In the world of metals, titanium stands out for its excellent strength-to-weight ratio and corrosion resistance. But when it’s time to select a titanium grade for a specific project, you’ll quickly face a common question: Grade 2 or Grade 5, which is the right choice?

These two are the most commonly used and often confused titanium grades on the market. As a professional titanium supplier, Daxun Alloys Co., Ltd. frequently helps clients navigate this decision. This article will provide a clear, practical comparison to help you make an informed choice.

Grade 2 Titanium: Commercially Pure Titanium

Grade 2 belongs to the “commercially pure” titanium family. Its composition is very pure, with over 99% titanium content. You can think of it as a highly pure form of titanium, which gives it its standout advantage: excellent corrosion resistance, especially in environments like seawater or chlorides. At the same time, its weldability and formability are very good, making it easy to fabricate into various shapes.

Grade 5 Titanium: The High-Performance “Alloy”

Grade 5’s formal name is Ti-6Al-4V, and it is a titanium alloy. As the name suggests, it’s titanium with 6% aluminum and 4% vanadium added. The addition of these alloy elements significantly boosts its strength. In fact, Grade 5 is the most widely used titanium alloy. Its strength is nearly double that of pure titanium (like Grade 2), while still maintaining good corrosion resistance and low density.

Core Differences at a Glance

To make things clearer, here’s a table summarizing their key distinctions:

| Feature | Grade 2 Titanium | Grade 5 Titanium (Ti-6Al-4V) |

|---|---|---|

| Main Category | Commercially Pure | Titanium Alloy |

| Strength | Moderate | Very High |

| Corrosion Resistance | Excellent, especially against chlorides | Good, but slightly less than Grade 2 |

| Weldability | Excellent, easy to weld | Good, but requires more precise procedures |

| Formability | Excellent, easy to form | Fair, more difficult to form |

| Weight | Low | Low (similar to Grade 2, but much stronger) |

| Cost | Relatively lower | Relatively higher |

A Deeper Look: What Do These Differences Mean?

1. Strength and Weight

If your project needs to withstand high stress or loads—such as in aircraft structural parts, racing components, or high-performance sports equipment—then Grade 5 titanium is the clear choice. Its “strength-to-weight ratio” is its biggest advantage, meaning it provides far more structural support than Grade 2 at the same weight.

2. Corrosion Resistance

This is the absolute strong point of Grade 2 titanium. In applications like chemical processing equipment, marine engineering, desalination plants, or medical implants (which need to remain stable in the body’s fluids for long periods), the “purity” of Grade 2 makes it almost immune to erosion. While Grade 5’s corrosion resistance is also very good, in extremely aggressive environments, Grade 2 is the more reliable and durable option.

3. Fabrication and Cost

Grade 2 titanium is softer and therefore easier to cut, bend, and weld, which reduces fabrication difficulty and cost. Grade 5, due to its high strength and hardness, is more challenging to machine. It requires more specialized equipment and processes, which naturally leads to higher material and processing costs.

Applications

Typical Scenarios for Choosing Grade 2 Titanium:

- Chemical Industry: Heat exchangers, piping, reaction vessels.

- Marine Engineering: Ship propellers, seawater treatment equipment, offshore platform components.

- Medical Field: Dental implants, surgical instruments.

- Architecture: Roofing, exterior panels in coastal areas where resistance to salt air is crucial.

Typical Scenarios for Choosing Grade 5 Titanium:

- Aerospace: Airframe structural components, engine parts, fasteners.

- High-Performance Sports: Race car chassis, golf club heads, high-end bicycle frames.

- Industrial Sector: Turbine blades, oil drilling equipment.

- Military Applications: UAV components, armored vehicle parts.

Conclusion: How to Make the Final Choice?

The decision process is quite simple. Just ask yourself one core question:

“What is the most important factor for my project?”

- If the answer is “maximum corrosion resistance” and “ease of fabrication,” and the strength requirements are moderate, then Grade 2 titanium is a highly cost-effective choice.

- If the answer is “the highest possible strength” and “lightweighting,” and you are prepared for the higher cost, then Grade 5 titanium is the definitive option.

