Hastelloy G35 Plate - Daxun Alloy - The Best Alloy Supplier

Daxun Alloy supplies high quality Hastelloy G35 Plates to the world.

- Grade : Hastelloy G35

- Certification : SGS,ISO,CE

- Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

- Surface finish : Bright, Dull, Hair Line(HL), others

- Thickness : 0.5mm to 50 mm Thk

- Width : 500-2000mm

- Length : 2m, 2.44m, 3m, or as required

- Delivery Time : 7-15 days

- MOQ : ≥50kg

Characteristics & Properties of Hastelloy G35

Hastelloy G35 plate is a high-performance corrosion-resistant alloy plate based on nickel, designed for extreme chemical environments. Its core components include chromium (28-33%), molybdenum (4.0-8.0%) and copper (1.0-2.4%), which give it excellent acid resistance, especially strong tolerance to sulfuric acid, phosphoric acid and chloride-containing media, and can effectively resist pitting, crevice corrosion and stress corrosion cracking. At the same time, the alloy can remain stable in high temperature environments and is suitable for key equipment in chemical production such as sulfuric acid and phosphoric acid, such as reactors, heat exchangers and evaporators, especially for the concentration process of “wet” phosphoric acid.

This plate has excellent processing performance and reliable mechanical strength, supports hot processing, cold processing and various welding methods, and has a thickness range of 0.5-50mm. It is widely used in chemical, energy, marine engineering and other fields. Hastelloy G35 plates have shown long-term stability in the black liquor recovery system of pulp and paper, seawater desalination equipment, and highly corrosive environments in pharmaceutical and food processing. Its flexible specifications and reliable performance make it an ideal choice to replace traditional stainless steel and nickel-based alloys, significantly improving equipment life and safety, especially under harsh working conditions.

Fitur

Excellent corrosion resistance:

– Acid media: Excellent resistance to strong acids such as sulfuric acid, sulfates, phosphoric acid, hydrochloric acid, and hydrofluoric acid. It can effectively resist corrosion in the production and processing environment of sulfuric acid and phosphoric acid, such as in the chemical industry for production and processing equipment (reactors, heat exchangers, pipelines and pumps, etc.) of sulfuric acid and phosphoric acid. When processing “wet-process” phosphoric acid, it performs far better than other metal materials and can play a good role in resisting localized corrosion under the evaporator deposits of concentrated “wet-process” phosphoric acid.

– Oxidizing and reducing media: The high chromium content makes it extremely resistant to other oxidizing acids (such as nitric acid) and mixtures containing nitric acid; the considerable molybdenum content makes it moderately resistant to reducing acids. In addition, it can also resist localized corrosion and chloride ion stress corrosion cracking in chloride-containing media. Unlike other nickel-chromium-molybdenum alloys, it has strong resistance to “caustic dealloying” in hot sodium hydroxide.

Good high-temperature performance: It has excellent high-temperature stability and can maintain good strength and toughness in high-temperature environments, ensuring the normal operation of equipment under high-temperature conditions. However, the specific data of its high temperature performance (such as quantitative indicators such as high temperature strength and oxidation resistance) are less and less uniform in different materials. It is only known that it has certain performance at high temperature, but lacks specific numerical support such as tensile strength and yield strength.

Good processing performance: It has good hot processing, cold processing and welding performance. The hot processing temperature range is usually 1050-1200℃. The heating rate should be moderate to avoid excessive thermal stress. After hot processing, it needs to be properly cooled to ensure the structure and performance of the alloy; during cold processing, due to the high strength, a large processing force is required. Multiple cold processing and intermediate annealing processes can be used to reduce the difficulty of processing and improve the quality; welding can be carried out by tungsten inert gas shielded welding (TIG), melt inert gas shielded welding (MIG) and other methods. Before welding, the weldment should be strictly cleaned, the heat input should be controlled during welding, and heat treatment may be required after welding to eliminate welding stress.

Application field

Chemical industry: Applicable to the production and processing equipment of sulfuric acid and phosphoric acid, such as reactors, heat exchangers, pipelines and pumps. It is also widely used in various corrosion-resistant equipment in chemical production, such as reactors, evaporators, etc.

