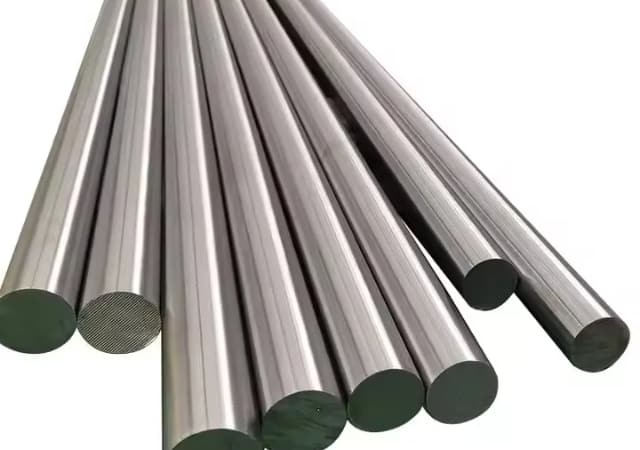

Daxun is an excellent manufacturer of Ti15333 (Ti-15V-3O-3Sn-3Al) titanium rods and bars.

- Titanium bar grade: Ti15333 / UNS R58153

- Titanium bar types: rolled bars, drawn bars, forged titanium bars

- Titanium bar density: The density of Ti 15333 titanium is 4.76 g/cm³

- Main standards: ASTM ASME GB GJB EN JIS DIN ISO ATP BS, etc.

- High corrosion resistance, excellent weldability, superior strength, lightweight, and outstanding performance in aggressive environments.

The global leader in commercially titanium alloy rod manufacturing services

Daxun, specializing in the production of alloy titanium rods for extreme environments

Titanium 15333 Bar (also known as TB5 or Ti-15V-3Cr-3Al-3Sn) is a high-performance beta titanium alloy, celebrated for its exceptional combination of strength, low density, and outstanding corrosion resistance. With a density of approximately 4.48-4.7 g/cm³, it offers significant lightweight advantages, making it a premier choice for demanding applications in aerospace, high-performance automotive, and chemical processing industries.In its solution-treated condition, the alloy exhibits impressive cold formability, allowing it to be shaped into complex geometries, a significant advantage over many other high-strength titanium alloys. Subsequent aging treatments can then elevate its tensile strength to an impressive 1200-1400 MPa, making it suitable for the most demanding structural roles.

Where is Grade titanium 15333 bar used?

- Aerospace: Used for airframe structural components, bulkheads, and engine parts that require a combination of strength and reduced mass.

- High-Performance Automotive: Found in components like valve springs, connecting rods, and exhaust systems where high strength and temperature resistance are beneficial.

- Chemical Processing: A suitable choice for equipment like heat exchangers, pressure vessels, and pump shafts that operate in corrosive environments.

- Fasteners: Its high strength makes it ideal for manufacturing critical bolts and screws used in demanding assemblies.

- Consumer Goods: The material’s properties lend themselves to high-end applications such as premium eyewear frames and medical instruments, where both durability and light weight are valued.

| Specification | Details |

|---|---|

| Material | Titanium 15333 rod and bar (UNS R58153) |

| Standard | ASTM B348, AMS 4928 |

| Dimensions | EN, ASTM, JIS, ASME, BS, AISI, GB, GJB, DIN |

| Diameter Range | 0.125″ – 14″ (3.175mm – 355.6mm), custom |

| Length Range | Up to 240″ (6096mm), custom |

| Finish | Cold (bright) drawn, centerless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centerless Ground & Black |

| Surface Finish | Cold drawn, Centerless Ground, Polished, Or Rough Turned, Black, NO.4 Finish, BA Finish, Matt Finish, etc. |

| Condition | Hardened & tempered, annealed |

| Tolerance | Diameter tolerance: +/- 0.005″ (0.127mm), length tolerance: +/- 0.125″ (3.175mm) |

| Form | Titanium square bars, titanium ingots, titanium round bars, rectangular titanium bars, triangular titanium bars, forged titanium bars, titanium hexagonal bars, etc. |

Daxun is your trusted titanium alloy rod production company. Daxun produces all grades of titanium alloys, including commercially pure titanium series CP, titanium alloy series, titanium nickel alloy, etc. They have reliable performance and provide high performance for your critical applications. In various industries and applications, you can rely on Daxun titanium alloy rods for high strength, high temperature and corrosive environments. For decades, Daxun Metals has been committed to producing highly engineered titanium alloy solutions to meet the most severe challenges.

