Daxun is a 316/316L stainless steel coil China supplier

Sebagai pemasok dan eksportir kumparan baja tahan karat terkemuka di Tiongkok, Daxun memasok kumparan baja tahan karat ke seluruh dunia.

- Coil grade: S31600-S31603

- Coil features: corrosion resistant, acid and alkali resistant,

- Coil thickness: 0.4 mm to 12.00 mm

- Coil width: 1000 mm, 1250 mm, 1500 mm and 2000 mm.

- Coil surface: 2B, BA, matte, polished, 8k mirror.

Jika perlu, kumparan baja tahan karat akan dilengkapi dengan lapisan pelindung untuk melindungi permukaan logam dari kerusakan yang tidak perlu.

Global leader in stainless steel Coil fabrication services

Shop Daxun’s extensive range of SS 316L Stainless Steel Coil, AISI 316 Coil, SUS 316L Coil, 2B Surface Treatment 316 Stainless Steel Coil, BA Surface Treatment 316L Stainless Steel Coil, 2b Surface Treatment 316L Grade Stainless Steel Coil, ASTM A240 316 BA Stainless Steel Coil, Astm 316 Stainless Steel Coil, SS 316L Cold Rolled Stainless Steel Coil, SS 316 Coil Manufacturers.Daxun is well-known as a manufacturer, trader, and supplier of 316/316L Stainless Steel Coils. The Steel Coils we offer are precisely constructed and meet international quality requirements. Daxun is an ISO 9001:2008 certified firm that is a major supplier and exporter of ASTM A240 316 /316L stainless steel coils. 316/316L Stainless Steel Coils can be cut to your requirements and include a complete set of Mill Test Reports. Custom lengths and widths are available up to 2000 mm. Exporting is our specialty! We can source several hard-to-find grades and/or non-standard sizes to meet our clients’ specific requirements. With our extensive experience in processing Steel Coil goods, we can cut all ASTM SS 316 Steel Coils to the needed sizes.

Type 316/316L is a chromium-nickel austenitic stainless steel that contains molybdenum. The inclusion of molybdenum improves the corrosion resistance of 316/316L in halide conditions and reducing acids like sulfuric and phosphoric acids. Type 316L can be dual certified as 316 if the composition meets the lower carbon limit of 316L and the slightly higher strength level of 316. Type 316L should be used for welding applications because the low carbon version eliminates chromium carbide precipitation and improves corrosion resistance in the welded condition.

Type 316/316L is resistant to both air corrosion and moderately oxidizing conditions. In addition, it is resistant to marine atmospheric corrosion and has high intergranular corrosion resistance when welded. Type 316/316L provides high strength and toughness at cryogenic temperatures. Type 316/316L is nonmagnetic when annealed, however it can become somewhat magnetic after extreme cold working. Type 316L stainless steel is an ultra-low carbon variant of Type 316 that reduces hazardous carbide deposition in the heat-affected zone during welding.

Data

- Parameter

- Elemen

- Sifat Mekanis

- SIFAT FISIK

- Semua setara

- 304 coil stock

| SS 316 / 316L Stainless Steel Coil Specification | ASTM A240 / ASME SA240 |

| SS 316 / 316L Stainless Steel Coil Manufacturing Process | Hot Rolled (HR) / Cold Rolled (CR) |

| SS 316 / 316L Stainless Steel Coil Grades | 202 / SS 316 / 316L / SS 316 / 316LL / SS 316 / 316LH / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. |

| UNS No. – UNS SSS 316 / 316L00, UNS SSS 316 / 316L03, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| EN No. – 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| SS 316 / 316L Stainless Steel Coil Thickness | 0.6 MM TO 80 MM THICKNESS |

| SS 316 / 316L Stainless Steel Coil Width | 1250 MM / 1500 MM / 2000 MM / 04 Feet / 05 Feet and Custom Cut Width as Per Requirement |

| SS 316 / 316L Stainless Steel Coil Length | 2400 MM / 2420 MM / 6000 MM / 08 Feet / 10 Feet / Coil Cut and Custom Cut Length as Per Requirement |

| SS 316 / 316L Stainless Steel Coil Surface Finish | 2B, 2D, BA, MATT, MATT PVC, No.4, No.5, SB, HR, No.8, Mirror, Hairline, Brush, Textured, Oil base wet Polished, Both sides Polished available. |

| SS 316 / 316L Stainless Steel Coil Coating | PVC coating Normal / Laser, Film: 100 micrometer, Color: black/white. |

| SS 316 / 316L Stainless Steel Coil Other Testing | NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, etc. |

| SS 316 / 316L Stainless Steel CoilValue Added Services | Gas Cutting / CNC Plasma Cutting / Profiling / Rolling / Bending / coil Metal Fabrication / Drill / Punch / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| SS 316 / 316L Stainless Steel Coil Packaging | Loose / Carrate / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps |

| SS 316 / 316L Stainless Steel Coil Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| SS 316 / 316L Stainless Steel Coil Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC |

| Produsen | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, VDM, Nippon Metal, Outokumpu, Qingshan, Delong. |

| Pelabuhan Pengiriman | Pelabuhan Shanghai / Ningbo / Tianjin / Qindao |

| CHEMICAL COMPOSITION: ASTM A240, A666 | ||

| Elemen | Type 316 | Type 316L |

| Karbon | 0,08 maks. | 0,030 maks. |

| Mangan | 2.00 max. | 2.00 max. |

| Belerang | 0,030 maks. | 0,030 maks. |

| Fosfor | 0.045 max. | 0.045 max. |

| Silikon | 0.75 max. | 0.75 max. |

| Kromium | 16.0 – 18.0 | 16.0 – 18.0 |

| Nikel | 10.00 – 14.00 | 10.00 – 14.00 |

| Molybdenum | 2.00 – 3.00 | 2.00 – 3.00 |

| Nitrogen | 0,10 maks. | 0,10 maks. |

| Jenis | Kekuatan Hasil 0,2% offset (KSI) | Kekuatan Tarik (KSI) | % Elongation (2″ Gauge length) |

| 316 | 30 min. | 75 menit. | 40 min. |

| 316L | 25 menit. | 70 min. | 40 min. |

| Kepadatan (lb./ in^2) @ RT | 0.29 | |

| Modulus Elastisitas dalam Ketegangan (psi x 10^6) | 28 | |

| Panas Spesifik (BTU/o F/lb.) | 32 hingga 212 oF | 0.12 |

| Konduktivitas Termal (BTU/jam/ft^2/ft) | 212oF | 9.4 |

| 932oF | 12.4 | |

| Koefisien Ekspansi Termal Rata-rata (dalam. x 10^-6 per o F) | 32 hingga 212oF | 8.9 |

| 32 hingga 600oF | 9 | |

| 32 hingga 1.000oF | 9.7 | |

| 32 to 1,200oF | 10.3 | |

| Resistivitas Listrik (mikro ohm - cm) | pada suhu 70oF | 29.4 |

| Rentang Titik Leleh (oF) | 2500 – 2550 |

| Kelas | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Nama | ||||

| 316l | S31603 | 316S11 | - | 1.4404 | X2CrNiMo17-12-2 | 2348 | SUS 316L |

| • Tisco Stainless Steel 316l coil | • Best selling 4’x8′ mirror finished ss 316l coil |

| • SS 316l Perforated coil | • Decorative hairline inox cold rolled ss 316l coil |

| • Stainless Steel 316l UNS S31635 coil | • Hair Line Finish SS 316l coil |

| • A 240 Chequered 316l coil | • Laser cutting ss 316l coil |

| • Aperam Stainless Steel 316l coil | • Tisco Supplier 3mm Thickness Stainless Steel 316l coil |

| • Stainless Steel 316l coil | • Decorative Stainless Steel 316l coil |

| • A 240 316l coil | • Scotch Brite SS 316l coil |

| • SS 316l Embossed coil | • Baosteel Stainless Steel 316l coil |

| • Outokumpu SS 316l coil | • Stainless Steel Cladding 316l coil |

| • SA 240 316l stainless steel coil | • Black SS 316l coil 4mm Thick |

| • Bright Hammered Pattern Decorative SS 316l coil | • Bright-pickled Stainless Steel 316l coil |

| • Jindal Stainless Steel 316l coil | • Cold rolled, heat treated 316l coil |

| • SS DIN 1.4404 coil | • 3mm Cold Rolled AISI SS 316l coil |

| • ThyssenKrupp Stainless Steel 316l coil | • Mill Supply SS 316l coil |

| • ASTM A240 Stainless Steel 316l coil | • Grade Prime SS 316l coil |

| • Surface Polishing SS 316l coil | • Carpenter Custom 450 Stainless Steel 316l coil |

| • 316l Stainless Steel HR coil | • Cut to Size Stainless Steel 316l coil |

| • 316l Stainless Steel Chequered coil | • Non Magnetic Polishing Stainless Steel 316l coil |

| • 316l Stainless Steel Golden Laser Pattern coil | • ASME SA240 316l coil |

| • Super thin-Mirror surface BA ss 316l coil | • Grade 316l Stainless Steel Finish coil |

| • Super Austenitic SS 316l coil | • 316l Stainless Steel Blank coil |

| • ASTM A240 316l coil | • 316l Stainless Steel Perforated coil |

| • JMSS cold rolled ss 316l coil | • Embossed ss 316l coil |

| • Cold Rolled No.1 Finish SS 316l coil | • Cheap cold rolled ss 316l coil with best price |

