Super Austenitic 904L Stainless Steel Plate Supplier

As China’s leading stainless steel plate supplier and exporter, Daxun provides 904L stainless steel plates to the world.

- Grade: AISI 904L-N08904

- Features: Super corrosion resistance

- Manufacturing: Cold-rolled plate, hot-rolled plate, forged plate

- Standards: ASTM, ASME, GB, DIN, JIS, ISO, EN, BS

- Type: Cold-rolled thin plate, hot-rolled thick plate

- Superficie: 2B, NO.1, NO.4, HL, BA, 8K, etc.

- Longitud: 2438mm3048mm6000mm se puede personalizar

- Origin: TISCO, Baosteel, Posco, Tsingshan, Delong, ATI,

Overview of 904L Stainless Steel

Alloy 904L is a superaustenitic stainless steel designed for moderate to high corrosion resistance in various process environments. This high alloy austenitic product is intended for use under severely corrosive conditions, making it a reliable choice for demanding applications. The high chromium and nickel content, along with the additions of molybdenum and copper, provide excellent corrosion resistance. With a highly alloyed chemistry that includes 25% nickel and 4.5% molybdenum, Alloy 904L is well-suited for applications requiring both high corrosion resistance and high strength. This unique composition allows it to withstand environments involving dilute sulfuric acid, hot phosphoric acid, and other inorganic acids, ensuring long-lasting performance in harsh conditions.

Dimensions and Sizes

Alloy 904L stainless steel plate is available in various dimensions and sizes to meet specific application requirements. The available thicknesses for Alloy 904L range from 3/16” through 2”, providing flexibility for different industrial needs. UNS N08904 Sheet can range up to 8mm in thickness, while 904L Plate is usually thicker than 8mm and can range up to 75mm in thickness. These dimensions can be customized to meet specific industry standards and specifications, ensuring that the material fits perfectly into any project. Additionally, 904L stainless steel plate can be easily welded and processed using standard shop fabrication practices, streamlining the manufacturing process and ensuring high-quality results.

Datos técnicos

- Parámetro

- Composiciones químicas

- Propiedades mecánicas

- PROPIEDADES FÍSICAS

- Estándar

| Stainless Steel 904L Plate, Sheet and Strip | ASTM B 168/ASME SB 168, ASTM B 906/ASME SB 906, ASME Code Cases 1827 and N-253, SAE/AMS 5540, BS 3072NA14 and 3073NA14, DIN 17750, ISO 6208, EN 10095, MIL-DTL-23228. |

| Standard Stainless Steel 904L Plate & Sheet Sizes | 1000 x 2000 mm, 1220 x 2440 mm, 1500 x 3000 mm, 2000 x 2000 mm, 2000 x 4000 mm |

| Cold rolled 904L Steel Plate 0.5-6.4 mm | |

| Hot rolled 904L Steel Plate 3.0–10.0 mm | |

| SS 904L Plate Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard Stainless Steel 904L Sheet suppliers |

| Availability of Stainless Steel 904L Foil sizes | Thickness : 8-100 microns (0.00031-0.004 in) |

| Width: Up to 500 mm (19.5 in) | |

| Weight (in rolls) : Up to 50 kg (110 lb); e.g. approxi- mately 1400 m at 8 microns and ap- proximately 112 m at 100 microns. | |

| Profiling | To provide a full profiling service in China we use numerous profiling methods including: |

| Laser Plate Cutting | |

| Plasma Plate Cutting | |

| Oxy-propane Flame Cutting | |

| Tolerances of width and thickness | EN 10258 (formerly DIN 59381) |

| EN 10151 Stainless Steel 904L strip for springs | |

| EN 10088 Stainless Steel 904L strip (general) | |

| Stainless Steel 904L Plates standards and approvals | EN ISO 18286 |

| EN 10051 | |

| EN 10088-1 | |

| ISO 15510 | |

| EN ISO 9445 | |

| ASTM A 480 | |

| ASTM A 959 | |

| ASME IID | |

| Plasma profiles | As per customer’s drawings |

| Value added services for Stainless Steel 904L Plate | Laser cutting, Waterjet cutting, Plasma cutting, Bending and mechanical processing, edge preparation, welding, sawing and shearing. |

| Value added services for Stainless Steel 904L Coil | Cut-to-length |

| Slitting | |

| Polishing | |

| Blanking | |

| SS 904L Plate Origin | China Origin, European Origin, Japanese Origin |

| Packing of 904L Steel Sheet | Bundles with waterproof cloth outside or plywood box |

