CP Grade 4 Titanium Pipe Manufacturer

As a leading supplier of titanium and titanium alloy tubes in China, Daxun provides high-performance titanium tubes to the world.

- Titanium tube Grade:UNS R50700

- Titanium tube types:Seamless Ti tube, Ti welded tube, forged Ti tube

- Standards:ASTM B338

- Softest Ti,High ductility, Very corrosion resistant, good cold formability

————Daxun produces titanium tubes in China to meet the diverse and ——demanding needs of customers!

CP Grade 4 Titanium Pipe Manufacturer

Grade 4 titanium pipe is recognized as the strongest among commercially pure titanium grades, delivering exceptional mechanical performance combined with superior corrosion resistance. Its high tensile strength and excellent ductility allow it to endure demanding operational environments, making it an ideal solution for industries where reliability and durability are critical. Unlike lower grades, Grade 4 titanium pipe provides a higher strength-to-weight ratio without sacrificing formability, ensuring versatility in both fabrication and end-use applications.

The advantages of grade 4 titanium pipe

In industrial settings, Grade 4 titanium pipe is widely used in chemical processing, marine engineering, and aerospace sectors due to its outstanding resistance to aggressive media, including chlorides and acids. Its ability to withstand high pressure and extreme temperatures makes it suitable for critical fluid transport, heat exchangers, and hydraulic systems. Additionally, its biocompatibility extends its utility to medical applications where long-term structural integrity and resistance to bodily fluids are essential.

The technical advantages of Grade 4 titanium pipe are further highlighted by its low maintenance requirements and extended service life, even under cyclic loading and exposure to corrosive environments. This translates to reduced downtime and lifecycle costs for operators, reinforcing its value as a premium material choice. For projects demanding uncompromised performance and resilience, Grade 4 titanium pipe stands out as a benchmark in high-performance piping solutions.

Grade 4 titanium pipe is the strongest among commercially pure titanium grades, offering an impressive combination of high tensile strength, excellent ductility, and superior corrosion resistance. With a minimum yield strength of 480 MPa and ultimate tensile strength exceeding 550 MPa, it outperforms Grades 1-3 in load-bearing applications while maintaining the renowned resistance to chloride-induced pitting and crevice corrosion. Its chemical composition, primarily titanium with trace amounts of oxygen, iron, and carbon, contributes to its robustness and biocompatibility, making it suitable for both industrial and medical environments.

When compared to other materials, Grade 4 titanium pipe surpasses stainless steel in corrosion resistance and offers a better strength-to-weight ratio than many nickel-based alloys. Although its initial cost is higher, its extended service life, reduced maintenance, and reliability in harsh environments often result in lower lifecycle costs. For projects requiring uncompromised performance—such as offshore oil rigs, chemical reactors, or high-performance aerospace systems—Grade 4 titanium pipe represents the optimal choice.

Veri

- Kimyasal Bileşim

- Fiziksel Özellikler

- Mekanik Özellikler

| Element |

Maximum Content (%)

|

| Azot (N) | 0.05 |

| Carbon © | 0.08 |

| Hydrogen (H) | 0.015 |

| Demir (Fe) | 0.5 |

| Oxygen (O) | 0.4 |

| Titanium (Ti) | Denge |

| Mülkiyet | Değer |

| Yoğunluk |

4.51 g/cm³ (0.163 lb/in³)

|

| Erime Noktası |

1660°C (3020°F)

|

| Termal İletkenlik |

~16.4 W/m·K (114 BTU·in/hr·ft²·°F)

|

| Elektriksel Dirençlilik |

5.4 × 10⁻⁵ Ω·cm

|

| Coefficient of Thermal Expansion (20–100°C) | 8.6 µm/m·°C |

| Mülkiyet | Değer |

| Tensile Strength, Ultimate |

550 MPa (80,000 psi) min

|

| Tensile Strength, Yield |

480 MPa (70,000 psi) min

|

| Kopma Uzaması | 15–25% |

| Elastisite Modülü |

~104 GPa (15,100 ksi)

|

| Sertlik, Vickers | ~280 HV |

Projenizin yükselmesine yardımcı olmak için Daxun'u seçin.

