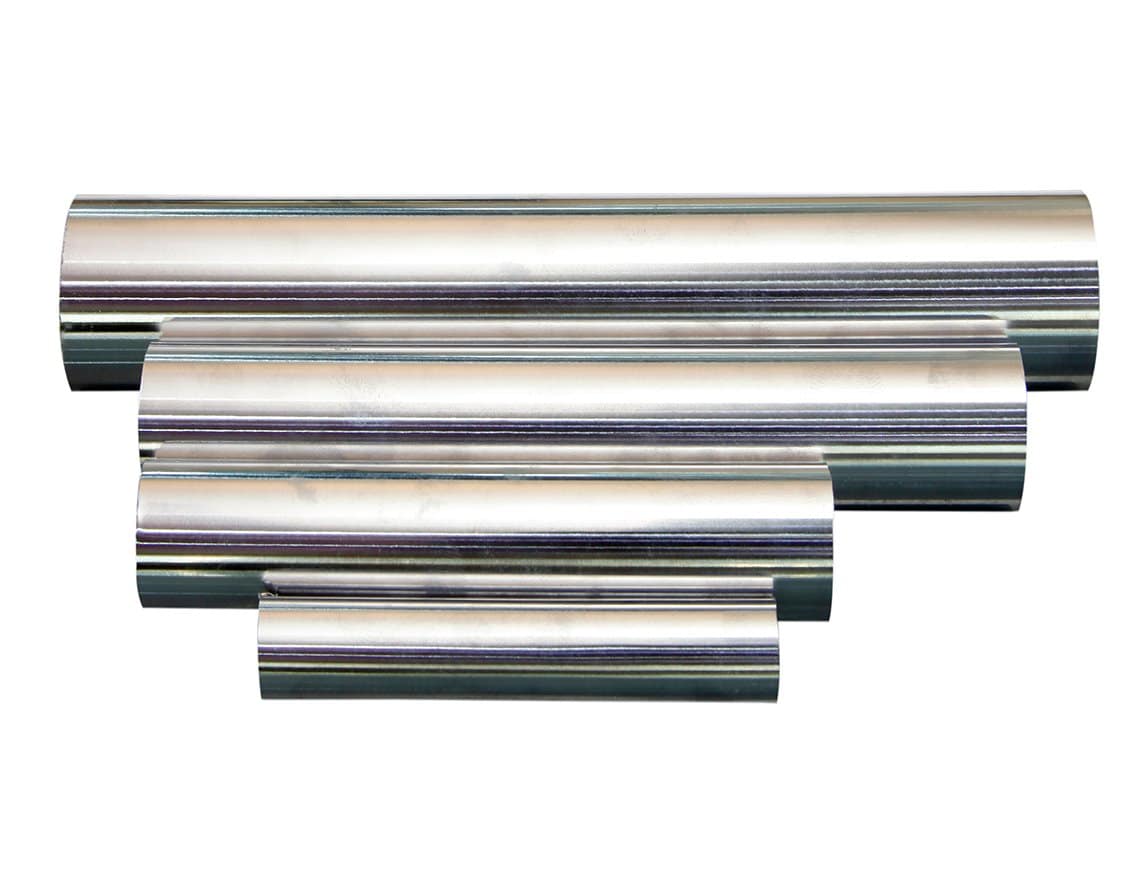

Daxun is an excellent manufacturer of CP-2-grade titanium rods

As China’s leading supplier of titanium and titanium alloy rods, Daxun provides high-performance titanium rods to the world.

- Titanium Rod Grade:CP-2(Grade 2)- UNS R50400-3.7035-TA2

- Types: Hot rolled rod, forged rod, cold drawn rod, extruded rod etc

- Shape: Titanium round bar, titanium square bar、Ti hexagonal bar

- Density of Titanium Rod: Density of Grade 2 Titanium Rod is 4.51g/cm3

- Standards: ASTM B 348,ASME SB348,DIN 17862,ASTM F67,ASTM 265

- Dimensions: GB, GJB, EN, ASTM, JIS, ASME, BS, AISI, DIN, ISO, etc.

상업용 순수 티타늄 막대 제조 서비스 분야의 글로벌 리더

Grade 2 Titanium Rod is the workhorse among titanium alloy rods, offering an excellent balance of strength and weight for weight-sensitive applications. As a commercially pure (CP) titanium alloy, it achieves an ideal combination of strength and ductility, making it suitable for a wide range of demanding uses. It provides high impact strength, is easily weldable, and is extremely corrosion-resistant in oxidizing conditions, alkaline media, brine solutions, weakly reducing environments, nitric acid, and wet chlorine. Additionally, its excellent resistance to seawater and saline solutions further enhances its versatility.