| • SEW 400 Stainless Steel 316l coil | • Brush finish ss 316l coil price list |

| • Hot Rolled Stainless Steel 316l coil | • SS URANUS B6 316l coil |

| • Sales Promotion SS 316l coil | • 2B SUS SS 316l coil |

| • Cr Stainless Steel 316l coil | • Food Grade Stainless Steel 316l coil |

| • SS 316l Mill Test Certificate coil | • No. 4 PVC Coated SS 316l coil |

| • ASTM A240 316l coil | • SS 316l coil Blasted Tin-Gold Rose |

| • Cold rolled, bright annealed 316l coil | • 2mm ASTM SS 316l coil |

| • Ground Stainless Steel 316l coil | • Stainless Steel Corrugated 316l coil |

| • Hot Selling AISI SS 316l coil | • ASTM B625 316l coil |

| • SS 316l Rose Golden coil | • Brushed or dull polished Stainless Steel 316l coil |

| • Surface coated Stainless Steel 316l coil | • Cold rolled, heat treated, pickled 316l coil |

| • Satin finish Stainless Steel 316l coil | • 10K Mirror Finish Surface SS 316l coil |

| • AISI stainless steel 316l armor coil | • Gold Etched SS 316l coil |

| • Satin finish Stainless Steel 316l coil | • 18 Gauge SS 316l coil |

| • Mirror Finish SS 316l coil | • Patterned Stainless Steel 316l coil |

| • SS 316l coil Gold Brush Finish | • #4 Finish Stainless Steel 316l coil |

| • 316l Stainless Steel CR coil | • Patterned Stainless Steel 316l coil |

| • 316l Stainless Steel 2B coil | • Passenger Elevator Cabin SS 316l coil |

| • 316l Stainless Steel B. Q. Profile coil | • Dimensional Stainless Steel Grade 316l coil |

Pilih Daxun dan buat pelanggan Anda puas.

Quick response 316 Stainless Steel coil

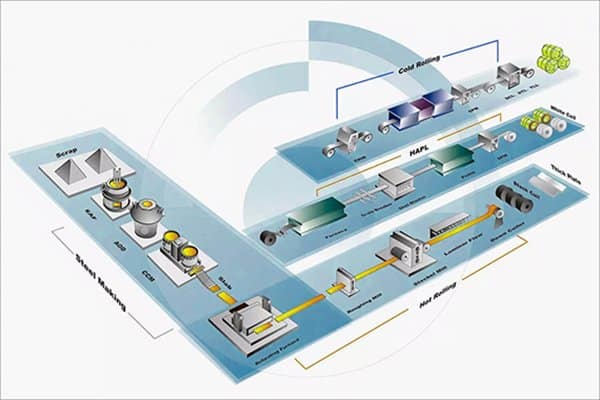

Kami menyediakan pengiriman produk baja tahan karat yang tepat waktu dan cepat untuk pelanggan dengan kebutuhan mendesak. Di balik kecepatan tersebut adalah dukungan sistem dari aliran informasi hingga logistik dan aliran modal. Misalnya, dalam hal aliran informasi, data pesanan Daxun didorong ke sistem logistik secara real time, dan data tersebut terhubung dengan mulus; dalam hal logistik, pusat pemrosesan dekat dengan jalan raya dan sungai dan laut, dengan penjadwalan yang wajar, respons yang cepat, hubungan penyimpanan dan transportasi, dan pemuatan yang efisien, memastikan bahwa tugas diselesaikan sesuai jadwal. bahan baja tahan karat Daxun memiliki kualitas yang dapat diandalkan, dan varietas, spesifikasi, serta bobot pengirimannya sangat sesuai dengan standar.

Keunggulan Daxun

Quality is belief, and integrity is a business card. Daxun pioneered the concept of “performance excellence management” and implemented the “PDCA+Lean” management model. The company’s business card says “Daxun = assured quality”. Daxun Stainless Steel achieves full traceability of each steel coil from the ERP system, including variety, specification, and origin, and advocates and encourages industry anti-counterfeiting. Daxun Stainless Steel relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strict monitoring during sales, and provides worry-free service guarantees after sales.

Stainless steel coil packaging

Daxun Alloy memastikan kualitas kemasan terbaik karena memainkan peran penting dalam pengiriman internasional di mana barang melewati berbagai saluran untuk mencapai tujuan akhir, jadi kami memberikan perhatian khusus pada pengemasan. Kami mengemas barang-barang kami dengan berbagai cara tergantung pada produknya. Kami mengemas produk kami dengan berbagai cara seperti:

- Kotak dan peti

- Kecilkan bungkus

- Palet kayu

- Kotak kayu

Kualitas, pengiriman, inspeksi

- Daxun juga melakukan beberapa tes jaminan kualitas. Pengujian ini meliputi uji perataan, uji lubang dan ketahanan, uji mekanis, uji kekerasan, identifikasi positif material, uji ekspansi, dll. Semua pengujian ini memastikan bahwa bahan tersebut cocok untuk aplikasi yang dibutuhkan.