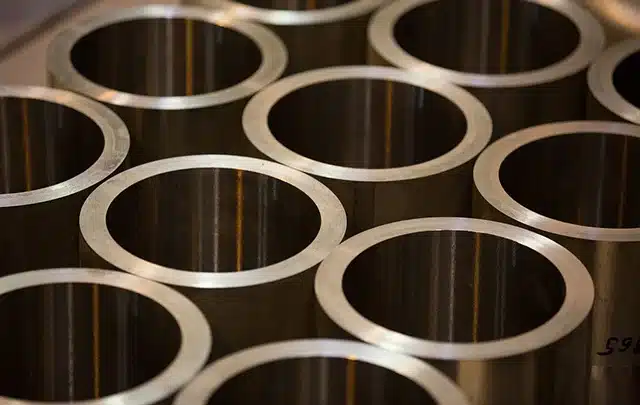

Advanced Production:Titanium seamless pipe

- CP Grade 4 titanium pipes are typically manufactured according to major international standards such as ASTM B338, ASME SB338, ASTM B861 (for seamless pipes), and ASTM B862 (for welded pipes). They are readily available in a variety of sizes, with diameters ranging from 3.35mm to 152mm and wall thicknesses from 0.020″ to 0.220″, accommodating diverse project requirements.

CP Grade 4 Titanium Tube Features

- Balanced Properties: As a commercially pure titanium, it offers a great balance of moderate strength and excellent corrosion resistance, stronger than Grade 1 and 2.

- Superior Corrosion Resistance: Exceptionally resistant to chloride and seawater environments, making it ideal for marine and chemical processing applications.

- Good Fabricability: It is well-suited for forming, welding, and machining, allowing for easy manufacturing of complex components.

- Biocompatible: Safe for use in medical implants and food processing equipment due to its non-toxic and hypoallergenic nature.

- Cost-Effective: Provides better performance than lower grades without the high cost of titanium alloys, offering a practical solution for many industrial uses.

Advanced Production: Titanium Welded Tube

Titanium Welded Tube: Diameter ranges from 6.0mm to 1219mm, wall thickness ranges from 0.3mm to 30mm (depending on diameter), length up to 25000mm, made from Gr1 titanium tube. Welded tubes are made from flat rolled billets (tube blanks) on electric tube welding machines using automatic tungsten inert gas (argon) welding, and heat treated on the mill line. Mechanical tests, geometric measurements, 100% ultrasonic and eddy current testing, pneumatic or hydrostatic testing are performed before the finished titanium welded tubes are packaged according to customer specifications. Manufacturing technology as well as inspection and testing equipment ensure that thin wall welded tubes meet ASTM B 338 and ASME SB 338 specifications.

Test Raporları

The test reports we provide include: Factory test certificate for CP Grade 4 titanium welded pipe and CP Grade 4 titanium seamless pipe, EN 10204 3.1, Chemical report, Mechanical report, PMI test report, Visual inspection report, Third-party inspection report, NABL approved laboratory report, Destructive test report, Non-destructive test report. (Daxun will provide according to customer’s requirements)

Applications and standards

CP Grade 4 Pipes and Tubing are extensively applied in extremely corrosive conditions in the below Industries:

- Chemical processing parts such as heat exchangers, reaction vessels, evaporators and delivery pipelines, automotive exhaust, oil and gas industry, petrochemical plants, chemical plants, industrial machinery, power industry, paper and pulp industry, food processing industry, refineries, pharmaceutical and food processing equipment, etc.

- Specifications : ASTM B861, B862, B338 / ASME SB861, SB862, SB338

Standard : ASTM, ASME and API

Kalite, teslimat, denetim

Daxun performs several quality assurance tests, these tests include flattening test, flaring test, ultrasonic flaw detection test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the Titanium Welded Pipe and Titanium Seamless Pipe materials are suitable for the required application. During the production process, we measure the diameter, thickness and surface of the products. Our standard delivery time is 5-7 days and the delivery time for special size products is 15-20 days.

- Teslimat süremiz kesinlikle sözleşmeye uygundur.

