Daxun is an experienced Ti 6Al 4V-Grade 5 Titanium Tube manufacturer

As a leading supplier of titanium and titanium alloy tubes in China, Daxun provides high-performance titanium tubes to the world.

- Titanium tube Grade:Grade 5 -Ti6Al 4V- UNS R56400-3.7165-TC4

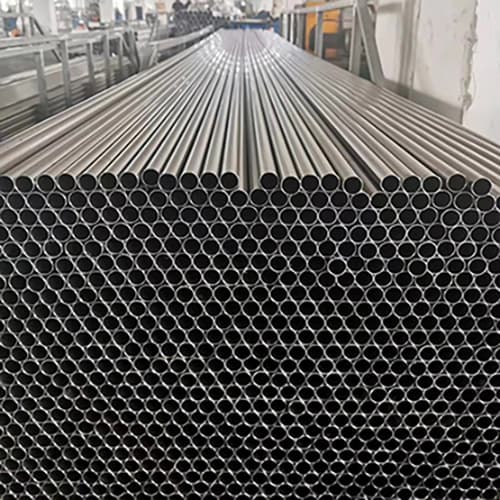

- Ti tube types:Seamless titanium tube, drawn tube, forged titanium tube

- Titanium tube density The density of grade 5 titanium is 4.51 g/cm3

- Main standards: ASTM ASME GB GJB EN JIS DIN ISO ATP BS etc.

- High strength, high temperature resistance, corrosion resistance, lightweight

————Daxun produces titanium tubes in China to meet the diverse and ——demanding needs of customers!

A global leader in commercially pure titanium tube fabrication services

Daxun Alloy, as a leading titanium alloy tube manufacturer and supplier in China, provides high-quality Grade 5 titanium pipes to the world and has been well received by many projects.

Ti 6Al-4V (Grade 5 Titanium) is the most widely used of all titanium alloy tubes, accounting for more than 50% of the total titanium usage. It is usually used in the annealed state and has an operating temperature of up to 400°C (750°F). Ti 6Al/4V is welded with matching or ELI filler wire. Ti 6Al/4V has significantly higher strength than commercial pure titanium tubes, while having better stiffness and thermal properties (excluding thermal conductivity), and the thermal conductivity of Grade 5 titanium tube is about 60% lower than CP titanium. Among its many advantages, it can be heat treated. Thus, more ideal strength and performance are obtained. The advantages of using Grade 5 titanium seamless tubes include not only strong formability and low density, but also excellent corrosion resistance.

This grade is a perfect combination of strength, corrosion resistance, weldability and machinability. Therefore, it is widely used, such as in military aircraft or aviation industry, rocket parts, precision-guided components, armor parts, ship equipment, military vacuum equipment and other parts. The close version of 6-4, 6-4ELI, is also used in surgical implants. Typically, it is used in applications up to 400°C to improve ductility and toughness in cold working conditions. It also has excellent specific strength. It is usually provided in the annealed state and is easy to heat treat to increase strength for a variety of applications. As a general-purpose titanium alloy, Ti 6Al-4V titanium seamless tube has a wide range of ideal properties at temperatures around -210°C – 400°C. Grade 5 titanium alloy tube is the most commercialized of all titanium alloys. It combines high strength and toughness. Grade 5 titanium alloy tube has good welding and processing characteristics.

Titanium Alloy Grade 5 Seamless Pipe, Titanium Gr 5 High Pressure Pipe, ASTM B338 Titanium Alloy Gr 5 Seamless Pipe, Titanium Gr 5 Thick Wall Pipe. China Titanium Grade 5 ERW Pipe Supplier. Titanium Alloy Gr 5 Pipe, Titanium Gr 5 Electropolished Pipe, Anti-corrosion Titanium Pipe, Titanium Tube, ASTM B338 Titanium Grade 5 Welded Pipe, ASTM B861 / ASME SB861 Titanium Grade 5 Seamless Pipe China Titanium Gr-5 Seamless Pipe Manufacturer. Ti-6al-4v Pipe Dealer, ASTM B338 Titanium Grade 5 Pipe, Titanium Gr 5 Bright Annealed Pipe, Ti-6al-4v Pipe, Gr 5 Pipe, Titanium Gr 5 Pipe, Titanium WERKSTOFF NR 3.7165 Pipe

Are you looking to purchase titanium tubes for your project or order a range of titanium tubes? Daxun produces a wide range of titanium tubes including Grade 1 (3.7025), Grade 2 (3.7035), Grade 3 (3.7055), Grade 5 (3.7165), Grade 7 (3.7235), Grade 9 (3.7195) and Grade 12 (3.7105).

Buy titanium tubes at Daxun Alloys.

We offer a wide range of sizes starting from 1.0 mm in diameter with multiple variations, available directly from stock or custom made to your specifications through our network. We have wrought titanium tubes, seamless titanium tubes and longitudinally welded titanium tubes immediately available from stock for a wide range of applications.

We offer heat exchanger tubing in standard specifications such as ASTM B 338, ASME SB 338, DIN 17866 and VD TÜV welded titanium tubes or seamless titanium tubes. When it comes to titanium tubes, we have a large supply of titanium welded tubes and titanium seamless tubes in China in standard sizes up to 100 mm thick. We will supply welded titanium tubes for larger pipe sizes. The most common specifications used in the industry are ASTM B 861, ASFM B 862, NACE and NORSOK and VD TÜV Tube 230/2, depending on the specifications of the plant designer.

Titanium tube surface treatment options include bright annealing, pickling and grinding. Material parameters vary depending on the application and product requirements. The corrosion and mechanical properties of titanium alloy tubes vary. We are happy to assist you in evaluating your needs. If you have a long-term supply commitment, you can establish a framework agreement with Daxun. We guarantee price and quantity for a specified period.