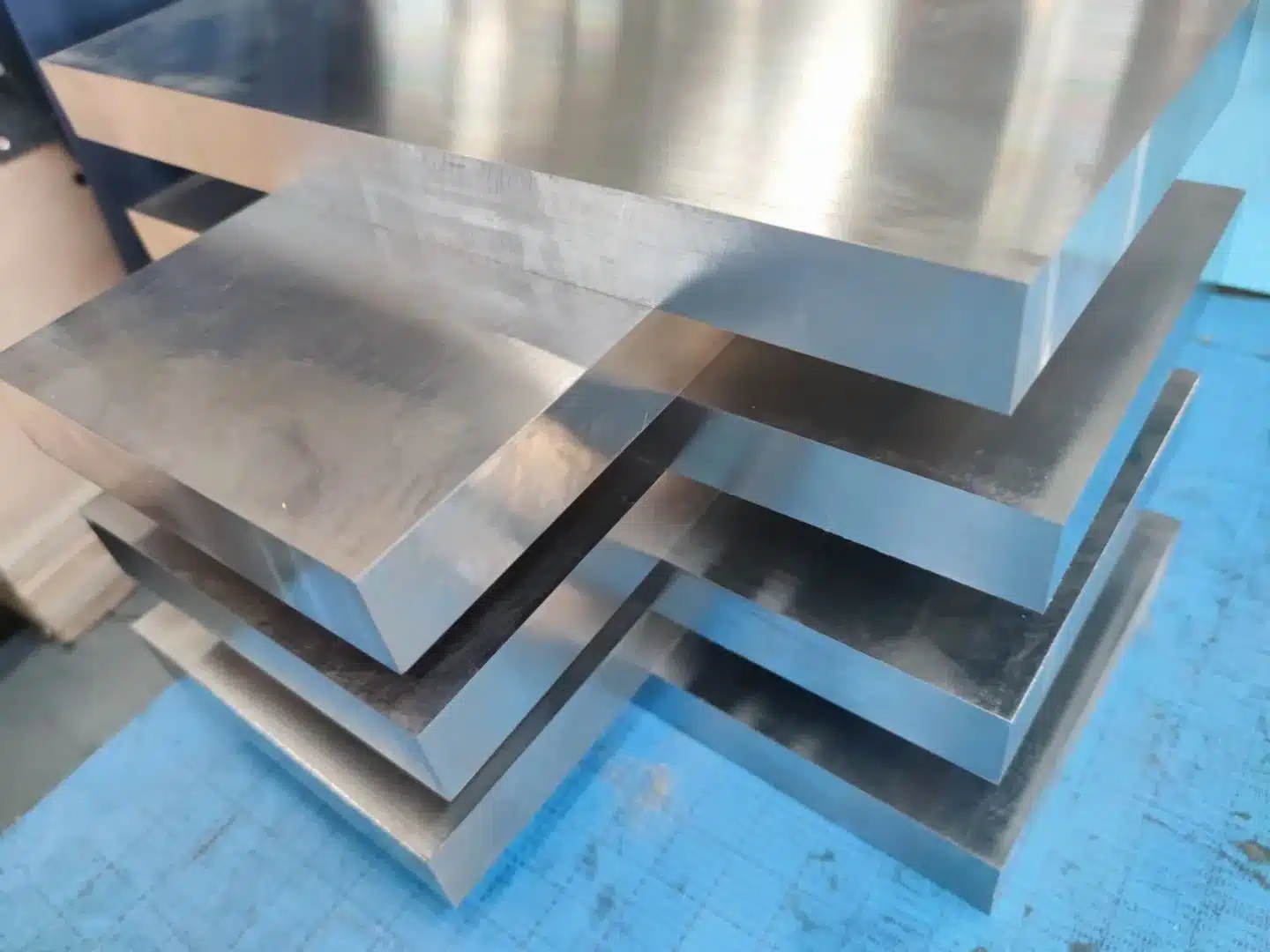

At Daxun Alloys Co., Ltd., we stock a wide range of both Grade 2 and Grade 5 titanium products, including bars, plates, and pipes. We understand that selecting the right material is the first step toward a successful project. If you are still unsure which grade is right for you, or if you’d like to check pricing and availability for specific sizes, feel free to contact our technical team. We are happy to provide expert advice and support based on your unique application needs.