Grade 9 (Ti-3Al-2.5V) Titanium Alloy Plate Manufacturer - Daxun Alloy

As a leading supplier of titanium in China, Daxun provides high-performance titanium plates to the world.

- Plate Grade:Grade 9 UNS R56320

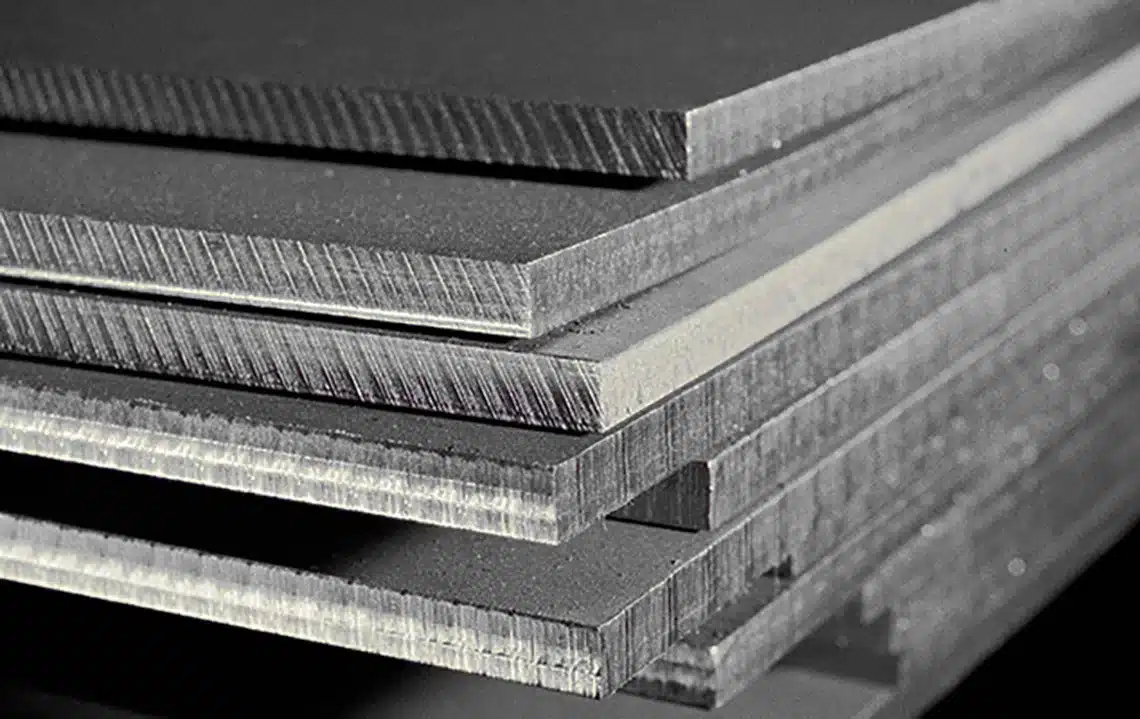

- Plate Production type:cold rolling, hot rolling, forging.

- Standard:ASTM B 265,ASME SB265,AMS491 etc

- Features:High strength, Lightweight, High-temperature resistance

- Surface:bright, polished, pickled, sandblasted, etc.

- Size:0.3mm ≤ 1000mm ≤ 2500mm or as your request

————Daxun produces titanium sheets in China to meet the diverse and ——exigentes necesidades de los clientes!.

Providing High-quality Grade 9 Titanium Plate to Serve Customers Worldwide

Grade 9 titanium plate is a high-performance near-alpha titanium alloy with a nominal composition of Ti-3Al-2.5V. It is based on pure titanium (Grades 1-4) reinforced with appropriate amounts of aluminum and vanadium, achieving an excellent balance of strength and toughness. Compared to pure titanium, Grade 9 boasts significantly higher strength and yield strength while maintaining good ductility and toughness. It is particularly renowned for its excellent weldability and cold formability. This material also offers lightweight, excellent corrosion resistance (especially in chloride environments), and good biocompatibility. It is both strong and durable, yet can withstand a variety of harsh operating conditions, making it an ideal choice for applications requiring high performance and reliability.

Where is Grade 9 titanium plate used?

In the aerospace industry, Grade 9 titanium plate is widely used in the manufacture of aircraft structures, fasteners, hydraulic systems, and engine components. Its combination of high strength and low density effectively reduces aircraft weight and improves fuel efficiency. In marine engineering and shipbuilding, its exceptional resistance to seawater corrosion makes it the material of choice for ship hull structures, desalination equipment, heat exchangers, and offshore platform components, ensuring long-term reliability in harsh marine environments. In the medical industry, Grade 9 titanium plate, due to its excellent biocompatibility and moderate strength, is widely used in the manufacture of orthopedic implants (such as plates and screws), dental implants, and surgical instruments. Furthermore, Grade 9 titanium plate demonstrates its unique value and adaptability in high-end sports equipment (such as bicycle frames and golf club heads), chemical equipment (corrosion-resistant reactors and heat exchangers), and precision mechanical components requiring lightweight and high strength.