Datos

- Parámetro

- Ingrediente

- Propiedades mecánicas

- PROPIEDADES FÍSICAS

- Búsquedas calientes

| Ti-6Al-4V Grade 5 Titanium pipe & Tubes Specification | ASTM B338 / ASTM B861 / ASTM B862 / ASME SB338 / ASME SB861 / ASME SB862 |

| Grade 5 Titanium pipe & Tubes Grades | Commercially pure titanium Grade 5-Ti-6Al4V- TC4- USN 56400 |

| Grade 5 Titanium pipe & Tubes Type | ot Rolled / Cold Drawn / Welded / ERW |

| Grade 5 Titanium pipe & Tubes Outer Diameter Size | Titanium seamless pipe – φ1.0mm to φ508.3mm |

| Titanium welded pipe – φ6.0mm to φ1219mm | |

| Grade 5 Titanium pipe & Tubes Wall Thickness | 1.0mm—50mm (customizable wall thickness) |

| Grade 5 Titanium pipe & Tubes Length | 5 to 7 Meters, 09 to 13 Meters, Single Random Length, Double Random Length And Customize Size. |

| Titanium pipe Form Ti-6Al-4V | ‘ Hollow, U’ bent, LSAW, Hydraulic, Straight Tube, Boiler, Round, Tube Coil, Square, Rectangular Etc |

| Marking TC4 1.37165 | All Titanium Tubes Tubing are marked as follows: Grade, Standard, Thickness, OD, Heat No., Length (Or according to the customer’s request.) |

| Uses of Titanium Alloy Tubes | Gas pipes, oil pipes, heat exchanger tubes, boiler tubes, fluid pipes, titanium exhaust pipes. |

| Grade 5 Titanium pipe & Tubes Pipe Ends | Plain Ends / Beveled Ends |

| Grade 5 Titanium pipe & Tubes Delivery Conditions | As Rolled, Cold Drawn, Hot Finish, Stress Relieved, Annealed, Hardened, Tempered |

| Grade 5 Titanium pipe & Tubes Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

| Grade 5 Titanium pipe & Tubes Other Testing | ardness Test, Hydrostatic Test, Eddy Current test, Eddy Current, Tensile Test, Flattening, Flare Test, Annealed, Hydrostatic Test, Tempered, Stress Relieved etc. |

| Grade 5 Titanium pipe & Tubes Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM And ASME |

| Grade 5 Titanium pipe & Tubes Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| Grade 5 Titanium pipe & Tubes Packaging | Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| Grade 5 Titanium pipe & Tubes Shipment & Transportation | By Road – Truck / Train, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| Grade 5 Titanium pipe & Tubes Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

| Composición química: | |||

| Símbolo | Elemento | Min % | Max % |

| Al | Aluminio | 5.50% | 6.75% |

| V | Vanadio | 3.50% | 4.50% |

| Fe | Hierro | 0.30% | |

| O | Oxígeno | 0.20% | |

| C | Carbono | 0.08% | |

| N | Nitrógeno | 0.05% | |

| H | Hidrógeno | 0.01% | |

| Y | Itrio | 0.01% | |

| Otros, cada uno | 0.10% | ||

| Otros, total | 0.40% | ||

| Ti | Titanio | Resto | |

| Propiedades físicas | Métrica | Inglés | Comentarios |

| Densidad | 4,43 g/cc | 0,16 lb/pulg³ | |

| Propiedades mecánicas | |||

| Dureza, Brinell | 334 | 334 | Estimación de Rockwell C. |

| Dureza, Knoop | 363 | 363 | Estimación de Rockwell C. |

| Dureza, Rockwell C | 36 | 36 | |

| Dureza, Vickers | 349 | 349 | Estimación de Rockwell C. |

| Resistencia a la tracción | mín. 895MPa | 129810 psi | |

| Límite elástico | mín. 828MPa | 120090 psi | |

| Alargamiento a la rotura | mín.10 % | 10 % | |

| Reducción de la superficie | mín.25 % | 25 % | |

| Módulo de elasticidad | 113,8 GPa | 16500 ksi | |

| Resistencia a la compresión | 970 MPa | 141000 psi | |

| Resistencia a la tracción | 1450 MPa | 210000 psi | Kt (factor de concentración de esfuerzos) = 6,7 |

| Resistencia máxima al rodamiento | 1860 MPa | 270000 psi | e/D = 2 |

| Límite elástico del rodamiento | 1480 MPa | 215000 psi | e/D = 2 |

| Relación de Poisson | 0.342 | 0.342 | |

| Impacto Charpy | 17 J | 12,5 ft-lb | Muesca en V |

| Resistencia a la fatiga | 240 MPa | 34800 psi | a 1E+7 ciclos. Kt (factor de concentración de tensiones) = 3,3 |

| Resistencia a la fatiga | 510 MPa | 74000 psi | Sin marcar 10.000.000 de ciclos |

| Resistencia a la fractura | 75 MPa-m½ | 68,3 ksi-in½ | |

| Módulo de cizallamiento | 44 GPa | 6380 ksi | |

| Resistencia al cizallamiento | 550 MPa | 79800 psi | Resistencia última al cizallamiento |

| Propiedades eléctricas | |||

| Resistividad eléctrica | 0,000178 ohm-cm | 0,000178 ohm-cm | |

| Permeabilidad magnética | 1.00005 | 1.00005 | a 1,6 kA/m |

| Susceptibilidad magnética | 3.30E-06 | 3.30E-06 | cgs/g |

| Propiedades térmicas | |||

| CTE, lineal 20°C | 8,6 µm/m-°C | 4,78 µin/in-°F | 20-100ºC |

| CTE, lineal 250°C | 9,2 µm/m-°C | 5,11 µin/in-°F | Media en el intervalo 20-315ºC |

| CTE, lineal 500°C | 9,7 µm/m-°C | 5,39 µin/in-°F | Media en el intervalo 20-650ºC |

| Capacidad calorífica específica | 0,5263 J/g-°C | 0,126 BTU/lb-°F | |

| Conductividad térmica | 6,7 W/m-K | 46,5 BTU-in/hr-ft²-°F | |

| Punto de fusión | 1604 - 1660 °C | 2920 - 3020 °F | |

| Solidus | 1604 °C | 2920 °F | |

| Liquidus | 1660 °C | 3020 °F | |

| Beta Transus | 980 °C | 1800 °F | |

| Beta Transus (F ± 25) | 1830 | ||||

| Coeficiente de dilatación térmica (10-6in./in./F) | 32-212 | 5 | |||

| 32-600 | 5.3 | ||||

| 32-1000 | 5.6 | ||||

| 32-1200 | 5.9 | ||||

| 32-1500 | 6.1 | ||||

| Densidad (lbs./cu. in.) | 0.16 | ||||

| Punto de fusión, aproximadamente (F) | 3200 | ||||

| Resistividad eléctrica a temperatura ambiente (microhms cm) | 171 | ||||

| Módulo de elasticidad - Tensión (106 psi) | 16.5 | ||||

| Módulo de elasticidad - Torsión (106 psi) | 6.1 | ||||

| Conductividad térmica | 3,9 a temperatura ambiente | ||||

| (Btu/hr/pie cuadrado/F/pie) | |||||

| Calor específico (Btu/lb./F) a temperatura ambiente. | 0.135 | ||||

| Soldabilidad | Feria | ||||

| Temp. de recocido (F) | Completo | 1300 - 1525°/15 Min. - 2 Hrs,; Aire Frío | |||