- Selama proses produksi, kami mengukur diameter, ketebalan, dan permukaan produk. Waktu pengiriman standar kami adalah 7-15 hari, kecuali untuk beberapa produk ukuran khusus, waktu pengiriman kami akan bertambah menjadi 20 hari.

Waktu pengiriman kami benar-benar sesuai dengan kontrak. - Mendukung agen pihak ketiga pelanggan untuk pergi ke pabrik untuk pemeriksaan

- Mendukung sampel gratis kepada pelanggan untuk pengujian

- Mendukung inspeksi pabrik di tempat atau video

316 Stainless Steel coil Ordering Information

Pesanan pembelian harus mencakup jumlah, kelas, jenis atau kategori, referensi API5L, ketebalan, lebar, panjang, dan lampiran yang berlaku atau persyaratan tambahan yang terkait dengan komposisi kimia, sifat mekanik, perlakuan panas, pengujian tambahan, proses pembuatan, pelapisan permukaan, atau hasil akhir. Hubungi Daxun sekarang, kami akan membalas email Anda sesegera mungkin.

Dukungan Teknis

Jika Anda memerlukan bantuan teknis tambahan, ahli metalurgi dan staf kami yang berpengetahuan luas akan dengan senang hati membantu. Selain itu, Daxun memiliki laboratorium pengujian bersertifikat-yang pertama dalam industri inventaris multi-logam dan plastik. Ini, menurut pendapat kami, menunjukkan dedikasi kami yang tak tergoyahkan terhadap kualitas dan filosofi kami sebagai pemasok layanan penuh.

SS 316/316L Stainless Steel Coil Features

Daxun Alloy Biarkan merek Anda meningkat dengan cepat

- Galeri

- Seri Produk

- Peralatan Utama

| Kelas | Jenis | Ketebalan | Permukaan |

| Austenitik | 304/304H/304L/304J1 | 0,25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0,3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferit | 430 | 0.4-3.0mm | 2B/BA/NO.4/8K/SB/HL |

| Ferit Ultra Murni | 443 | 0.4-2.0mm | 2B |

| 436L/439/444/441 | 0.5-3.0mm | 2B 、 2D | |

| 409L | 0,4-2,5 mm | 2B 、 2D | |

| Baja Austenitik Super | N08904 | 0,6-50mm | SWE / JPN / CHN |

| S31254 | 0,5-50mm | SWE / JPN / CHN | |

| N08926 | 0,5-50mm | SWE / JPN / CHN | |

| N08367 | 0,5-50mm | SWE / JPN / CHN | |

| Paduan Dasar Nikel | N08031 | 1.0-50mm | AS / JPN / GER |

| N08810 / N08800 | 0,8-50mm | AS / JPN / CHN | |

| N08028 | 1.0-20mm | AS / JERMAN / JPN | |

| N08020 | 1.0-20mm | AS / JERMAN / JPN | |

| N08825 | 0,8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50mm | AS / JERMAN / JPN | |

| N06022 | 1.0-50mm | AS / JERMAN / JPN | |

| N06625 | 0,8-20mm | AS / GER / CHN | |

| N04400 | 1.0-20mm | AS / JERMAN / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20mm | AS / JPN | |

| Titanium | TA1/Gr1 | 0,5-50mm | JPN / CHN |

| TA2/Gr2 | 0,5-50mm | JPN / CHN | |

| Bahan Pengelasan | ERNiCrMo-13 | 1.2 、 2.4mm | GER |

| ERNiCrMo-3 | 2.4mm | GER | |

| ERNiCrMo-4 | 2.4mm | AS |

| Entitas Anak | Peralatan Utama | Jumlah | Kapasitas Tahunan |

| Perusahaan baja tahan karat Daxun (JiangSu) | Mesin Penggorok | 1 | Lembar Dekoratif: 60.000 ton |

| Mesin Pemotong | 1 | ||

| No.4 Dan Mesin Pemoles Lembar Ke Lembar Rambut | 1 | ||

| No.4 / Mesin Pemoles Coil To Coil | 1 | ||

| 8K / Super Mirror Sheet To Sheet Polishing Machines | 2 | ||

| 8K / Super Mirror Coil Untuk Mesin Poles Coil | 3 | ||

| Mesin Pelapis Warna PVD | 4 | ||

| Mesin Pelapis Kimia Cair | 2 | ||

| Mesin Cetak Anti Jari | 2 | ||

| Mesin Pilih dan Tempatkan Otomatis | 16 | ||

| coil Washing Machine | 1 | ||

| Perusahaan baja tahan karat Daxun (Shanghai) | Mesin Penggulung Dingin | 3 | Kumparan 2B: 100.000 ton |

