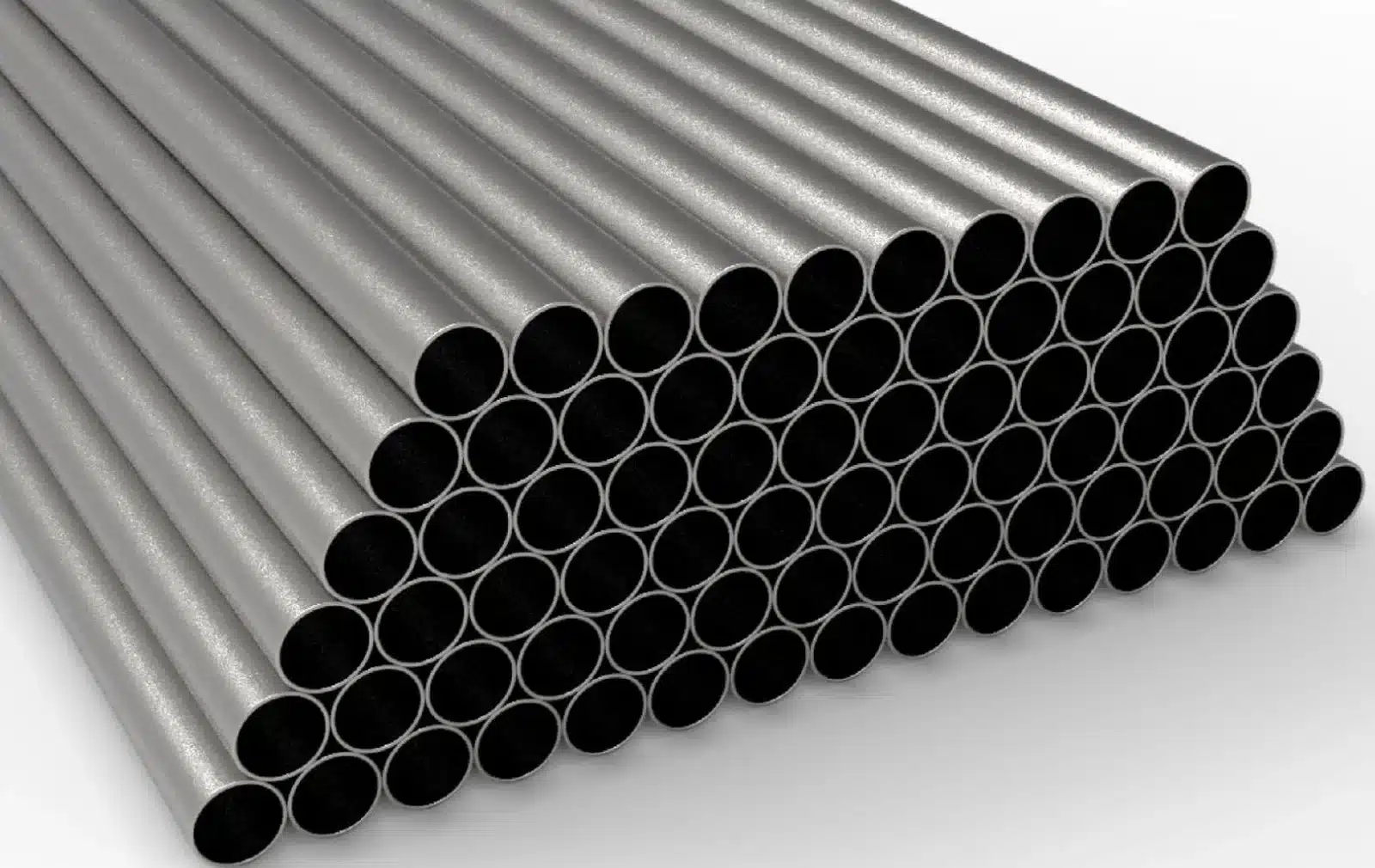

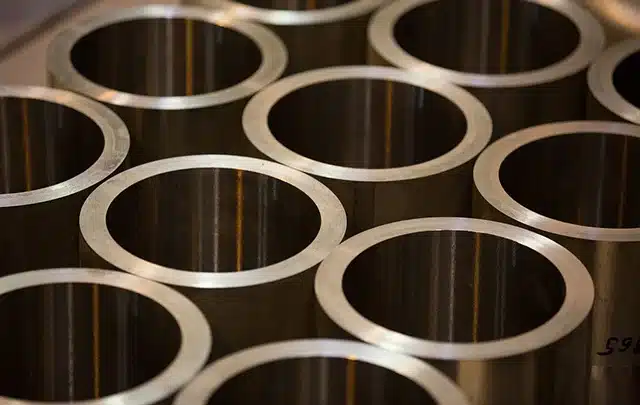

Daxun Alloy - Hastelloy C-4 pipe made in China

As a leading supplier of Hastelloy C-4 pipes in China, Daxun provides high-performance alloy tubes to the world.

- Hastelloy C-4 types: Seamless tube, welded tube, forged tube

- Certification : ASTM,SGS,ISO,CE

- Delivery Time : 7-15 days

- Surface finish: Annealed, polished etc.

- MOQ : ≥300kg

————Daxun produces hastelloy pipe in China to meet the diverse and ——نیازهای سختگیرانه مشتریان!

Characteristics & Properties of Hastelloy C-4

Hastelloy C-4 (UNS N06404) is a high-performance corrosion-resistant alloy of the nickel-chromium-molybdenum (Ni-Cr-Mo) series, developed by the American Hastelloy Alloy Company (Haynes International), and is a low-carbon titanium stabilized improved version of the Hastelloy C series. Hastelloy C-4 plate is an engineering material designed for high-temperature corrosion resistance. Its titanium stabilization + ultra-low carbon composition solves the sensitization problem of traditional nickel-based alloys. It is particularly suitable for welding parts and high-temperature and highly corrosive environments, and is irreplaceable in the fields of chemical industry, energy, etc.

Corrosion resistance:

Excellent resistance to chloride stress corrosion cracking (SCC).

Resistant to strong oxidizing media (such as nitric acid, chromic acid) and reducing media (such as sulfuric acid, hydrochloric acid).

Resistant to corrosion such as wet chlorine, hypochlorite, chlorine dioxide, etc.

Thermal stability:

No harmful phase precipitation in the range of 650-1040℃, avoiding intergranular corrosion.

Mechanical properties:

Good high temperature strength, suitable for high temperature and high pressure environment.