The Grade 2 Titanium Rod stands out for its lightweight nature, impressive strength-to-weight ratio, and outstanding resistance to corrosion, making it highly versatile and ideal for numerous industrial uses. From general industrial uses to military and aerospace applications, this material delivers reliable performance in challenging environments.

Daxun Alloys stocks Grade 2 Titanium Rods in a variety of diameters to meet the specific requirements of different projects. Our inventory includes sizes ranging from 1 mm to 300 mm, with the ability to accommodate custom orders for larger dimensions. All rods are certified to ASTM B348 and ASTM B381 standards.

For those seeking reliable suppliers, Daxun Alloys offers a comprehensive range of Grade 2 Titanium products, including ASTM B348 Titanium Grade 2 Round Bars, UNS R50400 Bright Bars, and WERKSTOFF NR. 3.7035 Round Bars. Whether you need round, forged, or square bars, we ensure consistent quality and competitive pricing.

Feel free to contact Daxun Alloys for inquiries or to request a quote. Our team is committed to providing high-quality Grade 2 Titanium Rods and is happy to assist with any questions or project-specific needs.

데이터

- 매개변수

- 성분

- 기계적 특성

- 물리적 속성

- Hot searches

| 사양 | 세부 정보 |

| 재료 | Titanium rod and bar Grade 2 (UNS R50400) |

| 표준 | ASTM B348, ASTM SB348, AMS 4921, AMS 4902 |

| 치수 | EN, ASTM, JIS, ASME, BS, AISI |

| 직경 범위 | 0.125″ – 14″ (3.175mm – 355.6mm), custom |

| 길이 범위 | Up to 240″ (6096mm), custom |

| 완료 | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| 표면 마감 | 냉간 인발, 센터리스 그라운드, 광택 또는 러프 턴, 블랙, NO.4 마감, BA 마감, 무광 마감 등. |

| 조건 | 경화 및 템퍼링, 어닐링 처리 |

| 허용 오차 | Diameter tolerance: +/- 0.005″ (0.127mm), length tolerance: +/- 0.125″ (3.175mm) |

| 양식 | 티타늄 사각형 바, 티타늄 잉곳, 티타늄 원형 바, 직사각형 티타늄 바, 삼각형 티타늄 바, 단조 티타늄 바, 티타늄 육각 바 등이 있습니다. |

| 물리적 속성 | Density: 0.163 lb/in³ (4.51 g/cm³), Melting Point: 3,020°F (1,660°C), Elongation: 20-30%, Modulus of Elasticity: 16.5 x 10⁶ psi (114 GPa) |

| 화학 성분 | Titanium (min): 99.2%, Oxygen (max): 0.25%, Carbon (max): 0.08%, Iron (max): 0.30%, Nitrogen (max): 0.03%, Hydrogen (max): 0.015% |

| 요소 | Weight % |

| C | ≤0.08 |

| O | ≤0.25 |

| N | ≤0.03 |

| H | ≤0.015 |

| Fe | ≤0.30 |

| *OEE | ≤0.10 |

| *OET | ≤0.40 |

| Ti | Remaining |

| Hardness, Knoop | 170 | 170 | |

| Hardness, Rockwell B | 80 | 80 | |

| Hardness, Vickers | 145 | 145 | |

| Tensile Strength, Ultimate | 344 MPa | 49900 psi | |

| Tensile Strength, Yield | 275 – 410 MPa | 39900 – 59500 psi | |

| Elongation at Break | 20 % | 20 % | |

| Reduction of Area | 35 % | 35 % | |

| 탄성 계수 | 105 GPa | 15200 ksi | In Tension |

| Compressive Modulus | 110 GPa | 16000 ksi | |

| Poisson’s Ratio | 0.37 | 0.37 | |

| Izod Impact | 114 – 171 J | 84.1 – 126 ft-lb | |

| Fatigue Strength | 300 MPa | 43500 psi | 1E+7 cycles, Unnotched |

| Fatigue Strength | 425 MPa | 61600 psi | 30,000 cycles, Unnotched |

| Fracture Toughness | 66 MPa-m½ | 60.1 ksi-in½ | K(Q); annealed |

| 전단 계수 | 45 GPa | 6530 ksi |

| 밀도 | Melting Range | Modulus of Elasticity (Tension) | Specific Heat | Mean Coefficient of Expansion | Thermal conductivity | 전기 저항 |

