Super Austenitic 904L Stainless Steel Plate Supplier

As China’s leading stainless steel plate supplier and exporter, Daxun provides 904L stainless steel plates to the world.

- Grade: AISI 904L-N08904

- Features: Super corrosion resistance

- Manufacturing: Cold-rolled plate, hot-rolled plate, forged plate

- Standar: ASTM, ASME, GB, DIN, JIS, ISO, EN, BS

- Type: Cold-rolled thin plate, hot-rolled thick plate

- Permukaan: 2B, NO.1, NO.4, HL, BA, 8K, dll.

- Panjang: 2438mm3048mm6000mm dapat disesuaikan

- Origin: TISCO, Baosteel, Posco, Tsingshan, Delong, ATI,

Overview of 904L Stainless Steel

Alloy 904L is a superaustenitic stainless steel designed for moderate to high corrosion resistance in various process environments. This high alloy austenitic product is intended for use under severely corrosive conditions, making it a reliable choice for demanding applications. The high chromium and nickel content, along with the additions of molybdenum and copper, provide excellent corrosion resistance. With a highly alloyed chemistry that includes 25% nickel and 4.5% molybdenum, Alloy 904L is well-suited for applications requiring both high corrosion resistance and high strength. This unique composition allows it to withstand environments involving dilute sulfuric acid, hot phosphoric acid, and other inorganic acids, ensuring long-lasting performance in harsh conditions.

Dimensions and Sizes

Alloy 904L stainless steel plate is available in various dimensions and sizes to meet specific application requirements. The available thicknesses for Alloy 904L range from 3/16” through 2”, providing flexibility for different industrial needs. UNS N08904 Sheet can range up to 8mm in thickness, while 904L Plate is usually thicker than 8mm and can range up to 75mm in thickness. These dimensions can be customized to meet specific industry standards and specifications, ensuring that the material fits perfectly into any project. Additionally, 904L stainless steel plate can be easily welded and processed using standard shop fabrication practices, streamlining the manufacturing process and ensuring high-quality results.

Data Teknis

- Parameter

- Komposisi Kimia

- Sifat mekanik

- SIFAT FISIK

- Standar

| Stainless Steel 904L Plate, Sheet and Strip | ASTM B 168/ASME SB 168, ASTM B 906/ASME SB 906, ASME Code Cases 1827 and N-253, SAE/AMS 5540, BS 3072NA14 and 3073NA14, DIN 17750, ISO 6208, EN 10095, MIL-DTL-23228. |

| Standard Stainless Steel 904L Plate & Sheet Sizes | 1000 x 2000 mm, 1220 x 2440 mm, 1500 x 3000 mm, 2000 x 2000 mm, 2000 x 4000 mm |

| Cold rolled 904L Steel Plate 0.5-6.4 mm | |

| Hot rolled 904L Steel Plate 3.0–10.0 mm | |

| SS 904L Plate Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard Stainless Steel 904L Sheet suppliers |

| Availability of Stainless Steel 904L Foil sizes | Ketebalan: 8-100 mikron (0,00031-0,004 inci) |

| Lebar: Hingga 500 mm (19,5 inci) | |

| Berat (dalam gulungan): Hingga 50 kg (110 lb); mis. sekitar 1400 m pada 8 mikron dan sekitar 112 m pada 100 mikron. | |

| Pembuatan profil | Untuk menyediakan layanan pembuatan profil lengkap di Cina, kami menggunakan berbagai metode pembuatan profil termasuk: |

| Laser Plate Cutting | |

| Plasma Plate Cutting | |

| Oxy-propane Flame Cutting | |

| Toleransi lebar dan ketebalan | EN 10258 (formerly DIN 59381) |

| EN 10151 Stainless Steel 904L strip for springs | |

| EN 10088 Stainless Steel 904L strip (general) | |

| Stainless Steel 904L Plates standards and approvals | EN ISO 18286 |

| EN 10051 | |

| EN 10088-1 | |

| ISO 15510 | |

| EN ISO 9445 | |

| ASTM A 480 | |

| ASTM A 959 | |

| ASME IID | |

| Profil plasma | Sesuai gambar pelanggan |

| Value added services for Stainless Steel 904L Plate | Pemotongan laser, pemotongan waterjet, pemotongan plasma, pembengkokan dan pemrosesan mekanis, persiapan tepi, pengelasan, penggergajian dan pemotongan. |

| Value added services for Stainless Steel 904L Coil | Dipotong sesuai panjangnya |

| Menggorok | |

| Polishing | |

| Blanking | |

| SS 904L Plate Origin | China Origin, European Origin, Japanese Origin |

| Packing of 904L Steel Sheet | Bundel dengan kain tahan air di luar atau kotak kayu lapis |

