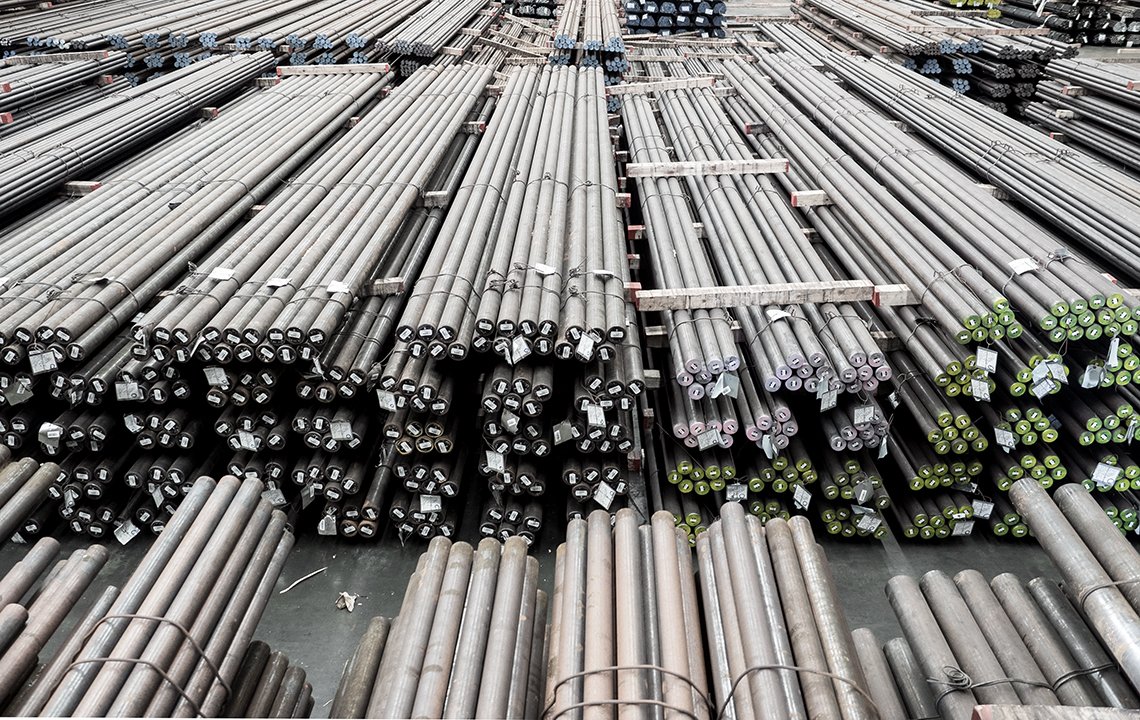

Daxun is an excellent manufacturer of grade 23 (Ti-6Al-4V ELI)titanium rods and bars.

As China’s leading supplier of titanium and titanium alloy rods, Daxun provides high-performance titanium rods to the world.

- Titanium bar grade: Grade 23-Ti6Al 4V ELI- USN R56401

- Titanium bar types: rolled bars, drawn bars, forged titanium bars

- Titanium bar density The density of grade 23 titanium is 4.43 g/cm3

- Main standards: ASTM ASME GB GJB EN JIS DIN ISO ATP BS, etc.

- High strength, high temperature resistance, corrosion resistance, light

- weight, excellent comprehensive performance.

————Daxun produces titanium rods in China to meet the diverse and ——требовательные потребности клиентов!

The global leader in commercially pure titanium rod manufacturing services

Daxun, specializing in the production of alloy titanium rods for extreme environments—Grade 23 titanium alloy rods.

Grade 23 titanium bar, also known as Ti-6Al-4V ELI, is a high-performance alloy known for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. It is widely used in aerospace, medical, and high-tech industries due to its ability to withstand extreme conditions while remaining lightweight. Compared to other titanium grades, Grade 23 offers enhanced ductility and fracture toughness, making it ideal for critical applications such as aircraft components, surgical implants, and advanced engineering parts.

Даксун is your trusted titanium alloy rod production company. Daxun produces all grades of titanium alloys, including commercially pure titanium series CP, titanium alloy series, titanium nickel alloy, etc. They have reliable performance and provide high performance for your critical applications. In various industries and applications, you can rely on Daxun titanium alloy rods for high strength, high temperature and corrosive environments. For decades, Daxun Metals has been committed to producing highly engineered titanium alloy solutions to meet the most severe challenges.

