Carbon Steel Pipe

Carbon Steel Seamless Pipe

Carbon steel seamless pipes are made by perforation or hot extrusion. Seamless pipes are very suitable for very large diameter to wall thickness ratios, with very good external dimensional tolerances and mechanical properties. Widely used in chemical, nuclear power, petroleum industries, etc.

Carbon Steel Welded Pipe

Welded pipe products are primarily made from strip, roll-formed and fusion welded along the longitudinal seam, using arc welded pipe, high frequency or low frequency electric resistance welded pipe. The welding process used by Daxun does not use any filler metal in the welding process.

Carbon Steel Drawn Pipe

Tube drawing is ideal for producing thick-walled, large-diameter tubes that cannot be welded directly to size but still offer cost savings over seamless tubes.

Carbon Steel Product Information

| Product Parameters: Carbon Steel Pipe | |||

| OD | 3mm~2000mm | thickness | 0.3mm~100mm |

| Standard | ASTM A53、ASTM A106、ASTM A500、ASTM A333、ASTM A252、API 5L、API 5CT、GB/T 8162、GB/T 8163、GB/T 3087、GB/T 5310、GB/T 9711、GB/T 6479、DIN 17175、DIN 2440、DIN 2441、JIS G3454、JIS G3455、JIS G3456、EN 10216-1、EN 10217、ISO 3183 BS 1387 | ||

| DATA | SeamlessTube weldedTube precisionTube polishTube picklingTube hairlineTube etc | ||

| shape | Round square rectangle Hexagonal Special-shaped etc | ||

| Grade | ASTM A53,ASTM A106,API 5L,ASTM A333,ASTM A500,ASTM A179, ASTM A192,etc. | ||

Daxun is a carbon steel pipe manufacturer from China that produces precision seamless and welded steel pipes, including standard pipe specifications and close tolerances, thin-walled pipes and carbon steel pipes in various materials. Daxun also manufactures condenser tubes that meet specific ASTM standards for seamless cold drawn low carbon steel tubes, ideal for applications such as heat exchangers.

Backed by a global service and support network, we provide a large range of quality steel pipes and pipelines to the power, petrochemical, nuclear, offshore, oil industry, aerospace and defence industries.

Brands and characteristics of various stainless steel pipes

Our unmatched resources, technical expertise and highly skilled workforce produce consistently high-quality steel tubing.

Commonly used grades

A53 Grade A: For black and hot-dip galvanized, welded and seamless steel pipes, commonly used for general purpose steam, water, gas and air piping.

A53 Grade B: Similar to Grade A, but with higher strength for higher pressure applications.

A106 Grade A: Seamless carbon steel pipes suitable for high temperatures, widely used in high-temperature equipment and pipelines in the petroleum, chemical and other industries.

A106 Grade B: The most commonly used grade, with good mechanical properties and high temperature resistance.

Grade B: Seamless and welded steel pipes for pipeline transportation, suitable for transporting oil, natural gas, etc.

X42, X52, X60, X65, X70: As the grade increases, the strength of the steel pipe also increases accordingly, suitable for higher pressure pipelines.

ASTM A179 is a seamless low carbon steel pipe mainly used in heat exchangers and condensers. It is characterized by thin wall and good heat conduction performance.

ASTM A192 is a seamless carbon steel pipe designed for high pressure service, commonly used in boilers and superheaters. At Daxun, we have a full range of specifications, contact Daxun today to get high-quality steel pipes.

ASTM A210 is a seamless medium carbon steel pipe suitable for boiler tubes and boiler flue tubes, including safety ends, dome and support tubes, and superheater tubes with the minimum wall thickness.

ASTM A691 is an electric fusion welded carbon steel and alloy steel pipe for high temperature and high pressure service. This standard applies to steel pipe with a nominal outside diameter of 16 inches (400 mm) or more and a wall thickness of 3 inches (75 mm) or less.

Grade 1, Grade 6: Seamless and welded carbon steel pipes suitable for low temperature environments, commonly used in low temperature pressure vessels and pipelines.

Grade 9: Alloy steel pipes suitable for low temperature environments, with higher strength and toughness.

