Daxun is a 409 stainless steel sheet supplier in China

As China’s leading stainless steel plate supplier and exporter, Daxun provides 409 stainless steel plates to the world.

- Grade: AISI 409

- Manufaktur: pelat canai dingin, pelat canai panas, pelat tempa

- Standar: ASTM, ASME, GB, DIN, JIS, ISO, EN, BS

- Jenis: pelat tipis canai dingin, pelat tebal canai panas

- Permukaan: 2B, NO.1, NO.4, HL, BA, 8K, dll.

- Panjang: 2438mm3048mm6000mm dapat disesuaikan

- Asal: TISCO, Baosteel, Pohang, Tsingshan, Delong

410 Global leader in stainless steel sheet fabrication services

Daxun’s Grade 409 stainless steel plate has good corrosion resistance and is typically one of the least expensive varieties of stainless steel. It has a high tensile strength, is easily welded using arc welding, and is suited for resistance spot and seam welding. It is worth noting that welding type 409 does not reduce its corrosion resistance. It can be utilised in a variety of applications, including vehicle and truck exhaust systems, heat exchangers, agricultural spreaders, fuel filters, gas turbine exhaust mufflers, and others that demand precise shaping, toughness, and better weldability. One of this stainless steel grade’s primary advantages is improved weldability.

Grade 409 is a stabilised ferritic general-purpose stainless steel sheet with 11% chromium. It is especially well-suited for applications that require oxidation or corrosion resistance that carbon steel and some coated steels cannot provide. 409 has strong oxidation resistance and formability, but poor corrosion resistance because to its low chromium concentration. 409 has lower corrosion resistance than grades 304, 430, or 439, but it outperforms mild steels. Roll forming, stretch bending, deep drawing, and press forming are all options for shaping 409. When 409 is annealed, it will not harden when cold treated with mild roll forming processes such as press or stretch bending. Weldability for grade 409 is fair. This stainless material should not be utilised in shock-loaded structures because the grain structure grows in the heat-affected zone, which can have a direct impact on mechanical qualities. 409 is commonly used for tubing and stampings in automotive exhaust system applications. The mechanical qualities of this stainless steel sheet grade provide significant benefits in the automotive and agricultural industries. This offers good protection from exhaust gas and high-temperature ambient corrosion. However, the mechanical properties outweigh the stainless steel’s look. It is not advised for use in decorative purposes.

Data Teknis

- Parameter

- Komposisi Kimia

- Sifat mekanik

- SIFAT FISIK

- Standar

| Product Parameters: Stainless Steel Sheet/Plate | |||

| Lebar | 10mm ~ 2500mm | ||

| Ketebalan | 0.2mm ~ 100mm | Toleransi ketebalan | +/- 0,03mm |

| Standar | ASTM/ASME 240/480, JIS 4305, DIN EN 10088-2 | ||

| Permukaan | 2B, BA, 8K, NO.1, NO.4, NO.3, garis rambut, kotak-kotak, emas, hitam, emas mawar, dll | ||

| spesifikasi | 1000*2000/L,1219*2438/L,1250*2500/L,1500*3000/L1500*6000/L,1800*6000/L,2000*6000/L2200*6000L | ||

| Asal Pabrik | TISCO, ZPSS, BAOSTEEL, JISCO, ZSESS, ATI, SMC, HAYNES, VDM, ArcelorMittal, Outokumpu, dan lain-lain. | ||

| Sertifikasi | ISO, SGS, BV, TUV, CE, dll | ||

| Elemen | % Hadir (dalam bentuk produk) |

| Karbon (C) | 0.03 |

| Silikon (Si) | 1 |

| Mangan (Mn) | 1 |

| Fosfor (P) | 0.04 |

| Belerang (S) | 0.015 |

| Kromium (Cr) | 10.50 – 12.50 |

| Molibdenum (Mo) | 6 x (C+N) to 0.65 |

| Besi (Fe) | Keseimbangan |

| Formulir Produk | ||||

| C | H | |||

| Thickness (mm) Max | 8 | 13.5 | ||

| Yield Strength Rp0.2 N/mm2 | Longitudinal | 210 | ||

| Transverse | 220 | |||

| Kekuatan Tarik | Rm N/mm2 | 380 – 560 | ||

| Perpanjangan min. dalam % | A80mm1) <3mm (longitudunal + transverse) | 25 | ||

| A2) ≥3mm (longitudinal + transverse) | ||||

| Kepadatan | Konduktivitas Termal | Electrical | Modulus of | Coefficient of | Specific Heat | Meleleh |

