Heat exchangers efficiently transfer thermal energy from one medium to another without mixing the fluids. Whether heating chemical reactants to precise reaction temperatures, cooling critical equipment to prevent overheating, or recovering waste heat to reduce energy costs, heat exchangers form the cornerstone of countless industrial operations. However, the fluids and gases involved in these processes are often highly corrosive, abrasive, or operate under extreme pressures. Such harsh environments rapidly degrade conventional materials, leading to leaks, inefficiency, and costly failures. Engineers therefore turn to titanium—a material offering exceptional corrosion resistance and strength—enabling heat exchangers to reliably perform their critical function under the most demanding conditions. This article explores the primary types of titanium heat exchangers and how they operate.

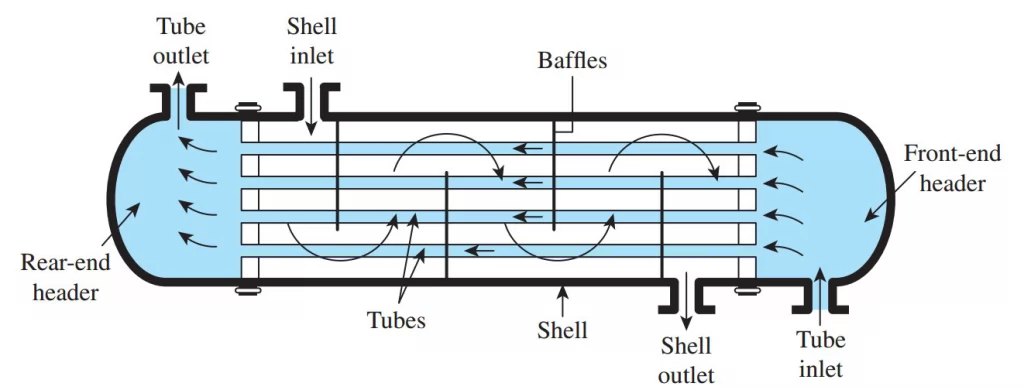

Shell and Tube Heat Exchangers

The shell and tube heat exchanger is the most prevalent and robust design found across heavy industries. Its construction is both powerful and straightforward: a large shell houses a bundle of smaller titanium tubes. One fluid flows through the inside of the tubes (the tube side), while a second fluid flows over the exterior of the tubes within the shell (the shell side). Heat is transferred through the tube walls without the two fluids ever mixing.

This design is revered for its ability to withstand extreme pressures and temperatures, making it a staple in chemical processing plants, oil and gas refineries, and power generation facilities. Its modular nature also allows for relatively easy cleaning and maintenance, as the tube bundle can often be removed for servicing. The longevity of these units in aggressive media, such as seawater or chlorinated solutions, is directly attributable to the corrosion-proof nature of the titanium tubes used in their construction.

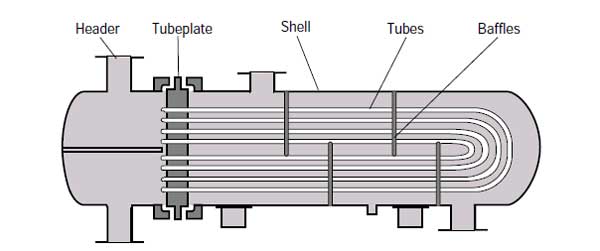

U-Tube Heat Exchangers

A clever variation of the shell and tube design is the U-tube heat exchanger. In this configuration, the titanium tubes are bent into a U-shape, with both ends of each tube anchored to a single tubesheet. This design elegantly solves the problem of thermal stress. As the tubes heat up and cool down, they can expand and contract freely within the shell without inducing stress on the tubesheet. This makes U-tube exchangers the preferred choice for applications with significant temperature differentials between the two fluids.

While the inside of the U-bends can be more challenging to clean mechanically, their ability to handle thermal cycling makes them indispensable in many processes, from temperature-controlled reactors to condensers. The integrity of the U-bend itself is a testament to the quality and ductility of the titanium tubes supplied by specialized manufacturers.