Данные

- Параметр

- Ingredient

- Механические свойства

- Физические свойства

| Specification | Details |

|---|---|

| Материал | Titanium rod and bar Grade 23 (UNS R56400) |

| Стандарт | ASTM B348, ASTM SB348, AMS 4921, AMS 4902 |

| Dimensions | EN, ASTM, JIS, ASME, BS, AISI, GB, GJB, DIN |

| Diameter Range | 0.125″ – 14″ (3.175mm – 355.6mm), custom |

| Length Range | Up to 240″ (6096mm), custom |

| Finish | Cold (bright) drawn, centerless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centerless Ground & Black |

| Отделка поверхности | Cold drawn, Centerless Ground, Polished, Or Rough Turned, Black, NO.4 Finish, BA Finish, Matt Finish, etc. |

| Condition | Hardened & tempered, annealed |

| Толерантность | Diameter tolerance: +/- 0.005″ (0.127mm), length tolerance: +/- 0.125″ (3.175mm) |

| Form | Titanium square bars, titanium ingots, titanium round bars, rectangular titanium bars, triangular titanium bars, forged titanium bars, titanium hexagonal bars, etc. |

| Физические свойства | Density: 0.163 lb/in³ (4.51 g/cm³), Melting Point: 3,020°F (1,660°C), Elongation: 20-30%, Modulus of Elasticity: 16.5 x 10⁶ psi (114 GPa) |

| Химический состав | Titanium (min): 99.2%, Oxygen (max): 0.25%, Carbon (max): 0.08%, Iron (max): 0.30%, Nitrogen (max): 0.03%, Hydrogen (max): 0.015% |

| Элемент | Minimum (%) | Maximum (%) |

|---|---|---|

| Titanium (Ti) | 99.2 | - |

| Aluminum (Al) | 5.5 | 6.75 |

| Vanadium (V) | 3.5 | 4.5 |

| Oxygen (O) | - | 0.25 |

| Carbon © | - | 0.08 |

| Железо (Fe) | - | 0.30 |

| Азот (N) | - | 0.03 |

| Hydrogen (H) | - | 0.015 |

| Недвижимость | Значение |

|---|---|

| Прочность на разрыв | 130,000–170,000 psi (900–1,170 MPa) |

| Yield Strength (0.2% Offset) | 115,000–150,000 psi (800–1,035 MPa) |

| Удлинение | 20–30% |

| Твердость (Бринелль) | 300–360 HB |

| Modulus of Elasticity | 16.5 × 10⁶ psi (114 GPa) |

| Недвижимость | Значение |

|---|---|

| Плотность | 0.163 lb/in³ (4.51 g/cm³) |

| Температура плавления | 3,020°F (1,660°C) |

| Thermal Conductivity | 13.4 W/m·K (at 25°C) |

| Coefficient of Thermal Expansion | 8.6 µm/m·°C (20–100°C) |

| Electrical Resistivity | 4.1 × 10⁻⁷ Ω·m |

Выберите Daxun, чтобы помочь вашему проекту взлететь.

DAXUN® Grade 23 Titanium Rod Features

DAXUN® Ti Grade 5 is a titanium alloy bar (6al-4v) featuring:

- Good hot formability and weldability;

- Tensile strength can reach 1000MPa;

- Dimensional work at high temperature

- Insensitive to seawater or seawater;

- Not affected by various corrosive media;

- High strength and good toughness;

- Resist crack initiation and crack propagation.

Daxun Factory Advantages

Daxun’s “Performance Excellence Management” concept promotes the “PDCA + Lean” management model. The company’s business card says “Daxun = Reliable Quality”. Daxun uses the ERP system to achieve full traceability of the variety, specification, and origin of each titanium rod, and advocates and encourages industry anti-counterfeiting. Daxun relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

Grade 23 Titanium Rod Production Method

Daxun produces high-quality titanium bars with high performance, and can also manufacture according to customer’s agreement:

- Titanium ingots need to go through heat treatment and machining, immersion ultrasonic testing, mechanical properties testing, macroscopic and microscopic structural inspection and other processes. Production process: hot-rolled titanium bars – high efficiency, stable performance, forged titanium bars – flexible size, multi-fire forging, improve the comprehensive performance of titanium bars, cold-drawn titanium bars – usually small-sized high-precision titanium bars; the above titanium bars are all delivered with bright surface.