| Test | UT, SGS testing, TUV etc |

| Elemento | % Presente (en forma de producto) |

| Carbono (C) | 0.02 |

| Silicio (Si) | 0.7 |

| Manganeso (Mn) | 2 |

| Fósforo (P) | 0.03 |

| Azufre (S) | 0.01 |

| Cromo (Cr) | 19.00 – 21.00 |

| Nickel (Ni) | 24.00 – 26.00 |

| Nitrogen (N) | 0.15 |

| Molybdenum (Mo) | 4.00 – 5.00 |

| Copper (Cu) | 1.20 – 2.00 |

| Hierro (Fe) | Saldo |

| Forma del producto | ||||||||

| C | H | P | L | L | TW/TS | |||

| Thickness (mm) Max. | 8 | 13.5 | 75 | 160 | 2502) | 60 | ||

| Yield Strength | Rp0.2聽N/mm2 | 2403) | 2203) | 2203) | 2304) | 2305) | 2306) | |

| Rp1.0聽N/mm2 | 2703) | 2603) | 2603) | 2603) | 2603) | 2503) | ||

| Resistencia a la tracción | Rm聽N/mm2 | 530 – 7303) | 530 – 7303) | 520 – 7203) | 530 – 7304) | 530 – 7305) | 520 – 7206) | |

| Alargamiento mín. en % | Jmin聽(Longitudinal) | - | 100 | 100 | 100 | - | 120 | |

| Jmin聽(Transverse) | - | 60 | 60 | - | 60 | 90 | ||

| Densidad a 20°C kg/m3 | 8 | |

| Thermal Conductivity W/m K at | 20°C | 12 |

| Modulus of Elasticity kN/mm2 at | 20°C | 195 |

| 200°C | 182 | |

| 400°C | 166 | |

| 500°C | 158 | |

| Capacidad térmica específica a 20°C J/kg K | 450 | |

| Electrical Resistivity at 20°C Ω mm2/m | 1 | |

| UNS S904L | 1.4539 | UNS N08904 |

| ASTM A240 | ASTM A240 | ASTM A240 |

| ASTM A480 | ASTM A480 | ASTM A480 |

| ASME SA240 | ASME SA240 | ASME SA240 |

| AMS 5521 | AMS 5521 | AMS 5521 |

Elija Daxun y haga que sus clientes queden satisfechos.

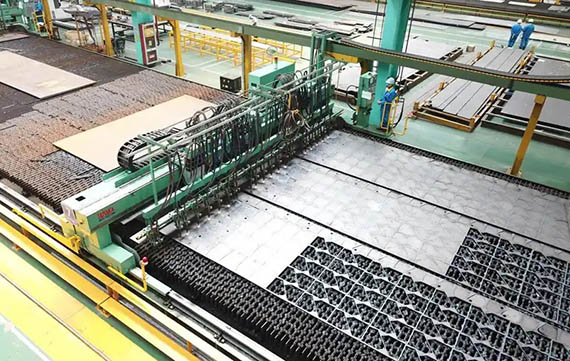

Entrega rápida

We provide timely and fast delivery of 904L stainless steel plate products for customers with urgent needs. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real time, and the data is seamlessly connected; in terms of logistics, the processing center is close to highways and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on time.

904L plate features

Type 904L is a high alloy austenitic stainless steel that is known for its corrosion properties.

- No magnético

- Stronger corrosion properties than Type 316L an 317L

- Good resistance to sulphuric, phosphoric and acetic acids

- High resistance to crevice and stress corrosion cracking

- Excellent formability and weldability

Stainless Steel 904L Applications

Application of using Type 904L stainless steel:

- Cooling equipment for seawater

- Chemical processing of sulphuric, phosphoric and acetic acids

- Heat exchangers

- Condenser tubes

- Gas washing

- Control and instrumentation

- Oil and gas industry

- Pharmaceutical production

- Wiring in electrostatic precipitators

Calidad, entrega, inspección

-

Daxun Alloy is committed to quality assurance. The company conducts various tests to ensure material suitability. These tests include flattening, pitting, and resistance tests. Mechanical, hardness, and expansion tests are also performed. Material positive identification is another key quality assurance measure. All these tests guarantee that the materials meet application requirements. Customers can trust Daxun Alloy for high-quality, suitable products.

- Durante el proceso de producción, medimos el diámetro, el grosor y la superficie del producto. Nuestro plazo de entrega estándar es de 7-15 días, excepto para algunos productos de tamaño especial, nuestro plazo de entrega aumentará a 20 días.

