Welded Titanium Tube

Tubular products are made from a strip that is roll-formed and fusion welded longitudinally without the use of any filler metal.

Titanium Welded & Drawn Tubing

Tubular products undergo a process where they are welded and then drawn over a mandrel to achieve the desired finished size. This “welded and drawn” method is particularly effective for producing tubes with heavy walls and larger diameters that cannot be welded directly to size. This approach offers significant cost savings compared to seamless tubes while maintaining excellent quality. All our welded and drawn tubes are bright annealed for superior finish and durability.

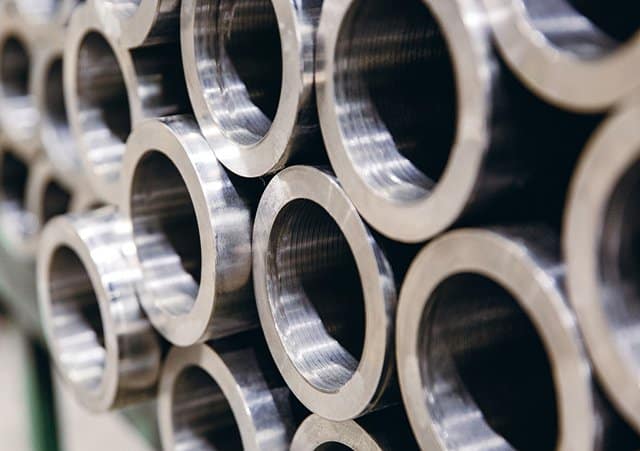

Seamless Titanium Tube

Seamless tubular products are crafted by drawing tube hollows, which are created either through billet piercing or a hot extrusion process. Seamless tubing is ideal for applications requiring very heavy diameter-to-wall ratios, offering exceptional precision in outside dimensional tolerances and superior performance in demanding conditions.

Introduction to titanium tube and pipe manufacturing process

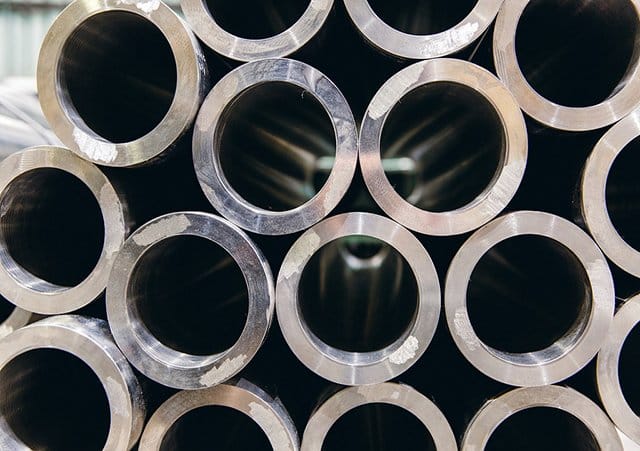

Titanium Seamless Tubes

DaXun produces:

● Hot-finished Titanium Tubes

These Titanium tubes are supplied in the form of hot-rolled or hot-extruded, straightened, machined inside and outside diameters, and surface polished. Titanium tubes are available in heat-treated or non-heat-treated forms. Our company has 100% ultrasonic flaw detection capabilities.

● Available Materials

Hot-rolled titanium tubes are offered with outer diameters ranging from 19mm to 1020mm, thicknesses between 9mm and 30mm, and lengths up to 12000mm, depending on agreements made between the manufacturer and the customer.

Hot-extruded titanium tubes are available with outer diameters from 50mm to 609mm, thicknesses of 3mm to 35mm, and lengths up to 8000mm, also customizable based on customer and manufacturer agreements.

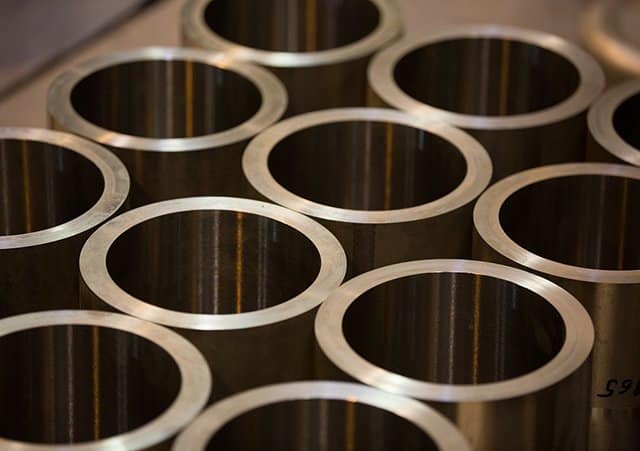

● Cold-finished Titanium Tubes

Cold-finished titanium tubes are available in various forms to meet specific manufacturing requirements. These include heat-treated, surface-etched, hydrostatically tested, or ultrasonically tested options, ensuring they meet the necessary standards and application needs.

