Duplex 2507 stainless steel plate, born for extreme environments

As China’s leading stainless steel plate supplier and exporter, Daxun provides 2507 stainless steel plates to the world.

- DGrade: AISI 2507-S32750

- Features: high strength and reliability

- Manufacturing: cold-rolled plate, hot-rolled plate, forged plate

- Standards: ASTM, ASME, GB, DIN, JIS, ISO, EN, BS

- Type: cold-rolled thin plate, hot-rolled thick plate

- Surface: 2B, NO.1, NO.4, HL, BA, 8K, etc.

- Length: 2438mm3048mm6000mm can be customized

- Origin: TISCO, Baosteel, Posco, Tsingshan, Delong, ATI,

2507/S32750Global leader in stainless steel sheet fabrication services

At Daxun, we are pleased to provide customers with high-quality super duplex 2507 stainless steel plates, which are a 50/50 mixture of austenite and ferrite, stronger than pure austenite or iron alloys. Since its birth in the United States in the 1940s, it has developed to the third generation, and its main feature is that the yield strength can reach 400-550MPa, which is twice that of ordinary stainless steel, so the duplex plate can save materials and reduce equipment manufacturing costs. In terms of corrosion resistance, especially in media environments (such as seawater, high chloride ion content), the resistance to pitting, crevice corrosion, stress corrosion, and corrosion fatigue of duplex stainless steel is better than that of ordinary austenitic stainless steel, and is comparable to high-alloy austenitic stainless steel. Daxun Alloys provides duplex 2507 stainless steel in a variety of forms and sizes, all of which comply with industry and international standards such as ASTM, ASME, EURONORM and AFNOR.

Daxun’s inventory now includes Duplex 2507 stainless steel plate, an excellent super duplex stainless steel containing 25% chromium, 4% molybdenum and 7% nickel. This plate is designed for applications requiring excellent strength and corrosion resistance; such as applications in the chemical processing industry, petrochemical and seawater equipment industries. This grade of plate has excellent resistance to chloride stress corrosion cracking, high thermal conductivity and low thermal expansion coefficient. The high chromium, molybdenum and nickel content provides excellent resistance to pitting, crevice corrosion and general corrosion. Ask Daxun today.

Technical Data

- Parameter

- Chemical Compositions

- Mechanical properties

- Physical Properties

- Standard

| ASTM Specification | ASTM A240 / ASME SA240 |

| Standard | MSRR, AMS, BS, ASTM A240 / ASME SA240 |

| Length& Sizes Duplex 2507 board | 1000 mm x 2000 mm, 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, 2000mm x 4000mm to 6000mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm, 2m, 2.44m, 3m, 36″ X 120″ or 48″ X 144″, 4′ x 8′, Cut to size available |

| Thickness | 0.1mm to 100 mm Thk |

| Width | 10-2500mm |

| Hardness Duplex 2507 board | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Temper | Annealed |

| Condition | Polished on both sides |

| Finish Duplex 2507 board | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Stock in form of Duplex 2507 board | Plate, Sheet, Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Clad Plate, Rolling Sheet, Flat Sheet, Rolling Plate, Flat Shim, Blank (Circle), hot rolled, cold rolled, annealed, soft annealed, descaled, sheared, tread plate, Checker Plate |

| Value Added Service | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

| Dealers & Distributor of | ATI, POSCO, JISCO, TISCO, LISCO, BAOSTEELESSAR, JINDAL, BHUSHAN, IMPORTED material |

| Test Report Duplex 2507 board | Raw Materials Certificate |

| EN 10204/3.1B | |

| 100% Radiography Test Report | |

| High special strength, high melt point | |

| Third Party Inspection Report, etc | |

| Excellent corrosive resistance, good thermal resistance | |

| Customer support after-sales service | |

| Strict Control from Raw Material to Finished | |

| Profiling Duplex 2507 board | To provide a full profiling service we use numerous profiling methods including: |

| Plasma Plate Cutting | |

| Laser Plate Cutting | |

| Oxy-propane Flame Cutting | |

| Specialized in Duplex 2507 board | material under 3/16 ” [5.00 mm] in thickness and 24″ [600 mm] and over in width |

| material 3/16″ [5.00 mm] and over in thickness and over 10″ [250 mm] in width | |

| cold-rolled material under 3/16″ [5.00 mm] in thickness and under 24″ [600 mm] in width | |

| Free Quote, Inquiry answered within 24 hours | |

| We offer a comprehensive services designed to add value to your project: plasma cutting, waterjet cutting, laser cutting, bending and mechanical processing, edge preparation, welding, sawing and shearing. | |

