In the world of construction, manufacturing, and design, stainless steel angles stand out as versatile, durable, and essential components. Whether you’re building a structural framework, designing architectural elements, or fabricating industrial equipment, understanding the ins and outs of stainless steel angles is critical to ensuring long-lasting, high-performance results. This ultimate guide breaks down everything you need to know—from types and benefits to selection tips—helping you make informed decisions for your next project.

What is Stainless Steel Angle?

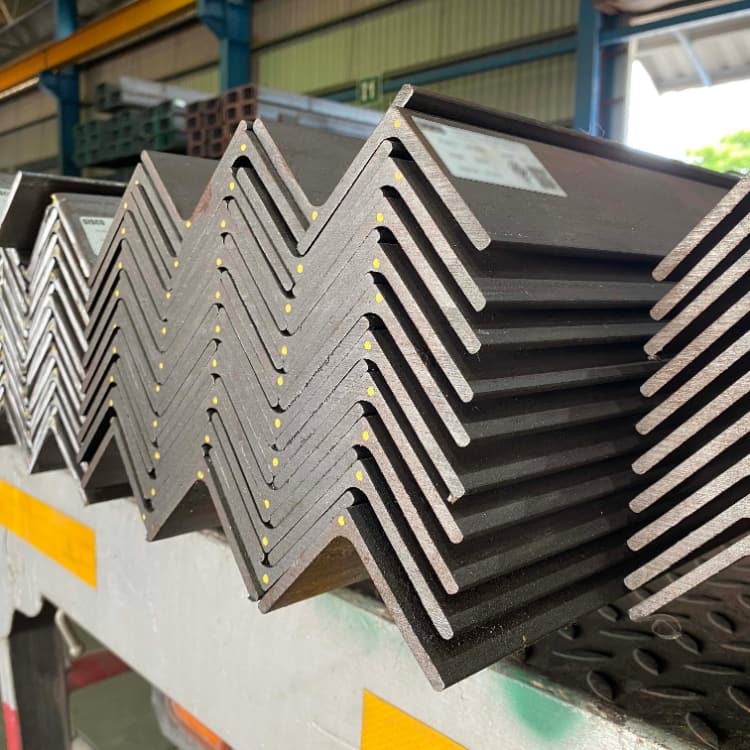

Stainless steel angles are L-shaped structural profiles with two equal or unequal legs, formed from stainless steel alloy. Known for their exceptional strength, corrosion resistance, and aesthetic appeal, they serve as foundational materials in industries ranging from construction to automotive manufacturing. The “angle” shape provides excellent load-bearing capacity while offering flexibility for various design configurations.

Unlike carbon steel, stainless steel angles contain a minimum of 10.5% chromium, which forms a passive oxide layer that protects against rust, staining, and chemical damage. This makes them ideal for both indoor and outdoor applications, even in harsh environments like coastal areas or chemical processing plants.

Key Types of Stainless Steel Angles

Stainless steel angles come in diverse configurations to suit specific needs. Here are the most common types:

- By Leg Configuration: Equal vs. Unequal

Equal Stainless Steel Angles: Both legs are of equal length (e.g., 2×2 inches, 3×3 inches). These are widely used in general structural applications, where balanced strength and symmetry are required.

Unequal Stainless Steel Angles: Legs have different lengths (e.g., 3×2 inches, 4×3 inches). They’re preferred for projects needing asymmetric support, such as bracket mounts or machinery frames.

- By Grade: 304, 316, and More

The grade of stainless steel determines its corrosion resistance, strength, and temperature tolerance. The two most popular grades for angles are:

304 Stainless Steel Angle: The “workhorse” grade, offering excellent corrosion resistance, formability, and weldability. Ideal for architectural projects, food processing equipment, and indoor structural use.

316 Stainless Steel Angle: Contains molybdenum, enhancing resistance to chlorides, saltwater, and harsh chemicals. Perfect for marine environments, coastal construction, and chemical storage facilities.

Other grades, like 201 (more affordable but lower corrosion resistance) and 316L (low-carbon for better weldability), are also available based on specific project requirements.

Top Benefits of Stainless Steel Angles

Why choose stainless steel angles over other materials? Here are the standout advantages:

- Superior Corrosion Resistance

The chromium in stainless steel creates a “self-healing” oxide layer, preventing rust and degradation—even in wet, high-humidity, or chemically exposed settings. This reduces maintenance costs and extends the lifespan of structures.

- High Strength-to-Weight Ratio

Stainless steel angles offer exceptional strength without excessive weight, making them easier to transport, install, and support lighter materials. This is especially valuable in modern construction, where lightweight yet durable components are in demand.

- Aesthetic Versatility

With a sleek, metallic finish, stainless steel angles add a modern, professional look to architectural and design projects. They can be polished, brushed, or matte-finished to complement any aesthetic, from industrial chic to minimalist elegance.

- Durability and Longevity

Resistant to dents, impacts, and extreme temperatures, stainless steel angles maintain their integrity over decades. Unlike wood or carbon steel, they won’t warp, crack, or corrode under normal conditions.

- Eco-Friendly and Recyclable

Stainless steel is 100% recyclable, and its long lifespan reduces the need for replacements. Choosing stainless steel angles aligns with sustainable building practices and environmental regulations.

Common Applications of Stainless Steel Angles

Stainless steel angles are used across industries due to their adaptability. Here are some key use cases:

- Construction & Structural Frameworks

Building Supports: Bracing, roof trusses, and column reinforcements.

Bridges and Infrastructure: Handrails, guardrails, and structural bracing for outdoor structures.

- Architectural & Design Projects

Decorative Elements: Wall accents, window frames, and modern furniture legs.

Cladding and Facades: Support frames for glass, metal, or stone exteriors.

- Industrial & Manufacturing

Machinery Frames: Base structures for equipment, conveyor systems, and assembly lines.

Chemical and Food Processing: Corrosion-resistant supports for tanks, pipes, and processing equipment.

- Automotive & Marine

Vehicle Components: Brackets, chassis reinforcements, and exhaust system supports.

Boat and Dock Hardware: Rails, cleats, and structural frames exposed to saltwater.

Conclusion

Stainless steel angles, with their combination of durability, corrosion resistance, and versatility, are indispensable materials for countless applications. Understanding the types, benefits, and selection criteria of stainless steel angles outlined in this guide will help you choose the right angles to ensure your project’s success for years to come.

Ready to source high-quality stainless steel angles for your project? Contact Daxun Alloy, your trusted stainless steel supplier, today to discuss your needs and receive a quote!