Good plasticity and toughness, easy to process and shape.

Typical application areas

Chemical industry: reactors, heat exchangers, piping systems (especially chloride ion environments).

Environmental engineering: flue gas desulfurization (FGD) systems, wastewater treatment equipment.

Petroleum and natural gas: acidic oil and gas extraction (resistant to H₂S and CO₂ corrosion).

Pharmaceutical industry: production equipment for strong acid media.

Nuclear industry: corrosive media containers in nuclear fuel reprocessing.

Processing and welding

Hot processing: It is recommended to heat to 1100-1200℃ for forging or rolling, and avoid staying in the 700-900℃ range for a long time.

Cold processing: Intermediate annealing is required to eliminate stress, and the annealing temperature is usually 1120-1170℃.

Welding: Applicable to TIG, MIG, arc welding, etc., it is recommended to use matching welding materials (such as HC-4 welding wire). Generally, no heat treatment is required after welding.

Hastelloy C-4 Parameters

- ترکیب شیمیایی

- Physical properties

- خواص مکانیکی

| نی | کروم | مو | آهن | Co | C |

| ≥65% | 14.0 – 18.0 | 14.0 – 17.0 | ≤3.0 | ≤2.0 | ≤0.015 |

| سی | امان | تیتانیوم | W | P | S |

| ≤0.08 | ≤1.0 | ≤0.70 | ≤0.50 | ≤0.025 | ≤0.010 |

| مالکیت | تراکم | نقطه ذوب | Coefficient of Thermal Expansion (20-100°C) | Thermal Conductivity (20°C) | Electrical Resistivity (20°C) | نفوذپذیری مغناطیسی |

| ارزش | 8.64 g/cm³ | 1350 – 1400°C | 12.6 μm/m·°C | 10.1 W/m·K | 1.25 μΩ·m | Non-magnetic (<1.001) |

| مالکیت | Tensile Strength (UTS) | Yield Strength (0.2% offset) | Elongation | Hardness (Brinell, HB) | Elastic Modulus |

| ارزش | ≥690 MPa | ≥310 MPa | ≥40% | ≤220 | 210 GPa |

داکسون را انتخاب کنید تا به پروژهتان کمک کند اوج بگیرد.