| Tes | UT, pengujian SGS, TUV dll |

| Elemen | % Hadir (dalam bentuk produk) |

| Karbon (C) | 0.02 |

| Silikon (Si) | 0.7 |

| Mangan (Mn) | 2 |

| Fosfor (P) | 0.03 |

| Belerang (S) | 0.01 |

| Kromium (Cr) | 19.00 – 21.00 |

| Nikel (Ni) | 24.00 - 26.00 |

| Nitrogen (N) | 0.15 |

| Molibdenum (Mo) | 4.00 – 5.00 |

| Copper (Cu) | 1.20 – 2.00 |

| Besi (Fe) | Keseimbangan |

| Formulir Produk | ||||||||

| C | H | P | L | L | TW/TS | |||

| Thickness (mm) Max. | 8 | 13.5 | 75 | 160 | 2502) | 60 | ||

| Kekuatan Hasil | Rp0.2聽N/mm2 | 2403) | 2203) | 2203) | 2304) | 2305) | 2306) | |

| Rp1.0聽N/mm2 | 2703) | 2603) | 2603) | 2603) | 2603) | 2503) | ||

| Kekuatan Tarik | Rm聽N/mm2 | 530 – 7303) | 530 – 7303) | 520 – 7203) | 530 – 7304) | 530 – 7305) | 520 – 7206) | |

| Perpanjangan min. dalam % | Jmin聽(Longitudinal) | - | 100 | 100 | 100 | - | 120 | |

| Jmin聽(Transverse) | - | 60 | 60 | - | 60 | 90 | ||

| Density at 20°C kg/m3 | 8 | |

| Thermal Conductivity W/m K at | 20°C | 12 |

| Modulus of Elasticity kN/mm2 at | 20°C | 195 |

| 200°C | 182 | |

| 400°C | 166 | |

| 500°C | 158 | |

| Specific Thermal Capacity at 20°C J/kg K | 450 | |

| Electrical Resistivity at 20°C Ω mm2/m | 1 | |

| UNS S904L | 1.4539 | UNS N08904 |

| ASTM A240 | ASTM A240 | ASTM A240 |

| ASTM A480 | ASTM A480 | ASTM A480 |

| ASME SA240 | ASME SA240 | ASME SA240 |

| AMS 5521 | AMS 5521 | AMS 5521 |

Pilih Daxun dan buat pelanggan Anda puas.

Pengiriman cepat

We provide timely and fast delivery of 904L stainless steel plate products for customers with urgent needs. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real time, and the data is seamlessly connected; in terms of logistics, the processing center is close to highways and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on time.

904L plate features

Type 904L is a high alloy austenitic stainless steel that is known for its corrosion properties.

- Non-magnetik

- Stronger corrosion properties than Type 316L an 317L

- Good resistance to sulphuric, phosphoric and acetic acids

- High resistance to crevice and stress corrosion cracking

- Excellent formability and weldability

Stainless Steel 904L Applications

Application of using Type 904L stainless steel:

- Cooling equipment for seawater

- Chemical processing of sulphuric, phosphoric and acetic acids

- Penukar panas

- Condenser tubes

- Gas washing

- Control and instrumentation

- Oil and gas industry

- Pharmaceutical production

- Wiring in electrostatic precipitators

Kualitas, pengiriman, inspeksi

-

Daxun Alloy is committed to quality assurance. The company conducts various tests to ensure material suitability. These tests include flattening, pitting, and resistance tests. Mechanical, hardness, and expansion tests are also performed. Material positive identification is another key quality assurance measure. All these tests guarantee that the materials meet application requirements. Customers can trust Daxun Alloy for high-quality, suitable products.

- Selama proses produksi, kami mengukur diameter, ketebalan, dan permukaan produk. Waktu pengiriman standar kami adalah 7-15 hari, kecuali untuk beberapa produk ukuran khusus, waktu pengiriman kami akan bertambah menjadi 20 hari.

Waktu pengiriman kami benar-benar sesuai dengan kontrak. - Mendukung agen pihak ketiga pelanggan untuk pergi ke pabrik untuk pemeriksaan

- Mendukung sampel gratis kepada pelanggan untuk pengujian

- Mendukung inspeksi pabrik di tempat atau video

Technical Services

Jika Anda memerlukan bantuan teknis tambahan, ahli metalurgi dan staf kami yang berpengetahuan luas akan dengan senang hati membantu. Selain itu, Daxun memiliki laboratorium pengujian bersertifikat-yang pertama dalam industri inventaris multi-logam dan plastik. Ini, menurut pendapat kami, menunjukkan dedikasi kami yang tak tergoyahkan terhadap kualitas dan filosofi kami sebagai pemasok layanan penuh.

