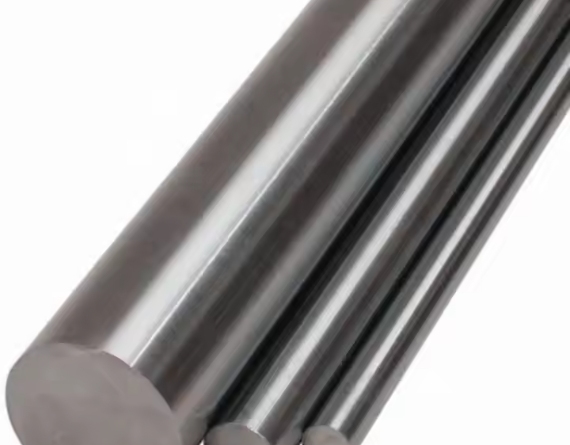

Daxun is an excellent manufacturer of grade 9 (Ti-3Al-2.5V) titanium rods and bars.

As China’s leading supplier of titanium and titanium alloy rods, Daxun provides high-performance titanium rods to the world.

- Titanium bar grade: Grade 9 UNS R56320

- Titanium bar types: rolled bars, drawn bars, forged titanium bars

- Titanium bar density The density of Grade 9 titanium is 4.48 g/cm3

- Main standards: ASTM ASME GB GJB EN JIS DIN ISO ATP BS, etc.

- High strength, high temperature resistance, corrosion resistance, light

- weight, excellent comprehensive performance.

————Daxun produces titanium rods in China to meet the diverse and ——顧客の厳しいニーズ!

The global leader in commercially pure titanium rod manufacturing services

Grade 9 Titanium Alloy Rod Manufacturer – Daxun Alloy

Providing High-Quality Grade 9 Titanium Rods to Customers Worldwide

Grade 9 titanium rod is a versatile alpha-beta alloy (Ti-3Al-2.5V), offering an optimal balance between pure titanium’s formability and Grade 5’s strength. It features moderate strength, exceptional weldability, and outstanding corrosion resistance in diverse environments. Its density (4.48 g/cm³) is approximately 60% that of steel, yet it delivers strength comparable to some steels, making it ideal for weight-sensitive applications. The alloy excels in aerospace components, fasteners, and structural parts due to its high strength-to-weight ratio and fatigue resistance.

Key Applications:

Aerospace & Defense: Used in hydraulic systems, fasteners, and airframe structures where lightweight durability is critical.

Industrial Machinery: Employed in high-strength fasteners (e.g., Grade 9 nuts) for heavy equipment like earth-moving machinery, offering 20% higher strength than standard steel fasteners.

Marine & Chemical: Resists seawater and chemical corrosion in pump shafts, valve components, and subsea hardware.

Medical & Sports: Utilized in biocompatible implants and high-performance sports equipment (e.g., bicycle components) for its fatigue resistance and low density.

Energy Sector: Applied in downhole tools and heat exchangers for oil/gas operations, combining corrosion resistance with mechanical stability.

Manufactured under ASTM B348 standards, Grade 9 titanium rods are available in custom sizes to meet global industrial demands.

大順 is your trusted titanium alloy rod production company. Daxun produces all grades of titanium alloys, including commercially pure titanium series CP, titanium alloy series, titanium nickel alloy, etc. They have reliable performance and provide high performance for your critical applications. In various industries and applications, you can rely on Daxun titanium alloy rods for high strength, high temperature and corrosive environments. For decades, Daxun Metals has been committed to producing highly engineered titanium alloy solutions to meet the most severe challenges.

データ

- パラメータ

- 原材料

- 機械的特性

- 物理的性質

| 仕様 | Details |

|---|---|

| 素材 | Titanium rod and bar Grade 9 (UNS R56320) |

| スタンダード | ASTM B348, ASTM SB348, AMS 4921, AMS 4902 |

| 寸法 | EN, ASTM, JIS, ASME, BS, AISI, GB, GJB, DIN |

| Diameter Range | 0.125″ – 14″ (3.175mm – 355.6mm), custom |

| Length Range | Up to 240″ (6096mm), custom |

| 表面処理 | Cold (bright) drawn, centerless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centerless Ground & Black |

| Surface Finish | Cold drawn, Centerless Ground, Polished, Or Rough Turned, Black, NO.4 Finish, BA Finish, Matt Finish, etc. |

