Super Austenitic 904l Stainless Steel Coil China Supplier

Sebagai pemasok dan eksportir kumparan baja tahan karat terkemuka di Tiongkok, Daxun memasok kumparan baja tahan karat ke seluruh dunia.

- Coil grade: 904L-N08904

- Stronger corrosion properties than Type 316L an 317L

- Good resistance to sulphuric, phosphoric and acetic acids

- High resistance to crevice and stress corrosion cracking

- Excellent formability and weldability

Global leader in stainless steel Coil fabrication services

Type 904L is a high alloy austenitic stainless steel that is renowned for its corrosion resistance. 904L alloy (UNS N08904) is a super austenitic stainless steel that may be used in a variety of process settings and has moderate to high corrosion resistance. The high chromium and nickel content, along with molybdenum and copper, ensures good to outstanding corrosion resistance. With a highly alloyed chemistry (25% nickel and 4.5% molybdenum), 904L offers better resistance to chloride stress corrosion cracking, pitting, and general corrosion than 316L and 317L molybdenum reinforced stainless steels. The 904L alloy was originally created to withstand dilute sulfuric acid conditions. It is also resistant to most organic acids and other inorganic acids, including hot phosphoric acid. 904L alloy is easily weldable and may be handled using typical shop fabrication procedures.

Dah Hsun is an ISO 9001:2008 certified firm that is a major supplier and exporter of ASTM A240 Stainless Steel Coils. Stainless steel coils can be cut to your requirements and include a full set of mill test results. Custom lengths and widths are available up to 2000mm. Exporting is our specialty! We can obtain several hard-to-find grades and/or non-standard sizes to satisfy our customers’ specific needs. We have vast experience processing steel coil goods and can divide all stainless steel coils to the desired sizes. Introducing our extensive line of Dah Hsun Stainless Steel goods – the pinnacle of dependability, durability, and performance. We are glad to provide a wide selection of grades and varieties to fulfill the diverse needs of industrial and architectural applications.

Our stainless steel coil goods, which range from the Austenitic series to the Ferritic series and other special categories, are well-known for their high performance and extensive requirements. The austenitic series includes 304/304L/304J1, 321 and 316/316L/317L/316Ti/310/309, which can fulfill varied thickness requirements and give a variety of surface treatments, including 2B, BA, NO.4, 8K, SB, HL, NO.1, and so on.

Our ferrite line, which includes 430, ultra-pure ferrite 443, and 436L/439/444/441, caters to customers looking for unique qualities and applications. These materials can accommodate thicknesses ranging from 0.4mm to 3.0mm and offer a variety of surface treatment options such as 2B, BA, NO.4, 8K, SB, HL, and so on.

By selecting our stainless steel coils, you are investing in a material that ensures long service life, great reliability, and exceptional performance. Don’t compromise on quality; choose our stainless steel solutions and see the impact they can make in your project. Contact Daxun today for additional information or to place an order for the stainless steel coil specs and quantities that you require.

Data

- Parameter

- Elemen

- Sifat Mekanis

- SIFAT FISIK

- Semua setara

- 904L coil stock

| 904L Stainless Steel Coil Specification | ASTM A240 / ASME SA240 |

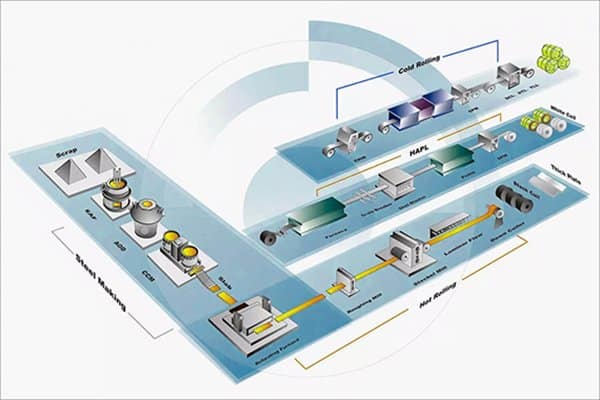

| 904L Stainless Steel Coil Manufacturing Process | Hot Rolled (HR) / Cold Rolled (CR) |

| 904L Stainless Steel Coil Grades | 201 / 304 / 304L/ 904L / 309S / 420 / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. |

