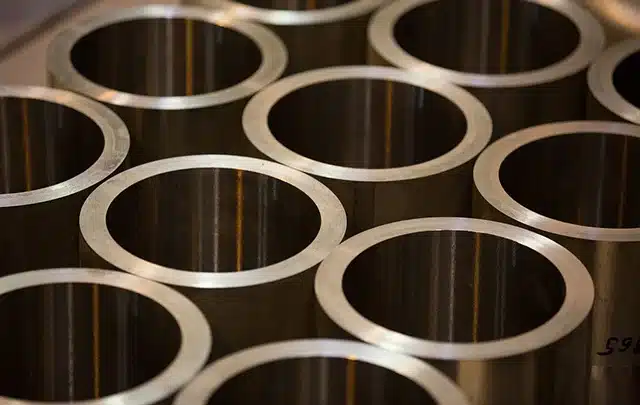

Daxun Alloy - Hastelloy C2000 pipe made in China

As a leading supplier of Hastelloy C2000 pipes in China, Daxun provides high-performance alloy tubes to the world.

- Hastelloy C2000 types: Seamless tube, welded tube, forged tube

- Certification : ASTM,SGS,ISO,CE

- Delivery Time : 7-15 days

- Surface finish: Annealed, polished etc.

- MOQ : ≥300kg

————Daxun produces hastelloy pipe in China to meet the diverse and ——exigentes necesidades de los clientes!.

Characteristics & Properties of Hastelloy C2000

Hastelloy C2000 pipe is a nickel-based alloy pipe with excellent performance, which plays an important role in many industrial fields.It entered the market in late 1995 and has been highly recognized by the market for its versatility.

In terms of composition, it cleverly combines multiple key elements such as nickel, chromium, and molybdenum. Nickel gives the pipe good toughness and basic corrosion resistance; chromium enhances its corrosion resistance in oxidizing environments, enabling it to resist the erosion of various oxidizing media; molybdenum significantly improves the pipe’s resistance to pitting and crevice corrosion in reducing acids, greatly expanding its application range.

Hastelloy C2000 pipe has extremely excellent corrosion resistance. Whether facing harsh chemical media such as strong acids and alkalis, or in extreme environments such as high temperature and high pressure, it can maintain stable chemical properties and effectively resist corrosion. In the chemical industry, many chemical reaction processes will produce extremely corrosive substances, which ordinary pipes cannot withstand, but Hastelloy C2000 pipes can operate stably for a long time to ensure the normal operation of production equipment.

Its mechanical properties are also excellent. It has high strength and good toughness, and can withstand certain pressure and impact without deformation or rupture. This makes it an ideal choice for some occasions that require high mechanical properties of pipes, such as high-pressure pipeline systems and large reaction vessels.

In practical applications, Hastelloy C2000 pipes are widely used. In the petrochemical industry, it is often used in pipeline systems that transport various corrosive media to ensure the safety and stability of the petrochemical production process; in the field of marine engineering, due to its excellent seawater corrosion resistance, it is widely used in seawater desalination equipment, offshore platform pipelines and other facilities; in the power industry, it can be used to manufacture key components such as boiler feed water pipelines to ensure efficient power production.

However, due to the special material and properties of Hastelloy C2000 pipes, its processing difficulty is relatively large. During the welding process, it is necessary to strictly control the welding process parameters and use appropriate welding methods and materials to ensure the welding quality. Otherwise, welding defects are prone to occur, affecting the performance and service life of the pipe.

Hastelloy C2000 Parameters

- Composición química

- Physical properties

- Propiedades mecánicas

| Ni | Cr | Mo | W | Cu | Fe | C | Mn |

| 55% – 62% | 15% – 23%| | 6% – 16% | 2% – 4.5% | 1.3% – 1.9% | ≤3.0% | ≤0.01% – 0.25% | ≤0.5% |

| Si | P | S | Al | Ti | Nb | Co | |

| ≤0.08% – 0.080% | ≤0.02% | ≤0.08% | ≤0.3 – 0.5%≤0.2 – 0.5% | ≤3% | ≤2% |

| Propiedad | Densidad | Punto de fusión | Capacidad calorífica específica | Conductividad térmica | Resistividad eléctrica | Coefficient of Thermal Expansion | Elastic Modulus | Hardness | Operating Temperature |