Nuestro plazo de entrega se ajusta estrictamente a lo estipulado en el contrato. - Apoyar a las agencias externas del cliente para que vayan a la fábrica a inspeccionar

- Ofrecer muestras gratuitas a los clientes para que las prueben

- Apoyo a la inspección in situ o por vídeo en fábrica

Technical Services

Si necesita asistencia técnica adicional, nuestro metalúrgico residente y nuestro personal experto estarán encantados de ayudarle. Además, Daxun cuenta con un laboratorio de pruebas certificado, una primicia en la industria de inventarios multimetal y plástico. Esto, en nuestra opinión, demuestra nuestra inquebrantable dedicación a la calidad y nuestra filosofía como proveedor de servicios completos.

Advanced machining

Quality is belief, and integrity is a business card. Daxun pioneered the concept of “performance excellence management” and implemented the “PDCA+Lean” management model. The company’s business card says “Daxun = assured quality”. Daxun Stainless Steel uses the ERP system to achieve full traceability of the variety, specification, and origin of each stainless steel plate, and advocates and encourages industry anti-counterfeiting. Daxun Stainless Steel relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

904L plate stainless steel Features

Daxun Deje que su marca mejore rápidamente

- Galería

- Tolerancia

- Estado de entrega

- Otras series de productos

| Tolerancia para chapa 2B | |||

| Talla | Rango de tolerancia | ||

| Grupo 1 | Grupo 2 | Grupo 3 | |

| 0.4 | 0.3 ~ 0.32 | 0.33 ~ 0.37 | 0.37 ~ 0.39 |

| 0.5 | 0.4 ~ 0.42 | 0.43 ~ 0.47 | 0.47 ~ 0.49 |

| 0.6 | 0.5 ~ 0.52 | 0.53 ~ 0.56 | 0.57 ~ 0.59 |

| 0.7 | 0.6 ~ 0.62 | 0.63 ~ 0.67 | 0.67 ~ 0.69 |

| 0.8 | 0.7 ~ 0.72 | 0.73 ~ 0.77 | 0.74 ~ 0.79 |

| 0.9 | 0.8 ~ 0.82 | 0.83 ~ 0.87 | 0.87 ~ 0.89 |

| 1 | 0.89 ~ 0.9 | 0.91 ~ 0.94 | 0.94 ~ 0.99 |

| 1.2 | 1.02 ~ 1.08 | 1.09 ~ 1.15 | 1.16 ~ 1.18 |

| 1.5 | 1.32 ~ 1.38 | 1.39 ~ 1.45 | 1.46 ~ 1.48 |

| 2 | 1.72 ~ 1.79 | 1.8 ~ 1.86 | 1.87 ~ 1.9 |

| 2.5 | 2.23 ~ 2.36 | 2.32 ~ 2.42 | 1.42 ~ 1.47 |

| 3 | 2.7 ~ 2.77 | 2.78 ~ 2.82 | 2.85 ~ 2.9 |

| Tolerancia de la chapa laminada en caliente n.º 1 | |||

| Talla | Rango de tolerancia | ||

| Grupo 1 | Grupo 2 | Grupo 3 | |

| 3 | 2.6 ~ 2.75 | 2.75 ~ 2.85 | 2.86 ~ 2.9 |

| 4 | 3.5 ~ 3.6 | 3.6 ~ 3.75 | 3.76 ~ 3.95 |

| 5 | 4.5 ~ 4.6 | 4.6 ~ 4.75 | 4.75 ~ 4.95 |

| 6 | 5.4 ~ 5.6 | 5.6 ~ 5.75 | 5.75 ~ 5.85 |

| 8 | 7.3 ~ 7.5 | 7.5 ~ 7.65 | 7.65 ~ 7.85 |

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9.6 ~ 9.85 |

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11.6 ~ 11.85 |

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13.6 ~ 13.85 |

| 16 | 15.2~ 15.5 | 15.5~ 15.7 | 15.7~ 16.1 |

| 18 | 17.2~ 17.5 | 17.5~ 17.7 | 17.7~ 18.1 |

| 20 | 19.2~ 19.5 | 19.5~ 19.7 | 19.7~ 20.1 |

| 30 | 29.2~ 29.5 | 29.5~ 29.7 | 29.7-30.1 |

| 40 | 39.2~ 39.5 | 39.5~ 39.7 | 39.7~ 40.1 |

| 50 | 49.2~ 49.5 | 49.5~ 49.7 | 49.7~ 50.1 |

| 60 | 59.2~ 59.5 | 59.5~ 59.7 | 59.7~ 60.1 |

| Elección del Estado de entrega | Estado de la superficie |

| Laminado en frío | 2B |

| 2D | |

| BA | |

| Línea del cabello | |

| No.3 | |

| No.4 | |

| 6K | |

| 8K | |

| Nota: | |

| 1. Si necesita un estado de entrega diferente al indicado anteriormente, confírmelo con nosotros. | |