The Titanium tubes offered range from an outer diameter of 6mm to 1020mm, with wall thicknesses between 0.5mm and 50mm, and lengths of up to 6000mm. Specific dimensions and conditions can be customized through mutual agreement between the manufacturer and the customer.

Titanium Welded Pipes

Daxun specializes in the production and supply of high-quality titanium welded pipes with diameters ranging from 12.7 mm to 1020 mm, wall thicknesses from 0.4 mm to 50 mm, and lengths up to 25,000 mm. Made from electrical titanium alloy grades 1, 2, and 12, these pipes are designed for use in heat exchangers, petroleum engineering, and the chemical industry.

The production process begins with flat-rolled raw material, which is then automatically welded using tungsten inert gas (argon) welding with an electric tube welder, followed by heat treatment directly on the rolling mill. Each finished titanium welded tube undergoes rigorous quality control, including mechanical testing, dimensional measurement, 100% ultrasonic and eddy current testing, and pneumatic or hydrostatic pressure testing.

To ensure compliance with ASTM B338 and ASME SB338 standards, DaXun employs advanced manufacturing processes and precision inspection equipment. Pipes are meticulously packed according to customer specifications, ensuring they meet the highest standards of quality and reliability.

Brands and characteristics of various titanium tubes

Each titanium tube material has its own different usages.

Industrial pure titanium tube pipe is easy to weld, corrosion-resistant, and can work at 300°C for a long time. Used in electric power, petrochemical, nuclear energy, military industry, etc.

Titanium welded pipes are corrosion-resistant and are used in chemical equipment and pipelines such as heat exchangers, condensers, evaporators, etc.

Titanium welded pipes are corrosion-resistant and are used in chemical equipment and pipelines such as heat exchangers, condensers, evaporators, etc.

Suitable for aerospace parts production, high temperature resistance and high strength.

Titanium seamless pipe have good strength and toughness, and the grains are refined.

Forged titanium tubes have good strength and toughness, and the Tube Wall Thickness can be fully customized.

Titanium tube and pipe grade 12 Have better corrosion resistance

Suitable for titanium tubes for precision equipment such as medical, instrumentation, fluid equipment, etc.

From oil and gas to power generation, upstream and downstream, E&P and pipelines, and refining and nuclear.

From oil and gas to power generation, upstream and downstream, E&P and pipelines, and refining and nuclear.

Used for exhaust pipes of automobiles and equipment, with excellent elongation and corrosion resistance.

Titanium heat exchanger tubes For various heat exchanger pipes.

Titanium tube and pipe production flow

With our reliable Titanium tube and pipe, their properties can be customized to suit your application.

The main features of titanium tube and pipe

The density of titanium metal is 4.506g/cm3

Titanium is 100 times more corrosion resistant than steel

Suitable for situations where magnetic field interference is avoided

Titanium alloy has high strength (even with the least tube wall thickness)

Daxun’s titanium tube manufacturing capabilities

Daxun is equipped with advanced forming technology, including cutting-edge extrusion and cold-working techniques for tube and pipe production. Our assets include one of the world’s largest Pilger mills and specialized hydroforming processes for creating high-quality fittings.

Daxun’s pipe processing capabilities

As a fully integrated manufacturer, Daxun offers comprehensive solutions tailored to a wide range of project needs, whether for large-scale production or specific machining tasks. Our extensive services include straightening, drilling, honing, trepanning, cutting, testing, boring, machining, laser welding, polishing, turning, and a host of specialized processes. With this all-in-one approach, we ensure precision, efficiency, and quality at every stage of production.

Bigger, Better Pipe Solutions

Equipped with vertical and horizontal presses ranging from 12,000 to 35,000 tons, Daxun provides unmatched pipe extrusion capabilities. This advanced machinery enables us to manufacture pipes with the longest lengths and largest diameters available on the global market, setting a new standard for production scale and versatility.

State-of-the-Art Testing

Before delivery, our titanium tubes undergo comprehensive quality inspections, including hydrostatic testing, eddy current/ultrasonic examination, flattening and flaring tests, corrosion testing, tensile performance evaluation, dimensional measurement, and surface appearance inspection. Only after passing all inspections and issuing the corresponding reports will the products be shipped. At Daxun, we place the highest priority on titanium tube quality, ensuring our customers receive products with absolute reliability and peace of mind.

Powerful Pipe Solutions

Daxun serves the power generation sector with a range of products, including ductwork, boiler tubes, main steam tubes, thermal reheat tubes, and flue gas desulfurization units. Our solutions are designed for nuclear, coal-fired, renewable energy, and combined cycle applications.

