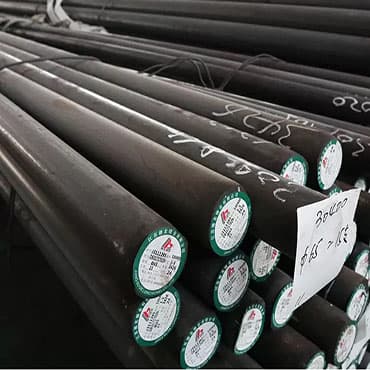

SS 420 stainless steel bars and round bars China supplier

As a leading stainless steel supplier and exporter in China, Daxun supplies stainless steel barsRod (Round Bar)to all over the world.

- Grade: AISI 420

- Manufacturing: hot rolled, cold drawn, forged

- Standards: ASTM, ASME, GB, DIN, JIS, ISO

- It is magnetic in both annealed and hardened conditions

- Different heating methods produce various properties

- Hardenable

- High strength

- Corrosion resistant

Stainless Steel 420 Rod (SS 420 Rod) offers several advantages including high tensile strength, premium finish, low maintenance, superior quality and durability. In view of the domestic and international quality of raw materials, Daxun also offers UNS S42000 Round Rod in customized diameters and lengths to cater to the unique needs of our valued clients at competitive market prices.

Global leader in stainless rod and Round Bar fabrication services

Daxun employs a team of specialists and professionals. Our staff thoroughly tests everything before putting it into any form. We are well-known in the industry for our exceptional work. We offer SS 420 Round Bars/Rods constructed from high-quality raw materials.

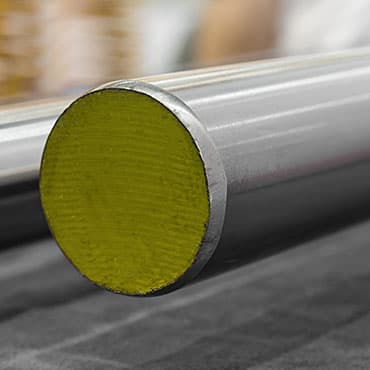

420 stainless steel contains more carbon than 410 stainless steel. 420 grade steel is a ductile and corrosion-resistant steel with a smooth surface after polishing. After polishing, the surface becomes extremely hard, making it resistant to all types of corrosion. It possesses outstanding shaping and welding properties. It can be deeply drawn without cracking. This makes it ideal for creating sinks, hollow utensils, and pans. It possesses great tensile strength. These bars require less maintenance, making them easier to use. These bars are also highly durable, flexible, and resistant to pitting.

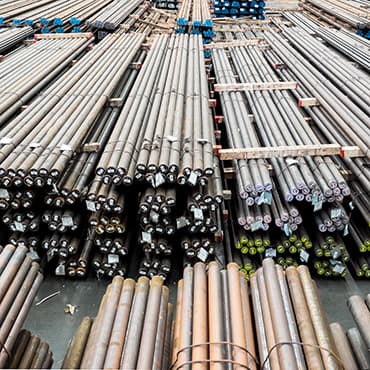

Our network of service centers stock stainless steel bar products for fast, ready supply of bar in common sizes and alloys.We also produce custom-sized stainless steel rods and can arrange inventory schedules for quick turnaround in a timely manner if quantities are below factory minimums.Daxun Alloys stocks stainless steel round bars with diameters ranging from 1/16″ to 26″. Round bars are available in nearly every grade of stainless steel, including 302, 303, 304/L, 309/S, 310/S, 316/L, 317/L, 321, 321/H, 347, 347H, 410, 416, 420, 440C, 17-4PH, Duplex 2205, and Alloy 20. Heat treated stainless steel round bars are offered in 17-4PH, H900 temper (on request), H1025, H1150, Double H1150, and H1150M. Other heat-treated tempers can be manufactured upon request. We stock the following 400 series stainless steels: 410, 430, and 416. We also carry 303, 304, and 316/L precision and bearing quality stainless steel round bars. The majority of our inventory consists of our unique machined bar grades: stainless steel round bars that are melted to consistent standards to increase machinability and lower total cost per component. Our stainless steel bar processing machinery allows Daxun Alloys to produce to our customers’ exact specifications.