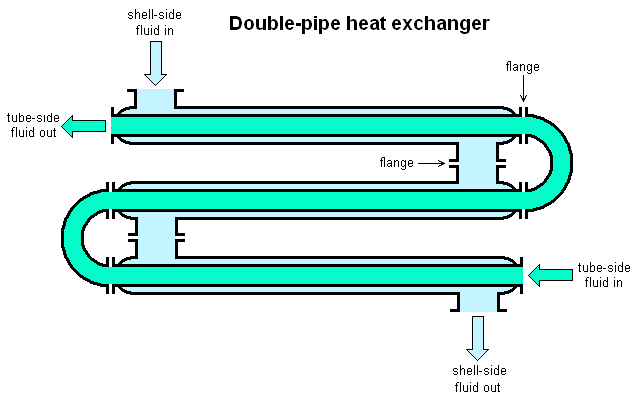

Double Pipe Heat Exchangers

For simpler applications or smaller heat loads, the double pipe heat exchanger offers a highly effective and economical solution. This design consists of one pipe placed inside a larger diameter pipe, creating an annular space. One fluid flows through the inner pipe, and the other flows through the annular space. The most significant advantage of this design is its ability to achieve true counter-current flow, where the two fluids move in opposite directions. This maximizes the mean temperature difference across the length of the exchanger, leading to highly efficient heat transfer.

Often constructed using seamless titanium pipes, these exchangers are easy to construct and can be arranged in series or in banks, known as hairpin exchangers, to handle larger capacities. They are particularly well-suited for high-pressure applications and for heating or cooling viscous fluids.

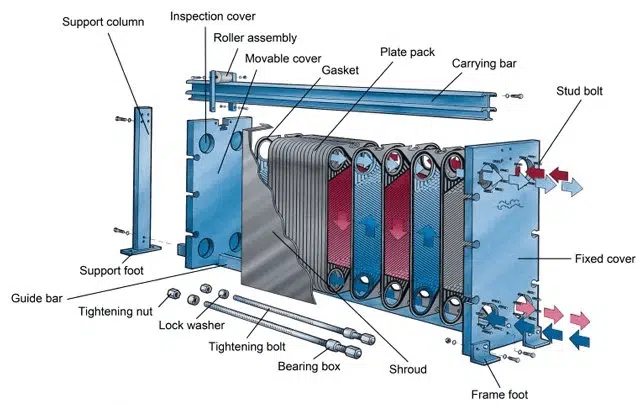

Plate Heat Exchangers

Moving beyond tubular designs, the plate heat exchanger represents a leap in efficiency and compactness. Instead of tubes, this design uses a series of thin, corrugated titanium plates stacked together. Gaskets around the edge of each plate direct the hot and cold fluids into alternating flow channels. The corrugation of the plates creates a highly turbulent flow, which significantly boosts the heat transfer coefficient and minimizes fouling. The result is an extremely efficient unit that occupies a fraction of the footprint of a comparable shell and tube exchanger.

The use of thin titanium plates is essential here, providing the necessary corrosion resistance and strength while allowing for the high thermal conductivity required. These exchangers are ideal for marine applications like desalination, HVAC systems, and the food and beverage industry, where their compact size and ease of disassembly for cleaning are major benefits.

Conclusion

At Daxun Alloy Co., Ltd., we specialize in providing the premium-grade titanium plates, tubes, and custom alloys that serve as the foundation for these critical industrial systems. We understand that engineering excellence is built upon a base of material reliability. Whether your project requires seamless tubes for a high-pressure U-tube exchanger or precision-rolled plates for a compact system, our commitment is to supply products that meet the most stringent specifications. Partner with Daxun Alloy Co., Ltd. to ensure your heat exchangers are not just built, but built to last. Contact us today to discuss your project needs.