| Alivio del estrés | 900 - 1200°/1 -4 Hrs.; Aire frío | ||||

| Forja* Temp. (F) | Bloqueo | 1750 - 1800° | |||

| Acabado | 1650 - 1750° | ||||

| Aplicación típica | Álabes de compresores, discos, componentes aeronáuticos, recipientes a presión, carcasas de motores de cohetes; | ||||

| la aleación de titanio más versátil. | |||||

| Titanium Grade 5 Pipes | 4 inch Ti Alloy Grade 5 Seamless Pipes |

| Ti Alloy Grade 5 Pipes | Titanium gr 5 Welded Pipes |

| Grade 5 Titanium Seamless Steel Pipes | Titanium UNS R56400 Cold Drawn Welded Pipes |

| Ti Alloy Grade 5 Welded Pipes | Grade 5 Pure Titanium Cold Drawn Pipes |

| Titanium gr 5 ERW Pipes | Schedule 5S Grade 5 Titanium Seamless Pipe |

| Grade 5 Pure Titanium EFW Pipes | Schedule 40 Titanium 3.7165 Pipes |

| Grade 5 Titanium Cold Drawn Seamless Pipes | Titanium gr 5 Precision Pipes |

| Alloy Grade 5 Seamless Steel Precision Pipes | High pressure ASTM B337 Titanium Grade 5 Pipes |

| Titanium 3.7165 Cold Drawn Seamless Pipes | Titanium Alloy Grade 5 Electropolished Pipes |

| Ti Alloy Grade 5 Custom Pipes | Titanium Grade 5 Cold Drawn Pipes |

| UNS R56400 Round Pipes | Gr 5 Ti Exhaust Pipes |

| Gr 5 Titanium Rectangular Pipes | Small diameter Titanium Alloy Grade 5 Pipes |

| Grade 5 Titanium Hexagonal Pipe | Ti Alloy Grade 5 Pipe material |

| UNS R56400 Welded Pipe | Grade 5 Titanium Hexagonal Pipe |

| Ti Alloy Grade 5 Welded Pipe | Titanium Alloy Gr 5 Pipe |

| Titanium Gr 5 EFW Pipe | Grade 5 Titanium Seamless Pipe |

| Alloy Grade 5 Bush Hex Pipe | DIN 3.7165 Precision Steel Pipes |

| Grade 5 Pure Titanium Fabricated Pipe | UNS R56400 Annealed pipe |

| Ti Grade 5 Beveled End Pipe | Grade 5 Pure Titanium Rectangle Pipe |

| ASTM B337 Titanium Grade 5 Cold Drawn Pipe | Cold Drawn Alloy Grade 5 Welded Pipe |

| Titanium Grade 5 Seamless Tubes | Titanium Alloy Gr 5 Welded Tubes |

| Titanium Gr 5 High Pressure Tube | Titanium UNS R56400 Welded Tube |

| ASTM B338 Titanium Alloy Gr 5 Seamless Tubing | Ti. Alloy WERKSTOFF NR. 3.7165 Welded Tubes |

| Titanium Alloy Gr 5 Tubes | ASTM B338 Gr.5 Titanium Welded Tubes |

| Titanium Gr 5 Santiary Tube | Grade 5 Alloy Round Tube |

| Titanium Gr 5 Cold Rolled Coiled Tube | Grade 5 Titanium Alloy Round Tubes |

| Gr 5 Titanium Welded Tubes | Titanium Grade 5 Round Tube |

| Dealer of ASTM B338 Titanium Grade 5 Tube | UNS R56400 Round Tubes |

| Titanium Gr 5 Decorative Tube | Titanium Alloy Gr 5 Round Tube |

| Gr 5 Titanium Bright Annealed Tube | ASME SB338 Gr 5 Titanium Round Tubes |

| Ti. Alloy Grade 2 ERW Tubes | UNS R56400 Gr5 Ti Alloy Tubing |

| Titanium UNS R56400 Tubing | Grade 5 Ti Tubing |

| Titanium NCF Gr 5 Tubes | ASTM B558 Titanium Alloy Welded Tubes |

| Titanium Gr 5 Tubing | WERKSTOFF NR. 3.7165 Gr5 Titanium Tubes |

| Titanium WERKSTOFF NR. 3.7165 Tubing | Ti-6Al-4V Tube |

| Titanium Alloy Gr 5 Tubing | Titanium Alloy Grade 5 Seamless Tubes |

| Titanium Gr 5 Electropolish Tube | Titanium Alloy Grade 5 Round Tube |

| ASTM B338 Titanium Grade 5 Welded Tubing | Titanium Grade 5 Elliptical and Oval Tubes |