Technical Information

We provide pipe and tubing products to the defense sector, along with a range of mechanical and structural applications that require high-performance tubing. Our high-alloy nickel casing and mechanical tube products are specifically designed for use in some of the world’s most challenging industries and environments, including those with sour conditions, extreme pressures, and high temperatures.

In chemical processing, our products include pipes and tubes used in ethylene production, caustic soda production, and heat exchanger applications. Additionally, we manufacture a wide variety of products for the medical and general industrial sectors, such as components for x-ray machines, thermocouple sheathing tubes for industrial furnaces, and boiler tubes.

Titanium tube and pipe application cases in different industries

It can be used for titanium alloy structural parts such as fuselages, aerospace equipment, rockets, artificial satellites, missiles, spacecraft shells, blades, etc.

Serving the Chemical/Can be used in: electrolyzers, blowers, reaction towers, heat exchangers, pressure shafts, distillation towers, valves, pumps, etc.When you choose Daxun as your pipeline supplier, you know we truly understand the oil and gas industry. Contact Daxun today.

Deep-sea exploration equipment Deep-sea exploration is one of the important directions in the field of ocean engineering, and titanium alloy has become an ideal material for various deep-sea exploration equipment due to its corrosion resistance and high strength. Deep-sea buoys, detectors, sonar equipment, etc. can all be made of titanium alloy to ensure long-term reliable operation in harsh marine environments.

Serving the pharmaceutical and biopharmaceutical industries has been a welcome challenge for Daxun. From raw material selection to delivery, we have developed high purity and ultra-high purity services to meet and exceed industry standards. When only the best tubing and piping can meet demand, more and more pharmaceutical and biopharmaceutical companies trust Daxun.

Serving the power generation industry, Daxun is able to combine technical expertise and experience to produce the best pipe and pipe available today. When you choose the best, you get the best. Follow what countless other companies have done – trust Daxun. Highly demanding industries need Daxun.

Our titanium tube stock sizes

- Titanium Pipe Size Chart

| Nominal Bore | Outside Diameter | Sch-5S | Sch-10S | Sch-40S | Sch-80S | Sch-160S | Sch-XXS | |||||||

| mm | INCH | mm | Wt | Weight | Wt | Weight | Wt | Weight | Wt | Weight | Wt | Weight | Wt | Weight |

| mm | (Kg/mt) | mm | (Kg/mt) | mm | (Kg/mt) | mm | (Kg/mt) | mm | (Kg/mt) | mm | (Kg/mt) | |||

| 3 | 1/8 | 10.3 | 1.24 | 0.276 | 1.24 | 0.28 | 1.73 | 0.37 | 2.41 | 0.47 | – | – | – | – |

| 6 | 1/4 | 13.7 | 1.24 | 0.39 | 1.65 | 0.49 | 2.24 | 0.631 | 3.02 | 0.8 | – | – | – | – |

| 10 | 3/8 | 17.1 | 1.24 | 0.49 | 1.65 | 0.63 | 2.31 | 0.845 | 3.2 | 1.1 | – | – | – | – |

| 15 | 1/2 | 21.3 | 1.65 | 0.8 | 2.11 | 1 | 2.77 | 1.27 | 3.75 | 1.62 | 4.75 | 1.94 | 7.47 | 2.55 |

| 20 | 3/4 | 26.7 | 1.65 | 1.03 | 2.11 | 1.28 | 2.87 | 1.68 | 3.91 | 2.2 | 5.54 | 2.89 | 7.82 | 3.63 |

| 25 | 1 | 33.4 | 1.65 | 1.3 | 2.77 | 2.09 | 3.38 | 2.5 | 4.55 | 3.24 | 6.35 | 4.24 | 9.09 | 5.45 |

| 32 | 1 1/4 | 42.2 | 1.65 | 1.65 | 2.77 | 2.7 | 3.56 | 3.38 | 4.85 | 4.47 | 6.35 | 5.61 | 9.7 | 7.77 |

| 40 | 1 1/2 | 48.3 | 1.65 | 1.91 | 2.77 | 3.11 | 3.68 | 4.05 | 5.08 | 5.41 | 7.14 | 7.25 | 10.16 | 9.54 |

| 50 | 2 | 60.3 | 1.65 | 2.4 | 2.77 | 3.93 | 3.91 | 5.44 | 5.54 | 7.48 | 8.74 | 11.1 | 11.07 | 13.44 |

| 65 | 2 1/2 | 73 | 2.11 | 3.69 | 3.05 | 5.26 | 5.16 | 8.63 | 7.01 | 11.4 | 9.53 | 14.9 | 14.2 | 20.39 |