| Condition | Annealed |

| 寛容 | Diameter tolerance: +/- 0.005″ (0.127mm), length tolerance: +/- 0.125″ (3.175mm) |

| 様式 | Titanium square bars, titanium ingots, titanium round bars, rectangular titanium bars, triangular titanium bars, forged titanium bars, titanium hexagonal bars, etc. |

| 物理的性質 | Density: 0.161 lb/in³ (4.48 g/cm³), Melting Point: 3,020°F (1,660°C), Elongation: 10-15%, Modulus of Elasticity: 16.5 x 10⁶ psi (114 GPa) |

| 化学組成 | Titanium (balance), Aluminum: 2.5-3.5%, Vanadium: 2.0-3.0%, Oxygen (max): 0.20%, Iron (max): 0.25%, Carbon (max): 0.08%, Nitrogen (max): 0.03%, Hydrogen (max): 0.015% |

| エレメント |

組成範囲(wt.%)

|

| ティ |

Balance (>90%)

|

| アル | 2.50–3.50% |

| V | 2.00–3.00% |

| フェ | ≤0.25% |

| O | ≤0.13% |

| C | ≤0.08% |

| N | ≤0.03% |

| H | ≤0.015% |

| その他 |

≤0.4% (single element)

|

| プロパティ | 値(インペリアル単位) | 値(メトリック) |

| 引張強度 | 130–140 ksi | 895–965 MPa |

| 降伏点(0.2%変形) | 120–125 ksi | 825–860 MPa |

| 伸び | 10–15% | 10–15% |

| 面積の減少 | 25–30% | 25–30% |

| 硬度(ブリネル) | 280–320 HB | 290–330 HBW |

| 弾性係数 | 16.5 × 10⁶ psi | 114 GPa |

|

高温性能

|

||

| Temperature (°F) | Tensile Strength (ksi) |

Yield Strength (ksi)

|

| 400°F (200°C) | 115–125 | 105–110 |

| 600°F (315°C) | 100–110 | 90–95 |

| 800°F (425°C) | 85–95 | 75–80 |

| プロパティ | 値(インペリアル単位) | 値(メトリック) |

| 密度 | 0.160 lb/in³ | 4.43 g/cm³ |

| 融点 | 3,000–3,050°F | 1,650–1,680°C |

| 熱伝導率 | 6.5 Btu/(hr·ft·°F) | 11.2 W/(m·K) |

| 熱膨張係数 | 5.3 × 10⁻⁶/°F | 9.5 × 10⁻⁶/K |

| 電気抵抗率 | 120 µΩ·cm | 120 nΩ·m |

Daxunを選んで、あなたのプロジェクトを成功に導きましょう。.

DAXUN® Grade 9 Titanium Rod Features

DAXUN® Ti Grade 5 is a titanium alloy bar (6al-4v) featuring:

- Good hot formability and weldability;

- Tensile strength can reach 1000MPa;

- Dimensional work at high temperature

- Insensitive to seawater or seawater;

- Not affected by various corrosive media;

- High strength and good toughness;

- Resist crack initiation and crack propagation.

Daxun Factory Advantages

Daxun’s “Performance Excellence Management” concept promotes the “PDCA + Lean” management model. The company’s business card says “Daxun = Reliable Quality”. Daxun uses the ERP system to achieve full traceability of the variety, specification, and origin of each titanium rod, and advocates and encourages industry anti-counterfeiting. Daxun relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strictly monitors during sales, and provides worry-free service guarantees after sales.