The Main features of Carbon steel pipes

Carbon steel pipes are renowned for their exceptional strength and durability, making them suitable for high-pressure applications and heavy-duty structural uses.

Compared to other materials, carbon steel pipes are more economical, providing a cost-effective solution for various industries without compromising performance.

These pipes are versatile and can be used in various applications, making them a popular choice across various industries.

Carbon steel pipes have good corrosion resistance and can resist the erosion of harsh environments and chemicals.

Steel pipe processing service capabilities

As a fully integrated manufacturer, we provide comprehensive, one-stop solutions to meet your needs, whether you’re looking for complete project management or assistance with a specific machining task. Our expertise spans a wide range of services, including straightening, drilling, honing, trepanning, cutting, testing, boring, machining, laser welding, polishing, and turning. With a focus on delivering professional and reliable support, we specialize in precision services tailored for steel pipes.

Bigger, Better Pipe Solutions

Daxun boasts one of the most extensive pipe extrusion capabilities globally, with both vertical and horizontal presses ranging from 12,000 to 35,000 tons. These advanced capabilities empower us to produce some of the industry’s longest lengths and largest diameter pipes, setting us apart as a leader in the field.

Buy Carbon Steel Pipes in Daxun, China

Buy more advantageous carbon steel pipes in China, whether seamless or welded, Daxun will provide an excellent product and a competitive price. Contact Daxun today to get carbon steel prices.

Powerful Pipe Solutions

Daxun supplies the power generation market with ductwork, boiler tubes, main steam tubes, thermal reheat tubes, flue gas desulfurization units and other products for nuclear, coal-fired, renewable energy and combined cycle applications.

Contact China's Strong Steel Pipe Manufacturer

We supply carbon steel piping products to the petroleum and chemical industries as well as a variety of mechanical and structural applications where piping products are used. Petroleum casing and mechanical pipe products are used in the world’s most technically demanding industries and applications, including sour services, high pressures and high temperatures.

Our chemical processing product range includes pipes and tubes designed for applications such as ethylene production, caustic soda production, and heat exchangers. In addition, we manufacture a diverse array of products for the medical and industrial sectors, including components for x-ray machines, thermocouple sheathing tubes used in industrial furnaces, and durable boiler tubes.

At Daxun, we maintain state-of-the-art testing labs and equipment to verify the actual weight and quality of our steel pipes prior to shipment. Our dedicated quality control team performs thorough 100% inspections at every stage of production, ensuring that each pipe meets the highest standards of excellence.

At TuoLian, our commitment to support and service extends well beyond the initial stages of our transactions. Even after you have received your orders, we continue to offer exceptional after-sales service. Our team remains available to assist you, providing ongoing support and warranty coverage for your products.

Application cases of carbon steel pipes in different industries

High-temperature and high-pressure pipelines: Gasification, liquefaction and other processes in the coal chemical process need to be carried out under high-temperature and high-pressure conditions. Steel pipes are used to transport high-temperature and high-pressure process media to ensure the safety and efficiency of production.

Corrosion-resistant pipelines: Coal chemical production involves a variety of corrosive media, such as acids, alkalis, salts, etc. The use of special anti-corrosion materials such as epoxy coal tar anti-corrosion steel pipes can effectively resist corrosion and extend the service life of pipelines. Heat exchanger pipelines: In coal chemical plants, heat exchangers are used to heat or cool the medium. Steel pipes, as the main components of heat exchangers, are required to have good thermal conductivity and pressure resistance. Structural support: Steel pipes are also used for the frame structure and equipment support of coal chemical plants to provide the necessary mechanical strength and stability.

Superheater and reheater pipes: These components need to withstand high-temperature and high-pressure steam, and high-strength heat-resistant steel pipes such as SA213 T91, TP347H, etc. are often used to ensure safe operation.

Main steam and reheat steam pipes: Used to transport high-temperature and high-pressure steam, requiring steel pipes to have excellent high-temperature creep strength and oxidation resistance, and P91, P92 and other materials are often used.

Water-cooled wall tubes: Located on the inner wall of the furnace, directly radiated by the flame, they need to have good high-temperature resistance and corrosion resistance, and heat-resistant alloy steel pipes are usually used.