Отчеты о тестировании

The test reports we provide include: Grade 2 Titanium Rod and Grade 2 Titanium Round Bar Factory Test Certificate, EN 10204 3.1, Chemical Report, Mechanical Report, PMI Test Report, Visual Inspection Report, Third Party Inspection Report, NABL Approved Laboratory Report, Destructive Test Report, Non-destructive Testing Report. (Daxun will provide according to customer requirements)

Grade 23 Rods Applications and Standards

Grade 23 Titanium Rods are widely used in the following industries under extreme corrosive conditions:

- Aerospace, shipbuilding, oil and gas industry, marine engineering, chemical plants, industrial machinery, power industry, paper and pulp industry, food processing industry, refineries, military industry, pharmaceutical and food processing equipment, etc.

- Specifications: AMS 4928,AMS 4967,AMS 4965 ,AMS 6931 ,ASTM B 348

- Standards: ASTM, ASME, EN, JIS, DIN, GB, GJB, API

Качество, доставка, проверка

Daxun performs several quality assurance tests, these tests include mechanical tests like area tensile, chemical analysis, material positive identification – PMI test, micro and macro testing, intergranular corrosion (IGC) test, ultrasonic flaw detection test, pitting and resistance test, hardness test, material positive identification, expansion test etc. All these tests ensure that the Grade 2 Titanium Rod and Grade 2 Titanium Round Bar material is suitable for the required application. During the production process, we measure the diameter, thickness and surface of the product.

- Сроки доставки строго соответствуют договору.

- Поддержка сторонних агентств клиентов для посещения завода для проверки

- Поддержка бесплатных образцов для тестирования клиентов

- Поддержка инспекции на месте или видеоинспекции на заводе

Упаковка

Daxun Alloy обеспечивает наилучшее качество упаковки, поскольку она играет важную роль в международных перевозках, где товары проходят через различные каналы, чтобы достичь конечного пункта назначения, поэтому мы уделяем особое внимание упаковке. Мы упаковываем наши товары различными способами в зависимости от продукта. Мы упаковываем наши товары различными способами, такими как:

- Коробки и ящики

- Термоусадочная пленка

- Деревянные поддоны

- Деревянные ящики

Техническая поддержка

Если вам потребуется дополнительная техническая помощь, наш постоянный металлург и компетентный персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией - впервые в отрасли производства инвентаря из нескольких металлов и пластика. Это, по нашему мнению, демонстрирует нашу неизменную приверженность качеству и философию поставщика полного цикла.

Daxun Grade 23 Titanium Rods help your brand improve quickly

- Tolerances for Grade 23 Titanium Round Bars (BS EN ISO 286-2)

| NOMINAL SIZE | h5 | h6 | h7 | h8 | h9 | H10 | H11 | h12 |

|---|---|---|---|---|---|---|---|---|

| DIAMETER mm | ||||||||

| ~ to 3 | +0.004/0 | +0.006/0 | +0.01/0 | +0.014/0 | +0.025/0 | +0.04/0 | +0.06/0 | +0.1/0 |

| over 3 to 6 | +0.005/0 | +0.008/0 | +0.012/0 | +0.018/0 | +0.03/0 | +0.048/0 | +0.075/0 | +0.12/0 |

| over 6 to 10 | +0.006/0 | +0.009/0 | +0.015/0 | +0.022/0 | +0.036/0 | +0.058/0 | +0.09/0 | +0.15/0 |

| over 10 to 18 | +0.008/0 | +0.011/0 | +0.018/0 | +0.027/0 | +0.043/0 | +0.07/0 | +0.11/0 | +0.18/0 |

| over 18 to 30 | +0.009/0 | +0.013/0 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 | +0.13/0 | +0.21/0 |

| over 30 to 50 | +0.011/0 | +0.016/0 | +0.025/0 | +0.039/0 | +0.062/0 | +0.1/0 | +0.16/0 | +0.25/0 |

| over 50 to 80 | +0.013/0 | +0.019/0 | +0.03/0 | +0.046/0 | +0.074/0 | +0.12/0 | +0.19/0 | +0.3/0 |

| over 80 to 120 | +0.015/0 | +0.022/0 | +0.035/0 | +0.054/0 | +0.087/0 | +0.14/0 | +0.22/0 | +0.35/0 |

| over 120 to 180 | +0.018/0 | +0.025/0 | +0.04/0 | +0.063/0 | +0.1/0 | +0.16/0 | +0.25/0 | +0.4/0 |

| over 180 to 250 | +0.02/0 | +0.029/0 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 | +0.29/0 | +0.46/0 |

Types of Ti-6AL-4V Grade 23 Titanium Rods (3)

Титановый стержень

Последние проекты и продукты для горячих случаев

Сопутствующие товары (8)

Daxun has a state-of-the-art production facility in China that produces highly competitive, high-precision Grade 23 titanium bars. Excellent surface, tolerance, straightness and material quality provide you with technological leadership and consistent production processes. These advantages apply to a wide range of diameters and materials. In addition, our comprehensive stock program at our service center enables just-in-time delivery.

ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

AMS 4928 – Bars, Forgings, and Forging Stock (Annealed)

AMS 4965 – Bars, Forgings (Solution treated and aged)

AMS 4967 – Bars, Forgings (Annealed, Heat Treatable)

HEAT TREATMENT

When high hardness, tensile strength, and fatigue strength are required, annealing can be performed at 1,700-1,900°F (927 – 1,038°C).

DAXUN 6-4™ Grade 23 alloy can be heat treated in a variety of ways:

- Anneal: 1,275 – 1,400°F (691 – 760°C), ½ to 2 hours, air or furnace cool

- Stress Relief Anneal: 1,000 – 1,200°F (538 – 649°C), 1 to 8 hours, air or furnace cool

- Solution Heat Treat: 1,675 – 1,750°F (913 – 954°C), 1 hour, water quench

- Aging: 975 – 1,025°F (524 – 552°C), 4 to 8 hours – air cool

In the solution treated and aged condition, rapid quenching of small sections yields optimum properties. Larger section sizes and/or delayed quenching may result in less than optimum properties.

HARDNESS

Typical hardness in the annealed condition is Rockwell C 30-34, and about Rockwell C 35-39 in the solution and aged condition.

Forgeability / Formability

Ti-6Al-4V ELI (Grade 23) alloy bar is forged at 1,750°F (954°C) with a final forging temperature of 1,450°F (788°C). A minimum of 35% reduction is recommended for optimum properties.

Grade 23 alloy bar is difficult to form at room temperature, even in the annealed condition. Therefore, severe forming operations such as bending or stretching can be performed on annealed material at temperatures up to 1,200°F (649°C) without affecting mechanical properties. Hot sizing or forming can be accomplished by creep forming in the range of 1,000 – 1,200°F (538 – 649°C).

Machinability

Ti-6Al-4V ELI (Grade 23) alloy bar can be machined using austenitic stainless steel machining methods with slow machining speeds, high feeds, rigid tools, and the use of large amounts of non-chlorinated cutting fluids.

Свариваемость

Grade 23 titanium rod is readily weldable in the annealed condition or in the solution and partially aged condition, with aging being accomplished during post weld heat treatment. Precautions must be taken to prevent contamination with oxygen, nitrogen, and hydrogen. Fusion welding may be performed in an inert gas filled chamber or with inert gas to weld the molten metal and adjacent heated zones, with a tail shield. Spot, seam, and flash welding may be performed without the aid of a protective atmosphere.

Special Considerations

Grade 23 titanium alloy rod may be contaminated with hydrogen from improper pickling, and with oxygen, nitrogen, and carbon during forging, heat treating, brazing, etc. This contamination may result in a loss of ductility, which may adversely affect notch sensitivity and forming characteristics.

Size Range

Grade 23 Titanium Bar Dimensions

Ø 0.7 – 30 mm (drawn, ground)

Ø 16 – 400 mm (hot rolled, peeled)

Tolerances: h11–h5 (ISO 286-2)

Tighter or different tolerances available on request

Lengths up to 9,000 mm long, depending on diameter

For larger diameters, other bar lengths and tolerances can be agreed upon request

Availability Grade 23 Titanium Rods

Processing options include:

- Drawing, straightening

- Drawing, straightening, polishing

- Drawing, grinding, polishing

- Drawing, straightening, grinding, polishing

- Drawing, annealing, straightening

- Drawing, annealing, polishing

- Drawing, annealing, grinding, polishing

- Drawing, annealing, straightening, grinding, polishing

We produce bars according to your requirements.

Excellent surface and straightness, perfect roundness and tightest diameter tolerances (according to ISO 286-2 up to h5). Available in straightened, ground, polished conditions.

Sawing

- Band saws (up to Ø510 mm)

- Bench band saws (up to 6,000 x 3,000 x 400 mm)

- High-performance sawing machines for precise sawing

Titanium Bar End Machining

- Single or double sided

- Chamfer 90° (45°)

- Point 60° (30°)

- Flat end

- Centered

Delivery Form

- ASTM American Society for Testing and Materials Standards

- AMS American Aerospace Materials Standards

- NACE American Association of Corrosion Engineers International Standards

- ASME American Society of Mechanical Engineers Standards

- GB Chinese National Standards

- GJB Chinese National Military Standards

- ISO International Standards

- DIN German Standards

- EN European Standards

- API American Petroleum Institute Standards

Detection Method

Non-destructive testing > 100% testing

Testing methods:

- Eddy current testing / eddy current crack testing

- Defect-free surface (level 4)

- Flat bottom hole diameter 0.7 mm and 0.4 mm

- Blind area can be cut off according to fixed length > Test to the end of the bar

- Full diameter ultrasonic testing

Our Titanium Bar Material Services

As an experienced service center, we can tailor your titanium bar material to your specifications, work with various certification bodies such as TÜV Rheinland or DNV to approve the specifications, and initiate the upgrading of titanium semi-finished products to meet appropriate applications.