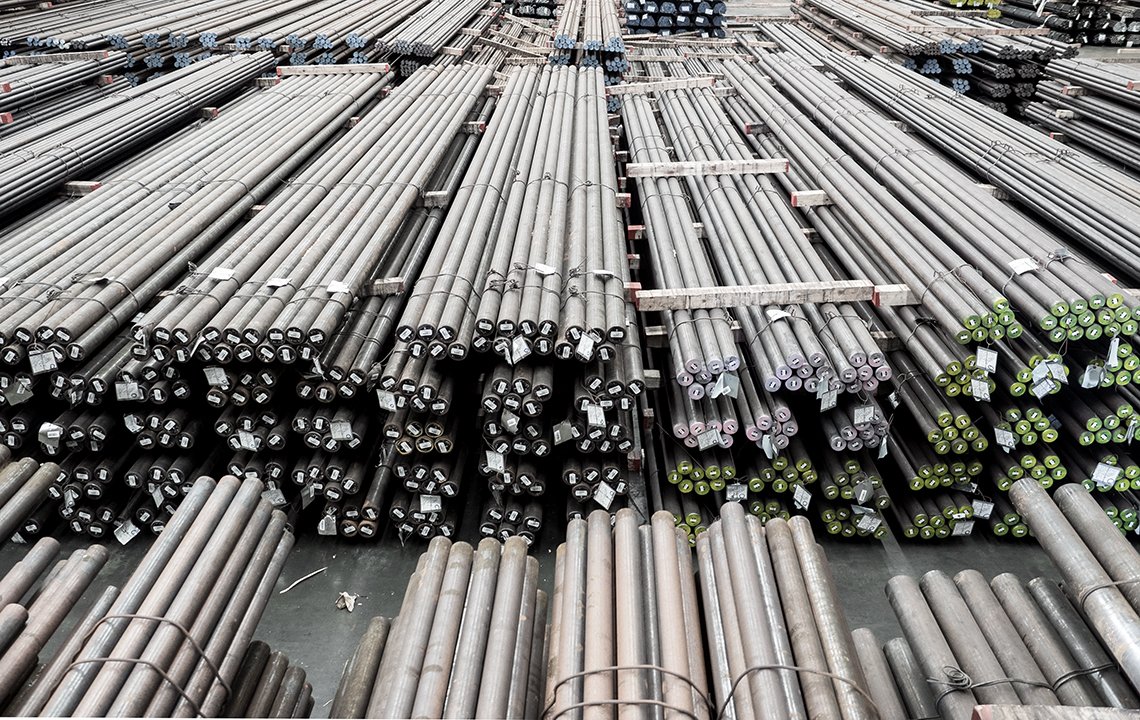

Grade 9 Titanium Rod Production Method

Daxun produces high-quality titanium bars with high performance, and can also manufacture according to customer’s agreement:

- Titanium ingots need to go through heat treatment and machining, immersion ultrasonic testing, mechanical properties testing, macroscopic and microscopic structural inspection and other processes. Production process: hot-rolled titanium bars – high efficiency, stable performance, forged titanium bars – flexible size, multi-fire forging, improve the comprehensive performance of titanium bars, cold-drawn titanium bars – usually small-sized high-precision titanium bars; the above titanium bars are all delivered with bright surface.

試験報告書

The test reports we provide include: Grade 2 Titanium Rod and Grade 2 Titanium Round Bar Factory Test Certificate, EN 10204 3.1, Chemical Report, Mechanical Report, PMI Test Report, Visual Inspection Report, Third Party Inspection Report, NABL Approved Laboratory Report, Destructive Test Report, Non-destructive Testing Report. (Daxun will provide according to customer requirements)

Grade 9 Rods Applications and Standards

Grade 9 Titanium Rods are widely used in the following industries under extreme corrosive conditions:

- Aerospace, shipbuilding, oil and gas industry, marine engineering, chemical plants, industrial machinery, power industry, paper and pulp industry, food processing industry, refineries, military industry, pharmaceutical and food processing equipment, etc.

- Specifications: AMS 4928,AMS 4967,AMS 4965 ,AMS 6931 ,ASTM B 348

- Standards: ASTM, ASME, EN, JIS, DIN, GB, GJB, API

品質、納期、検査

Daxun performs several quality assurance tests, these tests include mechanical tests like area tensile, chemical analysis, material positive identification – PMI test, micro and macro testing, intergranular corrosion (IGC) test, ultrasonic flaw detection test, pitting and resistance test, hardness test, material positive identification, expansion test etc. All these tests ensure that the Grade 2 Titanium Rod and Grade 2 Titanium Round Bar material is suitable for the required application. During the production process, we measure the diameter, thickness and surface of the product.

- 当社の納期は、契約に厳密に従います。.

- 顧客の第三者機関が工場に検査に行くのをサポートする。

- 顧客テストのための無料サンプルをサポート

- 現場検査またはビデオ工場検査をサポート

パッケージング

国際貨物は様々な経路を経て最終目的地に到着するため、梱包は重要な役割を担っています。商品によって、様々な方法で梱包しています。当社では、以下のような様々な方法で商品を梱包しています:

- 箱と木箱

- シュリンクラップ

- 木製パレット

- 木製ボックス

テクニカルサポート

さらに技術的なサポートが必要な場合は、常駐の冶金学者と知識豊富なスタッフが喜んでお手伝いいたします。さらに、Daxunは、マルチメタルおよびプラスチック在庫業界初の認定試験所を誇っています。これは、当社の品質への揺るぎないこだわりと、フルサービスサプライヤーとしての理念を示すものだと考えています。.