| Grade 5 Titanium Alloy Seamless Tubing | Titanium Grade 5 Rectangular Tube |

| Titanium Grade 5 Welded Tubes0 | Titanium Grade 5 Sighting Tube |

| Gr 5 Titanium Heat Exchanger Tube | Titanium Grade 5 Polish Tubes |

| ASTM B338 Titanium Gr 5 Tube | Titanium Grade 5 Aerospace tubes |

| Gr 5 Titanium Tubing | Titanium Grade 5 High Pressure Tube |

| Titanium Grade 5 Tube | Titanium Alloy Grade 5 Coiled Tubing |

| Grade 5 Titanium Alloy Seamless Tubes | Grade 5 Titanium Capillary Tubing |

| Titanium Grade 5 Welded Tube | Titanium Alloy Grade 5 Seamless Tubing |

| Titanium Alloy Grade 5 Tubing | Titanium Grade 5 Condenser Tubes |

| Grade 5 Ti. Alloy Tubing | Titanium Grade 5 Aero engine tubes |

| Ti. Alloy Gr 5 Seamless Tubes | Titanium Alloy Grade 5 Straight Tube boiler |

| Gr 5 Alloy Seamless Tube | Titanium Grade 5 Furnace Tube |

| Titanium Alloy Gr.5 Seamless Tubes | Grade 5 Titanium Seamless Tube |

| UNS R56400 Seamless Tube | Grade 5 Titanium Tube |

| WERKSTOFF NR. 3.7165 Seamless Tubes | Titanium Grade 5 Tubing |

| ASME SB338 Gr.5 Titanium Seamless Tube | Grade 5 Alloy Welded Tube |

| Titanium Alloy Grade 5 Welded Tubes | Titanium Grade 5 Seamless Tubes |

Elija Daxun para que su proyecto despegue.

Advanced Production:Titanium seamless pipe

- Grade 5 steel seamless pipes are processed by hot turning or hot pressing, straightening, inner and outer diameter processing, and can be provided in heat treatment or non-heat treatment forms. / Hot rolled seamless pipe: outer diameter 1.0mm to 325mm, wall thickness 0.3mm to 50mm, length up to 12000mm. Cold rolled seamless pipe: cold processed pipes are heat treated, surface engraved, water pressure tested or ultrasonically tested according to the manufacturing standards of outer diameter 6mm to 102mm, wall thickness 0.5mm to 20mm, and length up to 9000mm.

(The above is determined according to the specific situation of the manufacturer and the customer)

Grade 5 Titanium Tube Features

Ti-6Al4V Grade 5 Titanium Alloy Tube is the most commercially available of all Titanium alloys. It combines high strength and toughness. Grade 5 Titanium alloy has good welding and processing characteristics:

- High Strength Titanium Alloy

- Heat Treatable

- Good Ductility

- Good Machinability

- Good Weldability

We stock and sell Grade 5 Titanium Alloy Seamless Tubes, Forged Seamless Tubes, Welded Tubes, etc.

Advanced Production: Forged Titanium Alloy Tube

Forged Titanium Seamless Tubes: Diameters range from 100mm to 1219mm, wall thickness ranges from 5mm to 100mm (depending on diameter), lengths up to 2000mm, made from Grade 5 Titanium. Forged Titanium alloy tubes undergo multiple forgings to achieve more uniform grains and metallographic structures, better performance and stability, and are finally heat treated. Before the finished products are packaged according to customer specifications, they undergo mechanical testing, geometric measurements, 100% ultrasonic and eddy current testing, pneumatic or hydrostatic testing. Manufacturing technology as well as inspection and testing equipment ensure that forged 6-4 titanium tubes meet ASTM and ASME specifications.

Informes de las pruebas

The test reports we provide include: Factory test certificate for Grade 5 Titanium Seamless Pipe and Ti-6al-4v Titanium Seamless Pipe, EN 10204 3.1, Chemical Report, Mechanical Report, PMI Test Report, Visual Inspection Report, Third Party Inspection Report, NABL Approved Laboratory Report, Destructive Test Report, Non-destructive Testing Report. (DaXun will provide according to customer requirements)

Applications and standards

Grade 5 titanium tubes are widely used in the following industries under extreme corrosive conditions:

- Chemical processing parts, military industry, aerospace, chemical energy, marine engineering, oil and gas industry, rockets and missiles, military armor, ships and vessels, industrial machinery, power industry, paper and pulp industry, pharmaceutical and food processing equipment, etc.

- Specifications: ASTM B861, B862, B338 / ASME SB861, SB862, SB338

- Standards: ASTM, GB, GJB, ASME and API

Calidad, entrega, inspección

Daxun performs several quality assurance tests, these tests include flattening test, flaring test, ultrasonic flaw detection test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the Grade 1 Titanium Welded Pipe and Grade 1 Titanium Seamless Pipe materials are suitable for the required application. During the production process, we measure the diameter, thickness and surface of the products. Our standard delivery time is 5-7 days and the delivery time for special size products is 15-20 days.

- Nuestro plazo de entrega se ajusta estrictamente a lo estipulado en el contrato.

- Apoyar a las agencias externas del cliente para que vayan a la fábrica a inspeccionar

- Muestras gratuitas para las pruebas de los clientes

- Apoyo a la inspección in situ o por vídeo en fábrica

Embalaje

Daxun Alloy ensures the best quality of titanium tube packaging, because it plays an important role in international freight, and the goods go through various channels to reach the final destination, so we pay special attention to packaging. We pack our goods in many ways according to the products. We pack our products in many ways, such as:

- Cajas y cajones

- Retráctil

- Palés de madera

- Cajas de madera

Asistencia técnica

Si necesita asistencia técnica adicional, nuestro metalúrgico residente y nuestro personal experto estarán encantados de ayudarle. Además, Daxun cuenta con un laboratorio de pruebas certificado, una primicia en la industria de inventarios multimetal y plástico. Esto, en nuestra opinión, demuestra nuestra inquebrantable dedicación a la calidad y nuestra filosofía como proveedor de servicios completos.

Grade 5 Titanium TUBE Features

Daxun Grade 5 Titanium TUBE Let your brand improve rapidly

- Galería

- Titanium pipe/tube

- Superficie

- Types of

- Weight

| Apart from the products listed below, other available metal products are not listed here. Other metal products DAXUN can manufacture and supply include Tantalum, Niobium, Zirconium, Hafnium, Nickel, Copper etc., which are mainly in the form of pipe/tube Bar and Tube. | |

| Productos/Norma de transformación | Grado/Tamaño |

| Titanium pipe/tube, — ASME SB265, AMS 4911, AMS 4919, AMS 4914,ASTM F67, ASTM F136 | GR1, GR2, GR3, GR4, GR5, GR7,GR9, GR12, GR16, GR17, GR23,Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3(Espesor:( 0.0197”-6”)Anchura máxima: 12 pies,Longitud máxima: 50 pies) |