- Müşterinin üçüncü taraf acentelerinin denetim için fabrikaya gitmesine destek olun

- Müşteri testleri için ücretsiz numune desteği

- Yerinde veya video fabrika denetimini destekleyin

Paketleme

Daxun Alloy, malların nihai varış noktasına ulaşmak için çeşitli kanallardan geçtiği uluslararası taşımacılıkta önemli bir rol oynadığı için en iyi ambalaj kalitesini sağlar, bu nedenle ambalajlamaya özel önem veririz. Ürünlerimizi ürüne bağlı olarak birçok şekilde paketliyoruz. Ürünlerimizi aşağıdaki gibi birçok şekilde paketliyoruz:

- Kutular ve kasalar

- Shrink ambalaj

- Ahşap paletler

- Ahşap kutular

Teknik Destek

Herhangi bir ek teknik yardıma ihtiyacınız olursa, yerleşik metalürji uzmanımız ve bilgili personelimiz size yardımcı olmaktan memnuniyet duyacaktır. Ayrıca Daxun, çoklu metal ve plastik envanter endüstrisinde bir ilk olan sertifikalı bir test laboratuvarına sahiptir. Bu, bize göre, kaliteye olan sarsılmaz bağlılığımızı ve tam hizmet tedarikçisi olarak felsefemizi göstermektedir.

Daxun CP Grade 4 Titanium TUBE Let your brand improve rapidly

- Galeri

CP Grade 4 titanium tube form (4)

Güncel sıcak vaka projeleri ve ürünleri

İlgili Ürünler (3)

Grade 4 titanium pipe is the strongest of the commercially pure titanium grades. Its key characteristics include high tensile strength, excellent ductility, and superior corrosion resistance, especially against chlorides and acids. It offers an outstanding strength-to-weight ratio, making it both durable and lightweight.

The primary difference is strength. Grade 4 titanium has a significantly higher minimum yield strength (480 MPa) compared to Grade 2 (275 MPa). While Grade 2 is more formable and often used for general corrosion resistance, Grade 4 is chosen for applications requiring higher mechanical strength and pressure resistance, such as in aerospace or demanding chemical processing components.

Due to its robust properties, Grade 4 titanium pipe is commonly used in the aerospace industry for hydraulic and fuel lines, in chemical processing for heat exchangers and pressure vessels, and in marine engineering for desalination plants and offshore platforms. It is also found in medical implants where high strength and biocompatibility are essential.

Absolutely. Laser cutting is an excellent method for fabricating Grade 4 titanium pipe, offering high precision, clean cuts, and a minimal heat-affected zone. This is particularly beneficial for creating complex shapes or preparing pipe ends for welding. It’s crucial to use optimized cutting parameters and an assist gas like argon or nitrogen to prevent oxidation and maintain the material’s corrosion resistance.

The higher initial cost is due to the complex extraction and refining processes required for titanium. However, Grade 4 titanium pipe often provides a lower total cost of ownership. Its exceptional corrosion resistance leads to a much longer service life and significantly reduced maintenance and replacement costs, especially in harsh environments where stainless steel would fail quickly.

Titanyum sınıfı maliyeti biraz artırsa da, toplam maliyet öncelikle ihtiyacınız olan titanyum şekli ve formu tarafından belirlenir.

At DAXUN, we offer a wide range of titanium products, including tubes, tubes, coils and bars. The length, width and quantity of each item you require will affect the amount you pay at checkout.

Ne yazık ki, projeniz ve titanyumun ne için kullanılacağı hakkında çok fazla bilgi sahibi olmadan çevrimiçi bir fiyat bulmak zordur.

Neyse ki, uzman ekibimiz titanyum ihtiyaçlarınız konusunda size yardımcı olmak ve tavsiyelerde bulunmak için her zaman burada. [email protected] adresine bir e-posta göndererek, size bazı tavsiyeler ve doğru bir fiyat teklifi ile geri dönebileceğiz.

İhtiyaçlarınızı daha iyi anlamak için ihtiyacınız olan titanyum sınıfı, şekli ve miktarı hakkında mümkün olduğunca fazla bilgi eklediğinizden emin olun.

Lütfen “Bize Ulaşın” sayfasındaki formu doldurun veya “+86 13382898899” adresinden satış müdürümüzü arayın, en kısa sürede sizinle iletişime geçeceğiz. WhatsApp'ımız çevrimiçidir ve e-posta ([email protected]) 6 saat içinde kontrol edilecektir. Her soruya veya mesaja derhal yanıt verilecektir. Ayrıca, her hafta müşterilerimizle pazar bilgilerini paylaşıyoruz

Kaliteyi kontrol etmeniz için paslanmaz çelik sac örnekleri sağlayabiliriz. Numune ücretsizdir ve siz sadece navlunu ödersiniz.

Kanada, Şili, Kuveyt, Almanya, Güney Kore, Suudi Arabistan, Singapur gibi 42'den fazla ülkeye ihracat yaptık.

Deneme siparişleri bir hafta içinde teslim edilebilir. Normal siparişler için bu süre yaklaşık iki haftadır.