Advanced Production:Hastelloy alloy pipe

Hastelloy C4 alloy is an all-around nickel-chromium-molybdenum-tungsten alloy with good resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidative aqueous media, including wet chlorine, nitric acid or mixed acids of oxidizing acids containing chloride ions. At the same time, Hastelloy C4 alloy also has ideal resistance to reducing and oxidizing environments encountered in the process. Relying on this versatile performance, it can be used in some troublesome environments or in factories for a variety of production purposes.

Hastelloy C-4 Pipe Features

Hastelloy C4 alloy has an exceptional resistance to various chemical environments, including strong oxidizing substances, such as ferric chloride, cupric chloride, chlorine, thermally contaminated solutions (organic and inorganic), formic acid, acetic acid, acetic anhydride, seawater and salt solutions, etc. Hastelloy C4 alloy has the ability to resist the formation of grain boundary precipitation in the heat affected zone of welding, so that it can also be used in many chemical processes in the welding state.

کیفیت، تحویل، بازرسی

Daxun conducts a series of quality assurance tests on Hastelloy C-4 pipes. These tests include flattening test, flaring test, ultrasonic flaw detection, crevice corrosion resistance test, mechanical property test, hardness test, material positive identification, and expansion test, etc. All these tests are designed to ensure that the Hastelloy C-4 pipes meet the requirements of the intended applications. During the production process, we meticulously measure the outer diameter, wall thickness, and surface quality of the products. Our standard delivery time is 5 – 7 days, and for special sizes, it is 15 – 20 days.

- زمان تحویل ما دقیقاً مطابق قرارداد است.

- از آژانسهای ثالث مشتری برای انجام بازرسی به کارخانه پشتیبانی کنید.

- از نمونههای رایگان برای آزمایش مشتری پشتیبانی کنید.

- حمایت از بازرسی کارخانهای حضوری یا ویدیویی

بستهبندی

داکسون آلیاژ بهترین کیفیت بستهبندی را تضمین میکند، زیرا بستهبندی نقش مهمی در حملونقل بینالمللی دارد که کالاها از مسیرهای مختلف عبور میکنند تا به مقصد نهایی برسند؛ بنابراین ما توجه ویژهای به بستهبندی داریم. ما کالاهای خود را بسته به محصول به روشهای مختلف بستهبندی میکنیم. روشهای بستهبندی محصولات ما عبارتند از:

• جعبهها و صندوقها

• سلفون منقبضشونده

• پالتهای چوبی

• جعبههای چوبی

پشتیبانی فنی

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. [همین حالا با ما تماس بگیرید]Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry. This, in our opinion, demonstrates our unwavering dedication to quality and our philosophy as a full-service supplier.

Daxun is a trustworthy stainless steel tube manufacturer

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all titanium tubes are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the stainless steel tubes have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

محصولات مرتبط (8)

لطفاً فرم صفحه “تماس با ما” را پر کنید یا با مدیر فروش ما به شماره +86 13382898899 تماس بگیرید. ما در اسرع وقت با شما تماس خواهیم گرفت. واتساپ ما آنلاین است و ایمیل ([email protected]) ظرف ۶ ساعت بررسی میشود. به هر پرسش یا پیام بهسرعت پاسخ داده خواهد شد. علاوه بر این، ما هر هفته اطلاعات بازار را با مشتریان خود به اشتراک میگذاریم.

ما میتوانیم نمونههای ورق فولاد ضدزنگ را برای بررسی کیفیت در اختیار شما قرار دهیم. نمونه رایگان است و شما فقط هزینه حمل را پرداخت میکنید.

ما به بیش از ۴۲ کشور مانند کانادا، شیلی، کویت، آلمان، کرهٔ جنوبی، عربستان سعودی، سنگاپور و غیره صادرات داشتهایم.

The minimum order quantity for our Hastelloy products is 300kg

سفارشهای آزمایشی را میتوان ظرف یک هفته تحویل داد. برای سفارشهای معمولی تقریباً دو هفته زمان لازم است.