| lbm/in^3 | (BTU/h ft. °F) | Resistivity | Elasticity | Ekspansi Termal | (BTU/lb/ | Range |

| (in x 10^-6) | (psi x 10^6) | (in/in)/ | °F) | (°F) | ||

| °F x 10^-6 | ||||||

| 12.4 at 932 °F | 39.4 at 752°F | 6.60 at 32 – 1000°F | ||||

| 49.6 at 1652 °F | 6.86 at 32 – 1500°F | |||||

| at 68°F: 0.280 | 9.4 at 212°F | 28.3 at 68°F | 29 | 5.84 at 32 – 212°F | 0.114 at 68°F to 212°F | 2500 to 2590 |

| UNS 409 | 1.4512 | 409L |

| ASTM A240 | ASTM A240 | ASTM A240 |

| ASTM A480 | ASTM A480 | ASTM A480 |

| ASME SA240 | ASME SA240 | ASME SA240 |

| AMS 5521 | AMS 5521 | AMS 5521 |

Pilih Daxun dan buat pelanggan Anda puas.

Pengiriman cepat

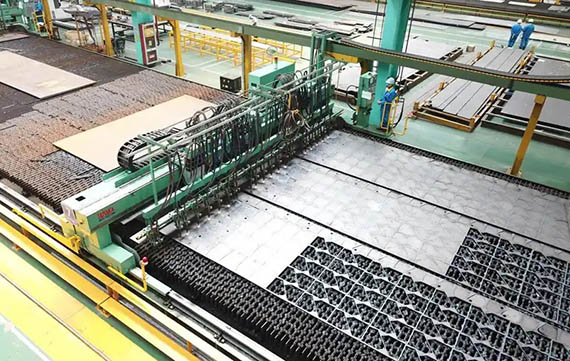

We provide timely and fast delivery of stainless steel products for customers with urgent needs. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real time, and the data is seamlessly connected; in terms of logistics, the processing center is close to highways and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on schedule.

Advantages/Disadvantages

This stainless steel grade has mechanical qualities that provide significant benefits in the automotive and agricultural industries. This offers enhanced protection from exhaust gas and air corrosion at high temperatures. However, the mechanical characteristics of this stainless steel outweigh its visual look. It is not advised for use in decorative purposes.

Stainless Steel 409 Applications

- 409 stainless steel plate for agricultural machinery

- 409 stainless steel plate for automotive panels

- 409 stainless steel plate for stamping products

- 409 stainless steel plate for cookware

- 409 stainless steel plate for home appliances

- 409 stainless steel plate for kitchens

- 409 stainless steel plate for food service equipment

- 409 stainless steel plate for sinks

- 409 stainless steel plate for railway vehicles

- 409 stainless steel plate for exhaust

Kualitas, pengiriman, inspeksi

- Daxun juga melakukan beberapa tes jaminan kualitas. Pengujian ini meliputi uji perataan, uji lubang dan ketahanan, uji mekanis, uji kekerasan, identifikasi positif material, uji ekspansi, dll. Semua pengujian ini memastikan bahwa bahan tersebut cocok untuk aplikasi yang dibutuhkan.

- Selama proses produksi, kami mengukur diameter, ketebalan, dan permukaan produk. Waktu pengiriman standar kami adalah 7-15 hari, kecuali untuk beberapa produk ukuran khusus, waktu pengiriman kami akan bertambah menjadi 20 hari.

Waktu pengiriman kami benar-benar sesuai dengan kontrak. - Mendukung agen pihak ketiga pelanggan untuk pergi ke pabrik untuk pemeriksaan

- Mendukung sampel gratis kepada pelanggan untuk pengujian

- Mendukung inspeksi pabrik di tempat atau video

Dukungan Teknis

Jika Anda memerlukan bantuan teknis tambahan, ahli metalurgi dan staf kami yang berpengetahuan luas akan dengan senang hati membantu. Selain itu, Daxun memiliki laboratorium pengujian bersertifikat-yang pertama dalam industri inventaris multi-logam dan plastik. Ini, menurut pendapat kami, menunjukkan dedikasi kami yang tak tergoyahkan terhadap kualitas dan filosofi kami sebagai pemasok layanan penuh.