| kg/m3 | °C | GPa | J/kg. °C | x10 -6 / °C | W / m. °C | micro-ohm.m |

| 4,507 | 1668± 10 | 103 | 519 | 8.41 | 11.4 | 0.42 |

| ASTM B348 Alloy Gr 2 Hex Bar Polished | grade 2 titanium Hexagonal Bar |

| ASTM B348 Alloy Gr 2 Rectangular Bar | Titanium WERKSTOFF NR. 3.7035 Threaded Bar Black |

| Titanium UNS R50400 Round Bar | grade 2 titanium Din 3.7035 Flat Bar |

| Titanium Grade 2 Bar | Alloy grade 2 titanium Flat Bar Black |

| Alloy Gr 2 Rounds | ASME SB 338 gr 2 Flat Bar Bright |

| Titanium Alloy Grade 2 Bright Bar | Alloy Gr 2 Flat Bar Polished |

| Alloy grade 2 titanium Hex Bar Annealed | Titanium WERKSTOFF NR. 3.7035 Cold Drawn Round Bar |

| ASTM B348 grade 2 titanium Round Bars | Titanium Grade 2 Flat Bar stock |

| Titanium WERKSTOFF NR. 3.7035 Hex Bar | Alloy Gr 2 Threaded Bar |

| Titanium Grade 2 Square Bar Polished | Titanium UNS R50400 Bright Bar Hot Rolled |

| 3.7035 grade 2 titanium Hex Bar Bright | Alloy Gr 2 Alloy Hollow Bar |

| Gr 2 Titanium Rectangular Bar Annealed | Alloy grade 2 titanium Polished Hex Bar |

| ASME SB 338 gr 2 Forged Bar | Gr 2 Titanium Polished Bar |

| Alloy Gr 2 Alloy Rods | UNS R50400 Titanium Flat Bar Cold Drawn |

| Alloy Gr 2 Square Bar Cold Drawn | Titanium Grade 2 Bright Bar material |

| grade 2 titanium Rod | Titanium UNS R50400 Flat Bar Annealed |

프로젝트의 성공을 위해 Daxun을 선택하세요.

DAXUN® Grade 2 Titanium Rod Features

DAXUN® Ti Grade 2 is a commercially pure (CP) titanium bar known for its standout features:

- Excellent general corrosion resistance in seawater

- Resistant to stress corrosion cracking in chloride and sour gas environments

- Excellent resistance to pitting, crevice, and erosion-corrosion

- High heat transfer efficiency

- Good formability and weldability

- Extremely low thermal expansion

- Moderate strength

닥순 공장 장점

Daxun’s “Performance Excellence Management” concept promotes the “PDCA + Lean” management model. The company’s business card says “Daxun = Reliable Quality”. Daxun uses the ERP system to achieve full traceability of the variety, specification, and origin of each titanium rod, and advocates and encourages industry anti-counterfeiting. Daxun relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