Economizer and air preheater pipes: Used to recover flue gas waste heat and improve boiler efficiency. The steel pipes used must have good thermal conductivity and corrosion resistance.

Transportation pipelines: Steel pipes are used for long-distance transportation of submarine oil and gas, connecting offshore platforms with land terminals. These pipelines need to withstand the high pressure and corrosion of the marine environment to ensure the safe transmission of oil and gas.

Structural support: In marine engineering, steel pipes are used to build load-bearing structures such as deepwater platforms, wind power stations, etc. These structures require materials with high strength and durability to withstand the harsh marine environment. Flexible pipelines: Flexible pipelines are made of metal and polymer materials and have good fatigue resistance and corrosion resistance. They are suitable for complex submarine terrain and are widely used in marine oil and gas gathering and transportation pipelines. High-quality sea pipes: With the advancement of deep-sea energy development, the demand for high-quality sea pipes has increased. For example, the high-quality sea pipes for deep water developed by Tianjin Steel Pipe Company have the characteristics of uniform performance over the entire length and circumference, meeting the demanding requirements of the deep-sea environment.

In the nuclear power industry, carbon steel pipes are mainly used in piping systems of conventional islands and non-nuclear grade parts of nuclear islands. These pipes usually carry fluids at room temperature or medium temperature, requiring the material to have good mechanical properties and corrosion resistance. Commonly used carbon steel pipe grades include 20# steel, Q235, S355, etc. In addition, in order to improve the performance of fluid accelerated corrosion (FAC), some carbon steel pipes use chromium-nickel microalloying technology to enhance their corrosion resistance and low-temperature impact toughness. With the development of nuclear power technology, the performance requirements for carbon steel pipes are also constantly improving to meet higher safety and durability standards.

Focusing on the performance requirements of welded pipes for LNG, Daxun has made breakthroughs in key technologies such as welding and heat treatment in the product processing and manufacturing process and developed large-diameter carbon steel pipes for LNG with excellent corrosion resistance, low-temperature toughness and good low-temperature strength.

However, due to its poor corrosion resistance, carbon steel’s application in the aerospace field is often limited to some relatively loose conditions, and it is usually plated or surface treated to improve its durability and corrosion resistance. For some parts that require higher corrosion resistance and high strength, materials such as stainless steel or titanium alloys are usually selected.

Oil and gas transportation: Carbon steel pipes are often used to transport crude oil, natural gas, and other petroleum products. Due to its high strength, ability to withstand greater pressure and transportation distance, carbon steel pipes are widely used in long-distance pipeline systems for oil and gas.

Refinery pipelines: In refineries, carbon steel pipes are used to transport crude oil, natural gas, petroleum products (such as gasoline, diesel, etc.) and chemical raw materials. In some medium and low temperature and normal pressure environments, carbon steel pipes can provide sufficient strength and durability.

Chemical transportation pipelines: Carbon steel pipes are also used in petrochemical production to transport various chemicals, including acids, alkalis, solvents, ammonia, chlorine, etc. Although carbon steel may not perform as well as stainless steel when facing some corrosive substances, it is still widely used in the transportation of some non-corrosive chemicals.

Weapon systems:

Barrels and gun barrels: Carbon steel pipes are used to manufacture barrels and gun barrels for some artillery, machine guns, rifles and other weapons. These pipes need to have high strength and pressure resistance to withstand the impact of explosions and high temperature conditions.

Missile systems: Carbon steel pipes are used in the manufacture of some missile launchers, engines and their components. They need to withstand large impact forces and high temperature environments.

Armored vehicles:

Turrets and weapon system brackets: Carbon steel pipes are also used in the brackets and piping systems of armored vehicle turrets and their internal weapon systems.

Military aircraft and spacecraft:

Cooling systems and drainage pipes: Carbon steel pipes are often used in the cooling and drainage systems in ships, which are suitable for liquid transmission under normal working conditions.

Fuel pipes: Carbon steel pipes are used in the fuel system of ships to connect the ship’s fuel tanks with the engine. Due to its pressure bearing capacity and durability, carbon steel pipes can effectively transport fuels such as heavy oil and diesel.