409 plate stainless steel Features

Daxun Biarkan merek Anda meningkat dengan cepat

- Galeri

- Toleransi

- Status pengiriman

- Seri produk lainnya

| Toleransi untuk Lembar 2B | |||

| Ukuran | Peringkat Toleransi | ||

| Kelompok 1 | Kelompok 2 | Kelompok 3 | |

| 0.4 | 0.3 ~ 0.32 | 0.33 ~ 0.37 | 0.37 ~ 0.39 |

| 0.5 | 0.4 ~ 0.42 | 0.43 ~ 0.47 | 0.47 ~ 0.49 |

| 0.6 | 0.5 ~ 0.52 | 0.53 ~ 0.56 | 0.57 ~ 0.59 |

| 0.7 | 0.6 ~ 0.62 | 0.63 ~ 0.67 | 0.67 ~ 0.69 |

| 0.8 | 0.7 ~ 0.72 | 0.73 ~ 0.77 | 0.74 ~ 0.79 |

| 0.9 | 0.8 ~ 0.82 | 0.83 ~ 0.87 | 0.87 ~ 0.89 |

| 1 | 0.89 ~ 0.9 | 0.91 ~ 0.94 | 0.94 ~ 0.99 |

| 1.2 | 1.02 ~ 1.08 | 1.09 ~ 1.15 | 1.16 ~ 1.18 |

| 1.5 | 1.32 ~ 1.38 | 1.39 ~ 1.45 | 1.46 ~ 1.48 |

| 2 | 1.72 ~ 1.79 | 1.8 ~ 1.86 | 1.87 ~ 1.9 |

| 2.5 | 2.23 ~ 2.36 | 2.32 ~ 2.42 | 1.42 ~ 1.47 |

| 3 | 2.7 ~ 2.77 | 2.78 ~ 2.82 | 2.85 ~ 2.9 |

| Toleransi untuk Pelat Canai Panas No.1 | |||

| Ukuran | Peringkat Toleransi | ||

| Kelompok 1 | Kelompok 2 | Kelompok 3 | |

| 3 | 2.6 ~ 2.75 | 2.75 ~ 2.85 | 2.86 ~ 2.9 |

| 4 | 3.5 ~ 3.6 | 3.6 ~ 3.75 | 3.76 ~ 3.95 |

| 5 | 4.5 ~ 4.6 | 4.6 ~ 4.75 | 4.75 ~ 4.95 |

| 6 | 5.4 ~ 5.6 | 5.6 ~ 5.75 | 5.75 ~ 5.85 |

| 8 | 7.3 ~ 7.5 | 7.5 ~ 7.65 | 7.65 ~ 7.85 |

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9.6 ~ 9.85 |

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11.6 ~ 11.85 |

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13.6 ~ 13.85 |

| 16 | 15.2~ 15.5 | 15.5~ 15.7 | 15.7~ 16.1 |

| 18 | 17.2~ 17.5 | 17.5~ 17.7 | 17.7~ 18.1 |

| 20 | 19.2~ 19.5 | 19.5~ 19.7 | 19.7~ 20.1 |

| 30 | 29.2~ 29.5 | 29.5~ 29.7 | 29.7-30.1 |

| 40 | 39.2~ 39.5 | 39.5~ 39.7 | 39.7~ 40.1 |

| 50 | 49.2~ 49.5 | 49.5~ 49.7 | 49.7~ 50.1 |

| 60 | 59.2~ 59.5 | 59.5~ 59.7 | 59.7~ 60.1 |

| Pilihan Status Pengiriman | Kondisi Permukaan |

| Digulung Dingin | 2B |

| 2D | |

| BA | |

| Garis rambut | |

| No.3 | |

| No.4 | |

| 6K | |

| 8K | |

| Catatan: | |

| 1. Jika Anda memerlukan status pengiriman yang berbeda dari yang tercantum di atas, mohon konfirmasi dengan kami. | |

| 2. Jika ada pertanyaan atau pesanan, mohon beritahukan kepada kami persyaratan tambahan yang tidak disebutkan di sini. | |