| Garis Anil & Pengawetan | 2 | Lembaran Dekoratif; 30.000 ton | |

| Mesin Penggorok | 1 | ||

| Mesin Potong Memanjang | 1 | ||

| Mesin Poles No.4 / HL (Lembar ke Lembar) | 3 | ||

| Mesin Pemoles 8K (Lembar ke Lembar) | 13 | ||

| Mesin Pelapis Titanium PVD | 4 | ||

| Mesin Pelapis Kimia Cair | 1 | ||

| Perusahaan baja tahan karat Daxun (Shandong) | Mesin Penggulung Dingin | 3 | Kumparan 2B & BA: 220.000 ton |

| Jalur Anil & Pengawetan (2B & BA) | 2 | Lembar Dekoratif: 60.000 ton | |

| Pengungkit Ketegangan & Skin Pass | 1 | ||

| Mesin Penggorok | 1 | ||

| Mesin Potong Memanjang | 1 | ||

| Mesin Poles No.4 / HL (Lembar ke Lembar) | 1 | ||

| Mesin Pemoles 8K (Lembar ke Lembar) | 11 | ||

| Mesin Pelapis Tembaga Otomatis | 1 | ||

| Mesin Cetak Digital | 1 | ||

| Mesin Pelapis Titanium PVD | 3 | ||

| Mesin Pelapis Kimia Cair | 1 | ||

| Mesin Anti Jari | 1 | ||

| Perusahaan baja tahan karat Daxun (Sichuan) | Mesin Penggorok | 1 | Kumparan 2B & BA: 180.000 ton |

| Mesin Pemotong | 1 | Lembar Dekoratif: 50.000 ton | |

| No.4 Dan Mesin Pemoles Lembar Ke Lembar Rambut | 1 | ||

| No.4 / Mesin Pemoles Coil To Coil | 1 | ||

| 8K / Super Mirror Sheet To Sheet Polishing Machines | 1 | ||

| 8K / Super Mirror Coil Untuk Mesin Poles Coil | 1 | ||

| Mesin Pelapis Warna PVD | 1 | ||

| Mesin Pelapis Kimia Cair | 1 | ||

| Mesin Cetak Anti Jari | 1 |

SS 316/316L Surface Types of Stainless Steel Coils (6)

Informasi yang tersedia untuk referensi dan diunduh

Daxun adalah produsen kumparan baja tahan karat yang dapat dipercaya

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless steels are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the stainless steel coils have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

Proyek dan produk hot case terbaru

Produk Terkait (10)

Pemasok kumparan baja tahan karat terkemuka di Cina

Daxun telah terlibat dalam bisnis internasional selama lebih dari sepuluh tahun. Pada tahun 2023, pendapatan ekspornya melebihi US $ $100 juta, dan volume ekspornya berada di antara produsen baja nirkarat teratas di Tiongkok. Daxun terus meningkatkan keterampilan layanannya. Untuk melayani pasar global, kami telah mendirikan tiga fasilitas layanan ekspor di China dan bekerja sama dengan perusahaan teknik, pabrik baja, dan perusahaan perdagangan internasional. Daxun menyediakan layanan rantai baja tahan karat dan telah menjalin hubungan kerja sama jangka panjang dengan puluhan pabrik baja terkenal di seluruh dunia. Persediaannya mencakup 50.000 ton gulungan baja tahan karat konvensional dan 20.000 ton baja dupleks, paduan berbasis nikel, baja tahan panas, dan logam lainnya. Bahan baja tahan karat Daxun memiliki kualitas yang konsisten. Jenis, spesifikasi, dan bobot pengiriman secara ketat mematuhi standar.

What is 316L stainless steel coil?

- 316L stainless steel coil is an austenitic stainless steel that has excellent corrosion resistance and strength. It shares mechanical qualities with 304L coil but is more resistant to pitting and crevice corrosion.

- It has a lower melting temperature than 304L coil, making it better suited to applications where the material is subjected to greater temperatures before being formed into a component, such as welding or brazing.

- 316L stainless steel coils can be made via rolling, drawing, or forging. It is utilized in a variety of applications, including marine, chemical, and food processing equipment.

What applications can 316L stainless steel coils be used in?

- 316L stainless steel coils are commonly utilized in construction, transportation, and other industries. It is a common type of stainless steel with excellent corrosion resistance to many hostile substances, particularly chloride ions.

- 316L stainless steel coils offer outstanding mechanical qualities and can withstand high temperatures. It is also ideal for welding, cutting, and bending.

- 316L stainless steel coils are widely used in a variety of sectors.

- Chemical production industries frequently employ 316L stainless steel tubes to convey corrosive chemicals. It has excellent corrosion resistance to acids, alkalis, and a variety of other chemical compounds.