| UNS No. – UNS S904L, UNS S31008, UNS S31600, UNS S31603, UNS S31603, UNS S31600, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| EN No. 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| 904L Stainless Steel Coil Thickness | 0.6 MM TO 16 MM THICKNESS |

| 904L Stainless Steel Coil Width | 1250 MM / 1500 MM / 2000 MM / 04 Feet / 05 Feet and Custom Cut Width as Per Requirement |

| 904L Stainless Steel Coil Length | 2400 MM / 2420 MM / 6000 MM / 08 Feet / 10 Feet / Coil Cut and Custom Cut Length as Per Requirement |

| 904L Stainless Steel Coil Surface Finish | 2B, 2D, BA, MATT, MATT PVC, No.4, No.5, SB, HR, No.8, Mirror, Hairline, Brush, Textured, Oil base wet Polished, Both sides Polished available. |

| 904L Stainless Steel Coil Coating | PVC coating Normal / Laser, Film: 100 micrometer, Color: black/white. |

| 904L Stainless Steel Coil Other Testing | NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, etc. |

| 904L Stainless Steel CoilValue Added Services | Gas Cutting / CNC Plasma Cutting / Profiling / Rolling / Bending / coil Metal Fabrication / Drill / Punch / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| 904L Stainless Steel Coil Packaging | Loose / Carrate / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps |

| 904L Stainless Steel Coil Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| 904L Stainless Steel Coil Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC |

| Produsen | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, VDM, Nippon Metal, Outokumpu, Qingshan, Delong. |

| Pelabuhan Pengiriman | Pelabuhan Shanghai / Ningbo / Tianjin / Qindao |

| Elemen | % Hadir (dalam bentuk produk) |

| Karbon (C) | 0.02 |

| Silikon (Si) | 0.7 |

| Mangan (Mn) | 2 |

| Fosfor (P) | 0.03 |

| Belerang (S) | 0.01 |

| Kromium (Cr) | 19.00 – 21.00 |

| Nikel (Ni) | 24.00 - 26.00 |

| Nitrogen (N) | 0.15 |

| Molibdenum (Mo) | 4.00 – 5.00 |

| Copper (Cu) | 1.20 – 2.00 |

| Besi (Fe) | Keseimbangan |

| Kekuatan Hasil | Ultimate Tensile | Perpanjangan | Kekerasan | ||

| 0.2% Offset | Strength | in 2 in. | |||

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 31,000 | 220 | 71,000 | 490 | 36 | 70-90 Rockwell B |

| Reference data on some physical properties | ||

| Density at 20°C kg/m3 | 8 | |

| Thermal Conductivity W/m K at | 20°C | 12 |

| Modulus of Elasticity kN/mm2 at | 20°C | 195 |

| 200°C | 182 | |

| 400°C | 166 | |

| 500°C | 158 | |

| Specific Thermal Capacity at 20°C J/kg K | 450 | |

| Electrical Resistivity at 20°C Ω mm2/m | 1 | |

| STANDAR | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

| SS 904L | 1.4539 | N08904 | SUS 904l | Z2 NCDU 25-20 | 904S13 | - | X1NiCrMoCu25-20-5 |

| • 904L Stainless Steel HR coil | • Baosteel Stainless Steel 904L coil |

| • 904L Stainless Steel Chequered coil | • Stainless Steel Cladding 904L coil |

| • 904L Stainless Steel Golden Laser Pattern coil | • Black SS 904L coil 4mm Thick |

| • Super thin-Mirror surface BA ss 904L coil | • Bright-pickled Stainless Steel 904L coil |

| • Super Austenitic SS 904L coil | • Cold rolled, heat treated 904L coil |

| • ASTM A240 904L coil | • 3mm Cold Rolled AISI SS 904L coil |

| • JMSS cold rolled ss 904L coil | • Mill Supply SS 904L coil |

| • Cold Rolled No.1 Finish SS 904L coil | • Grade Prime SS 904L coil |

| • SEW 400 Stainless Steel 904L coil | • Carpenter Custom 450 Stainless Steel 904L coil |

| • Hot Rolled Stainless Steel 904L coil | • Cut to Size Stainless Steel 904L coil |

| • Sales Promotion SS 904L coil | • Non Magnetic Polishing Stainless Steel 904L coil |

| • Cr Stainless Steel 904L coil | • ASME SA240 904L coil |

| • SS 904L Mill Test Certificate coil | • Grade 904L Stainless Steel Finish coil |