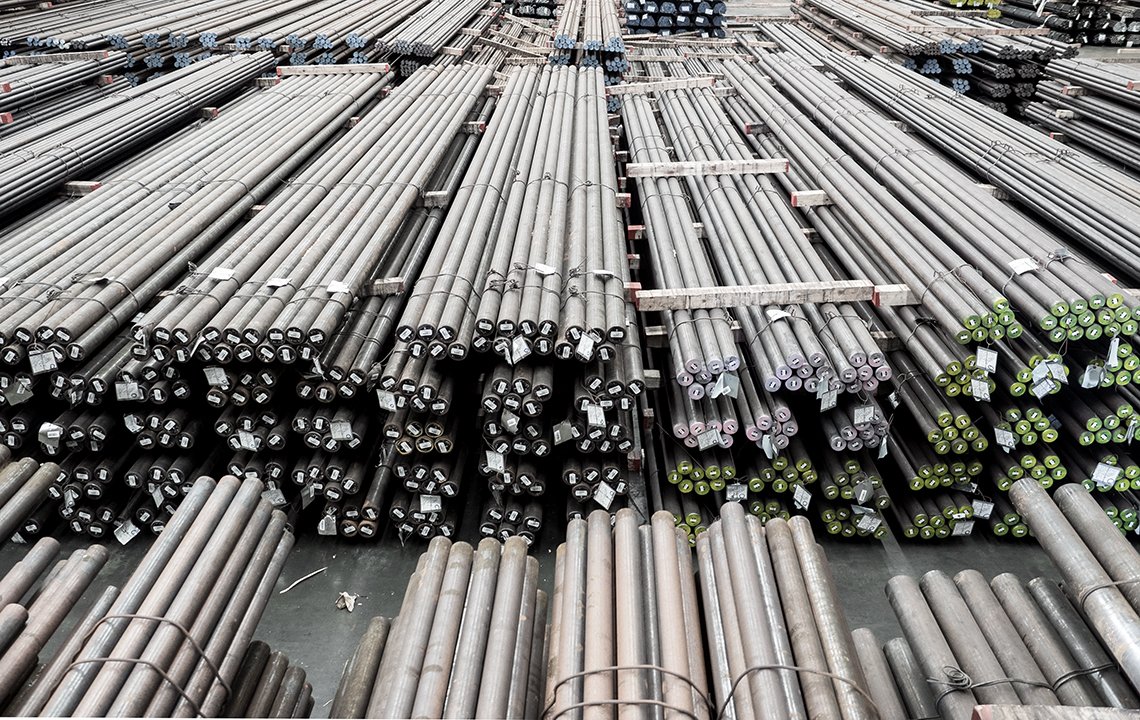

Grade 2 Titanium Rod Production Method

Daxun specializes in producing high-quality titanium bars known for their exceptional performance. Additionally, we offer customized manufacturing services to meet specific requirements as outlined in the customer’s agreement.

- Titanium ingots need to go through heat treatment and machining, immersion ultrasonic testing, mechanical properties testing, macroscopic and microscopic structural inspection and other processes. Production process: hot-rolled titanium bars – high efficiency, stable performance, forged titanium bars – flexible size, multi-fire forging, improve the comprehensive performance of titanium bars, cold-drawn titanium bars – usually small-sized high-precision titanium bars; the above titanium bars are all delivered with bright surface.

테스트 보고서

저희가 제공하는 테스트 보고서에는 다음이 포함됩니다: 2 등급 티타늄로드 및 2 등급 티타늄 라운드 바 공장 테스트 인증서, EN 10204 3.1, 화학 보고서, 기계 보고서, PMI 테스트 보고서, 육안 검사 보고서, 타사 검사 보고서, NABL 승인 실험실 보고서, 파괴 테스트 보고서, 비파괴 테스트 보고서. (고객의 요구 사항에 따라 Daxun이 제공합니다.)

Grade 2 Rods Applications and Standards

Grade 2 Titanium Rods are widely used in the following industries under extreme corrosive conditions:

- Aerospace, military, oil and gas industry, marine engineering, chemical plants, industrial machinery, power industry, paper and pulp industry, food processing industry, refineries, pharmaceutical and food processing equipment, etc.

- Specifications: ASTM B861, B862, B338 / ASME SB861, SB862, SB338

- 표준 ASTM, ASME, EN, JIS, DIN, GB, GJB, API

품질, 배송, 검사

Daxun ensures the reliability of Grade 2 Titanium Rods and Round Bars through rigorous quality assurance tests. These include tensile testing, chemical analysis, PMI for material consistency, micro and macro testing, IGC testing for corrosion resistance, ultrasonic flaw detection, and hardness and expansion evaluations.

Throughout production, Daxun carefully measures diameter, thickness, and surface quality, guaranteeing materials meet the highest standards and application requirements.

- 배송 시간은 엄격하게 계약에 따릅니다.

- 고객 타사 대행사가 공장에 가서 검사할 수 있도록 지원

- 고객 테스트를 위한 무료 샘플 지원

- 현장 또는 비디오 공장 검사 지원

패키징

상품이 다양한 경로를 거쳐 최종 목적지에 도착하는 국제화물에서 포장은 중요한 역할을 하기 때문에 대순합금은 포장에 각별한 주의를 기울이고 있으며 최고의 품질을 보장합니다. 제품에 따라 다양한 방법으로 상품을 포장합니다. 다음과 같은 다양한 방법으로 제품을 포장합니다:

- 상자 및 상자

• Shrinkwrap

- 목재 팔레트

- 나무 상자

기술 지원

If you require additional technical assistance, our resident metallurgist and knowledgeable staff are ready to support you. At Daxun, we take pride in our certified testing laboratory, a first in the multi-metal and plastic inventory industry. This reflects our unwavering commitment to quality and reinforces our philosophy as a full-service supplier dedicated to meeting your needs.

