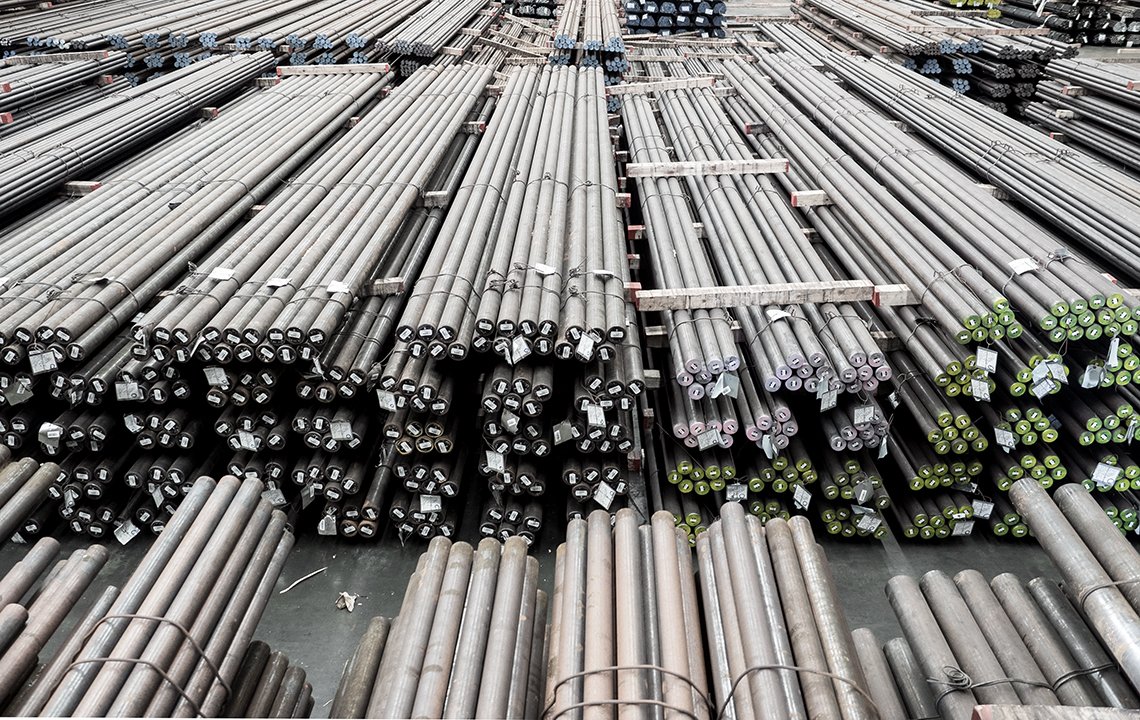

Daxun is an excellent manufacturer of CP Grade 4 titanium rods and bars.

- Titanium bar grade: UNS R50700

- Titanium bar types: rolled bars, drawn bars, forged titanium bars

- Main standards: ASTM ASME GB GJB EN JIS DIN ISO ATP BS, etc.

- High corrosion resistance, excellent weldability, superior strength, lightweight, and outstanding performance in aggressive environments.

The global leader in commercially titanium alloy rod manufacturing services

Daxun, specializing in the production of alloy titanium rods for extreme environments

CP Grade 4 titanium bar represents the highest strength variant within the commercially pure titanium family, combining exceptional mechanical properties with outstanding corrosion resistance. As an unalloyed titanium grade, it maintains the inherent biocompatibility and weldability of pure titanium while delivering significantly enhanced tensile strength, with minimum yield strength reaching 480 MPa and ultimate tensile strength exceeding 550 MPa. This unique combination makes CP Grade 4 titanium bars particularly valuable in applications demanding both structural integrity and environmental durability.

The chemical composition of CP Grade 4 titanium bar consists primarily of titanium with controlled amounts of oxygen (0.40% maximum), iron (0.50% maximum), carbon (0.08% maximum), and nitrogen (0.05% maximum). The elevated oxygen content compared to other CP grades directly contributes to its superior strength characteristics. These bars exhibit excellent ductility, allowing for various forming processes while maintaining their enhanced mechanical properties, making them suitable for cold working, machining, and fabrication into complex components.

Key Application Areas

- 航空宇宙 Used for critical structural components, aircraft fasteners, and springs where high strength-to-weight ratio is essential.

- 化学処理: Ideal for pump shafts, valve components, and heat exchanger parts exposed to aggressive media.

- 海洋工学: Employed for hardware and components that require long-term durability in seawater.