| Name | 2507/S32750 |

| UNS | S32750; S39275 |

| En No. | 1.441 |

| C (max.) | 0.03 |

| Mn | 1.2 |

| Si | 0.8 |

| Cr | 24.0-26.0 |

| Ni | 6.0-8.0 |

| Mo | 3.0-5.0 |

| N | 0.24-0.32 |

| Cu | 0.5 |

| Other | S 0.020 max; P 0.035 max |

| PREN | 40-43 |

| Property | Value |

| Density (g/cm3) | 7.8 |

| 0.2% Offset Yield Strength | 80 ksi |

| Ultimate Tensile Strength | 116 ksi |

| 0.1% Offset Yield Strength 0.2% | 91 ksi |

| Elongation in 2 inches, % | 15% |

| Hardness Rockwell C | 32 |

| Impact Energy | 74 ft.-lbs |

| Density | 0.28 lb per inch3 |

| Modulus of elasticity | 28 x 10(6) psi |

| Coefficient of thermal expansion | 7.2 x 10(-6) per of at 68 to 212 of |

| Thermal conductivity | 8.7 Btu/hr ftoF |

| Heat capacity | 0.12 Btu/ lb oF |

| Electrical resistivity | 31.5 x10(-6) ohm-inch |

| Interval | Thermal | °C | Resistivity | Thermal | Specific | Young | Shear |

| Temper | expansion | conductivity | heat | modulus | modulus | ||

| °C | ax10M-bK-1 | (μ_ cm) | (W.m-1.K-1) | (J.kg-1.K-1 | E | G | |

| (GPa) | (GPa) | ||||||

| 20-100 | 13 | 20 | 80 | 17 | 450 | 200 | 75 |

| 20-100 | 13 | 100 | 92 | 18 | 500 | 190 | 73 |

| 20-200 | 13.5 | 200 | 100 | 19 | 530 | 180 | 70 |

| 20-300 | 14 | 300 | 105 | 20 | 560 | 170 | 67 |

| Grade | UNS | Industry Specifications |

| 2507 Duplex Stainless Steel | UNS S32750 | ASTM A182 F53, A240, A276, A479, A789, A790, A815, A928, A988 |

| UNS S32760 | ASTM A182 F55, A240, A276, A314, A473, A479, A789, A790, A815, A928, A988 | |

| SAE J405 |

Choose Daxun and make your customers satisfied.

Fast delivery

We provide timely and fast delivery of 2507 stainless steel plate products for customers with urgent needs. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real time, and the data is seamlessly connected; in terms of logistics, the processing center is close to highways and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on time.

2507 stainless steel plate advantages:

- 2507 stainless steel plate has high resistance to pitting corrosion, with a PREN value of up to 43, and has excellent corrosion resistance. Duplex 2507 steel plate also exhibits excellent resistance to other forms of corrosion, including stress corrosion cracking (SCC), crevice corrosion, and general corrosion. These combined corrosion resistance properties make duplex 2507 a versatile and reliable choice for a wide range of applications in harsh environments.

- 2507 has a yield strength that is twice that of 300 series stainless steel. This strength advantage allows the use of thinner steel sections under the same load conditions and reduces the material cost of the equipment.

- It has a yield strength and tensile strength that is twice that of ordinary stainless steel. This significantly improves wear resistance.

Stainless Steel 2507 Applications

- Desalination.

- Oil and gas industry equipment, including offshore platforms, pipelines, and well casings.

- Chemical processing equipment, especially for handling corrosive chemicals.

- Pulp and paper industry, particularly bleaching process equipment.

- Petrochemical industry applications, including PVC strippers.

- Water desalination plants.

- Power industry equipment, such as flue gas desulfurization (FGD) systems.

- Marine components, including ship propellers and shafts.

- Pollution control equipment such as scrubbers.

- Fittings are crucial components for connecting and controlling the flow of fluids in pipelines and systems. This includes elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples, among others.

Quality, delivery, inspection

- Daxun also conducts several quality assurance tests. These tests include flattening test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the material is suitable for the required application.

- During the production process, we measure the diameter, thickness, and surface of the product. Our standard delivery time is 7-15 days, except for some special size products, our delivery time will increase to 20 days.

Our delivery time is strictly in accordance with the contract. - Support customer third-party agencies to go to the factory for inspection

- Support free samples to customers for testing

- Support on-site or video factory inspection

Technical Support

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry. This, in our opinion, demonstrates our unwavering dedication to quality and our philosophy as a full-service supplier.