Daxun Grade 9 Titanium Rods help your brand improve quickly

- Tolerances for Grade 9 Titanium Round Bars (BS EN ISO 286-2)

| NOMINAL SIZE | h5 | h6 | h7 | h8 | h9 | H10 | H11 | h12 |

|---|---|---|---|---|---|---|---|---|

| DIAMETER mm | ||||||||

| ~ to 3 | +0.004/0 | +0.006/0 | +0.01/0 | +0.014/0 | +0.025/0 | +0.04/0 | +0.06/0 | +0.1/0 |

| over 3 to 6 | +0.005/0 | +0.008/0 | +0.012/0 | +0.018/0 | +0.03/0 | +0.048/0 | +0.075/0 | +0.12/0 |

| over 6 to 10 | +0.006/0 | +0.009/0 | +0.015/0 | +0.022/0 | +0.036/0 | +0.058/0 | +0.09/0 | +0.15/0 |

| over 10 to 18 | +0.008/0 | +0.011/0 | +0.018/0 | +0.027/0 | +0.043/0 | +0.07/0 | +0.11/0 | +0.18/0 |

| over 18 to 30 | +0.009/0 | +0.013/0 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 | +0.13/0 | +0.21/0 |

| over 30 to 50 | +0.011/0 | +0.016/0 | +0.025/0 | +0.039/0 | +0.062/0 | +0.1/0 | +0.16/0 | +0.25/0 |

| over 50 to 80 | +0.013/0 | +0.019/0 | +0.03/0 | +0.046/0 | +0.074/0 | +0.12/0 | +0.19/0 | +0.3/0 |

| over 80 to 120 | +0.015/0 | +0.022/0 | +0.035/0 | +0.054/0 | +0.087/0 | +0.14/0 | +0.22/0 | +0.35/0 |

| over 120 to 180 | +0.018/0 | +0.025/0 | +0.04/0 | +0.063/0 | +0.1/0 | +0.16/0 | +0.25/0 | +0.4/0 |

| over 180 to 250 | +0.02/0 | +0.029/0 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 | +0.29/0 | +0.46/0 |

Types of Ti-3AL-2.5V Grade 9 Titanium Rods (3)

チタン棒

関連商品 (8)

Daxun Grade 9 Titanium Bar Production & Specifications

Daxun operates an advanced production facility in China manufacturing high-precision Grade 9 titanium bars (Ti-3Al-2.5V). With superior surface finish, dimensional tolerance, straightness and material purity, we ensure technological leadership and consistent production processes. These advantages extend across a wide diameter range and material variants. Our comprehensive service center inventory enables just-in-time delivery globally.

仕様

- AMS 4911 – Bars, Forgings, and Forging Stock (Annealed)

- ASTM B348 – Standard Specification for Titanium and Titanium Alloy Bars and Billets

HEAT TREATMENT

For enhanced hardness, tensile strength, and fatigue resistance:

- アニーリング: 1,300-1,450°F (704-788°C), 1-2 hours, air/furnace cool

- Stress Relief: 1,000-1,200°F (538-649°C), 1-4 hours, air cool

HARDNESS

- Annealed condition: Rockwell C 25-30

- Solution treated & aged: Rockwell C 30-35

Forgeability / Formability

Grade 9 titanium bars are forged at 1,650-1,750°F (899-954°C) with final forging temperature ≥1,400°F (760°C). Minimum 30% reduction recommended for optimal properties. Unlike Grade 23, Grade 9 exhibits excellent cold formability in annealed condition, enabling bending/stretching at room temperature. Hot forming is feasible at 800-1,200°F (427-649°C) without compromising mechanical properties.

加工性

Machinable using austenitic stainless steel methods with:

- Low cutting speeds

- High feed rates

- Rigid tooling

- Non-chlorinated cutting fluids

溶接性

Grade 9 titanium rods are readily weldable in annealed condition. Requires inert gas shielding (argon/helium) to prevent oxygen/nitrogen/hydrogen contamination. Post-weld stress relief at 1,000-1,200°F (538-649°C) is recommended.