- Medical Implants: Utilized for surgical instruments and implant devices that demand both high strength and biocompatibility.

Manufacturing & Product Forms

- Production Processes: Can be produced through hot rolling, forging, or extrusion, followed by annealing.

- Available Forms: Supplied in various shapes, including round, square, hexagonal, and flat bars.

- Custom Dimensions: Available in a wide range of sizes, with options for custom dimensions to meet specific project needs.

- Machining: Can be effectively machined using appropriate tooling and cooling strategies, though it requires more robust parameters than lower titanium grades.

| 仕様 | Details |

|---|---|

| 素材 | CP Grade 4 Titanium Bar |

| スタンダード | ASTM B348, ASTM F67, AMS 4921, ISO 5832-2 |

| 寸法 | EN, ASTM, JIS, ASME, BS, AISI, GB, GJB, DIN |

| Diameter Range | 0.125″ – 14″ (3.175mm – 355.6mm), custom |

| Length Range | Up to 240″ (6096mm), custom |

| 様式 | Round Bar, Square Bar, Hexagonal Bar |

| Surface Finish | Cold drawn, Centerless Ground, Polished, Rough Turned, Black, NO.4 Finish, BA Finish, Matt Finish |

| Condition | Annealed, Hardened & tempered |

| 寛容 | Diameter tolerance: +/- 0.005″ (0.127mm), length tolerance: +/- 0.125″ (3.175mm) |

| 様式 | Titanium square bars, titanium ingots, titanium round bars, rectangular titanium bars, triangular titanium bars, forged titanium bars, titanium hexagonal bars |

データ

- Chemical Composition (% by Weight)

- 機械的特性

- 物理的性質

| エレメント | Minimum | Maximum |

|---|---|---|

| チタン (Ti) | 99.2 | – |

| Oxygen (O) | 0.35 | 0.40 |

| 鉄(Fe) | – | 0.50 |

| Carbon © | – | 0.08 |

| 窒素(N) | – | 0.05 |

| Hydrogen (H) | – | 0.015 |

| プロパティ | Minimum Value | Unit |

|---|---|---|

| Ultimate Tensile Strength | 550 | MPa |

| 降伏点(0.2%変形) | 480 | MPa |

| 伸び | 15 | % |

| 面積の縮小 | 30 | % |

| Brinell Hardness | 320 | HBW |

| Modulus of Rigidity | 44 | GPa |

| プロパティ | 価値 | Unit |

|---|---|---|

| 密度 | 4.51 | g/cm³ |

| 融点 | 1668 | °C |

| 弾性係数 | 105 | GPa |

| 熱伝導率 | 16.4 | W/m·K |

| 電気抵抗率 | 560 | nΩ·m |

| Specific Heat | 0.52 | J/g·K |

Daxunを選んで、あなたのプロジェクトを成功に導きましょう。.

Daxun Factory Advantages

Daxun’s “Performance Excellence Management” concept promotes the “PDCA + Lean” management model. The company’s business card says “Daxun = Reliable Quality”. Daxun uses the ERP system to achieve full traceability of the variety, specification, and origin of each titanium rod, and advocates and encourages industry anti-counterfeiting. Daxun relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

CP Grade 4 Titanium Rod Production Method

Daxun produces high-quality titanium bars with high performance, and can also manufacture according to customer’s agreement:

- Titanium ingots need to go through heat treatment and machining, immersion ultrasonic testing, mechanical properties testing, macroscopic and microscopic structural inspection and other processes. Production process: hot-rolled titanium bars – high efficiency, stable performance, forged titanium bars – flexible size, multi-fire forging, improve the comprehensive performance of titanium bars, cold-drawn titanium bars – usually small-sized high-precision titanium bars; the above titanium bars are all delivered with bright surface.

品質、納期、検査

Daxun performs several quality assurance tests, these tests include mechanical tests like area tensile, chemical analysis, material positive identification – PMI test, micro and macro testing, intergranular corrosion (IGC) test, ultrasonic flaw detection test, pitting and resistance test, hardness test, material positive identification, expansion test etc. All these tests ensure that the CP Grade 4 Titanium Rod and CP Grade 4 Titanium Round Bar material is suitable for the required application. During the production process, we measure the diameter, thickness and surface of the product.

- 当社の納期は、契約に厳密に従います。.