Cooling water pipes: The engine and other equipment of ships usually require a cooling system. Carbon steel pipes are widely used in cooling water pipe systems for transporting coolants, seawater, etc.

Hydraulic system pipes: Hydraulic system pipes on ships use carbon steel pipes to transport hydraulic oil to support the operation of components such as lifting equipment and steering gear.

Deep-sea exploration equipment is one of the important directions in the field of marine engineering, and stainless steel pipes have become an ideal material for various deep-sea exploration equipment due to their corrosion resistance, high strength and other advantages. Deep-sea pipelines, detectors, sonar equipment, etc. can all be made of stainless steel pipes to ensure long-term reliable operation in harsh marine environments.

Serving the pharmaceutical and biopharmaceutical industries has been a welcome challenge for Daxun. From raw material selection to delivery, we have developed high purity and ultra-high purity services to meet and exceed industry standards. When only the best stainless steel tubing and stainless steel pipes can meet the demand, more and more pharmaceutical and biopharmaceutical companies trust Daxun.

Serving the power generation industry, Daxun is able to combine technical expertise and experience to produce the best pipe and pipe available today. When you choose the best, you get the best. Follow what countless other companies have done – trust Daxun. Highly demanding industries need Daxun

Technical Information

- Partial inventory

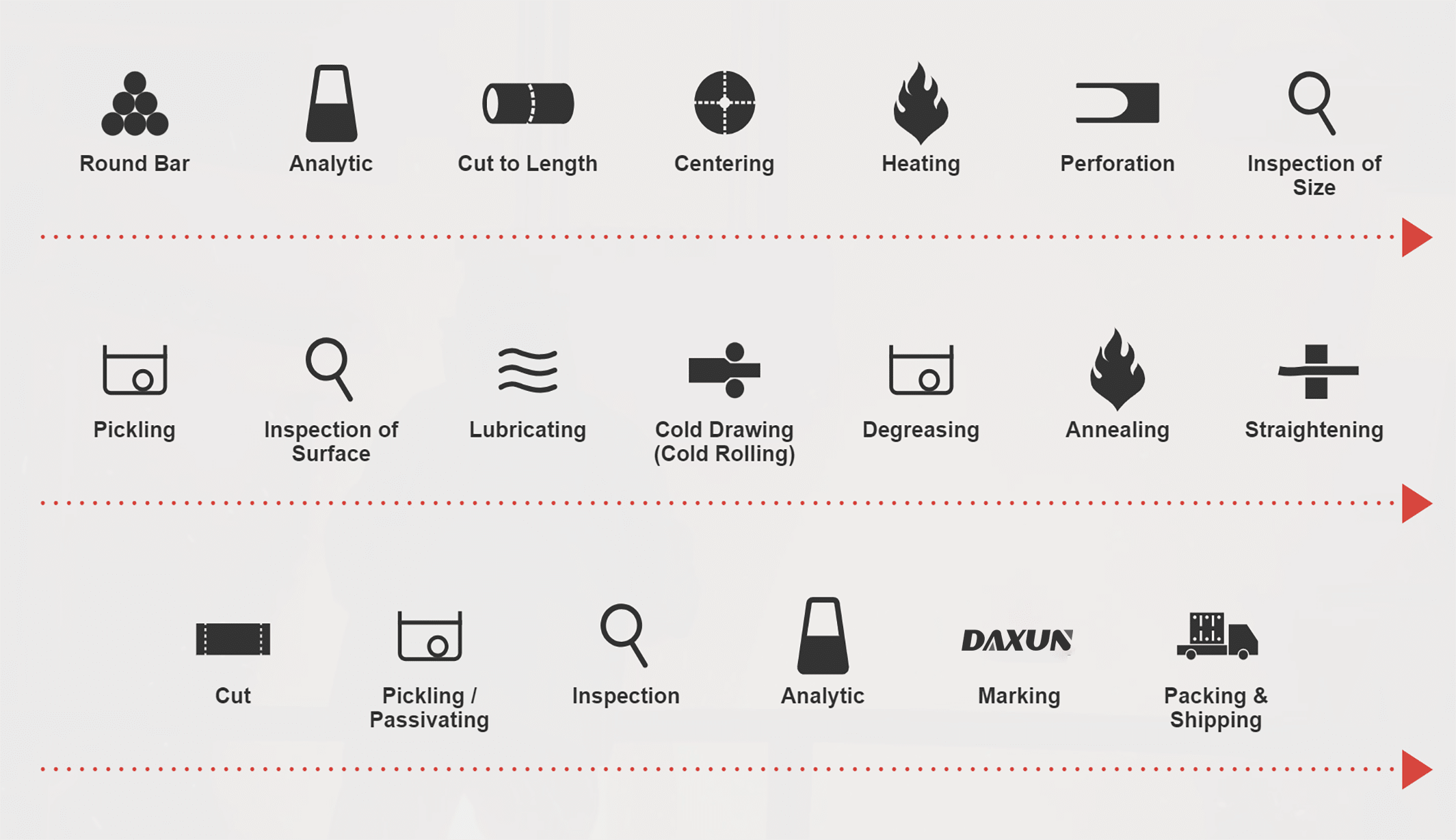