- Construction industry: We frequently utilize 316L stainless steel pipes to convey water or sewage from one locati0n to another. The material is strong enough for long-term use.

- Food industry: We typically use 316L stainless steel pipes as boiling tubes because they can withstand high temperatures without deforming during the cooking process, whereas other materials are readily destroyed by heat.

Features of 316L Stainless Steel Coils

Ketahanan Korosi

316L stainless steel coil has superior corrosion resistance than 304 stainless steel coil and is suitable for use in the pulp and paper industries. In addition, 316L stainless steel coil is resistant to saltwater erosion and the corrosive industrial climate.

Tahan panas

In intermittent applications below 1600 degrees, 316 stainless steel coil has excellent oxidation resistance.

316L stainless steel coil is more resistant to carbide precipitation than standard 316 grade stainless steel coils.

Ketahanan Korosi

- 316 stainless steel is highly corrosion resistant in a variety of situations. It performs well in air circumstances, can withstand most settings, and is frequently employed in marine regions or areas with high industrial pollution. The best appearance is maintained when the design allows for even rain washing of the surface, or when dirt deposits are occasionally rinsed off the steel.

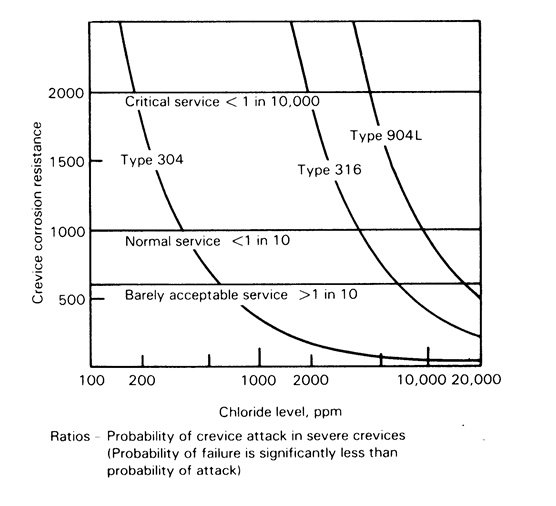

- Grade 316 has also provided great service in potable water. Pitting and crevice corrosion may occur in waters with higher chloride concentrations, with 2000 ppm recognized as the top limit. 316’s greater molybdenum concentration makes it substantially more corrosion resistant than 304.

- 316 stainless steel can be used with seawater as long as precautions are taken to prevent crevice corrosion from forming under sediments, precipitation, and biofouling, as well as in planned fissures.

- Grades 316 and 304 may experience stress corrosion cracking in chloride-containing solutions at temperatures over 60°C. Stress corrosion cracking should be considered for all corrosion services using corrosive liquids that may contain chlorine.

Toughness/Hardness

- Austenitic stainless steels are intrinsically robust, and 316 stainless steel is no exception, maintaining the ductile fracture mode and high absorbed energy in impact tests at cryogenic temperatures (-200°C).

- AS1210 specifies that grade 316 can be used in pressure vessels up to 800°C. The standard permits for higher design stresses in 316H at all temperatures.

High-temperature corrosion

- The commonly accepted maximum service temperatures for grade 316 (and grade 304) in air are 870°C for intermittent use and 925°C for continuous use.

- Cold Fabrication

Grade 316 is generally workable using typical coil metal working processes, with the limitation that it cannot be oxygen cut. Plasma cutting is commonplace. Grade 316 has exceptional deep drawing capabilities because to its strong austenite stability. - 316 is an easy austenitic stainless steel to forge at temperatures above 925°C.

Kemampuan mesin

- Grade 316 is generally straightforward to process, but more difficult than carbon steel. More power is needed to machine grade 316. Cutting speed should be reduced, feed rate increased, and tools and equipment heavier. The machinability of 316 is roughly 60% that of AISI B1112 resulphurized free cutting carbon steel. There is a free-machining variant of 316 available as a bar.

- Heat treatment involves annealing the solution at 1065-1120°C, followed by quick cooling to prevent chromium carbide precipitation. 316 cannot be toughened through heat treatment. Stress relief is rarely required due to 316’s strong ductility.

Kemampuan las

- Grade 316 stainless steel can be welded using most fusion procedures (GTAW / TIG, GMAW / MIG / MAG, MMAW / stick, SAW), with no need for preheat, postheat, or interpass temperature regulation. It is typically welded using filler metals of the same grade, 316 or 316L (or silicon-containing variants), which maintain corrosion resistance and strength. These grades are pre-qualified weld metals under AS1554.6:1994 for welding grade 316 to itself.

Apa saja permukaan kumparan baja tahan karat yang umum digunakan?