Data

- Ingredient

- Mechanical Properties

- Physical Properties

| Element | Content (%) |

| Titanium(Ti) | 75 |

| Vanadium(V) | 15 |

| Chromium(Cr) | 3 |

| Aluminum(Al) | 3 |

| Tin(Sn) | 3 |

| Iron(Fe) | ≤ 0.25 |

| Oxygen(O) | ≤ 0.13 |

| Carbon(C) | ≤ 0.05 |

| Nitrogen(N) | ≤ 0.05 |

| Hydrogen(H) | ≤ 0.015 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 1100-1200 |

| Yield Strength (MPa) | 950-1050 |

| Elongation (%) | 10-15 |

| Reduction of Area (%) | 25-35 |

| Hardness (HB) | 350-400 |

| Fatigue Strength (MPa) | 550-650 |

| Shear Strength (MPa) | 670-770 |

| Impact Toughness (J) | 40-60 |

| Property | Value |

|---|---|

| Density (g/cm³) | 4.8 |

| Melting Point (°C) | 1600-1650 |

| Thermal Conductivity (W/m·K) | 6.7-8.0 |

| Specific Heat (J/kg·K) | 510 |

| Electrical Resistivity (μΩ·m) | 1.30 |

| Coefficient of Thermal Expansion (10^-6/K) | 8.6-9.4 |

Choose Daxun to help your project take off.

Daxun Factory Advantages

Daxun’s “Performance Excellence Management” concept promotes the “PDCA + Lean” management model. The company’s business card says “Daxun = Reliable Quality”. Daxun uses the ERP system to achieve full traceability of the variety, specification, and origin of each titanium rod, and advocates and encourages industry anti-counterfeiting. Daxun relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

Ti 15333 Titanium Rod Production Method

Daxun produces high-quality titanium bars with high performance, and can also manufacture according to customer’s agreement:

- Titanium ingots need to go through heat treatment and machining, immersion ultrasonic testing, mechanical properties testing, macroscopic and microscopic structural inspection and other processes. Production process: hot-rolled titanium bars – high efficiency, stable performance, forged titanium bars – flexible size, multi-fire forging, improve the comprehensive performance of titanium bars, cold-drawn titanium bars – usually small-sized high-precision titanium bars; the above titanium bars are all delivered with bright surface.

Quality, delivery, inspection

Daxun performs several quality assurance tests, these tests include mechanical tests like area tensile, chemical analysis, material positive identification – PMI test, micro and macro testing, intergranular corrosion (IGC) test, ultrasonic flaw detection test, pitting and resistance test, hardness test, material positive identification, expansion test etc. All these tests ensure that the Grade 2 Titanium Rod and Grade 2 Titanium Round Bar material is suitable for the required application. During the production process, we measure the diameter, thickness and surface of the product.

- Our delivery time is strictly in accordance with the contract.

- Support customer third-party agencies to go to the factory for inspection

- Support free samples for customer testing

- Support on-site or video factory inspection

Packaging

Daxun Alloy ensures the best quality of packaging as it plays an important role in international freight where goods go through various channels to reach the final destination, so we pay special attention to packaging. We pack our goods in many ways depending on the product. We pack our products in many ways such as:

• Boxes and crates

• Shrink wrap

• Wooden pallets

• Wooden boxes

Technical Support

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry. This, in our opinion, demonstrates our unwavering dedication to quality and our philosophy as a full-service supplier.

Daxun Ti 15333 Titanium Rods help your brand improve quickly

- Tolerances for Ti 15333 Titanium Round Bars (BS EN ISO 286-2)

| NOMINAL SIZE | h5 | h6 | h7 | h8 | h9 | H10 | H11 | h12 |

|---|---|---|---|---|---|---|---|---|

| DIAMETER mm | ||||||||

| ~ to 3 | +0.004/0 | +0.006/0 | +0.01/0 | +0.014/0 | +0.025/0 | +0.04/0 | +0.06/0 | +0.1/0 |

| over 3 to 6 | +0.005/0 | +0.008/0 | +0.012/0 | +0.018/0 | +0.03/0 | +0.048/0 | +0.075/0 | +0.12/0 |

| over 6 to 10 | +0.006/0 | +0.009/0 | +0.015/0 | +0.022/0 | +0.036/0 | +0.058/0 | +0.09/0 | +0.15/0 |