| AMS-T-9046 | |

| Titanium and Titanium alloy pipe/tube | |

| Titanio comercialmente puro (CP) | |

| Designación del código | Límite elástico |

| mínimo, ksi 1 / | |

| CP-1 | 70 |

| CP-2 | 55 |

| CP-3 | 40 |

| CP-4 | 25 |

| Aleaciones de titanio alfa(A) | |

| Designación del código | Composición |

| A-1 | 5A1-2.5Sn |

| A-2 | 5A1-2,5Sn(ELI) 2 / |

| A-3 | 6A1-2Cb-1Ta-0,8Mo |

| A-4 | 8A1-1Mo-1V |

| Aleaciones de titanio alfa-beta (AB) | |

| Designación del código | Composición |

| AB-1 | 6A1-4V |

| AB-2 | 6A1-4V(ELI) |

| AB-3 | 6A1-6V-2Sn |

| AB-4 | 6A1-2Sn-4Zr-2Mo |

| AB-5 | 3A1-2,5V |

| AB-6 | 8Mn |

| Aleaciones beta de titanio(B) | |

| Designación del código | Composición |

| B-1 | 13V-11Cr-3A1 |

| B-2 | 11,5Mo-6Zr-4,5Sn |

| B-3 | 3A1-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3A1 |

| Procesando: | |

| Laminación en caliente | Laminación en frío |

| Grados disponibles: | |

| CP Grado 1 | Calidad 6Al-2Sn-4Zr-2Mo (6-2-4-2) |

| CP Grado 2 | Grado 6Al-4V ELI (antes grado 23) |

| Grado 7 | Grado 6Al-6V-2Sn (6-62) |

| Grado 19 | Grado 8Al-1Mo-1V (8-1-1) |

| Grado 5 (6Al-4V) | Grado 9 (3Al-2,5V) |

| Grado 6 (5Al-2,5Sn) | CP Grado 3 |

| Aplicación | |

| Industria química | Desalinización del agua de mar |

| Industria petroquímica | Aeroespacial |

| Mecanizado, Automoción | Componente de teléfono móvil Campo. |

| urface Finish | Internal Surface(ID) | Exterbal Surface(OD) | |||

| Roughness Average(RA) | Roughness Average(RA) | ||||

| μ inch | μm | μ inch | μm | ||

| BA | Beight Annealed | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| EP | Electro Polish | 15,10,7,5 | 0.38,0.25,0.20;0.13 | 32 | 0.8 |

| MP | Mechanical Polish | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| AP | Annealed & Pickled | Not defined | Not defined | 40 or Not defined | 1.0 or Not defined |