Permukaan akhir dari 201 kumparan baja tahan karat dapat bervariasi tergantung pada metode pemrosesan penggulungan dingin yang digunakan dan perawatan permukaan yang digunakan setelah penggulungan. Perawatan permukaan untuk kumparan baja tahan karat meliputi NO.1, 2B, 4, HL, 6, 8, BA, TR keras, penggulungan berat 2H cerah, dipoles cerah, dan perawatan permukaan lainnya:

- NO.1: Permukaan yang diperoleh setelah pengerolan panas, perlakuan panas dan pengawetan strip baja tahan karat. Ini digunakan untuk menghilangkan kerak oksida hitam yang terbentuk oleh pengawetan atau proses serupa selama pengerolan panas dan perlakuan panas. Ini menempati urutan pertama dalam perawatan permukaan. Permukaan No. 1 berwarna putih keperakan dan matte. Umumnya digunakan dalam industri tahan panas dan tahan korosi yang tidak membutuhkan kilap permukaan yang tinggi, seperti industri alkohol, industri kimia, wadah besar, dll.

- 2B: Tidak seperti permukaan 2D, permukaan 2B dihaluskan oleh roller ringan, dan permukaannya lebih cerah. Nilai Ra kekasaran permukaan yang diukur oleh peralatan berkisar antara 0,1 hingga 0,5μm, yang merupakan nilai tipikal untuk sebagian besar jenis pemrosesan. Permukaan strip baja tahan karat ini memiliki kemampuan beradaptasi terkuat dan cocok untuk industri seperti kimia, pembuatan kertas, perminyakan, medis, dan berbagai bidang seperti membangun dinding tirai.

- Permukaan keras TR: Baja tahan karat TR juga disebut baja keras. Kelas baja yang khas meliputi 304 dan 301, yang digunakan untuk barang-barang yang membutuhkan kekuatan dan kekerasan tinggi, seperti kendaraan kereta api, ban berjalan, pegas, dan mesin cuci. Idenya adalah menggunakan karakteristik pengerasan kerja baja tahan karat austenitik untuk meningkatkan kekuatan dan kekerasan gulungan baja melalui metode pengerjaan dingin seperti pengerolan. Untuk mengganti kerataan lembut permukaan dasar 2B, bahan keras digulung dengan lembut beberapa persen hingga puluhan persen, dan tidak ada anil yang dilakukan setelah penggulungan. Oleh karena itu, permukaan keras TR dari bahan keras adalah permukaan yang digulung setelah proses penggulungan dingin.

- Penggulungan ulang 2H yang cerah: Setelah operasi penggulungan, strip baja tahan karat akan dianil dengan cerah. Garis anil kontinu dapat digunakan untuk mendinginkan strip dengan cepat. Strip baja tahan karat bergerak di sepanjang garis dengan kecepatan 60-80m / menit. Setelah proses ini, permukaan akhir akan digulung kembali menjadi cerah 2H.

- No. 4: Permukaan No. 4 memiliki efek pemolesan yang baik dan lebih cerah dari No. 3. Hal ini juga dapat diperoleh dengan memoles kumparan baja tahan karat canai dingin dengan permukaan 2D atau 2B, lalu memoles permukaan yang diproses dengan sabuk pengamplasan dengan ukuran partikel 150-180#. Alat ini mengukur kekasaran permukaan (Ra) antara 0,2 dan 1,5μm. Permukaan No. 4 banyak digunakan di restoran dan peralatan memasak, peralatan medis, dekorasi arsitektur, wadah dan aplikasi lainnya.

- HL: Permukaan HL sering disebut sebagai hasil akhir garis rambut. Standar JIS Jepang menetapkan permukaan abrasif garis rambut kontinu yang diperoleh dengan memoles menggunakan sabuk abrasif 150-240#. Pembatasan di bawah standar GB3280 Cina tidak jelas. Permukaan akhir HL biasanya digunakan untuk dekorasi arsitektur, seperti lift, eskalator, dan dinding eksterior.

- No. 6: Permukaan No. 6 dipoles lebih lanjut berdasarkan No. 4 dengan sikat Tampico atau bahan abrasif grit W63 yang ditentukan dalam standar GB2477. Permukaannya memiliki kilau logam yang bagus, kelembutan, pantulan yang lemah, dan tidak ada pencitraan. Karena kinerjanya yang bagus, ini sangat cocok untuk dinding gorden, dekorasi rumbai, dan perlengkapan memasak.

- BA: BA adalah permukaan yang diberi perlakuan panas cerah setelah penggulungan dingin. Perlakuan panas terang adalah anil dalam atmosfer pelindung untuk memastikan bahwa permukaan tidak teroksidasi dan mempertahankan kilau permukaan canai dingin, dan kemudian dipoles dengan roller halus presisi tinggi untuk meningkatkan kecerahan permukaan. Instrumen mengevaluasi kekasaran permukaan menjadi 0,05-0,1μm, yang menunjukkan bahwa permukaannya dekat dengan permukaan cermin. Permukaan BA dapat digunakan dalam berbagai aplikasi, termasuk peralatan makanan, peralatan rumah tangga, peralatan medis, suku cadang otomotif, dan dekorasi.