Data

- Parameter

- Ingredients

- Mechanical Properties

- All equivalent

- Types

| ASTM A479 420 Round Bar Specification | ASTM A479 / ASTM A479 /ASTM A182 / ASME SA479 / ASME SA479 / ASME SA182 |

| ASTM A479 420 Round Bar Manufacturing Process | Hot Rolled / Cold Rolled / Hot Forging / Rolling / Machining |

| ASTM A479 420 Round Bar Other Grades | 202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. |

| UNS No. – UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| DIN / EN No. – 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| AFNOR: Z2 CN 18.10, Z 6 CND 17-11, Z 2 CND 17-12,Z3 CrNi 22.05 AZ | |

| EURONORM: FeMi35Cr20Cu4Mo2, FeMi35Cr20Cu4Mo2, X1CrNiMo17 12 2, X3CrNiMo17 12 2, FeMi35Cr20Cu4Mo2, X2CrNiMoN 22.5.3 | |

| ASTM A479 420 Round Bar Dimension | Round Bars : Outside Diameter in the range of 4mm to 500mm |

| Bright Bars : Outside Diameter in the range of 4mm to 200mm | |

| Hex Bars : 18mm to 57mm (11/16″ to 2-3/4″) | |

| Square Bars : 18mm to 57mm (11/16″ to 2-3/4″) | |

| Flat Bars : 1/2″to 10″in thickness range of 2mm to 150mm, Custom Size Stainless Steel Flats available | |

| ASTM A479 420 Round Bar Length | 2 meters to 7.5 meters ( 8 feet to 24 feet), or Custom Length as per Requirement |

| ASTM A479 420 Round Bar Forms and Shape | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, HRAP, Bright, Shaft, Forging Etc. |

| ASTM A479 420 Round Bar Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| ASTM A479 420 Round Bar Dimension Standard | ASTM A 484 / ISO h11 / ISO K12 Tolerances F8 / h8, h9, h10, h11, h12, k12, k13, A-484, EN-10060, DIN-1013 etc. |

| ASTM A479 420 Round Bar Heat Treatment | Condition A in which the bars are Annealed |

| Condition H in which the bars are Hardened and Tempered at a relative Temperature | |

| Condition T in which the bars are Hardened and Tempered at a relatively High Temperature | |

| Condition S in which the bars are Strain Hardened or relatively Light Cold Worked | |

| Condition B in which the bars are Relatively severe Cold worked. | |

| Solution Annealed, Aging and Double Aging | |

| ASTM A479 420 Round Bar Surface Finish | Centreless Ground & Belt Polished, up to Ra value = 0.2 um (12 RMS), and Grit Polished of up to 180 to 600 |

| ASTM A479 420 Round Bar Chamfering | Available in 30°, 45° & 60° through fully automatic, both-end chamfering machine |

| ASTM A479 420 Round Bar Other Testing | NACE MR0175, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, Magnetic Particle Inspection (MPI), 100% tested thru Digital Ultrasonic Flaw Detector, as per ASTM A-388, EN 10308 (class 1to4),API 6A/ISO 10423:2003-PSL3,SEP 1920:1984 ( class A,B,C), MIL STD 2154 etc. |

| ASTM A479 420 Round Bar Value Added Services | Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Polishing |

| ASTM A479 420 Round Bar Packaging | Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps |

| ASTM A479 420 Round Bar Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| ASTM A479 420 Round Bar Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of CHINA Standards BIS Approved ETC |

| ASTM A479 420 Round Bar Documentation | Commercial Invoice which includes HS Code / Packing List including net weight and gross weight, number of boxes, Marks and Numbers / Certificate of Origin legalized/attested by Chamber of Commerce or Embassy / Fumigation Certificates / Raw Material Test Reports / Material Traceability Records / Quality Assurance Plan (QAP) / Heat Treatment Charts / Test Certificates certifying NACE MR0103, NACE MR0175 / Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 / Guarantee Letter / NABL approved Laboratory Test Reports / Welding Procedure Specification/Procedure Qualification Record, WPS/PQR / Form A for the purposes of the Generalized System of Preferences (GSP) |

| 420 | Max | Min |

| C | 0.15 | – |

| Mn | 1 | – |

| Si | 1 | – |

| P | 0.04 | – |

| S | 0.03 | – |

| Cr | 14 | 12 |

| 420 Stainless Steel Round Bar Mechanical & Physical Properties | |

| Element | SS 420 |

| Tensile Strength (PSI) | 95,000 |

| Yield Strength (PSI) | 50,000 |

| Reduction of Area | 55 |

| Elongation in 2″ | 25 |

| Brinell Hardness | 175 |

| Stainless Steel 420 Round Bars Equivalent Grades | |||||||

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 420 | 1.4021 | S42000 | SUS 420 J1 | 420S29 | – | – | FeMi35Cr20Cu4Mo2 |

| Stainless Steel 420 Round Bar Suppliers | ASME, ASTM, EN, BS, GB Stainless Steel 420 Black Bars |

| »420 Stainless Steel Square Bar Stock | Stainless Steel 420 Forged Bars Distributors |

| ASTM/ASME A276 420 Steel Bright Bar Stock | Stainless Steel 420 Hollow Bars Exporters |

| SS UNS S42000 Hexagon Bar Manufacturers | DIN 1.4021 Stainless Steel Bars Distributors |

| 420 Round Bar Exporters | ASME SA 479 420 Stainless Steel Cold Finished Round Bars |

| Stainless Steel AISI 420 Black Bar | Top Quality Stainless Steel 420 Round Bars |

| JIS SUS 420 Stainless Steel Bar | SS 420 Stainless Steel Rod |

Choose Daxun and make your customers satisfied.