Pulp and paper industry: can be used in black liquor recovery systems to withstand high temperature and highly corrosive environments.

Marine engineering: used for seawater desalination equipment and offshore platform structures to resist seawater corrosion.

Energy industry: in the fields of nuclear power and thermal power, used to manufacture corrosion-resistant high-temperature components; in the oil and gas industry, used for drilling and production facilities to resist hydrogen sulfide and other corrosive gases.

Food processing industry: suitable for equipment that handles acidic or alkaline foods, such as evaporators and heat exchangers.

Pharmaceutical industry: used to manufacture corrosion-resistant pharmaceutical equipment and containers.

Hastelloy G35 Parameters

- Chemical Composition

- Physical properties

- Sifat mekanik

| Ni | Cr | Co | W | Mo | Fe |

| Remainder | 28% – 33% | ≤1.0% | ≤4.0% | 4.0% – 8.0% | 1.3% – 2.0% |

| Cu | C | Si | Mn | P | S |

| 1.0% – 2.4% | ≤0.05% | ≤0.6% | ≤1.5% | ≤0.035% | ≤0.02% |

| Properti | Kepadatan | Titik Leleh | Konduktivitas Termal | Kapasitas Panas Spesifik | Coefficient of Thermal Expansion | Modulus Elastisitas |

| Nilai | 8.22 – 8.72 g/cm³ | 1325 – 1361°C | 10 – 23 W/(m·K) | 400 – 600 J/(kg·K) | 13.9×10⁻⁶/°C (20 – 100°C) | 177 GPa |

| Properti | Kekuatan Tarik | Kekuatan Hasil | Elongation (A5%) | Kekerasan |

| Nilai | σb ≥ 524 N/mm² | σ0.2 ≥ 200 N/mm² | δ ≥ 62% | HB ≤ 350 |

Pilih Daxun dan buat pelanggan Anda puas.

Pengiriman cepat

Daxun provides customers with timely and fast delivery of Hsatelloy G35 plate products. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real time, and the data is seamlessly connected; in terms of logistics, the processing center is close to ports and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on time.

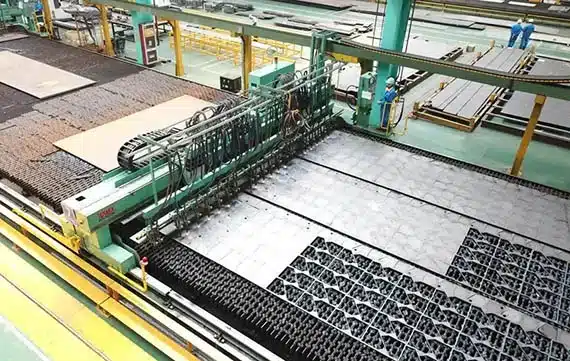

Pemesinan tingkat lanjut

Daxun’s typical service of “more, faster, better and cheaper” for Hastelloy G35 plate materials starts with Daxun’s alloy varieties, specifications and spot inventory. It has strategic resource support from many large steel mills at home and abroad to ensure a stable supply chain and meet customers’ personalized needs for specific materials. It can be called the “Wal-Mart” of the stainless steel industry. With more than 20 years of experience, it has established the brand image of “Look for Daxun for stainless steel plates” in the Chinese market.

Hastelloy G35 plate packaging

Daxun Alloy ensures the best quality of hastelloy plate packaging, because packaging plays an important role in international freight, and the goods go through various channels to reach the final destination, so we pay special attention to packaging. We pack our goods in many ways according to the products. We pack our products in many ways, such as:

- Kotak dan peti

- Kertas kraft + palet kayu

- Kecilkan bungkus

- Palet kayu bebas fumigasi

- Kotak kayu bebas fumigasi

Hastelloy G35 Plate Surface Treatment

1D: Permukaannya matte dengan bentuk partikel yang terputus-putus.

2D: Putih dengan nada keperakan.

2B: Abu-abu perak dengan kilap dan kerataan yang lebih baik daripada permukaan 2D.