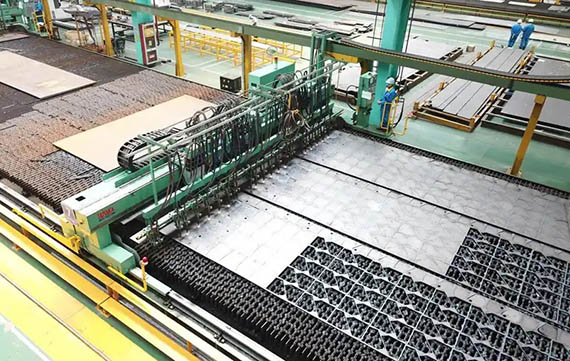

Advanced machining

Daxun Stainless Steel uses the ERP system to achieve full traceability of the type, specification, and origin of each stainless steel plate, and advocates and encourages industry anti-counterfeiting. Daxun Stainless Steel relies on technology for processing and customization, and its high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

2507 plate stainless steel Features

Daxun Let your brand improve rapidly

- Gallery

- Tolerance

- Delivery state

- Other product series

| Tolerance for 2B Sheet | |||

| Size | Tolerance Rank | ||

| Group 1 | Group 2 | Group 3 | |

| 0.4 | 0.3 ~ 0.32 | 0.33 ~ 0.37 | 0.37 ~ 0.39 |

| 0.5 | 0.4 ~ 0.42 | 0.43 ~ 0.47 | 0.47 ~ 0.49 |

| 0.6 | 0.5 ~ 0.52 | 0.53 ~ 0.56 | 0.57 ~ 0.59 |

| 0.7 | 0.6 ~ 0.62 | 0.63 ~ 0.67 | 0.67 ~ 0.69 |

| 0.8 | 0.7 ~ 0.72 | 0.73 ~ 0.77 | 0.74 ~ 0.79 |

| 0.9 | 0.8 ~ 0.82 | 0.83 ~ 0.87 | 0.87 ~ 0.89 |

| 1 | 0.89 ~ 0.9 | 0.91 ~ 0.94 | 0.94 ~ 0.99 |

| 1.2 | 1.02 ~ 1.08 | 1.09 ~ 1.15 | 1.16 ~ 1.18 |

| 1.5 | 1.32 ~ 1.38 | 1.39 ~ 1.45 | 1.46 ~ 1.48 |

| 2 | 1.72 ~ 1.79 | 1.8 ~ 1.86 | 1.87 ~ 1.9 |

| 2.5 | 2.23 ~ 2.36 | 2.32 ~ 2.42 | 1.42 ~ 1.47 |

| 3 | 2.7 ~ 2.77 | 2.78 ~ 2.82 | 2.85 ~ 2.9 |

| Tolerance for No.1 Hot Rolled Plate | |||

| Size | Tolerance Rank | ||

| Group 1 | Group 2 | Group 3 | |

| 3 | 2.6 ~ 2.75 | 2.75 ~ 2.85 | 2.86 ~ 2.9 |

| 4 | 3.5 ~ 3.6 | 3.6 ~ 3.75 | 3.76 ~ 3.95 |

| 5 | 4.5 ~ 4.6 | 4.6 ~ 4.75 | 4.75 ~ 4.95 |

| 6 | 5.4 ~ 5.6 | 5.6 ~ 5.75 | 5.75 ~ 5.85 |

| 8 | 7.3 ~ 7.5 | 7.5 ~ 7.65 | 7.65 ~ 7.85 |

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9.6 ~ 9.85 |

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11.6 ~ 11.85 |

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13.6 ~ 13.85 |

| 16 | 15.2~ 15.5 | 15.5~ 15.7 | 15.7~ 16.1 |

| 18 | 17.2~ 17.5 | 17.5~ 17.7 | 17.7~ 18.1 |

| 20 | 19.2~ 19.5 | 19.5~ 19.7 | 19.7~ 20.1 |

| 30 | 29.2~ 29.5 | 29.5~ 29.7 | 29.7-30.1 |

| 40 | 39.2~ 39.5 | 39.5~ 39.7 | 39.7~ 40.1 |

| 50 | 49.2~ 49.5 | 49.5~ 49.7 | 49.7~ 50.1 |

| 60 | 59.2~ 59.5 | 59.5~ 59.7 | 59.7~ 60.1 |

| Delivery State Choice | Surface Condition |

| Cold Rolled | 2B |

| 2D | |

| BA | |

| Hairline | |

| No.3 | |

| No.4 | |

| 6K | |

| 8K | |

| Note: | |

| 1. If you require different deliver state than the above listed, kindly confirm with us. | |