| • ASTM A240 904L coil | • 904L Stainless Steel Blank coil |

| • Cold rolled, bright annealed 904L coil | • 904L Stainless Steel Perforated coil |

| • Ground Stainless Steel 904L coil | • Embossed ss 904L coil |

| • Hot Selling AISI SS 904L coil | • Cheap cold rolled ss 904L coil with best price |

| • SS 904L Rose Golden coil | • Brush finish ss 904L coil price list |

| • Surface coated Stainless Steel 904L coil | • SS URANUS B6 904L coil |

| • Satin finish Stainless Steel 904L coil | • 2B SUS SS 904L coil |

| • AISI stainless steel 904L armor coil | • Food Grade Stainless Steel 904L coil |

| • Satin finish Stainless Steel 904L coil | • No. 4 PVC Coated SS 904L coil |

| • Mirror Finish SS 904L coil | • SS 904L coil Blasted Tin-Gold Rose |

| • SS 904L coil Gold Brush Finish | • 2mm ASTM SS 904L coil |

| • 904L Stainless Steel CR coil | • Stainless Steel Corrugated 904L coil |

| • 904L Stainless Steel 2B coil | • ASTM A240 904L coil |

| • 904L Stainless Steel B. Q. Profile coil | • Brushed or dull polished Stainless Steel 904L coil |

| • Best selling 4’x8′ mirror finished ss 904L coil | • Cold rolled, heat treated, pickled 904L coil |

| • Decorative hairline inox cold rolled ss 904L coil | • 10K Mirror Finish Surface SS 904L coil |

| • Hair Line Finish SS 904L coil | • Gold Etched SS 904L coil |

| • Laser cutting ss 904L coil | • 18 Gauge SS 904L coil |

| • Tisco Supplier 3mm Thickness Stainless Steel 904L coil | • Patterned Stainless Steel 904L coil |

| • Decorative Stainless Steel 904L coil | • Patterned Stainless Steel 904L coil |

| • Scotch Brite SS 904L coil | • Passenger Elevator Cabin SS 904L coil |

Pilih Daxun dan buat pelanggan Anda puas.

Quick response 904L Stainless Steel coil

Kami menyediakan pengiriman produk baja tahan karat yang tepat waktu dan cepat untuk pelanggan dengan kebutuhan mendesak. Di balik kecepatan tersebut adalah dukungan sistem dari aliran informasi hingga logistik dan aliran modal. Misalnya, dalam hal aliran informasi, data pesanan Daxun didorong ke sistem logistik secara real time, dan data tersebut terhubung dengan mulus; dalam hal logistik, pusat pemrosesan dekat dengan jalan raya dan sungai dan laut, dengan penjadwalan yang wajar, respons yang cepat, hubungan penyimpanan dan transportasi, dan pemuatan yang efisien, memastikan bahwa tugas diselesaikan sesuai jadwal. bahan baja tahan karat Daxun memiliki kualitas yang dapat diandalkan, dan varietas, spesifikasi, serta bobot pengirimannya sangat sesuai dengan standar.

Keunggulan Daxun

Quality is belief, and integrity is a business card. Daxun pioneered the concept of “performance excellence management” and implemented the “PDCA+Lean” management model. The company’s business card says “Daxun = assured quality”. Daxun Stainless Steel achieves full traceability of each steel plate from the ERP system, including variety, specification, and origin, and advocates and encourages industry anti-counterfeiting. Daxun Stainless Steel relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strict monitoring during sales, and provides worry-free service guarantees after sales.

904L Stainless Steel coil Packaging

Daxun Alloy memastikan kualitas kemasan terbaik karena memainkan peran penting dalam pengiriman internasional di mana barang melewati berbagai saluran untuk mencapai tujuan akhir, jadi kami memberikan perhatian khusus pada pengemasan. Kami mengemas barang-barang kami dengan berbagai cara tergantung pada produknya. Kami mengemas produk kami dengan berbagai cara seperti:

- Kotak dan peti

- Kecilkan bungkus

- Palet kayu

- Kotak kayu

Kualitas, pengiriman, inspeksi

- Daxun juga melakukan beberapa tes jaminan kualitas. Pengujian ini meliputi uji perataan, uji lubang dan ketahanan, uji mekanis, uji kekerasan, identifikasi positif material, uji ekspansi, dll. Semua pengujian ini memastikan bahwa bahan tersebut cocok untuk aplikasi yang dibutuhkan.