Grade 2 bar and rod features

Daxun Grade 2 Titanium Rods help your brand improve quickly

- Titanium rod/bar

- Types of Grade 2 Titanium Rods

- Tolerances for Grade 2 Titanium Round Bars (BS EN ISO 286-2)

| Apart from the products listed below, other available metal products are not listed here. Other metal products DAXUN can manufacture and supply include Tantalum, Niobium, Zirconium, Hafnium, Nickel, Copper etc., which are mainly in the form of rod/bar, Bar and Tube. | |

| Products/Processing Standard | Grade/Size |

| Titanium rod/bar— ASME SB265, AMS 4911, AMS 4919, AMS 4914,ASTM F67, ASTM F136 | GR1, GR2, GR3, GR4, GR5, GR7,GR9, GR12, GR16, GR17, GR23,Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3(Thickness:( 0.0197”-6”)Max Width: 12 feet,Max Length: 50 feet) |

| AMS-T-9046 | |

| Titanium and Titanium alloy rod/bar | |

| Commercially pure titanium (CP) | |

| Code designation | Yield strength |

| minimum, ksi 1 / | |

| CP-1 | 70 |

| CP-2 | 55 |

| CP-3 | 40 |

| CP-4 | 25 |

| Alpha titanium alloys(A) | |

| Code designation | Composition |

| A-1 | 5A1-2.5Sn |

| A-2 | 5A1-2.5Sn(ELI) 2 / |

| A-3 | 6A1-2Cb-1Ta-0.8Mo |

| A-4 | 8A1-1Mo-1V |

| Alpha-beta titanium alloys(AB) | |

| Code designation | Composition |

| AB-1 | 6A1-4V |

| AB-2 | 6A1-4V(ELI) |

| AB-3 | 6A1-6V-2Sn |

| AB-4 | 6A1-2Sn-4Zr-2Mo |

| AB-5 | 3A1-2.5V |

| AB-6 | 8Mn |

| Beta titanium alloys(B) | |

| Code designation | Composition |

| B-1 | 13V-11Cr-3A1 |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3A1-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3A1 |