| Titanium Grade 5 Seamless Pipe | Titanium DIN 3.7165 Seamless Pipe |

| Titanium UNS R56400 Seamless Pipe | |

| Titanium Grade 5 Seamless Pipes | |

| Titanium Alloy Gr.5 Seamless Pipe | |

| ASTM B337 Titanium Grade 5 Seamless Pipe | |

| ASME SB337 Ti Alloy Gr.5 Seamless Pipes | |

| Titanium Grade 5 Welded Pipe | Titanium DIN 3.7165 Welded Pipe |

| Titanium UNS R56400 Welded Pipe | |

| Titanium Grade 5 Welded Pipes | |

| Titanium Alloy Gr.5 Welded Pipe | |

| ASTM B337 Titanium Grade 5 Welded Pipes | |

| ASME SB337 Ti Alloy Gr.5 Welded Pipes | |

| Titanium Grade 5 Round Pipe | Titanium DIN 3.7165 Round Pipe |

| Titanium UNS R56400 Round Pipes | |

| Titanium Grade 5 Round Pipes | |

| Titanium Alloy Gr.5 Round Pipe | |

| Titanium Grade 5 Round Pipe | |

| Ti Alloy Gr.5 Round Pipes | |

| Titanium Gr.5 Seamless Tubes | Titanium DIN 3.7165 Seamless Tubes |

| Titanium UNS R56400 Seamless Tubes | |

| Titanium Grade 5 Seamless Tubing | |

| Titanium Alloy Gr.5 Seamless Tubes | |

| ASTM B338 Titanium Gr.5 Seamless Tubing | |

| ASME SB338 Ti Alloy Grade 5 Seamless Tubes | |

| Titanium Grade 5 Welded Tubes | Titanium DIN 3.7165 Welded Tubes |

| Titanium UNS R56400 Welded Tubes | |

| Titanium Grade 5 Welded Tubing | |

| Titanium Alloy Gr.5 Welded Tubes | |

| ASTM B338 Titanium Grade 5 Welded Tubing | |

| ASME SB338 Ti Alloy Gr.5 Welded Tubes | |

| Titanium Grade 5 Round Tubes | Titanium DIN 3.7165 Round Tubes |

| Titanium UNS R56400 Round Tubes | |

| Titanium Grade 5 Round Tubing | |

| Titanium Alloy Gr.5 Round Tubes | |

| Titanium Grade 5 Round Tubing | |

| Ti Alloy Gr.5 Round Tubes | |

| Titanium Grade 5 Pipe | Titanium DIN 3.7165 Pipe |

| Titanium UNS R56400 Pipes | |

| Titanium Grade 5 Pipe | |

| Titanium Alloy Gr.5 Pipes | |

| Titanium Grade 5 Pipes | |

| Ti Alloy Gr.5 Pipe | |

| Titanium Grade 5 Tube | Titanium DIN 3.7165 Tubes |

| Titanium UNS R56400 Tube | |

| Titanium Grade 5 Tubing | |

| Titanium Alloy Gr.5 Tubes | |

| Titanium Grade 5 Tubes | |

| Ti Alloy Gr.5 Tubes |

| NPS | Outside Diameter | Wall Thickness | Weight | Weight | |||

| in | mm | in | mm | Sched | kg/Mtr | Lb/ft | |

| 1/2″ | 0.84 | 21 | 0.109 | 2.769 | 40 STD | 1.268 | 0.851 |

| 0.147 | 3.734 | 80 STD | 1.621 | 1.088 | |||

| 3/4″ | 1.05 | 27 | 0.113 | 2.87 | 40 STD | 1.684 | 1.131 |

| 0.154 | 3.912 | 80 STD | 2.195 | 1.474 | |||

| 1″ | 1.315 | 33 | 0.133 | 3.378 | 40 STD | 2.501 | 1.679 |

| 0.179 | 4.547 | 80 STD | 3.325 | 2.172 | |||

| 1 1/4″ | 1.66 | 42 | 0.14 | 3.556 | 40 STD | 3.385 | 2.273 |

| 0.191 | 4.851 | 80 STD | 4.464 | 2.997 | |||

| 1 1/2″ | 1.9 | 48 | 0.145 | 3.683 | 40 STD | 4.048 | 2.718 |

| 0.2 | 5.08 | 80 STD | 5.409 | 3.361 | |||

| 2″ | 2.375 | 60 | 0.154 | 3.912 | 40 STD | 5.441 | 3.653 |

| 0.218 | 5.537 | 80 STD | 7.48 | 5.022 | |||

| 2 1/2″ | 2.875 | 73 | 0.203 | 5.516 | 40 STD | 8.629 | 5.793 |

| 0.276 | 7.01 | 80 STD | 11.411 | 7.661 | |||

| 3″ | 3.5 | 89 | 0.216 | 5.486 | 40 STD | 11.284 | 7.576 |

| 0.3 | 7.62 | 80 STD | 15.272 | 10.253 | |||

| 4″ | 4.5 | 114 | 0.237 | 6.02 | 16.073 | 10.79 | |

| 0.337 | 8.56 | 22.318 | 14.983 | ||||

| 6″ | 6.625 | 168 | 0.188 | 4.775 | 19.252 | 12.924 | |

| 0.203 | 5.516 | 20.739 | 13.923 | ||||

| 0.219 | 5.563 | 22.318 | 14.983 | ||||

| 0.25 | 6.35 | 25.354 | 17.021 | ||||

| 0.28 | 7.112 | 40 STD | 58.263 | 18.974 | |||

| 0.312 | 7.925 | 31.334 | 21.036 | ||||

| 0.375 | 9.525 | 37.285 | 25.031 | ||||

| 0.432 | 10.973 | 80 XHY | 42.561 | 28.573 | |||

| 0.5 | 12.7 | 48.719 | 32.708 | ||||

| 8″ | 8.625 | 219 | 0.188 | 4.775 | 25.233 | 16.94 | |

| 0.203 | 5.156 | 27.198 | 18.259 | ||||

| 0.219 | 5.563 | 29.286 | 19.661 | ||||

| 0.25 | 6.35 | 20 | 33.308 | 22.361 | |||

| 0.277 | 7.036 | 30 | 36.786 | 24.696 | |||

| 0.322 | 8.179 | 40 | 42.352 | 28.554 | |||

| 0.375 | 9.525 | 49.216 | 33.041 | ||||

| 0.406 | 10.312 | 60 | 53.085 | 35.638 | |||

| 0.5 | 12.7 | 80 XHY | 64.627 | 43.388 | |||

| 10″ | 10.75 | 273 | 0.188 | 4.775 | 31.588 | 21.207 | |

| 0.219 | 5.563 | 36.689 | 24.631 | ||||

| 0.25 | 6.35 | 20 | 41.759 | 28.035 | |||

| 0.307 | 7.798 | 30 | 51.002 | 34.24 | |||

| 0.344 | 8.738 | 56.946 | 38.231 | ||||

| 0.365 | 9.271 | 40 STD | 63.301 | 40.483 | |||

| 0.438 | 11.125 | 71.852 | 48.238 | ||||

| 0.5 | 12.7 | 60 XHY | 81.53 | 54.735 | |||

| 0.594 | 15.088 | 80 | 95.969 | 64.429 | |||

| 12″ | 12.75 | 324 | 0.188 | 4.775 | 37.57 | 25.222 | |

| 0.219 | 5.563 | 43.657 | 29.309 | ||||

| 0.25 | 6.35 | 49.713 | 33.375 | ||||

| 0.281 | 7.137 | 55.739 | 37.42 | ||||

| 0.312 | 7.925 | 61.735 | 41.445 | ||||

| 0.375 | 9.525 | 73.824 | 49.562 | ||||

| 0.406 | 10.312 | 79.727 | 53.525 | ||||

| 0.5 | 12.7 | 97.438 | 65.415 | ||||

| 0.562 | 14.275 | 108.966 | 73.154 | ||||

| 14″ | 14 | 356 | 0.188 | 4.775 | 41.308 | 27.732 | |

| 0.219 | 5.563 | 48.012 | 32.233 | ||||

| 0.25 | 6.35 | 20 | 54.685 | 36.713 | |||

| 0.281 | 7.137 | 61.327 | 41.172 | ||||

| 0.312 | 7.925 | 67.939 | 45.611 | ||||

| 0.375 | 9.525 | STD | 81.281 | 54.568 | |||

| 0.438 | 11.125 | 40 | 94.498 | 63.441 | |||

| 0.5 | 12.7 | XHY | 107.381 | 72.09 | |||

| 0.625 | 15.875 | 132.983 | 89.278 | ||||

| 16” | 16 | 406 | 0.188 | 4.775 | 47.29 | 21.748 | |

| 0.219 | 5.563 | 54.98 | 36.91 | ||||

| 0.25 | 6.35 | 10 | 62.639 | 42.053 | |||