- Selama proses produksi, kami mengukur diameter, ketebalan, dan permukaan produk. Waktu pengiriman standar kami adalah 7-15 hari, kecuali untuk beberapa produk ukuran khusus, waktu pengiriman kami akan bertambah menjadi 20 hari.

Waktu pengiriman kami benar-benar sesuai dengan kontrak. - Mendukung agen pihak ketiga pelanggan untuk pergi ke pabrik untuk pemeriksaan

- Mendukung sampel gratis kepada pelanggan untuk pengujian

- Mendukung inspeksi pabrik di tempat atau video

904L Stainless Steel coil Ordering Information

Pesanan pembelian harus mencakup jumlah, kelas, jenis atau kategori, referensi API5L, ketebalan, lebar, panjang, dan lampiran yang berlaku atau persyaratan tambahan yang terkait dengan komposisi kimia, sifat mekanik, perlakuan panas, pengujian tambahan, proses pembuatan, pelapisan permukaan, atau hasil akhir. Hubungi Daxun sekarang, kami akan membalas email Anda sesegera mungkin.

Dukungan Teknis

Jika Anda memerlukan bantuan teknis tambahan, ahli metalurgi dan staf kami yang berpengetahuan luas akan dengan senang hati membantu. Selain itu, Daxun memiliki laboratorium pengujian bersertifikat-yang pertama dalam industri inventaris multi-logam dan plastik. Ini, menurut pendapat kami, menunjukkan dedikasi kami yang tak tergoyahkan terhadap kualitas dan filosofi kami sebagai pemasok layanan penuh.

904L Stainless Steel Coil Features

Daxun Alloy Biarkan merek Anda meningkat dengan cepat

- Galeri

- Seri Produk

- Peralatan Utama

| Kelas | Jenis | Ketebalan | Permukaan |

| Austenitik | 304/304H/304L/304J1 | 0,25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0,3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferit | 430 | 0.4-3.0mm | 2B/BA/NO.4/8K/SB/HL |

| Ferit Ultra Murni | 443 | 0.4-2.0mm | 2B |

| 436L/439/444/441 | 0.5-3.0mm | 2B 、 2D | |

| 409L | 0,4-2,5 mm | 2B 、 2D | |

| Baja Austenitik Super | N08904 | 0,6-50mm | SWE / JPN / CHN |

| S31254 | 0,5-50mm | SWE / JPN / CHN | |

| N08926 | 0,5-50mm | SWE / JPN / CHN | |

| N08367 | 0,5-50mm | SWE / JPN / CHN | |

| Paduan Dasar Nikel | N08031 | 1.0-50mm | AS / JPN / GER |

| N08810 / N08800 | 0,8-50mm | AS / JPN / CHN | |

| N08028 | 1.0-20mm | AS / JERMAN / JPN | |

| N08020 | 1.0-20mm | AS / JERMAN / JPN | |

| N08825 | 0,8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50mm | AS / JERMAN / JPN | |

| N06022 | 1.0-50mm | AS / JERMAN / JPN | |

| N06625 | 0,8-20mm | AS / GER / CHN | |

| N04400 | 1.0-20mm | AS / JERMAN / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20mm | AS / JPN | |

| Titanium | TA1/Gr1 | 0,5-50mm | JPN / CHN |

| TA2/Gr2 | 0,5-50mm | JPN / CHN | |

| Bahan Pengelasan | ERNiCrMo-13 | 1.2 、 2.4mm | GER |

| ERNiCrMo-3 | 2.4mm | GER | |

| ERNiCrMo-4 | 2.4mm | AS |

| Entitas Anak | Peralatan Utama | Jumlah | Kapasitas Tahunan |

| Perusahaan baja tahan karat Daxun (JiangSu) | Mesin Penggorok | 1 | Decorative coil:60,000 tons |

