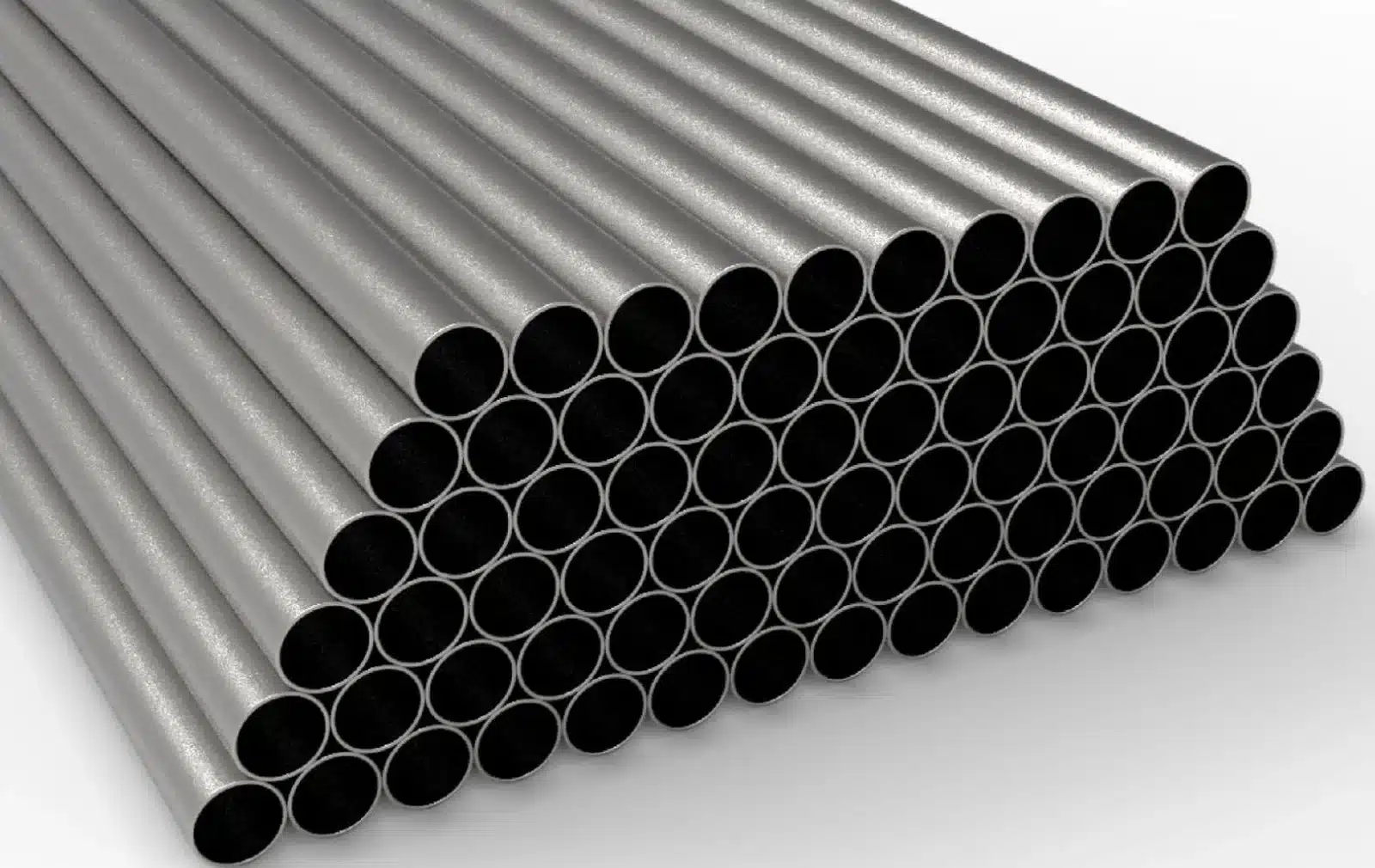

Daxun Alloy - Hastelloy C-22 pipe made in China

As a leading supplier of Hastelloy C-22 pipes in China, Daxun provides high-performance alloy tubes to the world.