| 80 | 3 | 88.9 | 2.11 | 4.51 | 3.05 | 6.45 | 5.49 | 11.3 | 7.62 | 15.2 | 11.1 | 21.3 | 15.24 | 27.65 |

| 100 | 4 | 114.3 | 2.11 | 5.84 | 3.05 | 8.36 | 6.02 | 16.07 | 8.56 | 22.3 | 13.49 | 33.54 | 17.12 | 41.03 |

| 125 | 5 | 141.3 | 2.77 | 9.47 | 3.4 | 11.57 | 6.55 | 21.8 | 9.53 | 31.97 | 15.88 | 49.11 | 19.05 | 57.43 |

| 150 | 6 | 168.3 | 2.77 | 11.32 | 3.4 | 13.84 | 7.11 | 28.3 | 10.97 | 42.7 | 18.2 | 67.56 | 21.95 | 79.22 |

| 200 | 8 | 219.1 | 2.77 | 14.79 | 3.76 | 19.96 | 8.18 | 42.6 | 12.7 | 64.6 | 23 | 111.2 | 22.23 | 107.8 |

| 250 | 10 | 273.1 | 3.4 | 22.63 | 4.19 | 27.78 | 9.27 | 60.5 | 12.7 | 96 | 28.6 | 172.4 | 25.4 | 155.15 |

| 300 | 12 | 323.9 | 3.96 | 31.25 | 4.57 | 36 | 9.52 | 73.88 | 12.7 | 132 | 33.32 | 238.76 | 25.4 | 186.97 |

| 350 | 14 | 355.6 | 3.96 | 34.36 | 4.78 | 41.3 | 11.13 | 94.59 | 19.05 | 158.08 | 35.71 | 281.7 | – | – |

| 400 | 16 | 406.4 | 4.19 | 41.56 | 4.78 | 47.29 | 12.7 | 123.3 | 21.41 | 203.33 | 40.46 | 365.11 | – | – |

| 450 | 18 | 457.2 | 4.19 | 46.8 | 4.78 | 53.42 | 14.27 | 155.8 | 23.8 | 254.36 | 45.71 | 466.4 | – | – |

| 500 | 20 | 508 | 4.78 | 59.25 | 5.54 | 68.71 | 15.09 | 183.42 | 26.19 | 311.2 | 49.99 | 564.68 | – | – |

| 600 | 24 | 609.6 | 5.54 | 82.47 | 6.35 | 94.45 | 17.48 | 255.41 | 30.96 | 442.08 | 59.54 | 808.22 | – | – |

| For larger or non-standard sizes, please contact Daxun for inquiries. | ||||||||||||||

Related Product

Daxun Alloy

Regarding titanium tube and pipe, we can handle any type of inquiry. Please feel free to ask us. We will make recommendations based on each client’s needs.

Yes, we have complete specifications and inventory and can quickly meet your needs.

We mainly supply titanium tubes in Grades 1, 2, 5 (Ti-6Al-4V), 7, and 12, in accordance with ASTM B338/B861 standards. Other customized grades are also available on request.

Our regular MOQ is 50 kg or 10 pieces, but for trial orders or samples, we can provide smaller quantities.

Yes, we can supply small samples for material confirmation. The sample cost can be deducted from the bulk order.

Normally, our lead time is 7–15 days for stock items and 20–30 days for customized production.

Yes, we offer both seamless and welded titanium tubes, depending on your application requirements

We can supply tubes with pickled, polished, or sandblasted surfaces according to customer requirements.

All tubes are packed in wooden cases with plastic film protection to prevent scratches and corrosion during transportation.

Titanium tubes are widely used in aerospace, marine, chemical processing, desalination, medical devices, and heat exchangers due to their high strength, low weight, and excellent corrosion resistance.

We usually accept T/T (wire transfer), L/C at sight, and PayPal for small orders. Other payment methods can be negotiated.

Yes, we can provide SGS, BV, or other third-party inspection reports upon request. Mill test certificates (EN 10204 3.1/3.2) are included with every order.

Absolutely. We provide OEM & ODM services and can customize dimensions, tolerances, and surface finishes according to your specifications.

Every tube undergoes strict testing, including chemical composition analysis, mechanical property tests, ultrasonic inspection, and dimensional checks. Photos and videos of the final inspection can be shared before delivery.

We mainly ship from Shanghai and Tianjin ports, but we can arrange delivery from other ports if required.

We offer sea freight, air freight, and express courier (DHL, FedEx, UPS) depending on order size and urgency.

Yes, we welcome long-term cooperation and can set up annual supply agreements with stable pricing and guaranteed delivery schedules.