- 顧客の第三者機関が工場に検査に行くのをサポートする。

- 顧客テストのための無料サンプルをサポート

- 現場検査またはビデオ工場検査をサポート

パッケージング

国際貨物は様々な経路を経て最終目的地に到着するため、梱包は重要な役割を担っています。商品によって、様々な方法で梱包しています。当社では、以下のような様々な方法で商品を梱包しています:

- 箱と木箱

- シュリンクラップ

- 木製パレット

- 木製ボックス

テクニカルサポート

さらに技術的なサポートが必要な場合は、常駐の冶金学者と知識豊富なスタッフが喜んでお手伝いいたします。さらに、Daxunは、マルチメタルおよびプラスチック在庫業界初の認定試験所を誇っています。これは、当社の品質への揺るぎないこだわりと、フルサービスサプライヤーとしての理念を示すものだと考えています。.

Daxun CP Grade 4 Titanium Rods help your brand improve quickly

- Tolerances for CP Grade 4 Titanium Round Bars

|

NOMINAL SIZE

|

h5

|

h6

|

h7

|

h8

|

h9

|

H10

|

H11

|

h12

|

|

DIAMETER mm

|

||||||||

| ~ to 3 | +0.004/0 | +0.006/0 | +0.01/0 | +0.014/0 | +0.025/0 | +0.04/0 | +0.06/0 | +0.1/0 |

| over 3 to 6 | +0.005/0 | +0.008/0 | +0.012/0 | +0.018/0 | +0.03/0 | +0.048/0 | +0.075/0 | +0.12/0 |

| over 6 to 10 | +0.006/0 | +0.009/0 | +0.015/0 | +0.022/0 | +0.036/0 | +0.058/0 | +0.09/0 | +0.15/0 |

| over 10 to 18 | +0.008/0 | +0.011/0 | +0.018/0 | +0.027/0 | +0.043/0 | +0.07/0 | +0.11/0 | +0.18/0 |

| over 18 to 30 | +0.009/0 | +0.013/0 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 | +0.13/0 | +0.21/0 |

| over 30 to 50 | +0.011/0 | +0.016/0 | +0.025/0 | +0.039/0 | +0.062/0 | +0.1/0 | +0.16/0 | +0.25/0 |

| over 50 to 80 | +0.013/0 | +0.019/0 | +0.03/0 | +0.046/0 | +0.074/0 | +0.12/0 | +0.19/0 | +0.3/0 |

| over 80 to 120 | +0.015/0 | +0.022/0 | +0.035/0 | +0.054/0 | +0.087/0 | +0.14/0 | +0.22/0 | +0.35/0 |

| over 120 to 180 | +0.018/0 | +0.025/0 | +0.04/0 | +0.063/0 | +0.1/0 | +0.16/0 | +0.25/0 | +0.4/0 |

| over 180 to 250 | +0.02/0 | +0.029/0 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 | +0.29/0 | +0.46/0 |

Types of CP Grade 4 Titanium Rods (3)

チタン棒

関連商品 (6)

CP Grade 4 is the strongest of all the commercially pure titanium grades. Its key differentiator is its higher oxygen content, which gives it a minimum yield strength of 480 MPa, significantly higher than CP Grade 2 (275 MPa). This makes it the preferred choice when high strength and durability are critical, while still maintaining excellent corrosion resistance.

Due to its high strength-to-weight ratio and biocompatibility, CP Grade 4 titanium bar is widely used in the aerospace industry for fasteners and springs, in chemical processing for pump and valve components, in marine engineering for durable hardware, and in the medical field for surgical instruments and implants that require superior structural integrity.

While it is more challenging to machine than lower grades due to its strength, it can be effectively machined with proper tooling and cooling. It is also readily weldable using standard methods like TIG welding, but it requires an inert gas shield (like argon) to protect the weld area from atmospheric contamination and prevent embrittlement.

The primary advantage is its superior corrosion resistance, especially in chloride environments like seawater, where stainless steel is prone to pitting and stress corrosion cracking. CP Grade 4 also offers a much better strength-to-weight ratio. Although the initial cost is higher, its extended service life and reduced maintenance in harsh environments often result in a lower total cost of ownership.

お問い合わせ “ページのフォームにご記入いただくか、”+86 13382898899 “までお電話ください。WhatsAppはオンライン、Eメール([email protected])は6時間以内に確認いたします。すべてのお問い合わせやメッセージに迅速に対応させていただきます。また、毎週お客様と市場情報を共有しています。

We can provide titanium rod samples for you to check the quality. Sample is free and you just pay the freight.

カナダ、チリ、クウェート、ドイツ、韓国、サウジアラビア、シンガポールなど42カ国以上に輸出しています。.

トライアル・オーダーは1週間以内にお届けできます。通常のご注文の場合、おおよそ2週間かかります。.