- Hastelloy C-22 types: Seamless tube, welded tube, forged tube

- Certification : ASTM,SGS,ISO,CE

- Delivery Time : 7-15 days

- Surface finish: Annealed, polished etc.

- MOQ : ≥300kg

————Daxun produces hastelloy pipe in China to meet the diverse and ——고객의 까다로운 요구 사항!

Characteristics & Properties of Hastelloy C-22

Hastelloy C-22(UNS N06022) alloy is an all-around nickel-chromium-molybdenum-tungsten alloy with better overall corrosion resistance than other existing nickel-chromium-molybdenum alloys, including Hastelloy C-276, C-4 alloy and 625 alloy. Hastelloy C-22 alloy has good resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidizing aqueous media, including wet chlorine, nitric acid or mixed acids containing oxidizing acids with chloride ions. At the same time, Hastelloy C-22 alloy also has ideal resistance to reducing and oxidizing environments encountered in the process. Relying on this versatile performance, it can be used in some troublesome environments or in factories with multiple production purposes. Hastelloy C-22 alloy has an exceptional resistance to various chemical environments, including strong oxidizing substances such as ferric chloride, cupric chloride, chlorine, hot contaminated solutions (organic and inorganic), formic acid, acetic acid, acetic anhydride, seawater and salt solutions. Hastelloy C-22 alloy has the ability to resist the formation of grain boundary precipitation in the heat-affected zone of welding, so that it can also be used in many chemical processes in the welded state.

Corrosion resistance

The corrosion resistance of Hastelloy C-22 is its most outstanding feature, and it is suitable for a variety of corrosive environments:

Oxidizing media: such as nitric acid, chromic acid, hypochlorite, etc.

Reducing media: such as sulfuric acid, hydrochloric acid, phosphoric acid, etc.

Local corrosion: It has strong resistance to pitting, crevice corrosion and stress corrosion cracking (SCC).

Mixed acid environment: complex media such as sulfuric acid + hydrochloric acid, nitric acid + hydrofluoric acid.

High temperature corrosion: It can still maintain good corrosion resistance at high temperatures.

Comparison with other alloys

Compared with Hastelloy C-276, C-22 has a higher chromium content and stronger oxidation resistance.

Compared with stainless steel, C-22 has significantly better pitting and crevice corrosion resistance in chloride environments.

Processing performance

Hastelloy C-22 has good processing performance, but its high strength and work hardening tendency should be noted:

Cold processing: It can be processed by cold rolling, cold drawing, etc., but attention should be paid to work hardening.

Hot working: The hot working temperature range is 950-1200°C, and overheating should be avoided.

Welding: TIG (tungsten inert gas shielded welding), MIG (metal inert gas shielded welding), plasma arc welding and other methods can be used. Heat treatment is usually not required after welding, but heat input needs to be controlled to avoid intergranular corrosion.

Application areas

Hastelloy C-22 is widely used in the following fields:

Chemical industry: used to manufacture reactors, heat exchangers, pipelines, valves and other equipment, especially in strong acid, strong alkali and mixed acid environments.

Oil and gas: used for downhole tools, valves, pumps, pipelines, etc., to resist corrosion from hydrogen sulfide, carbon dioxide and chlorides.

Environmental protection field: used for flue gas desulfurization (FGD) systems, wastewater treatment equipment, etc.

Pharmaceutical industry: used for high-purity equipment to resist corrosive media.

Nuclear industry: used for nuclear waste treatment equipment to resist corrosion from radioactive media.

Hastelloy C-22 Parameters

- 화학 성분

- 물리적 속성

- 기계적 특성

| Ni | Cr | Mo | W | Fe | Co |

| 56% | 20-22.5% | 12.5-14.5% | 2.5-3.5% | 2-6% | ≤2.5% |

| Mn | Si | C | P | S | |

| ≤0.5% | ≤0.08% | ≤0.015% | ≤0.02% | ≤0.02% |

| 속성 | 밀도 | 녹는점 | Thermal Expansion Coefficient | 열 전도성 | 전기 저항 | Elastic Modulus |