- Seamless pipe production process

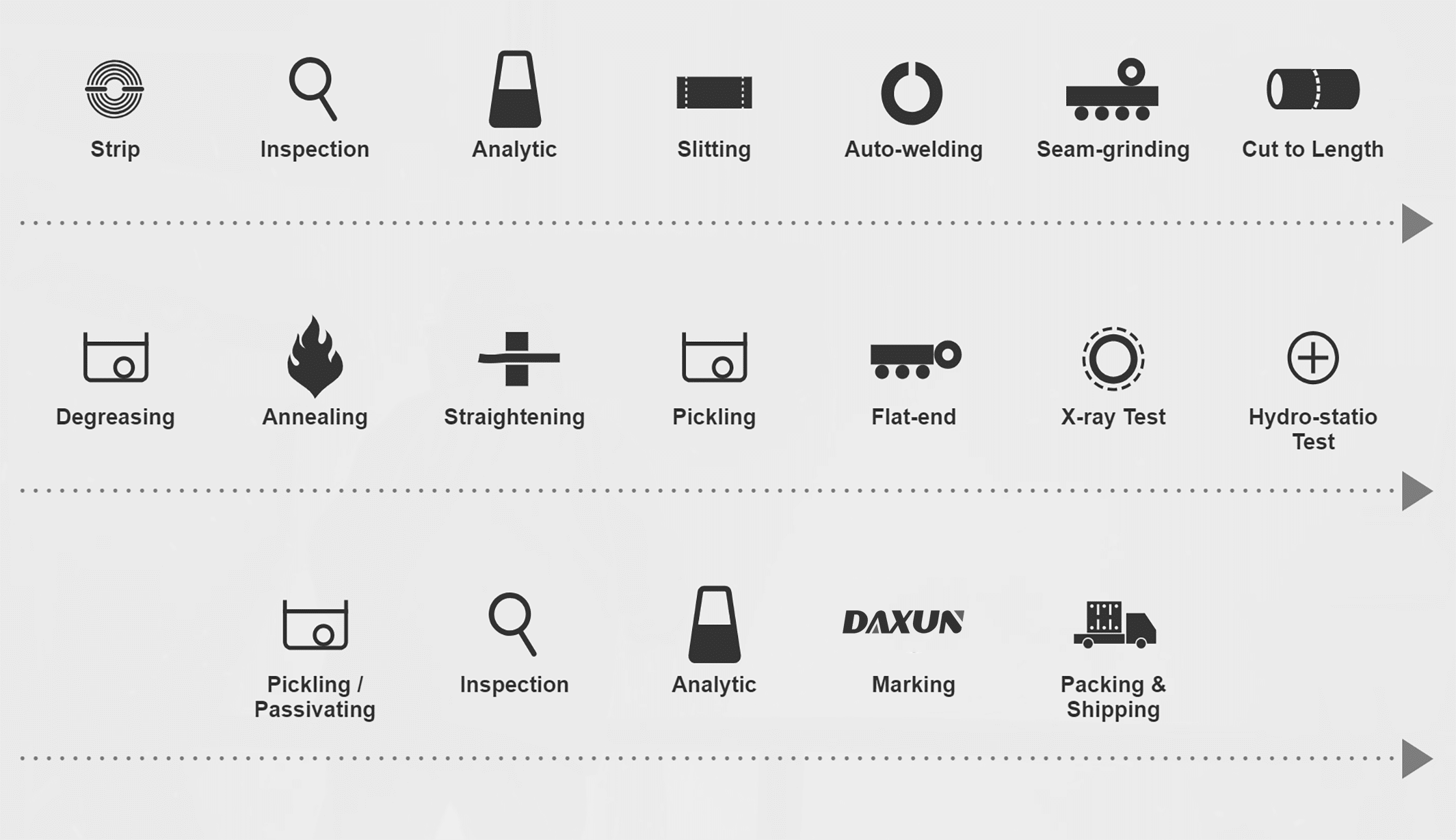

- Welded pipe production process

| Diam (mm) | Thickness(mm) | Length (mm) | Comment |

| φ3.0-12.0 | 0.3-1.0 | 6000-12000 | AAA |

| φ19.0-22.0 | 0.6-3.0 | 6000-12000 | AAA |

| φ25.0-27.2 | 0.8-10.0 | 6000-12000 | AAA |

| φ32.0-60.3 | 0.8-15.0 | 6000-12000 | AAA |

| φ76.3-102.1 | 0.8-205.0 | 6000-12000 | AAA |

| φ114.3-168.3 | 0.8-20.0 | 6000-12000 | AAA |

| φ180.0-219.2 | 3.0-20.0 | 6000-12000 | AAA |

| φ273.1-325.3 | 4.0-30.0 | 6000-12000 | AAA |

| φ377.2-426.3 | 5.0-30.0 | 6000-12000 | AAA |

| φ508.1-711.0 | 5.0-30.0 | 6000-12000 | AAA |

| 711.0+

|

5.0-30.0

|

6000-12000

|

AAA

If you need to know more about the size, please contact Daxun |

Daxun Alloy

We can handle any type of inquiry regarding Carbon Steel Pipes. Please feel free to ask us. We will make recommendations based on each customer’s needs.

Answer: Carbon steel pipes are widely used in industries such as petrochemical, shipbuilding, aerospace, defense, construction, and mechanical manufacturing. They are mainly used for fluid and gas transportation, structural support, heat exchange, and heating systems.

Answer: The main advantages of carbon steel pipes include high strength, good pressure resistance, strong processability, and low cost. They also have good toughness and impact resistance, making them suitable for a variety of applications.

Answer: Carbon steel pipes have relatively poor corrosion resistance, especially in humid or marine environments. To improve their corrosion resistance, carbon steel pipes are often galvanized or coated, or suitable corrosion protection measures (such as painting or adding a protective layer) are used.

Answer: Common specifications for carbon steel pipes include outer diameters (OD) ranging from a few millimeters to several hundred millimeters, with various wall thicknesses (WT) available. Common standards include ASTM A106, ASTM A53, and DIN 17175. Different industries and applications may have different requirements.

Answer: The pressure capacity of carbon steel pipes depends on their specifications (outer diameter and wall thickness), material, and usage conditions. Generally, carbon steel pipes are suitable for medium-pressure applications (such as petrochemical pipelines, steam systems, etc.), but for extremely high-pressure situations, high-alloy steel pipes may be required.

Answer: Carbon steel pipes are suitable for medium to low-temperature environments. For high-temperature applications (such as boilers or heat exchangers), high-temperature carbon steel materials (e.g., low-alloy steel pipes) can be used. However, if the operating temperature exceeds the limits of carbon steel (typically between 300°C and 500°C), other materials such as stainless steel may be necessary.

Answer: Carbon steel pipes are generally not suitable for food and drinking water pipelines, especially if they are untreated. Due to the corrosive nature of carbon steel, improper use may lead to water contamination. If used for such pipelines, proper surface anti-corrosion treatment must be applied, or safer materials like stainless steel pipes should be chosen.