Ba: Dekat dengan permukaan cermin dengan kilap dan daya pantul yang istimewa.

No.3: Kilauan yang bagus dan permukaan yang kasar.

No.4: Permukaannya memiliki garis-garis halus dan kilap yang bagus.

HL: Abu-abu perak dengan rambut keemasan.

8K: Permukaan cermin.

Hastelloy G35 Sheet Processing:

- Pemrosesan etsa

- Pemrosesan pengelasan

- Pemrosesan pembengkokan

- Pemrosesan timbul

- Pemrosesan sandblasting

- Pemrosesan pemolesan

- Pemrosesan meninju

- Pemrosesan stamping

- Pemrosesan pemotongan

Daxun adalah produsen logam yang dapat dipercaya

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all metal plates are certified by ISO9001, SGS, CE, OQC and more international quality standards.We also have strict quality control to ensure that the metal plates have less defects. At Daxun, rest assured that all products are durable, high quality and high performance.

Produk Terkait (13)

Daxun metal plates are in high demand, have good quality, and are honest and trustworthy.

- Daxun International telah berkecimpung dalam bisnis internasional selama lebih dari sepuluh tahun. Pada tahun 2022, pendapatan ekspornya melampaui $100 juta, dan volume ekspornya termasuk di antara perusahaan pengolahan baja nirkarat teratas di Tiongkok. Untuk melayani pasar luar negeri, kami telah membangun tiga fasilitas layanan ekspor di Tiongkok dan berkolaborasi dengan organisasi teknik, pabrik baja, dan perusahaan perdagangan internasional. Kami terus meningkatkan kemampuan layanan kami, membangun tiga basis layanan ekspor di Tiongkok, dan berkolaborasi dengan perusahaan teknik, pabrik baja, dan perusahaan perdagangan internasional untuk berkembang ke pasar baru.

- Daxun memiliki hubungan jangka panjang dengan puluhan pabrik baja terkenal di seluruh dunia, memasok 30.000 ton pelat baja tahan karat standar dan 20.000 ton logam seperti baja dupleks, paduan berbasis nikel, dan baja tahan panas. Bahan stainless steel Daxun memiliki kualitas yang konsisten dan tidak pernah dipalsukan. Jenis, spesifikasi, dan bobot pengiriman secara ketat mematuhi standar.

- Daxun memiliki beberapa peralatan pemrosesan pelat baja tahan karat, pusat pengujian fisik dan kimia profesional, dan jalur produksi “pemotongan, penggilingan, pembentukan, beveling, pengelasan, perlakuan panas, permesinan, dan penyemprotan”. Layanan disediakan di sekitar 30 industri, termasuk kendaraan, peralatan rumah tangga, lift, energi baru, semikonduktor vakum, makanan dan minuman / biofermentasi, petrokimia, dan peralatan energi. Berkolaborasi dengan pabrik baja, lembaga penelitian, dan organisasi lain untuk menawarkan layanan komprehensif mulai dari desain proyek dan pengembangan material hingga optimalisasi proses pengolahan dan manufaktur.

Metal materials “more, faster, better, and cheaper” customised services

- First, it refers to Daxun’s metal plate kinds and specifications, as well as its spot inventories.Daxun has strategic resource assistance from many large steel mills at home and abroad, ensuring the stability of the metal plate supply chain and meeting clients’ individualised needs on specific materials.

- Kedua, teknologi pemrosesan Daxun beragam.

processes, including metal plate cutting, grinding, cutting, forming, welding, and machining, to provide customers with “one-stop” service.

Daxun melayani sejumlah besar konsumen di berbagai sektor.

- Daxun alloy company focuses on the key sectors of equipment manufacture. far, it has served over 30,000 customers, including over 10,000 active customers from more than 30 industries and a big number of major businesses. This demonstrates Daxun’s extensive service experience, as well as its widespread consumer recognition across industries.

Customers with urgent needs can rest assured that we will supply metal plate products on time and quickly.