Datos

- Parámetro

- Propiedades físicas

- Propiedades mecánicas

| Elemento | Composition Range (wt.%) |

|---|---|

| Ti | Balance (>90%) |

| Al | 2.50–3.50% |

| V | 2.00–3.00% |

| Fe | ≤0.25% |

| O | ≤0.13% |

| C | ≤0.08% |

| N | ≤0.03% |

| H | ≤0.015% |

| Otros | ≤0.4% (single element) |

Key Characteristics

- Relación resistencia/peso: Higher than pure titanium (Grades 1–4) but lower than Ti-6Al-4V (Grade 5).

- Resistencia a la corrosión: Excellent in marine, chemical, and chloride environments.

- Biocompatibilidad: Non-toxic and MRI-compatible, but less commonly used in implants than Grade 23.

- Formability: Superior to Grade 5; suitable for complex forming, welding, and machining.

Aplicaciones típicas

- Aeroespacial: Hydraulic tubing, aircraft fittings, fasteners.

- Marine: Heat exchangers, seawater components, propeller shafts.

- Medical: Surgical instruments, non-implantable devices.

- Industrial: Chemical processing equipment, pressure vessels.

| Propiedad | Value (Imperial) | Value (Metric) |

|---|---|---|

| Densidad | 0.160 lb/in³ | 4.43 g/cm³ |

| Punto de fusión | 3,000–3,050°F | 1,650–1,680°C |

| Conductividad térmica | 6.5 Btu/(hr·ft·°F) | 11.2 W/(m·K) |

| Coefficient of Thermal Expansion | 5.3 × 10⁻⁶/°F | 9.5 × 10⁻⁶/K |

| Resistividad eléctrica | 120 µΩ·cm | 120 nΩ·m |

Room Temperature Properties (Annealed Condition)

| Propiedad | Value (Imperial) | Value (Metric) |

|---|---|---|

| Resistencia a la tracción | 130–140 ksi | 895–965 MPa |

| Yield Strength (0.2% offset) | 120–125 ksi | 825–860 MPa |

| Elongation | 10–15% | 10–15% |

| Reduction in Area | 25–30% | 25–30% |

| Dureza (Brinell) | 280–320 HB | 290–330 HBW |

| Módulo de elasticidad | 16.5 × 10⁶ psi | 114 GPa |

Rendimiento a altas temperaturas

| Temperature (°F) | Tensile Strength (ksi) | Yield Strength (ksi) |

|---|---|---|

| 400°F (200°C) | 115–125 | 105–110 |

| 600°F (315°C) | 100–110 | 90–95 |

| 800°F (425°C) | 85–95 | 75–80 |

Elija Daxun para que su proyecto despegue.

Common applications

Grade 9 titanium plates and sheets are primarily used for components that require an excellent balance of strength, ductility, and corrosion resistance, offering superior weldability and formability compared to other titanium alloys.

- Applications include aerospace components such as airframe structures, pressure vessels, and engine components that require moderate strength but exceptional corrosion resistance.

- Industrial applications include chemical processing equipment, heat exchangers, and marine components due to their outstanding resistance to corrosive environments.

- Oil and gas industry components, including downhole drilling equipment and subsea systems, where both strength and corrosion resistance are critical.

- Medical implants and surgical instruments, particularly where biocompatibility and moderate strength are required.

- Performance automotive components, including exhaust systems, suspension parts, and high-performance vehicle frames that benefit from titanium’s strength-to-weight ratio.

Entrega rápida

Daxun provides customers with timely and fast delivery of grade 9 titanium plate products. Behind the speed is the system support from professional production capacity, and information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real-time, and the data is seamlessly connected.

Custom Cutting

Daxun Alloy provides customers with customized cutting solutions of various sizes to help you control the size loss of titanium plates, thereby saving your processing costs and time. Our cutting methods include:

- Water jet cutting

- Laser cutting

- Plasma cutting

- Wire cutting

- Bending

- Slitting

- Serrar

Embalaje

We pay special attention to packaging. We pack our goods in many ways depending on the product. We pack our products in many ways such as:

- Cajas y cajones

• Shrinkwrap

- Palés de madera

- Cajas de madera

Asistencia técnica

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry.