| 0.281 | 7.137 | 70.268 | 47.174 | ||||

| 0.312 | 7.925 | 20 | 77.866 | 52.275 | |||

| 0.344 | 8.738 | 85.677 | 57.519 | ||||

| 0.375 | 9.525 | 30 | 93.213 | 62.578 | |||

| STD | |||||||

| 0.438 | 11.125 | 108.433 | 72.797 | ||||

| 0.5 | 12.7 | 40 | 123.289 | 82.77 | |||

| XHY | |||||||

| 18″ | 18 | 457 | 0.219 | 5.563 | 61.948 | 41.588 | |

| 0.25 | 6.35 | 70.593 | 47.393 | ||||

| 0.281 | 7.137 | 79.208 | 53.176 | ||||

| 0.312 | 7.925 | 20 | 87.792 | 58.939 | |||

| 0.375 | 9.525 | STD | 105.144 | 70.588 | |||

| 0.438 | 11.125 | 30 | 122.369 | 82.152 | |||

| 0.5 | 12.7 | XHY | 139.198 | 93.45 | |||

| 0.562 | 14.275 | 40 | 155.904 | 104.666 | |||

| 0.625 | 15.875 | 172.754 | 115.978 | ||||

| 20″ | 20 | 508 | 0.25 | 6.35 | 78.547 | 52.733 | |

| 0.282 | 7.163 | 88.458 | 59.386 | ||||

| 0.312 | 7.925 | 97.719 | 65.604 | ||||

| 0.375 | 9.525 | 20 STD | 117.075 | 78.598 | |||

| 0.438 | 11.125 | 136.305 | 91.508 | ||||

| 0.5 | 12.7 | 30 XHY | 155.106 | 104.13 | |||

| 0.594 | 15.088 | 40 | 183.378 | 123.11 | |||

| 0.625 | 15.875 | 192.64 | 129.328 | ||||

| 0.688 | 17.475 | 211.368 | 141.901 | ||||

| 24″ | 24 | 610 | 0.25 | 6.35 | 94.456 | 63.413 | |

| 0.281 | 7.137 | 106.029 | 71.183 | ||||

| 0.312 | 7.925 | 117.573 | 18.932 | ||||

| 0.375 | 9.525 | 20 STD | 140.938 | 64.618 | |||

| 0.438 | 11.125 | 164.176 | 110.219 | ||||

| 0.5 | 12.7 | XHY | 186.923 | 125.49 | |||

| 0.625 | 15.875 | 232.41 | 156.028 | ||||

| 0.688 | 17.475 | 40 | 255.148 | 171.293 | |||

| 0.75 | 19.05 | 277.401 | 186.233 | ||||

| 30″ | 30 | 762 | 0.25 | 6.35 | 118.318 | 79.433 | |

| 0.281 | 7.137 | 132.851 | 89.189 | ||||

| 0.312 | 7.925 | 10 | 147.353 | 98.925 | |||

| 0.375 | 9.525 | STD | 176.731 | 118.648 | |||

| 0.438 | 11.125 | 205.983 | 138.286 | ||||

| 0.5 | 12.7 | 20 XHY | 234.647 | 157.53 | |||

| 0.625 | 15.875 | 30 | 292.066 | 196.078 | |||

| 0.688 | 17.475 | 320.817 | 215.38 | ||||

| 0.75 | 19.05 | 348.988 | 234.293 | ||||

| 36″ | 36 | 914 | 0.25 | 6.35 | 142.18 | 95.453 | |

| 0.281 | 7.137 | 159.672 | 107.196 | ||||

| 0.312 | 7.925 | 10 | 177.133 | 118.918 | |||

| 0.375 | 9.525 | STD | 215.525 | 142.678 | |||

| 0.438 | 11.125 | 247.79 | 166.353 | ||||

| 0.5 | 12.7 | 20 XHY | 282.372 | 198.57 | |||

| 0.625 | 15.875 | 351.723 | 236.128 | ||||

| 0.688 | 17.475 | 386.487 | 259.467 | ||||

| 0.75 | 19.05 | 420.576 | 282.353 | ||||

| 42″ | 42 | 1067 | 0.312 | 7.925 | 206.914 | 138.911 | |

| 0.375 | 9.525 | STD | 248.319 | 166.708 | |||

| 0.5 | 12.7 | XHY | 33.097 | 221.61 | |||

| 0.75 | 19.05 | 492.163 | 330.413 | ||||

| 48″ | 48 | 1219 | 0.375 | 9.525 | STD | 284.112 | 190.738 |

| 0.438 | 11.125 | 331.404 | 222.487 | ||||

| 0.5 | 12.7 | XHY | 377.822 | 253.65 | |||

| 0.75 | 19.05 | 563.75 | 378.473 | ||||

| 0.875 | 22.225 | 655.969 | 440.383 | ||||

Grade 2 titanium tube form (4)

Información disponible para consulta y descarga

Daxun is a reliable manufacturer of grade 5 titanium tubes

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all titanium tubes are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the stainless steel plates have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

Proyectos y productos recientes

Productos relacionados (8)

Ti-6Al-4V- Grade 5 Titanium tube

- Titanium Alloy-(UNS R56400)

INTRODUCTION

- DAXUN Ti-6Al-4V, Grade 5 Alloy Tube (UNS R56400) is the most popular titanium alloy. It is a duplex alpha+beta titanium alloy that uses aluminium as an alpha stabiliser and vanadium as a beta stabiliser. This high-strength alloy can be employed at cryogenic temperatures of around 800°F (427°C). ATI Ti-6Al-4V, Grade 5 alloy is used in annealing, solution treatment, and ageing. Compressor blades, discs, and rings for jet engines; fuselage and space capsule components; pressure containers; rocket engine cases; helicopter rotor hubs; fasteners; and crucial forgings with a high strength-to-weight ratio.

- The alloy is initially melted using vacuum arc (VAR), electron beam (EB) or plasma arc hearth melting (PAM). Remelting is achieved in one or two vacuum arc steps.

ESPECIFICACIONES

•ASTE B338 – Tubes Titanium tubes standard heat treatable

• AMS 4928 – Forgings and forging stock (annealed)

• AMS 4965 – Forgings (solution treated and aged)

• AMS 4967 – Forgings (annealed, heat treatable)

PROPIEDADES FÍSICAS

- Melting Range: 2,800-3,000°F (1,538 – 1,649°C)

- Density: 0.160 lbs/cu. in.; 4.47 gm/cc

- Beta Transus Temperature: 1830°F (± 25°); 999°C (± 14°)

TRATAMIENTO TÉRMICO

- Annealing at 1,700-1,900°F (927 – 1,038°C) is done where high hardness, tensile and fatigue strength are desired.

- DAXUN 6-4™, Grade 5 Alloy can be heat treated in several ways.

- 1. Recocido: 1.275 -1.400°F; (691 - 760°C), ½ a 2 horas, enfriado al aire o en horno.

- 2. Recocido de alivio de tensión: 1.000 -1.200°F; (538 - 649°C), 1 a 8 horas, enfriado al aire o en horno.

- 3. Solution Heat Treatment: 1,675 -1,750°F; (913 – 954°C), 1 hour, water quench

- 4. Aging Treatment: 975 -1,025°F; (524 – 552°C), 4 to 8 hours – air cool

- The very best of properties In the solution treated and aged condition, small cross sections are obtained that are rapidly

quenched. Larger sections sizes and/or a quench delay may cause properties to be lower than the optimum values.