| Processing: | |

| 열간 압연 | 냉간 압연 |

| Available Grades: | |

| CP 1등급 | Grade 6Al-2Sn-4Zr-2Mo (6-2-4-2) |

| CP 2등급 | Grade 6Al-4V ELI (Formerly Grade 23) |

| 7학년 | Grade 6Al-6V-2Sn (6-62) |

| Grade 19 | Grade 8Al-1Mo-1V (8-1-1) |

| Grade 5 (6Al-4V) | Grade 9 (3Al-2.5V) |

| Grade 6 (5Al-2.5Sn) | CP 3등급 |

| 애플리케이션 | |

| 화학 산업 | Desalination Of Sea Water |

| Petrochemical Industry | 항공우주 |

| Machining Field, Automobile Field | Mobile Phone Component Field. |

| Titanium Grade 2 Hex Bar | Titanium Gr 2 Hex Bar |

| Grade 2 Titanium Hexagonal Bar | |

| Gr 2 Titanium Alloy Hex Bar | |

| UNS R50400 Titanium Hexagonal Bar | |

| ASTM B348 Grade 2 Titanium Hex Bar | |

| Titanium Alloy Grade 2 Square Bar | Titanium Grade 2 Square Bar |

| Grade 2 Titanium Square Bars | |

| Gr 2Titanium Alloy Square Bar | |

| UNS R50400 Titanium Square Bar | |

| WERKSTOFF NR. 3.7035 Square Bar | |

| ASTM B348 Gr 2 Titanium Square Bars | |

| Titanium Grade 2 Rectangular Bar | Titanium Grade 2 Rectangular Bar |

| Ti. Alloy Gr2 Rectangular Bars | |

| Gr 2 Titanium Alloy Rectangular Bar | |

| UNS R50400 Titanium Rectangular Bars | |

| WERKSTOFF NR. 3.7035 Rectangular Bar | |

| ASTM B348 Gr 2 Titanium Rectangular Bar | |

| Titanium Grade 2 Flat Bars | Titanium Grade 2 Flat Bar |

| Gr 2Titanium Alloy Flat Bars | |

| Titanium Gr 2Flat Bars | |

| UNS R50400 Titanium Flat Bars | |

| WERKSTOFF NR. 3.7035 Flat Bars | |

| ASTM B348 Gr 2 Titanium Flat Bars | |

| Titanium Grade 2 Polished Bar | Titanium Grade 2 Polished Bar |

| Grade 2Titanium Polished Bars | |

| Gr 2Titanium Alloy Polished Bar | |

| UNS R50400 Titanium Polished Bars | |

| WERKSTOFF NR. 3.7035 Polished Bar | |

| ASTM B348 Gr 2 Titanium Polished Bar | |

| Titanium Grade 2 Threaded Bar | Titanium Gr 2 Threaded Bar |

| Grade 2Titanium Threaded Bars | |

| Ti. Alloy Grade 2 Threaded Bar | |

| UNS R50400 Titanium Threaded Bar | |

| WERKSTOFF NR. 3.7035 Threaded Bar | |

| ASTM B348 Gr 2 Titanium Threaded Bar |

| 공칭 크기 | h5 | h6 | h7 | h8 | h9 | H10 | H11 | h12 |

|---|---|---|---|---|---|---|---|---|

| 직경 mm | ||||||||

| ~ ~ 3 | +0.004/0 | +0.006/0 | +0.01/0 | +0.014/0 | +0.025/0 | +0.04/0 | +0.06/0 | +0.1/0 |

| 3~6세 이상 | +0.005/0 | +0.008/0 | +0.012/0 | +0.018/0 | +0.03/0 | +0.048/0 | +0.075/0 | +0.12/0 |

| 6~10개 이상 | +0.006/0 | +0.009/0 | +0.015/0 | +0.022/0 | +0.036/0 | +0.058/0 | +0.09/0 | +0.15/0 |

| 10세 이상 18세 미만 | +0.008/0 | +0.011/0 | +0.018/0 | +0.027/0 | +0.043/0 | +0.07/0 | +0.11/0 | +0.18/0 |

| 18세 이상 30세 미만 | +0.009/0 | +0.013/0 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 | +0.13/0 | +0.21/0 |

| 30~50세 이상 | +0.011/0 | +0.016/0 | +0.025/0 | +0.039/0 | +0.062/0 | +0.1/0 | +0.16/0 | +0.25/0 |

| 50~80% 이상 | +0.013/0 | +0.019/0 | +0.03/0 | +0.046/0 | +0.074/0 | +0.12/0 | +0.19/0 | +0.3/0 |

| 80 이상 120 미만 | +0.015/0 | +0.022/0 | +0.035/0 | +0.054/0 | +0.087/0 | +0.14/0 | +0.22/0 | +0.35/0 |

| 120~180개 이상 | +0.018/0 | +0.025/0 | +0.04/0 | +0.063/0 | +0.1/0 | +0.16/0 | +0.25/0 | +0.4/0 |

| 180 이상 250 미만 | +0.02/0 | +0.029/0 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 | +0.29/0 | +0.46/0 |

2nd grade bar type (3)

참조 및 다운로드 가능한 정보

티타늄 로드

Daxun is a trustworthy titanium rod and bar manufacturer

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all titanium bars are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the Titanium rod have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

관련 제품 (8)

What are Grade 2 Titanium rods?

Ti CP Grade 2 has greater tolerated levels of iron and oxygen and is frequently utilized due to its outstanding formability, moderate strength, and superior corrosion resistance. It has a minimum yield strength of 275 Mpa (40 ksi) and relatively low amounts of impurity elements, placing it in the strength range of Grades 1 to 3.

Grade 2 Titanium Rod Equivalent Grade

| nation | name | usually |

| 러시아 | VT1-0 (VT1-0) | Gorst 19807-91 |

| Germany | 3.7035 | Job Number (3.7035) |

| Europe | Titanium Grade 2 | ZH-10204 3.1 |

| 일본 | Titanium Grade 2 | JIS H 4600 |

| People’s Republic of China | TA2 | GB/T 3621-2007 / GB/T 13810-2007 |

| USA | Titanium Grade 2 | ASTM B348 / B265 / B337,UNS R50400 |

내식성

Commercially pure (CP) titanium offers remarkable resistance to crevice corrosion in salt solutions, outperforming stainless steel. It retains its integrity against crevice corrosion at temperatures under 80 °C (176 °F), regardless of pH levels, even in environments with high chlorine concentrations.

Stress Corrosion Cracking (SCC)

Grade 2 titanium exhibits remarkable resistance to stress corrosion cracking. It performs exceptionally well in hot chloride solutions and is entirely immune to SCC in seawater, making it a dependable material for harsh environments.

Erosion Corrosion

Titanium exhibits exceptional durability in flowing seawater, withstanding velocities as high as 130 ft/sec (40 m/sec) without significant degradation. Even in the presence of abrasive particles like sand, its corrosion resistance remains largely unaffected, highlighting its reliability in demanding environments.

Hydrogen Embrittlement

When exposed to seawater, titanium absorbs minimal hydrogen, even at higher temperatures. However, absorption typically takes place only under certain specific conditions:

- pH levels below 3 or above 12

- Temperatures exceeding 80 °C (176 °F)

- A mechanism for hydrogen generation, such as galvanic coupling or an impressed current.