- No. 8: Permukaan cermin, reflektifitas maksimum, tidak ada partikel abrasif. Industri pengolahan dalam baja tahan karat juga mengacu pada papan 8K. Bahan BA sering digunakan sebagai bahan baku untuk pemrosesan cermin. Itu hanya perlu dipoles. Permukaannya indah setelah pemrosesan cermin dan sering digunakan pada pintu masuk gedung dan dekorasi interior.

What is the standard sea packaging stainless steel coil?

- Kemasan laut standar ekspor:

Gulungan Kertas Tahan Air + Film PVC + Tali Pengikat + Pallet Kayu atau Kotak Kayu; - Kemasan yang disesuaikan dengan permintaan Anda (Logo atau konten lain dapat dicetak pada kemasan);

- Kemasan khusus lainnya akan dirancang sesuai permintaan pelanggan;

Mata ke dinding dan mata ke langit keduanya tersedia; - Dengan Ekspres Internasional: DHL/UPS/FEDEX/EMS dan jalur ekspres kami sendiri;

- Melalui udara, laut atau darat;

- Pelabuhan Pengiriman: Shanghai, Ningbo, Qingdao, Tianjin atau sebagai permintaan Anda.

Why choose Daxun’s stainless steel coils?

Reliable Stainless Steel Coils and Sheets Inventory Guarantee

- Have you ever been in a situation where you required a significant quantity of stainless steel coils right away, only to discover that the supplier was running low on stock? This condition may impair your workflow and plans.

- Our Advantages: With us, this situation will be a thing of the past. Our inventory is always ample, guaranteeing that even the largest orders are fulfilled quickly and in accordance with your business schedule.

Custom Stainless Steel Material Processing

- You may have experienced a circumstance in which bespoke processing is required, but locating the correct supplier to match your exact requirements might be difficult.

- Our Advantages: We have great processing capabilities to satisfy any of your specific needs. Whether it is size, stainless steel surface treatment, or other unique requirements, we offer expert one-stop service.

Competitive Stainless Steel Prices

- When looking for a stainless steel coil provider, price is typically a major factor. You may have to make a compromise with your chosen supplier due to excessive costs.

- Our Advantages: We keep pricing low by implementing excellent cost control and improved sourcing methods. This implies that by choosing us, you will not only receive high-quality products but also outstanding value for money.

Various Specifications of Stainless Steel Coils in Stock

- Finding stainless steel coils with exact specifications might be a challenge. It is critical to select a supplier who understands and serves these specific needs.

- Our Advantages: Our portfolio demonstrates versatility, with a wide choice of materials, thicknesses, and widths. We take pleasure in our ability to satisfy your project’s exact specifications.

Precision Stainless Steel Shearing Service.

- Precision shearing is required for the usage of stainless steel coils, but not all vendors offer this precise service.

- Our Advantages: Our shearing service is both professional and efficient, delivering precise cuts that fit your exact demands.

Hubungi pemasok kumparan baja tahan karat Anda

- Anda dapat dengan mudah memesan gulungan baja tahan karat dalam berbagai ukuran dan jumlah secara online.

Atau, tim penjualan kami yang ramah akan dengan senang hati menerima pesanan Anda. Cukup hubungi +86 13382898899 atau email Daxunhejin@gmail dan kami akan menghubungi Anda sesegera mungkin.

Silakan isi formulir di halaman “Hubungi Kami”, atau hubungi manajer penjualan kami di “+86 13382898899”, kami akan menghubungi Anda sesegera mungkin. WhatsApp kami sedang online, dan email ([email protected]) akan diperiksa dalam waktu 6 jam. Setiap pertanyaan atau pesan akan segera ditanggapi. Selain itu, kami berbagi informasi pasar dengan pelanggan kami setiap minggu

Sampel dapat diberikan secara gratis, tetapi ongkos kirim ditanggung oleh pelanggan, dan akan dikembalikan setelah kerja sama.

Kami telah mengekspor ke lebih dari 42 negara, seperti Kanada, Chili, Kuwait, Jerman, Korea Selatan, Arab Saudi, Singapura, dll.

Our MOQ is 1 ton for stainless steel coil.

Kami memiliki organisasi yang lengkap mulai dari pembelian bahan baku hingga pemrosesan dan pengaturan pengiriman. Di seluruh rantai, orang dokumenter iklan QC akan mencari dan memeriksanya dengan persyaratan yang tepat, inspeksi pihak ketiga disambut baik.

Pesanan percobaan dapat dikirim dalam waktu satu minggu. Untuk pesanan reguler, kira-kira membutuhkan waktu dua minggu.