| 가치 | 8.69 g/cm³ | 1325-1370°C | 12.8 μm/m·°C | 10.1 W/m·K | 1.25 μΩ·m | 206 GPa |

| 속성 | Room Temperature (20°C) | High Temperature (600°C) | Test Standard/Notes |

| 인장 강도 | ≥690 MPa | ≥380 MPa | ASTM E8/E8M |

| Yield Strength (0.2%) | ≥310 MPa | ≥220 MPa | ASTM E8/E8M |

| 신장 | ≥45% | ≥30% | 50 mm gauge length |

| 경도(브리넬) | ≤220 HB | – | ASTM E10 |

프로젝트의 성공을 위해 Daxun을 선택하세요.

Advanced Production:Hastelloy alloy pipe

Hastelloy C22 alloy is an all-around nickel-chromium-molybdenum-tungsten alloy with good resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidative aqueous media, including wet chlorine, nitric acid or mixed acids of oxidizing acids containing chloride ions. At the same time, Hastelloy C22 alloy also has ideal resistance to reducing and oxidizing environments encountered in the process. Relying on this versatile performance, it can be used in some troublesome environments or in factories for a variety of production purposes.

Hastelloy C-22 Pipe Features

Hastelloy C22 alloy has an exceptional resistance to various chemical environments, including strong oxidizing substances, such as ferric chloride, cupric chloride, chlorine, thermally contaminated solutions (organic and inorganic), formic acid, acetic acid, acetic anhydride, seawater and salt solutions, etc. Hastelloy C22 alloy has the ability to resist the formation of grain boundary precipitation in the heat affected zone of welding, so that it can also be used in many chemical processes in the welding state.

품질, 배송, 검사

Daxun conducts a series of quality assurance tests on Hastelloy C-22 pipes. These tests include flattening test, flaring test, ultrasonic flaw detection, crevice corrosion resistance test, mechanical property test, hardness test, material positive identification, and expansion test, etc. All these tests are designed to ensure that the Hastelloy C-22 pipes meet the requirements of the intended applications. During the production process, we meticulously measure the outer diameter, wall thickness, and surface quality of the products. Our standard delivery time is 5 – 7 days, and for special sizes, it is 15 – 20 days.

- 배송 시간은 엄격하게 계약에 따릅니다.

- 고객 타사 대행사가 공장에 가서 검사할 수 있도록 지원

- 고객 테스트를 위한 무료 샘플 지원

- 현장 또는 비디오 공장 검사 지원

패키징

상품이 다양한 경로를 거쳐 최종 목적지에 도착하는 국제화물에서 포장은 중요한 역할을 하기 때문에 대순합금은 포장에 각별한 주의를 기울이고 있으며 최고의 품질을 보장합니다. 제품에 따라 다양한 방법으로 상품을 포장합니다. 다음과 같은 다양한 방법으로 제품을 포장합니다:

- 상자 및 상자

- 수축 포장

- 목재 팔레트

- 나무 상자

기술 지원

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. [지금 문의]Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry. This, in our opinion, demonstrates our unwavering dedication to quality and our philosophy as a full-service supplier.

Daxun is a trustworthy stainless steel tube manufacturer

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all titanium tubes are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the stainless steel tubes have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

관련 제품 (8)

“문의하기” 페이지의 양식을 작성하거나 영업 관리자(+86 13382898899)에게 전화하시면 최대한 빨리 연락드리겠습니다. WhatsApp은 온라인 상태이며 이메일([email protected])은 6시간 이내에 확인합니다. 모든 문의나 메시지는 신속하게 답변해 드립니다. 또한 매주 고객과 시장 정보를 공유합니다.

품질을 확인할 수 있도록 스테인리스 강판 샘플을 제공할 수 있습니다. 샘플은 무료이며 운임만 지불하면 됩니다.

캐나다, 칠레, 쿠웨이트, 독일, 한국, 사우디아라비아, 싱가포르 등 42개 이상의 국가에 수출하고 있습니다.

The minimum order quantity for our Hastelloy products is 300kg

체험판 주문은 일주일 이내에 배송됩니다. 일반 주문의 경우 대략 2주 정도 소요됩니다.