Quick response-431 Stainless Steel Rod

Daxun provides customers with timely and fast delivery of stainless steel bar 420 products. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real time, and the data is seamlessly connected; in terms of logistics, the processing center is close to ports and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on time.

Daxun Advantages

- Varieties: We offer a wide range of sizes and grades, including 300 series, 400, 600 series, and more.

- Flexibility: Whether you need hot-rolled or cold-drawn bars, our stainless steel bar lengths are designed to meet your specific project requirements.

- Quality Standards: Our 431 Stainless Steel Rod meet strict ASTM, ISO9001, GB, NSF/ANSI standards to ensure reliability and performance.

- Custom Orders: Looking for special sizes of stainless steel bars? We offer a variety of stainless steel bar customization options with competitive prices and convenient online ordering.

431 Stainless Steel Rod packaging

We pay attention to every 420 round bar manufacturing process to ensure quality. The packaging we usually adopt is to pack the stainless steel round bars in environmentally friendly plastic bags and then put them into fumigation-free wooden boxes or wooden pallets. Customized packaging, such as OEM, can also be negotiated. We provide almost everything to meet your round bar packaging requirements. We attach great importance to packaging. The round bars are packed in wooden corrugated boxes, wrapped with plastic packaging and bubble film on the outside.

Quality, delivery, inspection

- Daxun also conducts several quality assurance tests. These tests include flattening test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the material is suitable for the required application.

- During the production process, we measure the diameter, thickness, and surface of the product. Our standard delivery time is 7-15 days, except for some special size products, our delivery time will increase to 20 days.

Our delivery time is strictly in accordance with the contract. - Support customer third-party agencies to go to the factory for inspection

- Support free samples to customers for testing

- Support on-site or video factory inspection

Technical Support

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry. This, in our opinion, demonstrates our unwavering dedication to quality and our philosophy as a full-service supplier.

431 Stainless Steel Rod-Ordering Information

Purchase orders for 420 round bars shall include quantity, PSL grade, type or category, API5L reference, diameter, surface finish, length, and any applicable attachments or additional requirements related to chemical composition, mechanical properties, heat treatment, additional testing, manufacturing process, surface finish, or end treatment. Bars are solution bright annealed.

SS420 Stainless Steel Rod Features

Daxun Alloy Let your brand improve rapidly

- Gallery

- Delivery State

- Age Hardening

| Delivery State Choice | Surface Condition |

| Forged | Black |

| Polished | |

| Hot Rolled | Black |

| Polished | |

| Bright | |

| Pickled | |

| Cold Drawn | Polished |

| Bright | |

| Note: | |

| 1. If you require different deliver state than the above listed, kindly confirm with us. | |

| 2. In case of any enquiry or order, please kindly let us know any extra requirement not indicated here. | |

| Material in the solution annealed condition may be age hardened as follows:-*Denotes Double Overaged | ||||||||||||

| Condition | H900 (H480) | H925 (H495) | H1025 (H550) | H1075 (H580) | H1100 (H595) | H1150 (H620) | H1150M (H620M)* | Plus | H1150D (H620D)* | Plus | ||

| Heat to | ±15oF | 900oF | 925 oF | 1025oF | 1075oF | 1100oF | 1150oF | 1400oF | 1150oF | 1150oF | 1150oF | |

| ±9oC | 480oC | 495oC | 550oC | 580oC | 595oC | 620oC | 760oC | 620oC | 620oC | 620oC | ||

| Hold for Hours | 1 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | ||

| Cool to Below | Air | Air | Air | Air | Air | Air | Air | Air | Air | Air | ||

| 90oF (32oC) | ||||||||||||

Types of SS 420 Stainless Steel Rods (6)

Information available for reference and download

Stainless Steel Rod Production

Daxun is a trustworthy stainless steel rod and bar manufacturer

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless rod are certified by ISO9001, SGS, CE, OQC and more international quality standards.We also have strict quality control to ensure that the 431 Stainless Steel Rod have less defects. At Daxun, rest assured that all products are durable, high quality and high performance.

Recent hot case projects and products

Related Products (12)

We can provide 431 Stainless Steel Rod samples for you to check the quality. Sample is free and you just pay the freight.

We’ve exported to more than 42 countries, such as Canada, Chile, Kuwait, Germany, South Korea, Saudi Arabia, Singapore etc.

Our MOQ is 1 ton for 431 Stainless Steel Rod.

Trial orders can be delivered within a week. For regular orders, it takes two weeks roughly.