| over 10 to 18 | +0.008/0 | +0.011/0 | +0.018/0 | +0.027/0 | +0.043/0 | +0.07/0 | +0.11/0 | +0.18/0 |

| over 18 to 30 | +0.009/0 | +0.013/0 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 | +0.13/0 | +0.21/0 |

| over 30 to 50 | +0.011/0 | +0.016/0 | +0.025/0 | +0.039/0 | +0.062/0 | +0.1/0 | +0.16/0 | +0.25/0 |

| over 50 to 80 | +0.013/0 | +0.019/0 | +0.03/0 | +0.046/0 | +0.074/0 | +0.12/0 | +0.19/0 | +0.3/0 |

| over 80 to 120 | +0.015/0 | +0.022/0 | +0.035/0 | +0.054/0 | +0.087/0 | +0.14/0 | +0.22/0 | +0.35/0 |

| over 120 to 180 | +0.018/0 | +0.025/0 | +0.04/0 | +0.063/0 | +0.1/0 | +0.16/0 | +0.25/0 | +0.4/0 |

| over 180 to 250 | +0.02/0 | +0.029/0 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 | +0.29/0 | +0.46/0 |

Types of Ti 15333 Titanium Rods (3)

Titanium rod

Recent hot case projects and products

Related Products (8)

Titanium 15333, also known by its UNS number R30133, is a near-beta titanium alloy renowned for its exceptional combination of high strength, toughness, and excellent corrosion resistance. It is a premier choice for demanding applications in the aerospace, defense, and medical industries. Common uses for Titanium 15333 bar include manufacturing critical components like airframe structural parts, landing gear, fasteners, engine components, and high-strength medical implants. Its superior properties make it ideal where both performance and reliability are non-negotiable.

The Ti-15333 alloy is prized for its outstanding mechanical and physical properties. Key characteristics of our Titanium 15333 bar include:

- High Tensile Strength: Offers a superior strength-to-weight ratio compared to many steels and other titanium alloys.

- Excellent Toughness: Maintains high impact resistance, even at elevated temperatures.

- Superb Corrosion Resistance: Highly resistant to crevice corrosion and stress corrosion cracking in various environments.

- Good Weldability: Can be successfully welded using appropriate procedures.

- Forgeability: Exhibits good formability in the solution-treated condition.

These properties make Ti-15333 bar a top-tier material for high-performance engineering.

We supply Titanium 15333 bar in two primary heat-treated conditions to meet your specific requirements:

- Solution Annealed (STA): This condition provides excellent ductility and is ideal for forming or machining prior to a final aging treatment.

- Solution Treated and Aged (STA): This is the peak-strength condition, delivering the maximum mechanical properties the alloy can offer.

Our standard Titanium 15333 bar stock is available as round bar. We offer a wide range of diameters and can provide custom-cut lengths to your exact specifications. Please contact us with your required dimensions for a quick quote.

While Ti-6Al-4V (Grade 5) is the most common titanium alloy, Titanium 15333 (R30133) offers distinct advantages for certain applications. The primary difference is that Ti-15333 is a near-beta alloy capable of achieving higher strength and toughness levels than Ti-6Al-4V, especially in thicker sections. It also provides superior deep-hardenability. If your project requires the absolute highest strength and performance from a titanium alloy, Ti-15333 bar is often the superior choice, whereas Ti-6Al-4V remains a versatile and cost-effective option for many general-purpose applications.

Absolutely. As a leading supplier of specialty metals, we specialize in meeting custom requirements. We can provide Titanium 15333 bar cut-to-length according to your drawings. Furthermore, all our material is supplied with full material test certificates (MTCs). We can also provide additional certifications, such as AMS 4957 or other industry-specific standards, upon request. To discuss your custom Ti-15333 bar needs, please contact our sales team with your specifications.

Please fill in the form on the “Contact Us” page, or call our sales manager at “+86 13382898899”, we will contact you as soon as possible. Our WhatsApp is online, and email ([email protected]) will be checked within 6 hours. Every inquiry or message will be responded to promptly. In addition, we share market information with our customers every week

We can provide titanium rod samples for you to check the quality. Sample is free and you just pay the freight.

We’ve exported to more than 42 countries, such as Canada, Chile, Kuwait, Germany, South Korea, Saudi Arabia, Singapore etc.

Trial orders can be delivered within a week. For regular orders, it takes two weeks roughly.