- Di balik kecepatan tersebut adalah dukungan sistem, termasuk aliran informasi, logistik, dan aliran modal. Misalnya, dalam hal aliran informasi, data pesanan Daxun didorong ke sistem logistik secara real time, terhubung dengan mulus; dalam hal logistik, pusat pemrosesan dekat dengan pelabuhan, sungai, dan laut, dengan penjadwalan yang masuk akal, respons yang cepat, hubungan penyimpanan dan transportasi, dan pemuatan yang efisien untuk memastikan bahwa tugas selesai tepat waktu.

Kami memberikan kualitas yang sangat baik dan layanan berkualitas tinggi.

- Quality is belief, and integrity is a business card. Daxun pioneered the concept of “excellent performance management” and promoted the “PDCA+Lean” management model, making “Daxun = assured quality” the company’s business card. In terms of materials, Daxun Alloy has achieved full traceability of each steel plate from the ERP system, including varieties, specifications, and origins, and advocated and encouraged industry anti-counterfeiting.

- Daxun Alloy relies on technology for processing, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, closely monitors during sales, and provides worry-free service guarantees after sales.

Kami menghemat waktu, bahan, dan energi pelanggan kami, dan pada akhirnya menghemat uang mereka.

Keunggulan profesional Daxun memungkinkan kami untuk memberikan rekomendasi material yang paling hemat biaya berdasarkan kebutuhan pelanggan, dan meminimalkan biaya bagi pelanggan melalui metode seperti pemrosesan berkelanjutan dan pemrosesan bersarang.

Metode pemrosesan sarang kami yang inovatif mengoptimalkan pemanfaatan material dan pemotongan.

Pada saat yang sama, Daxun mencapai pengurangan biaya dan peningkatan efisiensi yang berkelanjutan dengan mempromosikan kegiatan peningkatan ramping dan memberikan manfaat kepada pelanggan. Daxun juga memiliki sistem penelusuran produk yang lengkap dan penanganan keberatan kualitas yang tepat waktu, yang mengurangi kekhawatiran pelanggan.

Leading Metal Sheet Suppliers in China

Contact the top suppliers in China for metal sheets (steel plates) in a variety of finishes. You need no other metal sheet supplier than Daxun Alloys, who offer free cutting services and delivery times as short as 5-7 days.

We can assist in providing metal sheets in any required size.

To meet your specific requirements, our metal sheets are available in three finishes and a variety of sizes. We can readily provide any custom size you may need with our free unlimited cutting service.

Kami dapat memenuhi kebutuhan ukuran apa pun antara 0,3 dan 30 mm dalam ketebalan dan antara 50 x 50 mm dan 2500 x 1250 mm. Selain itu, kami menyediakan pemotongan gratis tanpa batas untuk setiap pesanan, menggunakan mesin pemotong yang canggih untuk memenuhi kebutuhan Anda secara tepat.

Order metal Sheets by Phone or Online.

There has never been an easier way to get metal sheets. Simply refer to the simple and detailed instructions on our website. Alternatively, our sales staff will be happy to take your order or answer any questions when you call +86 13382898899 or email [email protected].

Waktu pengiriman kami hanya satu hingga dua hari.

Karakteristik:

Grade ini lebih tahan terhadap korosi dan pitting daripada 304 dan menawarkan kekuatan yang lebih tinggi pada suhu tinggi. Selain itu, 316L adalah variasi karbon ekstra rendah yang membantu menghindari pengendapan karbida akibat pengelasan.

Catatan Keselamatan Penting:

The edges of the metal sheets we sell are not polished, ground or finished, so they may be sharp, just like the edges of any metal sheet. We remind users to use, install and handle these devices with care.

We can provide metal sheet samples for you to check the quality. Sample is free and you just pay the freight.

Kami telah mengekspor ke lebih dari 42 negara, seperti Kanada, Chili, Kuwait, Jerman, Korea Selatan, Arab Saudi, Singapura, dll.

Our MOQ is 1 ton for metal sheet.

Pesanan percobaan dapat dikirim dalam waktu satu minggu. Untuk pesanan reguler, kira-kira membutuhkan waktu dua minggu.