Answer: Carbon steel pipes are primarily composed of iron and a small amount of carbon, offering high strength and durability but poor corrosion resistance. In contrast, stainless steel pipes contain a higher proportion of chromium, providing stronger corrosion resistance, heat resistance, and overall durability, but they are more expensive. The choice of material depends on the operating environment and budget requirements.

Answer: The service life of carbon steel pipes can be extended through corrosion-resistant coatings, galvanizing treatments, or regular inspections and maintenance. Additionally, in humid or highly corrosive environments, using anti-corrosion materials or implementing insulation measures can help reduce corrosion.

Answer: Carbon steel pipes have good welding performance, with common welding methods including arc welding, TIG (argon arc) welding, and CO2 welding. During the welding process, it is important to control heat input to prevent cracks or deformations in the weld. For thicker-walled carbon steel pipes, preheating or post-heating treatments are typically required to ensure welding quality.

Answer: The order transaction for carbon steel pipes is typically completed through a signed contract. The contract will specify important terms such as quantity, specifications, delivery time, price, and payment methods. We support various payment options, including bank transfers, letters of credit, etc. The specific payment method can be negotiated based on customer needs.

Answer: The delivery time for carbon steel pipes depends on the order quantity, specifications, and stock availability. Generally, it takes 7 to 15 working days from order confirmation to shipping. For customized products or large orders, it may take longer. The exact delivery time can be discussed during the order confirmation.

Answer: Yes, we support international shipping. We can ship carbon steel pipes worldwide by sea, air, or land. The shipping method will be determined based on the customer’s location, delivery time requirements, and logistics costs. We can provide complete logistics solutions to ensure safe and on-time delivery.

Answer: To ensure the safety of carbon steel pipes during transport, we use high-quality packaging materials such as wooden boxes, pallets, and steel straps. If necessary, we provide anti-rust packaging to prevent moisture from causing corrosion. We also choose the appropriate packaging based on the transportation method and destination requirements to ensure the product arrives intact.

Answer: Yes, we provide quality inspection reports for all carbon steel pipes. The reports include test results for material composition, dimensional tolerances, mechanical properties, etc. For customized products or large orders, we can also provide third-party inspection certification to ensure the product meets international quality standards.

Answer: Yes, we accept custom orders for carbon steel pipes. Customers can customize the specifications, length, wall thickness, etc., based on their actual needs. For specific applications, we can also provide customized anti-corrosion treatments or coatings to ensure the product meets specific requirements.

Answer: We support various payment methods, including bank transfer, letter of credit (LC), PayPal, and Alipay. The specific payment method can be determined based on the transaction scale, order specifics, and mutual agreement. We offer flexible payment options to meet customer needs.

Answer: Once an order is confirmed and enters the production or shipping phase, changes or cancellations are typically not possible. However, if a customer encounters special circumstances, they can request modifications or cancellations within a short time after order confirmation. We will cooperate according to production progress and logistics conditions. Please contact us promptly to avoid unnecessary costs and delays.

Answer: Yes, our packaging meets international shipping standards. To ensure the safety of carbon steel pipes during transport, the packaging materials and methods are optimized according to the destination’s requirements. For exports to seaport destinations, we use waterproof and anti-rust packaging, while for air shipments, we apply special packaging as per airline requirements.

Answer: If there are quality issues with the carbon steel pipes received, please contact us promptly and provide relevant evidence (such as photos, inspection reports, etc.). We will investigate the situation and take appropriate action based on the contract terms, such as compensation or replacement. We are committed to ensuring customer satisfaction and providing after-sales support to resolve any quality-related issues.

Answer: Yes, we can provide sample testing based on customer needs. Customers can order a small batch of samples first to ensure that the product’s quality and specifications meet their requirements. Sample fees and shipping costs can be negotiated, and in some cases, we can offer free samples for testing.

Answer: We value long-term cooperation, and we can offer discounts or special offers for bulk orders or long-term customers. The exact discount will be determined based on order volume, cooperation duration, and customer needs. Please contact us for more details.