| Mesin Pemotong | 1 | ||

| No.4 And Hairline coil To coil Polishing Machine | 1 | ||

| No.4 / Mesin Pemoles Coil To Coil | 1 | ||

| 8K/Super Mirror coil To coil Polishing Machines | 2 | ||

| 8K / Super Mirror Coil Untuk Mesin Poles Coil | 3 | ||

| Mesin Pelapis Warna PVD | 4 | ||

| Mesin Pelapis Kimia Cair | 2 | ||

| Mesin Cetak Anti Jari | 2 | ||

| Mesin Pilih dan Tempatkan Otomatis | 16 | ||

| Plate Washing Machine | 1 | ||

| Perusahaan baja tahan karat Daxun (Shanghai) | Mesin Penggulung Dingin | 3 | Kumparan 2B: 100.000 ton |

| Garis Anil & Pengawetan | 2 | Lembaran Dekoratif; 30.000 ton | |

| Mesin Penggorok | 1 | ||

| Mesin Potong Memanjang | 1 | ||

| Mesin Poles No.4 / HL (Lembar ke Lembar) | 3 | ||

| Mesin Pemoles 8K (Lembar ke Lembar) | 13 | ||

| Mesin Pelapis Titanium PVD | 4 | ||

| Mesin Pelapis Kimia Cair | 1 | ||

| Perusahaan baja tahan karat Daxun (Shandong) | Mesin Penggulung Dingin | 3 | Kumparan 2B & BA: 220.000 ton |

| Jalur Anil & Pengawetan (2B & BA) | 2 | Lembar Dekoratif: 60.000 ton | |

| Pengungkit Ketegangan & Skin Pass | 1 | ||

| Mesin Penggorok | 1 | ||

| Mesin Potong Memanjang | 1 | ||

| Mesin Poles No.4 / HL (Lembar ke Lembar) | 1 | ||

| Mesin Pemoles 8K (Lembar ke Lembar) | 11 | ||

| Mesin Pelapis Tembaga Otomatis | 1 | ||

| Mesin Cetak Digital | 1 | ||

| Mesin Pelapis Titanium PVD | 3 | ||

| Mesin Pelapis Kimia Cair | 1 | ||

| Mesin Anti Jari | 1 | ||

| Perusahaan baja tahan karat Daxun (Sichuan) | Mesin Penggorok | 1 | Kumparan 2B & BA: 180.000 ton |

| Mesin Pemotong | 1 | Lembar Dekoratif: 50.000 ton | |

| No.4 Dan Mesin Pemoles Lembar Ke Lembar Rambut | 1 | ||

| No.4 / Mesin Pemoles Coil To Coil | 1 | ||

| 8K / Super Mirror Sheet To Sheet Polishing Machines | 1 | ||

| 8K / Super Mirror Coil Untuk Mesin Poles Coil | 1 | ||

| Mesin Pelapis Warna PVD | 1 | ||

| Mesin Pelapis Kimia Cair | 1 | ||

| Mesin Cetak Anti Jari | 1 |

SS 904L Surface Types of Stainless Steel Coils (6)

Informasi yang tersedia untuk referensi dan diunduh

Daxun adalah produsen kumparan baja tahan karat yang dapat dipercaya

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless steels are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the stainless steel plates have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

Proyek dan produk hot case terbaru

Produk Terkait (10)

Silakan isi formulir di halaman “Hubungi Kami”, atau hubungi manajer penjualan kami di “+86 13382898899”, kami akan menghubungi Anda sesegera mungkin. WhatsApp kami sedang online, dan email ([email protected]) akan diperiksa dalam waktu 6 jam. Setiap pertanyaan atau pesan akan segera ditanggapi. Selain itu, kami berbagi informasi pasar dengan pelanggan kami setiap minggu

Sampel dapat diberikan secara gratis, tetapi ongkos kirim ditanggung oleh pelanggan, dan akan dikembalikan setelah kerja sama.

Kami telah mengekspor ke lebih dari 42 negara, seperti Kanada, Chili, Kuwait, Jerman, Korea Selatan, Arab Saudi, Singapura, dll.

MOQ kami adalah 1 ton untuk lembaran baja tahan karat.

Kami memiliki organisasi yang lengkap mulai dari pembelian bahan baku hingga pemrosesan dan pengaturan pengiriman. Di seluruh rantai, orang dokumenter iklan QC akan mencari dan memeriksanya dengan persyaratan yang tepat, inspeksi pihak ketiga disambut baik.

Pesanan percobaan dapat dikirim dalam waktu satu minggu. Untuk pesanan reguler, kira-kira membutuhkan waktu dua minggu.