Discover Our Premium Metal Products

Explore Daxun’s comprehensive range of high-performance alloys, crafted to meet the demands of aerospace, industrial, and energy sectors. From stainless steel to titanium and nickel alloys, our materials are engineered for durability, heat resistance, and precision in the most demanding applications. Discover the difference Daxun products can make in your projects today.

Our products

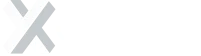

- Stainless steel

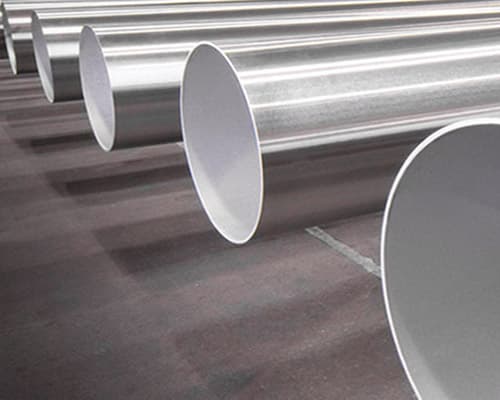

- Titanium

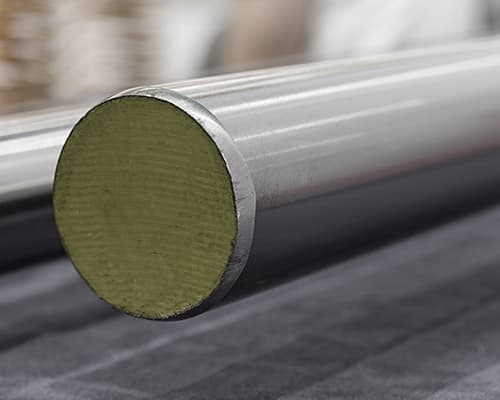

- Carbon Steel

We guarantee

Industries Served

Our premium stainless steel, titanium alloys, nickel alloys, and other materials are precisely engineered to deliver optimal heat resistance, durability, corrosion protection, and strength, tailored for demanding industrial applications.

A Legacy Built on Quality and Innovation

Combining a customer-focused approach with a diverse product portfolio, Daxun Alloy is here to meet your most demanding industrial needs.

Common Queries

Find answers to common questions about our products and services. More detailed answers can be found on FAQ page.

We offer stainless steel, titanium alloys, nickel alloys, and more. Contact us for specific requirements.

Our products meet rigorous international standards, including CE, SGS, TUV, and ISO-9001 certifications, ensuring superior quality.

We accept payment through Western Union, D/A, L/C, and T/T.

We are a customer-focused company, and we strive to accommodate your needs with the lowest possible MOQ. Please contact us to discuss your specific requirements.

Typical production lead time ranges from 1 to 4 weeks, depending on the product. Special products may require longer. Please provide your specifications, and our product managers will give you an accurate lead time along with any specific reasons for variations.

Latest Insights

As an industry leader in metal materials, Daxun is dedicated to developing high-performance alloys. Follow our blog for the latest updates and insights.