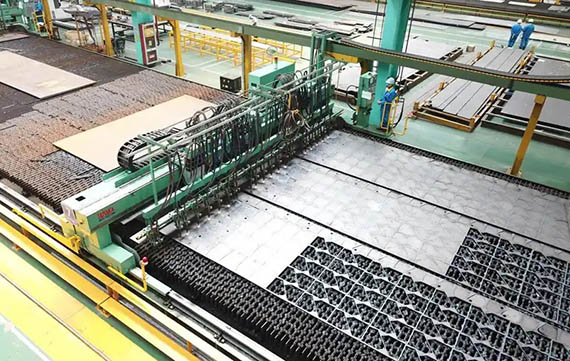

Pemesinan tingkat lanjut

Quality is belief, and integrity is a business card. Daxun pioneered the concept of “performance excellence management” and implemented the “PDCA+Lean” management model. The company’s business card says “Daxun = assured quality”. Daxun Stainless Steel uses the ERP system to achieve full traceability of the variety, specification, and origin of each stainless steel plate, and advocates and encourages industry anti-counterfeiting. Daxun Stainless Steel relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

904L plate stainless steel Features

Daxun Biarkan merek Anda meningkat dengan cepat

- Galeri

- Toleransi

- Status pengiriman

- Seri produk lainnya

| Toleransi untuk Lembar 2B | |||

| Ukuran | Peringkat Toleransi | ||

| Kelompok 1 | Kelompok 2 | Kelompok 3 | |

| 0.4 | 0.3 ~ 0.32 | 0.33 ~ 0.37 | 0.37 ~ 0.39 |

| 0.5 | 0.4 ~ 0.42 | 0.43 ~ 0.47 | 0.47 ~ 0.49 |

| 0.6 | 0.5 ~ 0.52 | 0.53 ~ 0.56 | 0.57 ~ 0.59 |

| 0.7 | 0.6 ~ 0.62 | 0.63 ~ 0.67 | 0.67 ~ 0.69 |

| 0.8 | 0.7 ~ 0.72 | 0.73 ~ 0.77 | 0.74 ~ 0.79 |

| 0.9 | 0.8 ~ 0.82 | 0.83 ~ 0.87 | 0.87 ~ 0.89 |

| 1 | 0.89 ~ 0.9 | 0.91 ~ 0.94 | 0.94 ~ 0.99 |

| 1.2 | 1.02 ~ 1.08 | 1.09 ~ 1.15 | 1.16 ~ 1.18 |

| 1.5 | 1.32 ~ 1.38 | 1.39 ~ 1.45 | 1.46 ~ 1.48 |

| 2 | 1.72 ~ 1.79 | 1.8 ~ 1.86 | 1.87 ~ 1.9 |

| 2.5 | 2.23 ~ 2.36 | 2.32 ~ 2.42 | 1.42 ~ 1.47 |

| 3 | 2.7 ~ 2.77 | 2.78 ~ 2.82 | 2.85 ~ 2.9 |

| Toleransi untuk Pelat Canai Panas No.1 | |||

| Ukuran | Peringkat Toleransi | ||

| Kelompok 1 | Kelompok 2 | Kelompok 3 | |

| 3 | 2.6 ~ 2.75 | 2.75 ~ 2.85 | 2.86 ~ 2.9 |

| 4 | 3.5 ~ 3.6 | 3.6 ~ 3.75 | 3.76 ~ 3.95 |

| 5 | 4.5 ~ 4.6 | 4.6 ~ 4.75 | 4.75 ~ 4.95 |

| 6 | 5.4 ~ 5.6 | 5.6 ~ 5.75 | 5.75 ~ 5.85 |

| 8 | 7.3 ~ 7.5 | 7.5 ~ 7.65 | 7.65 ~ 7.85 |

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9.6 ~ 9.85 |

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11.6 ~ 11.85 |

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13.6 ~ 13.85 |

| 16 | 15.2~ 15.5 | 15.5~ 15.7 | 15.7~ 16.1 |

| 18 | 17.2~ 17.5 | 17.5~ 17.7 | 17.7~ 18.1 |

| 20 | 19.2~ 19.5 | 19.5~ 19.7 | 19.7~ 20.1 |

| 30 | 29.2~ 29.5 | 29.5~ 29.7 | 29.7-30.1 |

| 40 | 39.2~ 39.5 | 39.5~ 39.7 | 39.7~ 40.1 |

| 50 | 49.2~ 49.5 | 49.5~ 49.7 | 49.7~ 50.1 |

| 60 | 59.2~ 59.5 | 59.5~ 59.7 | 59.7~ 60.1 |

| Pilihan Status Pengiriman | Kondisi Permukaan |

| Digulung Dingin | 2B |

| 2D | |

| BA | |

| Garis rambut | |

| No.3 | |

| No.4 | |

| 6K | |

| 8K | |

| Catatan: | |

| 1. Jika Anda memerlukan status pengiriman yang berbeda dari yang tercantum di atas, mohon konfirmasi dengan kami. | |