Daxun Grade 9 Titanium sheet Let your brand improve rapidly

- Other Titanium Plate Grades

| Aparte de los productos enumerados a continuación, otros productos metálicos disponibles no se enumeran aquí. Otros productos metálicos que DAXUN puede fabricar y suministrar incluyen tantalio, niobio, circonio, hafnio, níquel, cobre, etc., que se presentan principalmente en forma de placa, barra y tubo. | |

| Productos/Norma de transformación | Grado/Tamaño |

| Titanium Plate, Sheet, Coil— ASME SB265, AMS 4911, AMS 4919, AMS 4914,ASTM F67, ASTM F136 | GR1, GR2, GR3, GR4, GR5, GR7,GR9, GR12, GR16, GR17, GR23,Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3(Espesor:( 0.0197”-6”)Anchura máxima: 12 pies,Longitud máxima: 50 pies) |

| AMS-T-9046 | |

| Titanium and Titanium alloy sheet, plate | |

| Titanio comercialmente puro (CP) | |

| Designación del código | Límite elástico |

| mínimo, ksi 1 / | |

| CP-1 Gr1 | 70 |

| CP-2 Gr2 | 55 |

| CP-3 Gr3 | 40 |

| CP-4 Gr4 | 25 |

| Aleaciones de titanio alfa(A) | |

| Designación del código | Composición |

| A-1 | 5A1-2.5Sn |

| A-2 | 5A1-2,5Sn(ELI) 2 / |

| A-3 | 6A1-2Cb-1Ta-0,8Mo |

| A-4 | 8A1-1Mo-1V |

| Aleaciones de titanio alfa-beta (AB) | |

| Designación del código | Composición |

| AB-1 Gr5 | 6A1-4V |

| AB-2 Gr5 | 6A1-4V(ELI) |

| AB-3 | 6A1-6V-2Sn |

| AB-4 | 6A1-2Sn-4Zr-2Mo |

| AB-5 | 3A1-2,5V |

| AB-6 | 8Mn |

| Aleaciones beta de titanio(B) | |

| Designación del código | Composición |

| B-1 | 13V-11Cr-3A1 |

| B-2 | 11,5Mo-6Zr-4,5Sn |

| B-3 | 3A1-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3A1 |

| Procesando: | |

| Laminación en caliente | Laminación en frío |

| Grados disponibles: | |

| CP Grado 1 | Calidad 6Al-2Sn-4Zr-2Mo (6-2-4-2) |

| CP Grado 2 | Grado 6Al-4V ELI (antes grado 23) |

| Grado 7 | Grado 6Al-6V-2Sn (6-62) |

| Grado 19 | Grado 8Al-1Mo-1V (8-1-1) |

| Grado 5 (6Al-4V) | Grado 9 (3Al-2,5V) |

| Grado 6 (5Al-2,5Sn) | CP Grado 3 |

| Aplicación | |

| Industria química | Desalinización del agua de mar |

| Industria petroquímica | Aeroespacial |

| Mecanizado, Automoción | Componente de teléfono móvil Campo. |

Proyectos y productos recientes

Productos relacionados (7)

Grade 9 titanium (Ti-3Al-2.5V) offers an optimal balance between strength, ductility, and corrosion resistance. It contains 3% aluminum and 2.5% vanadium, which gives it approximately 20-30% higher strength than pure titanium (Grade 1-4) while maintaining excellent formability and weldability that surpasses many other titanium alloys.

Grade 9 titanium plates provide exceptional corrosion resistance, high strength-to-weight ratio, excellent weldability, and good formability. These properties make them ideal for applications requiring durability in harsh environments while reducing overall weight, which can lead to improved fuel efficiency in transportation applications.

Machining Grade 9 titanium requires slower speeds, lower feed rates, and ample coolant compared to steel or aluminum. Using sharp, high-quality carbide tools with rigid setups is essential. The material has a tendency to work-harden, so maintaining positive cutting action and avoiding dwell times is important for successful machining.

Grade 9 titanium excels in marine environments, offering outstanding resistance to seawater corrosion, crevice corrosion, and stress corrosion cracking. Unlike many stainless steels that may require regular maintenance or replacement in marine applications, Grade 9 titanium can provide decades of service with minimal degradation, making it cost-effective despite higher initial material costs.

Yes, Grade 9 titanium is highly suitable for welding and fabrication. It can be welded using TIG, MIG, plasma arc, and electron beam welding processes. The alloy requires proper shielding from atmospheric contamination during welding, but generally offers excellent weldability without the need for post-weld heat treatment in most applications.

Rellene el formulario de la página “Contacto” o llame a nuestro responsable de ventas al “+86 13382898899”, nos pondremos en contacto con usted lo antes posible. Nuestro WhatsApp está en línea, y el correo electrónico ([email protected]) se comprobará en un plazo de 6 horas. Cada consulta o mensaje será respondido con prontitud. Además, compartimos información de mercado con nuestros clientes cada semana

We can provide titanium sheet samples for you to check the quality. Sample is free and you just pay the freight.

Hemos exportado a más de 42 países, como Canadá, Chile, Kuwait, Alemania, Corea del Sur, Arabia Saudí, Singapur, etc.

Our MOQ is 1 ton for titanium sheet.

Los pedidos de prueba pueden entregarse en una semana. Los pedidos normales tardan unas dos semanas.