Bio-Corrosion

Titanium alloys exhibit complete immunity to microbiologically influenced corrosion. However, because they are non-toxic to marine organisms, biofouling can develop in seawater. This can be effectively managed through chlorination or by increasing the flow rate of water through heat exchangers.

Corrosion Fatigue

Unlike many materials, titanium maintains its fatigue performance in seawater. Fatigue endurance limits and crack growth rates are consistent, whether tested in air or seawater, making it a reliable choice for marine applications.

Galvanic Corrosion

Titanium ranks among the noble materials in the galvanic series, positioned near stainless steels, and generally serves as the cathode when paired with other metals. As a result, titanium remains resistant to galvanic corrosion but can increase corrosion in less noble metals. When paired with more noble substances, such as graphite, its passive properties become even stronger.

Fatigue Properties

Grade 2 Titanium Rod maintains its exceptional fatigue properties even in seawater. Its fatigue endurance limits and crack growth rates remain unchanged regardless of whether testing occurs in air or seawater, highlighting its consistent performance under varied conditions.

용접성

CP2 Grade Titanium Rod is highly weldable when appropriate precautions are observed. Given its reactive nature, an inert gas shield must protect both the outer diameter (OD) and inner diameter (ID) during welding. Additionally, the rod should be completely free of grease or oil to ensure optimal weld integrity.

Grade 2 Titanium Rod is most often welded using either manual or automatic TIG methods, with or without filler wire. A low heat input is advised to limit the size of the heat-affected zone. Post-weld heat treatment is generally not required, simplifying the process while maintaining the rod’s key properties.

This revised version maintains the technical depth and original structure while improving clarity, readability, and flow. Let me know if you’d like further refinements!

| Working material: | 3.7035 / UNS R50400 |

| Diameter: | 3 – 400 mm |

| Lengths: | 2.000 – 4.000 mm |

| Versions: | Rolled, forged, annealed |

| Surfaces: | Turned, peeled, polished |

| Standards: | ASTM B 348, ASME SB 348, DIN 17862, ASTM F 67, NACE MR 0175, ISO 1515156-3, ISO 5832-2 |

Buy Grade 2 Titanium Rods/Rounds at Daxun

Are you in need of round rod material made from Grade 2 Titanium Alloy Rod-3.7035? At Daxun, we specialize in providing customized titanium rods tailored to your project’s specifications. As an experienced supplier, we are committed to supporting your needs with precision and reliability.

Our Grade 2 Titanium bars are available in diameters ranging from 2.0 mm to 400 mm. Tolerances and execution may vary based on the size of the bar. Smaller diameters are provided centerless ground with h7 tolerances, while larger sizes come with h9 or h11 tolerances. Contact Daxun to discuss your requirements or to request a customized project quote.

Buy Grade 2 Titanium Bars: Features and Specifications.

- Forged bars can be peeled or pre-machined. The material is available in a variety of specifications depending on the application and market needs.

- Our titanium bars typically meet various requirements and certifications, including ASTM B348 and ASTM F 67, DIN 17860, VD TÜV Table 230-3, and Nace MR 0175.

- Titanium round bars are often used where they have excellent corrosion resistance and good mechanical properties.

- Grade 2 titanium bars (3,7035) are therefore suitable for use as a construction material for equipment and devices, as they are easy to process.

Our Titanium Bar Material Services

- As an experienced service center, we can tailor your titanium bar material to your specifications, work with various certification bodies such as TÜV Rheinland or DNV to approve the specifications, and initiate the upgrading of titanium semi-finished products to meet appropriate applications.

- We will be happy to provide you with a consultation and explain everything you need to know about obtaining titanium bar material, including which standards require greater attention for the components to be manufactured.

- If you have a long-term supply commitment, you can establish a framework agreement with Daxun. We guarantee prices and quantities for a specified period.

- Benefit from our extensive experience in the global market. We have been helping businesses around the world since 2003. If you need any additional information about the Grade 2 Titanium Bar, our professionals will be happy to help you. We look forward to hearing from you.

주문 정보

When placing a purchase order, make sure to include the quantity, grade, type or category, API5L reference, as well as the thickness, width, and length of the product. If you have any specific requirements, like chemical composition, mechanical properties, heat treatment, additional testing, manufacturing methods, surface coatings, or end finishes, let us know so we can meet your needs.

Feel free to contact Daxun with your order details. We are committed to responding to your inquiry promptly.