| 2. Jika ada pertanyaan atau pesanan, mohon beritahukan kepada kami persyaratan tambahan yang tidak disebutkan di sini. | |

| Status Pengiriman | |

| Pilihan Status Pengiriman | Kondisi Permukaan |

| Canai Panas | No.1 |

| No.3 | |

| No.4 | |

| 6K | |

| 8K | |

| Acar | |

| Catatan: | |

| 1. Jika Anda memerlukan status pengiriman yang berbeda dari yang tercantum di atas, mohon konfirmasi dengan kami. | |

| 2. Jika ada pertanyaan atau pesanan, mohon beritahukan kepada kami persyaratan tambahan yang tidak disebutkan di sini. | |

| Kelas | Jenis | Ketebalan | Permukaan |

| Austenitik | 304/304H/304L/304J1 | 0,25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0,3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferit | 430 | 0.4-3.0mm | 2B/BA/NO.4/8K/SB/HL |

| Ferit Ultra Murni | 443 | 0.4-2.0mm | 2B |

| 436L/439/444/441 | 0.5-3.0mm | 2B 、 2D | |

| 409L | 0,4-2,5 mm | 2B 、 2D | |

| Kelas | Jenis | Ketebalan | Asli |

| Baja tahan panas | 309S | 0,5-40mm | CHN |

| 310S | 0,5-40mm | CHN | |

| Baja Dupleks | 2101 | 1,5-50mm | CHN |

| 2304 | 3.0-50mm | CHN | |

| 2205 | 0,5-60mm | CHN | |

| 2507 | 1.0-60mm | SWE / JPN / CHN | |

| Baja Austenitik Super | N08904 | 0,6-50mm | SWE / JPN / CHN |

| S31254 | 0,5-50mm | SWE / JPN / CHN | |

| N08926 | 0,5-50mm | SWE / JPN / CHN | |

| N08367 | 0,5-50mm | SWE / JPN / CHN | |

| Paduan Dasar Nikel | N08031 | 1.0-50mm | AS / JPN / GER |

| N08810 / N08800 | 0,8-50mm | AS / JPN / CHN | |

| N08028 | 1.0-20mm | AS / JERMAN / JPN | |

| N08020 | 1.0-20mm | AS / JERMAN / JPN | |

| N08825 | 0,8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50mm | AS / JERMAN / JPN | |

| N06022 | 1.0-50mm | AS / JERMAN / JPN | |

| N06625 | 0,8-20mm | AS / GER / CHN | |

| N04400 | 1.0-20mm | AS / JERMAN / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20mm | AS / JPN | |

| Titanium | TA1/Gr1 | 0,5-50mm | JPN / CHN |

| TA2/Gr2 | 0,5-50mm | JPN / CHN | |

| Bahan Pengelasan | ERNiCrMo-13 | 1.2 、 2.4mm | GER |

| ERNiCrMo-3 | 2.4mm | GER | |

| ERNiCrMo-4 | 2.4mm | AS |

The surface and shape of 904L stainless steel plate (7)

Informasi yang tersedia untuk referensi dan diunduh

Daxun adalah produsen pelat baja tahan karat yang dapat dipercaya

Sebagai produsen profesional, Daxun memastikan bahwa semua produk yang kami hasilkan berkualitas tinggi. Oleh karena itu, kami memastikan bahwa semua pelat baja tahan karat disertifikasi oleh ISO9001, SGS, CE, OQC, dan lebih banyak standar kualitas internasional, serta memiliki kontrol kualitas yang ketat untuk memastikan bahwa pelat baja tahan karat memiliki lebih sedikit cacat. Di Daxun, yakinlah bahwa semua produk tahan lama, berkualitas tinggi, dan berkinerja tinggi.

Proyek dan produk hot case terbaru

Produk Terkait (13)

Kami dapat menyediakan sampel lembaran baja tahan karat untuk Anda periksa kualitasnya. Sampel gratis dan Anda hanya membayar ongkos kirim.

Kami telah mengekspor ke lebih dari 42 negara, seperti Kanada, Chili, Kuwait, Jerman, Korea Selatan, Arab Saudi, Singapura, dll.

MOQ kami adalah 1 ton untuk lembaran baja tahan karat.

Pesanan percobaan dapat dikirim dalam waktu satu minggu. Untuk pesanan reguler, kira-kira membutuhkan waktu dua minggu.