We will be happy to provide you with a consultation and explain everything you need to know about obtaining Grade 23 titanium bar material, including which standards require greater attention for the components to be manufactured.

If you have a long-term supply commitment, you can establish a framework agreement with Даксун. We guarantee prices and quantities for a specified period.

Benefit from our extensive experience in the global market. We have been helping businesses around the world since 2003. If you need any additional information about Grade 23 Titanium Bar, our professionals will be happy to help you. We look forward to hearing from you.

Информация для заказа

Purchase orders should include quantity, grade, type or category, API5L reference, thickness, width, length, and any applicable attachments or additional requirements related to chemical composition, mechanical properties, heat treatment, additional testing, manufacturing process, surface coating or end finish. Contact Даксун now, we will reply to your email as soon as possible.

The grade of titanium alloy you need depends on the project you are working on, as each grade has different benefits.

All grades of titanium alloy are extremely strong and corrosion resistant, which means they will continue to work well in the harshest conditions.

The higher grades of titanium alloy (5-12) are alloys designed for specific benefits. For example, grade 12 titanium alloy has excellent heat resistance, making it a perfect choice for shell and tube heat exchangers, hydraulic piping, and chemical industry equipment.

Grades 1-4 are pure titanium alloys, and they are a perfect choice if you need a weldable, ductile material for piping systems and tubing. You will find lower grades used in the marine and industrial industries.

If you are starting a project and are unsure which grade of titanium alloy is best for you, contact us today; we are more than happy to help you.

At DAXUN, we offer a wide range of titanium alloy grades from grade 1 to grade 12.

Grades 1-4 are pure titanium, while higher grades are alloys.

Alloy grades are popular for their high strength-to-weight ratio.

The most commonly used titanium alloy grade we find is grade 5. While still high in titanium, this grade is one of the most reliable because it can withstand temperatures up to 600°F and withstand extreme conditions.

Higher grades are favored by industries such as aerospace and marine industries for their wear and corrosion resistance.

Conversely, lower grades are primarily used for welding due to their lower strength.

To learn more about the differences between different grades of titanium alloy, call +86 13382898899 today to speak directly with our experts.

Хотя марка титана несколько повышает стоимость, общая стоимость в основном определяется формой и видом титана, который вам нужен.

At DAXUN, we offer a wide range of titanium products, including plates, tubes, coils and bars. The length, width and quantity of each item you require will affect the amount you pay at checkout.

К сожалению, сложно назвать цену в интернете, не зная подробностей вашего проекта и того, для чего будет использоваться титан.

К счастью, наша команда экспертов всегда готова помочь и проконсультировать вас по вопросам, связанным с титаном. Отправив письмо по адресу [email protected], мы сможем ответить вам советом и точным предложением.

Обязательно укажите как можно больше информации о сорте, форме и количестве титана, который вам требуется, чтобы лучше понять ваши потребности.

The team at DAXUN is experienced, knowledgeable, and friendly. With years of experience in the industry, they know all about titanium, including its uses, benefits, and grades.

For regular updates on titanium, its uses, and its applications across industries, be sure to check out our blog. Our experts have written easy-to-follow guides that you can always refer to when you have questions.

If you’re still having trouble, feel free to contact us; we’ll be happy to help.

By sending an email to [email protected], you’ll receive a quick response. Make sure to include as much detail as possible in your question so we can recommend a suitable solution.

Пожалуйста, заполните форму на странице “Контакты” или позвоните нашему менеджеру по продажам по телефону “+86 13382898899”, мы свяжемся с вами в кратчайшие сроки. Наш WhatsApp работает в режиме онлайн, а электронная почта ([email protected]) будет проверена в течение 6 часов. На каждый запрос или сообщение мы ответим незамедлительно. Кроме того, каждую неделю мы делимся с нашими клиентами информацией о рынке

We can provide titanium rod samples for you to check the quality. Sample is free and you just pay the freight.

Мы экспортировали продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и др.

Our MOQ is 300 Kg for titanium rod.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов требуется примерно две недели.