필요한 티타늄 합금의 등급은 각 등급마다 다른 이점이 있으므로 작업 중인 프로젝트에 따라 다릅니다.

모든 등급의 티타늄 합금은 매우 강하고 부식에 강하기 때문에 가장 혹독한 환경에서도 잘 작동합니다.

더 높은 등급의 티타늄 합금(5-12)은 특정 이점을 위해 설계된 합금입니다. 예를 들어, 12등급 티타늄 합금은 내열성이 뛰어나 쉘 및 튜브 열교환기, 유압 배관 및 화학 산업 장비에 적합합니다.

1~4등급은 순수 티타늄 합금으로, 배관 시스템과 튜빙에 용접 가능한 연성 소재가 필요한 경우 완벽한 선택입니다. 그보다 낮은 등급은 해양 및 산업 산업에서 사용됩니다.

프로젝트를 시작하면서 어떤 등급의 티타늄 합금이 가장 적합한지 잘 모르겠다면 지금 바로 문의하시면 기꺼이 도와드리겠습니다.

DAXUN에서는 1등급부터 12등급까지 다양한 티타늄 합금 등급을 제공합니다.

1~4등급은 순수 티타늄이고 그 이상 등급은 합금입니다.

합금 등급은 무게 대비 강도가 높기 때문에 인기가 높습니다.

가장 일반적으로 사용되는 티타늄 합금 등급은 5등급입니다. 티타늄 함량이 여전히 높지만 이 등급은 최대 600°F의 온도와 극한의 조건을 견딜 수 있기 때문에 가장 신뢰할 수 있는 등급 중 하나입니다.

항공우주 및 해양 산업과 같은 산업에서는 내마모성과 내식성 때문에 등급이 높을수록 선호합니다.

반대로 낮은 등급은 강도가 낮기 때문에 주로 용접에 사용됩니다.

To learn more about the differences between different grades of titanium alloy, call +86 13382898899 today to speak directly with our experts.

티타늄의 등급에 따라 비용이 약간 증가하지만, 총 비용은 주로 필요한 티타늄의 모양과 형태에 따라 결정됩니다.

At DAXUN, we offer a wide range of titanium products, including rod/bars, tubes, coils and bars. The length, width and quantity of each item you require will affect the amount you pay at checkout.

안타깝게도 프로젝트와 티타늄의 용도에 대해 잘 알지 못하면 온라인에서 가격을 책정하기 어렵습니다.

다행히도 저희 전문가 팀이 언제나 티타늄 관련 문의에 대해 도움을 드리고 조언해 드립니다. [email protected] 으로 이메일을 보내주시면 몇 가지 조언과 정확한 견적을 알려드리겠습니다.

필요한 티타늄의 등급, 모양 및 수량에 대해 가능한 한 많은 정보를 포함하여 요구 사항을 더 잘 파악할 수 있도록 하세요.

DAXUN의 팀은 경험이 풍부하고 지식이 풍부하며 친절합니다. 업계에서 다년간의 경험을 바탕으로 티타늄의 용도, 장점, 등급 등 티타늄에 대한 모든 것을 잘 알고 있습니다.

티타늄, 티타늄의 용도 및 산업 전반에 걸친 티타늄의 활용에 대한 정기적인 업데이트를 확인하려면 블로그를 확인하세요. 궁금한 점이 있을 때 언제든지 참고할 수 있도록 전문가들이 쉽게 따라할 수 있는 가이드를 작성했습니다.

여전히 문제가 있는 경우 언제든지 문의해 주세요. 기꺼이 도와드리겠습니다.

[email protected] 으로 이메일을 보내주시면 빠른 답변을 받으실 수 있습니다. 적합한 솔루션을 추천할 수 있도록 질문에 가능한 한 자세한 내용을 포함해 주세요.

“문의하기” 페이지의 양식을 작성하거나 영업 관리자(+86 13382898899)에게 전화하시면 최대한 빨리 연락드리겠습니다. WhatsApp은 온라인 상태이며 이메일([email protected])은 6시간 이내에 확인합니다. 모든 문의나 메시지는 신속하게 답변해 드립니다. 또한 매주 고객과 시장 정보를 공유합니다.

We can provide Titanium rod. samples for you to check the quality. Sample is free and you just pay the freight.

캐나다, 칠레, 쿠웨이트, 독일, 한국, 사우디아라비아, 싱가포르 등 42개 이상의 국가에 수출하고 있습니다.

Our MOQ is 1 ton for Titanium rod.

체험판 주문은 일주일 이내에 배송됩니다. 일반 주문의 경우 대략 2주 정도 소요됩니다.