In the energy industry, every component counts. A single part that fails can bring a multi-million dollar project to a halt, leading to costly downtime and safety risks. That’s why more and more project managers and engineers are turning away from traditional materials and choosing titanium. It’s not just another metal; it’s a solution to some of the toughest problems in power generation.

Why Titanium Excels in Energy Applications

Titanium’s energy sector dominance stems from three fundamental properties that solve critical engineering challenges:

Corrosion Immunity in Extreme Environments

Unlike stainless steel, which relies on chromium oxide films vulnerable to chlorides, titanium forms an impervious titanium dioxide (TiO₂) barrier that resists:

- Hot brine solutions (up to 300°C) with 250,000+ ppm chlorides

- Hydrogen sulfide (H₂S) environments in sour gas wells

- Seawater at flow velocities exceeding 25 m/s

- Acidic geothermal fluids (pH 3.5-5.0) containing arsenic and mercury

Strength-to-Weight Ratio for Offshore Efficiency

Titanium’s density of 4.51 g/cm³—43% lighter than steel—creates compounding benefits in marine energy systems:

- 35% weight reduction in offshore platform structural components

- 50% longer span capability for tidal turbine support frames

- Faster installation times due to lighter handling requirements

Thermal Stability for High-Efficiency Systems

With a coefficient of thermal expansion 55% lower than stainless steel, titanium maintains dimensional stability during rapid temperature cycling:

- Handles 300°C thermal shocks in concentrated solar power receivers

- Maintains seal integrity in nuclear waste storage containers during cooling cycles

- Prevents fatigue failure in hydrogen compressor components at -196°C to 150°C

Oil & Gas Production

- Downhole Safety Valves: Grade 12 (Ti-0.3Mo-0.8Ni) withstands 15,000 psi pressure and 200°C temperatures in H₂S service (NACE MR0175 compliant)

- Seawater Injection Systems: Grade 2 titanium piping eliminates microbiologically influenced corrosion (MIC) that plagues copper-nickel alloys

- Subsea Manifolds: Welded Grade 23 (Ti-6Al-4V ELI) structures survive 3,000m ocean depths with zero maintenance for 30+ years

Geothermal Energy

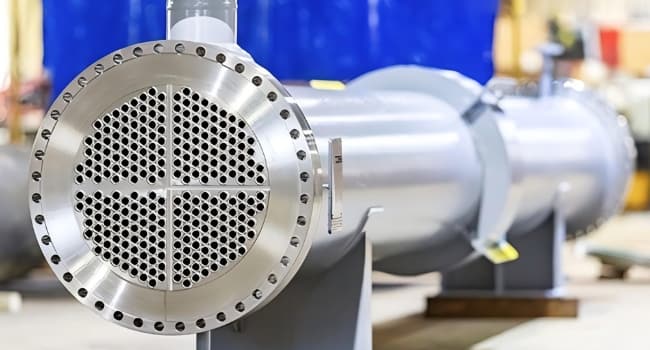

- Brine Heat Exchangers: Grade 7 (Ti-0.15Pd) handles 250°C brine with 15% dissolved solids where super duplex stainless fails within months

- Well Casing Components: Titanium’s non-magnetic properties prevent interference with directional drilling sensors

- Binary Cycle Systems: Titanium condenser tubes increase plant efficiency by 8% through improved heat transfer versus stainless steel

Hydrogen Economy

- Electrolyzer Bipolar Plates: Commercially pure titanium (Grade 1) enables 80,000+ hour service life in PEM electrolysis cells

- High-Pressure Storage: Grade 23 titanium vessels safely contain hydrogen at 700 bar for fuel cell vehicles

- Pipeline Components: Titanium’s resistance to hydrogen embrittlement makes it the only metal certified for pure hydrogen service per ASME B31.12

Nuclear Power

- Condenser Tubes: Titanium replaces admiralty brass in coastal nuclear plants, eliminating 90% of maintenance costs

- Spent Fuel Storage: Welded Grade 2 containers provide 100-year service life in pool storage environments

- Coolant Systems: Titanium’s low neutron absorption cross-section (5.6 barns) makes it compatible with reactor primary circuits

Renewable Marine Energy

- Tidal Turbine Blades: Grade 5 titanium composites withstand 20-year service in abrasive sand-laden seawater

- Wave Energy Converters: Titanium hydraulic cylinders operate continuously with zero seawater ingress

- Offshore Wind Foundations: Titanium anodes extend cathodic protection system life by 4x versus zinc

Pertanyaan yang Sering Diajukan

Q: Can titanium withstand the abrasion from sand in oil well production?

A: Yes—with proper grade selection. Grade 23 (Ti-6Al-4V ELI) has 3x the erosion resistance of 316 stainless steel in sand-laden flow. In North Sea wells with 15% sand content, titanium chokes last 12+ years versus 14 months for tungsten carbide-coated steel.

Q: How does titanium compare to super duplex stainless steel for offshore seawater systems?

A: Titanium costs 3-4x more initially but delivers 5-8x longer service life. In North Sea platforms, super duplex (2507) condenser tubes require replacement every 7-10 years due to crevice corrosion, while titanium systems operate 30+ years with zero tube failures. The break-even point is typically Year 4 for critical systems where downtime costs exceed $50,000/hour. For non-critical ballast systems, super duplex may remain economical.

Q: What is the maximum continuous service temperature for titanium in geothermal applications?

A: Grade 2 commercially pure titanium operates continuously at 300°C in geothermal brine, while Grade 7 (with palladium) handles 315°C. For temperatures above 350°C, titanium alloys lose strength rapidly—zirconium or nickel-based alloys become better choices.

Kesimpulan

As the global energy sector evolves toward hydrogen, geothermal, and marine renewables, titanium’s role becomes increasingly vital. Its unique properties solve corrosion challenges that limit conventional materials, enabling more efficient, longer-lasting energy systems. For engineers, titanium alloys are a strategic choice to ensure uninterrupted operation for decades in the harshest environments.

Daxun Alloy Co, Ltd. supplies ASTM-certified titanium components engineered specifically for energy applications. We provide testing reports for various titanium alloys and adhere to strict control standards. Contact us today to inquire about your titanium alloy project.