| Valor | 8.4 – 10.6 g/cm³ | 1280 – 1350°C | 0.102 – 0.46 J/(g·°C) | 7 – 13 W/m·K | 1.4 – 1.6 Ω·mm²/m | 12.4 – 20.0 μm/(m·°C) | 206 GPa | 132 – 247 HB | -196°Cto650°C |

| Propiedad | Resistencia a la tracción | Yield Strength | Elongation | Reducción de la superficie | Impact Toughness | Hardness |

| Valor | 752 – 1090MPa | 345 – 750MPa | 20% – 62% | ≥40% | ≥90J | 132 – 247HB |

Elija Daxun para que su proyecto despegue.

Advanced Production:Hastelloy alloy pipe

Hastelloy C2000 alloy is an all-around nickel-chromium-molybdenum-tungsten alloy with good resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidative aqueous media, including wet chlorine, nitric acid or mixed acids of oxidizing acids containing chloride ions. At the same time, Hastelloy C2000 alloy also has ideal resistance to reducing and oxidizing environments encountered in the process. Relying on this versatile performance, it can be used in some troublesome environments or in factories for a variety of production purposes.

Hastelloy C-2000 Pipe Features

Hastelloy C2000 alloy has an exceptional resistance to various chemical environments, including strong oxidizing substances, such as ferric chloride, cupric chloride, chlorine, thermally contaminated solutions (organic and inorganic), formic acid, acetic acid, acetic anhydride, seawater and salt solutions, etc. Hastelloy C2000 alloy has the ability to resist the formation of grain boundary precipitation in the heat affected zone of welding, so that it can also be used in many chemical processes in the welding state.

Calidad, entrega, inspección

Daxun conducts a series of quality assurance tests on Hastelloy C2000 pipes. These tests include flattening test, flaring test, ultrasonic flaw detection, crevice corrosion resistance test, mechanical property test, hardness test, material positive identification, and expansion test, etc. All these tests are designed to ensure that the Hastelloy C2000 pipes meet the requirements of the intended applications. During the production process, we meticulously measure the outer diameter, wall thickness, and surface quality of the products. Our standard delivery time is 5 – 7 days, and for special sizes, it is 15 – 20 days.

- Nuestro plazo de entrega se ajusta estrictamente a lo estipulado en el contrato.

- Apoyar a las agencias externas del cliente para que vayan a la fábrica a inspeccionar

- Muestras gratuitas para las pruebas de los clientes

- Apoyo a la inspección in situ o por vídeo en fábrica

Embalaje

Daxun Alloy garantiza la mejor calidad de embalaje, ya que desempeña un papel importante en el transporte internacional de mercancías, donde las mercancías pasan por varios canales para llegar al destino final, por lo que prestamos especial atención al embalaje. Embalamos nuestras mercancías de muchas maneras dependiendo del producto. Embalamos nuestros productos de muchas maneras, tales como:

- Cajas y cajones

- Retráctil

- Palés de madera

- Cajas de madera

Asistencia técnica

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. [Póngase en contacto con nosotros]Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry. This, in our opinion, demonstrates our unwavering dedication to quality and our philosophy as a full-service supplier.

Daxun is a trustworthy stainless steel tube manufacturer

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all titanium tubes are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the stainless steel tubes have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

Productos relacionados (8)

Rellene el formulario de la página “Contacto” o llame a nuestro responsable de ventas al “+86 13382898899”, nos pondremos en contacto con usted lo antes posible. Nuestro WhatsApp está en línea, y el correo electrónico ([email protected]) se comprobará en un plazo de 6 horas. Cada consulta o mensaje será respondido con prontitud. Además, compartimos información de mercado con nuestros clientes cada semana

Podemos proporcionarle muestras de chapa de acero inoxidable para que compruebe la calidad. La muestra es gratuita y usted sólo paga el flete.

Hemos exportado a más de 42 países, como Canadá, Chile, Kuwait, Alemania, Corea del Sur, Arabia Saudí, Singapur, etc.

The minimum order quantity for our Hastelloy products is 300kg

Los pedidos de prueba pueden entregarse en una semana. Los pedidos normales tardan unas dos semanas.