DUREZA

La dureza típica en la condición de recocido es Rockwell C 30-34, y alrededor de Rockwell C 35-39 en la condición de solución y envejecido.

FORGEABILITY/ FORMABILITY

- DAXUN Ti-6Al-4V, Grade 5 alloy tubes are forged at 1,750°F (954°C), with an end forging temperature of 1,450°F (788°C). For optimal results, a reduction of at least 35% is recommended.

- DAXUN Ti-6Al-4V, Grade 5 alloy is difficult to form at room temperature, even when annealed. As a result, harsh forming operations like bending or stretching can be conducted on annealed material at temperatures as high as 1,200°F (649°C) without altering its mechanical qualities. Creep forming can be used for hot sizing or forming at temperatures ranging from 1,000 to 1,200°F (538 to 649°C).

MACHINABILITY

- DAXUN Ti-6Al-4V, Grade 5 alloy can be machined using practices for austenitic stainless steels with slow speeds, heavy feeds, rigid

tooling, and large amounts of non-chlorinated cutting fluid.

WELDABILITY

- DAXUN Ti-6Al-4V Grade 5 Alloy Titanium Tube is easily welded in the annealed or solution and partially aged form, with ageing.

- done during the post-weld heat treatment. Precautions must be made to avoid contamination by oxygen, nitrogen, and hydrogen. Fusion welding can be performed in an inert gas-filled chamber or with an inert gas tail shield applied to the molten metal and nearby hot zone. Spot welding, seam welding, and flash welding can all be performed without the use of a protective environment.

SPECIAL PRECAUTIONS

- DAXUN Ti-6Al-4V, Grade 5 alloy may be contaminated with hydrogen as a result of incorrect pickling, as well as the absorption of oxygen, nitrogen, and carbon during forging, heat treatment, brazing, and so on. This contamination may reduce ductility, compromising notch sensitivity and forming properties.

El grado de aleación de titanio que necesita depende del proyecto en el que esté trabajando, ya que cada grado tiene ventajas diferentes.

Todos los grados de aleación de titanio son extremadamente fuertes y resistentes a la corrosión, lo que significa que seguirán funcionando bien en las condiciones más duras.

Los grados superiores de aleación de titanio (5-12) son aleaciones diseñadas para prestaciones específicas. Por ejemplo, la aleación de titanio de grado 12 tiene una excelente resistencia al calor, por lo que es una opción perfecta para intercambiadores de calor de carcasa y tubos, tuberías hidráulicas y equipos de la industria química.

Los grados 1-4 son aleaciones de titanio puro y son la elección perfecta si necesita un material soldable y dúctil para sistemas de tuberías y conductos. Los grados inferiores se utilizan en la industria naval e industrial.

Si está iniciando un proyecto y no está seguro de qué grado de aleación de titanio es el más adecuado para usted, póngase en contacto con nosotros hoy mismo; estaremos encantados de ayudarle.

En DAXUN, ofrecemos una amplia gama de grados de aleación de titanio, desde el grado 1 hasta el grado 12.

Los grados 1-4 son titanio puro, mientras que los grados superiores son aleaciones.

Los grados de aleación son populares por su elevada relación resistencia-peso.

El grado de aleación de titanio más utilizado que encontramos es el grado 5. Aunque sigue teniendo un alto contenido en titanio, este grado es uno de los más fiables porque puede soportar temperaturas de hasta 600 °F y soportar condiciones extremas.

Las calidades superiores son las preferidas por industrias como la aeroespacial y la naval por su resistencia al desgaste y a la corrosión.

Por el contrario, las calidades inferiores se utilizan principalmente para soldar debido a su menor resistencia.

To learn more about the differences between different grades of titanium alloy, call +86 13382898899 today to speak directly with our experts.

Aunque el grado de titanio aumenta ligeramente el coste, el coste total viene determinado principalmente por la forma del titanio que necesite.

En DAXUN ofrecemos una amplia gama de productos de titanio, como placas, tubos, bobinas y barras. La longitud, la anchura y la cantidad de cada artículo que necesite influirán en el importe que pague al realizar la compra.

Por desgracia, es difícil dar un precio en línea sin saber mucho sobre su proyecto y para qué se utilizará el titanio.

Afortunadamente, nuestro equipo de expertos está siempre a su disposición para ayudarle y asesorarle en sus necesidades de titanio. Enviando un correo electrónico a [email protected], podremos responderle con algunos consejos y un presupuesto preciso.

Asegúrese de incluir toda la información posible sobre el grado, la forma y la cantidad de titanio que necesita para conocer mejor sus necesidades.

El equipo de DAXUN es experimentado, experto y amable. Con años de experiencia en el sector, lo saben todo sobre el titanio, incluidos sus usos, ventajas y calidades.

Si desea información actualizada sobre el titanio, sus usos y aplicaciones en distintos sectores, no deje de consultar nuestro blog. Nuestros expertos han escrito guías fáciles de seguir a las que siempre podrá recurrir cuando tenga preguntas.

Si sigues teniendo problemas, no dudes en ponerte en contacto con nosotros; estaremos encantados de ayudarte.

Si envía un correo electrónico a [email protected], recibirá una respuesta rápida. Asegúrate de incluir en tu pregunta todos los detalles posibles para que podamos recomendarte una solución adecuada.

Rellene el formulario de la página “Contacto” o llame a nuestro responsable de ventas al “+86 13382898899”, nos pondremos en contacto con usted lo antes posible. Nuestro WhatsApp está en línea, y el correo electrónico ([email protected]) se comprobará en un plazo de 6 horas. Cada consulta o mensaje será respondido con prontitud. Además, compartimos información de mercado con nuestros clientes cada semana

We can provide stainless steel pipe/tube samples for you to check the quality. Sample is free and you just pay the freight.

Hemos exportado a más de 42 países, como Canadá, Chile, Kuwait, Alemania, Corea del Sur, Arabia Saudí, Singapur, etc.

Our MOQ is 1 ton for stainless steel pipe/tube

Los pedidos de prueba pueden entregarse en una semana. Los pedidos normales tardan unas dos semanas.