| 2. En caso de cualquier consulta o pedido, por favor, háganos saber cualquier requisito adicional no indicado aquí. | |

| Estado de entrega | |

| Elección del Estado de entrega | Estado de la superficie |

| Laminado en caliente | No.1 |

| No.3 | |

| No.4 | |

| 6K | |

| 8K | |

| En escabeche | |

| Nota: | |

| 1. Si necesita un estado de entrega diferente al indicado anteriormente, confírmelo con nosotros. | |

| 2. En caso de cualquier consulta o pedido, por favor, háganos saber cualquier requisito adicional no indicado aquí. | |

| Grado | Tipo | Espesor | Superficie |

| Austenítico | 304/304H/304L/304J1 | 0,25-150 mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80 mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0,3-80 mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferrita | 430 | 0,4-3,0 mm | 2B/BA/NO.4/8K/SB/HL |

| Ferrita ultrapura | 443 | 0,4-2,0 mm | 2B |

| 436L/439/444/441 | 0,5-3,0 mm | 2B、2D | |

| 409L | 0,4-2,5 mm | 2B、2D | |

| Grado | Tipo | Espesor | Original |

| Acero resistente al calor | 309S | 0,5-40 mm | CHN |

| 310S | 0,5-40 mm | CHN | |

| Acero dúplex | 2101 | 1,5-50 mm | CHN |

| 2304 | 3,0-50 mm | CHN | |

| 2205 | 0,5-60 mm | CHN | |

| 2507 | 1,0-60 mm | SWE / JPN / CHN | |

| Acero súper austenítico | N08904 | 0,6-50 mm | SWE / JPN / CHN |

| S31254 | 0,5-50 mm | SWE / JPN / CHN | |

| N08926 | 0,5-50 mm | SWE / JPN / CHN | |

| N08367 | 0,5-50 mm | SWE / JPN / CHN | |

| Aleación a base de níquel | N08031 | 1,0-50 mm | US / JPN / GER |

| N08810/N08800 | 0,8-50 mm | US / JPN / CHN | |

| N08028 | 1,0-20 mm | US / GER / JPN | |

| N08020 | 1,0-20 mm | US / GER / JPN | |

| N08825 | 0,8-40 mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50 mm | US / GER / JPN | |

| N06022 | 1,0-50 mm | US / GER / JPN | |

| N06625 | 0,8-20 mm | US / GER / CHN | |

| N04400 | 1,0-20 mm | US / GER / JPN | |

| N06600 | 1,0-50 mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20 mm | US / JPN | |

| Titanio | TA1/Gr1 | 0,5-50 mm | JPN / CHN |

| TA2/Gr2 | 0,5-50 mm | JPN / CHN | |

| Material de soldadura | ERNiCrMo-13 | 1.2、2.4mm | GER |

| ERNiCrMo-3 | 2,4 mm | GER | |

| ERNiCrMo-4 | 2,4 mm | US |

The surface and shape of 904L stainless steel plate (7)

Información disponible para consulta y descarga

Daxun es un fabricante de placas de acero inoxidable de confianza

Como fabricante profesional, Daxun asegura que todos los productos que producimos son de alta calidad. Por lo tanto, nos aseguramos de que todas las placas de acero inoxidable estén certificadas por ISO9001, SGS, CE, OQC y más normas internacionales de calidad.También tenemos un estricto control de calidad para garantizar que las placas de acero inoxidable tengan menos defectos. En Daxun, puede estar seguro de que todos los productos son duraderos, de alta calidad y alto rendimiento.

Proyectos y productos recientes

Productos relacionados (13)

Podemos proporcionarle muestras de chapa de acero inoxidable para que compruebe la calidad. La muestra es gratuita y usted sólo paga el flete.

Hemos exportado a más de 42 países, como Canadá, Chile, Kuwait, Alemania, Corea del Sur, Arabia Saudí, Singapur, etc.

Nuestro MOQ es de 1 tonelada de chapa de acero inoxidable.

Los pedidos de prueba pueden entregarse en una semana. Los pedidos normales tardan unas dos semanas.