| Status Pengiriman | |

| Pilihan Status Pengiriman | Kondisi Permukaan |

| Canai Panas | No.1 |

| No.3 | |

| No.4 | |

| 6K | |

| 8K | |

| Acar | |

| Catatan: | |

| 1. Jika Anda memerlukan status pengiriman yang berbeda dari yang tercantum di atas, mohon konfirmasi dengan kami. | |

| 2. Jika ada pertanyaan atau pesanan, mohon beritahukan kepada kami persyaratan tambahan yang tidak disebutkan di sini. | |

| Kelas | Jenis | Ketebalan | Permukaan |

| Austenitik | 304/304H/304L/304J1 | 0,25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0,3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferit | 430 | 0.4-3.0mm | 2B/BA/NO.4/8K/SB/HL |

| Ferit Ultra Murni | 443 | 0.4-2.0mm | 2B |

| 436L/439/444/441 | 0.5-3.0mm | 2B 、 2D | |

| 409L | 0,4-2,5 mm | 2B 、 2D | |

| Kelas | Jenis | Ketebalan | Asli |

| Baja tahan panas | 309S | 0,5-40mm | CHN |

| 310S | 0,5-40mm | CHN | |

| Baja Dupleks | 2101 | 1,5-50mm | CHN |

| 2304 | 3.0-50mm | CHN | |

| 2205 | 0,5-60mm | CHN | |

| 2507 | 1.0-60mm | SWE / JPN / CHN | |

| Baja Austenitik Super | N08904 | 0,6-50mm | SWE / JPN / CHN |

| S31254 | 0,5-50mm | SWE / JPN / CHN | |

| N08926 | 0,5-50mm | SWE / JPN / CHN | |

| N08367 | 0,5-50mm | SWE / JPN / CHN | |

| Paduan Dasar Nikel | N08031 | 1.0-50mm | AS / JPN / GER |

| N08810 / N08800 | 0,8-50mm | AS / JPN / CHN | |

| N08028 | 1.0-20mm | AS / JERMAN / JPN | |

| N08020 | 1.0-20mm | AS / JERMAN / JPN | |

| N08825 | 0,8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50mm | AS / JERMAN / JPN | |

| N06022 | 1.0-50mm | AS / JERMAN / JPN | |

| N06625 | 0,8-20mm | AS / GER / CHN | |

| N04400 | 1.0-20mm | AS / JERMAN / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20mm | AS / JPN | |

| Titanium | TA1/Gr1 | 0,5-50mm | JPN / CHN |

| TA2/Gr2 | 0,5-50mm | JPN / CHN | |

| Bahan Pengelasan | ERNiCrMo-13 | 1.2 、 2.4mm | GER |

| ERNiCrMo-3 | 2.4mm | GER | |

| ERNiCrMo-4 | 2.4mm | AS |

The surface and shape of 409 stainless steel plate (7)

Informasi yang tersedia untuk referensi dan diunduh

Daxun adalah produsen pelat baja tahan karat yang dapat dipercaya

Sebagai produsen profesional, Daxun memastikan bahwa semua produk yang kami hasilkan berkualitas tinggi. Oleh karena itu, kami memastikan bahwa semua pelat baja tahan karat disertifikasi oleh ISO9001, SGS, CE, OQC, dan lebih banyak standar kualitas internasional, serta memiliki kontrol kualitas yang ketat untuk memastikan bahwa pelat baja tahan karat memiliki lebih sedikit cacat. Di Daxun, yakinlah bahwa semua produk tahan lama, berkualitas tinggi, dan berkinerja tinggi.

Proyek dan produk hot case terbaru

Produk Terkait (13)

Kami dapat menyediakan sampel lembaran baja tahan karat untuk Anda periksa kualitasnya. Sampel gratis dan Anda hanya membayar ongkos kirim.

Kami telah mengekspor ke lebih dari 42 negara, seperti Kanada, Chili, Kuwait, Jerman, Korea Selatan, Arab Saudi, Singapura, dll.

MOQ kami adalah 1 ton untuk lembaran baja tahan karat.

Pesanan percobaan dapat dikirim dalam waktu satu minggu. Untuk pesanan reguler, kira-kira membutuhkan waktu dua minggu.