| 2. In case of any enquiry or order, please kindly let us know any extra requirement not indicated here. | |

| Delivery State | |

| Delivery State Choice | Surface Condition |

| Hot Rolled | No.1 |

| No.3 | |

| No.4 | |

| 6K | |

| 8K | |

| Pickled | |

| Note: | |

| 1. If you require different deliver state than the above listed, kindly confirm with us. | |

| 2. In case of any enquiry or order, please kindly let us know any extra requirement not indicated here. | |

| Grade | Type | Thickness | Surface |

| Austenitic | 304/304H/304L/304J1 | 0.25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0.4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0.3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferrite | 430 | 0.4-3.0mm | 2B/BA/NO.4/8K/SB/HL |

| Ultra Pure Ferrite | 443 | 0.4-2.0mm | 2B |

| 436L/439/444/441 | 0.5-3.0mm | 2B、2D | |

| 409L | 0.4-2.5mm | 2B、2D | |

| Grade | Type | Thickness | Original |

| Heat-resistant Steel | 309S | 0.5-40mm | CHN |

| 310S | 0.5-40mm | CHN | |

| Duplex Steel | 2101 | 1.5-50mm | CHN |

| 2304 | 3.0-50mm | CHN | |

| 2205 | 0.5-60mm | CHN | |

| 2507 | 1.0-60mm | SWE / JPN / CHN | |

| Super Austenitic Steel | N08904 | 0.6-50mm | SWE / JPN / CHN |

| S31254 | 0.5-50mm | SWE / JPN / CHN | |

| N08926 | 0.5-50mm | SWE / JPN / CHN | |

| N08367 | 0.5-50mm | SWE / JPN / CHN | |

| Nickel Base Alloy | N08031 | 1.0-50mm | US / JPN / GER |

| N08810/N08800 | 0.8-50mm | US / JPN / CHN | |

| N08028 | 1.0-20mm | US / GER / JPN | |

| N08020 | 1.0-20mm | US / GER / JPN | |

| N08825 | 0.8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0.5-50mm | US / GER / JPN | |

| N06022 | 1.0-50mm | US / GER / JPN | |

| N06625 | 0.8-20mm | US / GER / CHN | |

| N04400 | 1.0-20mm | US / GER / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0.5-20mm | US / JPN | |

| Titanium | TA1/Gr1 | 0.5-50mm | JPN / CHN |

| TA2/Gr2 | 0.5-50mm | JPN / CHN | |

| Welding Material | ERNiCrMo-13 | 1.2、2.4mm | GER |

| ERNiCrMo-3 | 2.4mm | GER | |

| ERNiCrMo-4 | 2.4mm | US |

The surface and shape of 2507 stainless steel plate (7)

Information available for reference and download

Daxun is a trustworthy stainless steel plate manufacturer

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless steel plates are certified by ISO9001, SGS, CE, OQC and more international quality standards.We also have strict quality control to ensure that the stainless steel plates have less defects. At Daxun, rest assured that all products are durable, high quality and high performance.

Recent hot case projects and products

Related Products (13)

Yes. Duplex 2507 stainless steel has good weldability and can be joined to itself and other materials using a variety of welding methods, including SMAW (shielded metal arc welding), PAW (plasma arc welding), GTAW (gas tungsten arc welding), FCW (flux cored wire) and SAW (submerged arc welding). When welding 2507, it is best to use 2507/P100 filler metal.

Yes. Although duplex 2507 stainless steel is very corrosion resistant, it can still rust in extreme situations. It is, nevertheless, less likely to rust than other varieties of stainless steel. The high quantities of chromium and molybdenum in 2507 make it extremely resistant to uniform corrosion caused by organic acids like formic and acetic acid. The exceptional corrosion resistance of 2507 steel makes it suited for use in corrosive conditions such as seawater, acids, and chemicals, where it retains its integrity and does not rust or corrode quickly.

Yes, the presence of ferritic grains within its composition renders 2507 duplex stainless steel a magnetic material.

Yes, duplex 2507 is an expensive metal. This is primarily due to its high alloying content, but it comes with the added benefit of exceptional corrosion resistance in extreme environments.

We can provide stainless steel sheet samples for you to check the quality. Sample is free and you just pay the freight.

We’ve exported to more than 42 countries, such as Canada, Chile, Kuwait, Germany, South Korea, Saudi Arabia, Singapore etc.

Our MOQ is 1 ton for stainless steel sheet.

Trial orders can be delivered within a week. For regular orders, it takes two weeks roughly.