Size Range

- Diameter: Ø 0.8 – 350 mm (drawn/ground/hot-rolled)

- 公差: h9–h6 (ISO 286-2)

- Lengths: Up to 6,000 mm (custom lengths negotiable)

Availability & Processing

Processing options include:

- Drawing, straightening, grinding, polishing

- Annealing (stress-relieved or full)

- Custom end machining (chamfering, centering, facing)

- Surface Finish: Defect-free (Level 4 per eddy current testing)

Delivery Standards

ASTM, AMS, ASME, GB, GJB, ISO, DIN, EN, NACE, API

Material Services

As an ISO-certified service center, we provide:

- 100% non-destructive testing (ultrasonic/eddy current)

- Third-party certification (TÜV, DNV)

- Long-term supply agreements with fixed pricing

- Global logistics support since 2003

ご注文について

Purchase orders must specify:

- Quantity, grade (Ti-3Al-2.5V), diameter, length

- Tolerance class (e.g., h6)

- Surface treatment (polished/ground)

- Applicable standards (ASTM B348/AMS 4911)

- Additional testing requirements

Contact Daxun for technical consultation and rapid quotation.

必要なチタン合金のグレードは、取り組んでいるプロジェクトによって異なります。各グレードには異なる利点があるためです。

すべてのグレードのチタン合金は極めて強靭で耐食性に優れており、過酷な環境下でも良好な性能を維持し続けます。

チタン合金の高グレード品(5~12)は、特定の利点を目的として設計された合金である。例えば、グレード12チタン合金は優れた耐熱性を有し、シェルアンドチューブ式熱交換器、油圧配管、化学工業用機器に最適な選択肢となる。

グレード1~4は純チタン合金であり、配管システムやチューブ用に溶接可能で延性のある材料が必要な場合に最適な選択肢です。低グレード品は船舶産業や工業分野で使用されています。

プロジェクトを開始するにあたり、どのグレードのチタン合金が最適かお悩みでしたら、ぜひ当社までご連絡ください。喜んでご支援いたします。

大迅では、グレード1からグレード12まで幅広いチタン合金グレードを提供しています。

グレード1~4は純チタンであり、それより上のグレードは合金である。

合金グレードは、高い強度重量比で人気がある。

最も一般的に使用されるチタン合金グレードはグレード5です。チタン含有量は依然として高いものの、このグレードは600°F(約315℃)までの高温に耐え、過酷な条件にも耐えられるため、最も信頼性の高いグレードの一つです。

航空宇宙産業や海洋産業などの業界では、耐摩耗性と耐食性に優れていることから、より高品位のグレードが好まれている。

逆に、低品位の鋼材は強度が低いため、主に溶接用として使用される。

各種チタン合金のグレードの違いについて詳しく知りたい方は、本日+86 13382898899までお電話ください。専門家が直接ご説明いたします。

チタンのグレードはコストをわずかに増加させますが、総コストは主に必要なチタンの形状と形態によって決定されます。

At DAXUN, we offer a wide range of titanium products, including plates, tubes, coils and bars. The length, width and quantity of each item you require will affect the amount you pay at checkout.

残念ながら、プロジェクトの詳細やチタニウムの使用目的がわからないと、オンラインで価格をお見積もりするのは難しいです。

幸いなことに、当社の専門家チームが常に皆様のチタンに関するご要望にお応えし、アドバイスを提供いたします。[email protected] までメールをお送りいただければ、アドバイスと正確な見積もりをご案内いたします。

ご要望のチタニウムのグレード、形状、数量について、可能な限り詳細な情報をご提供ください。これにより、お客様のニーズをより正確に把握できます。

DAXUNのチームは経験豊富で知識が深く、親しみやすいです。業界での長年の経験から、チタンの用途、利点、グレードに至るまで、あらゆることを熟知しています。

チタニウムの最新情報、用途、および産業分野における応用事例については、当社のブログをぜひご覧ください。専門家による分かりやすいガイドを掲載しており、疑問が生じた際にはいつでもご参照いただけます。

もし問題が解決しない場合は、お気軽にお問い合わせください。喜んでお手伝いいたします。

[email protected] 宛にメールをお送りいただければ、迅速なご返答を差し上げます。お問い合わせの際は、可能な限り詳細な情報をご記載ください。そうすることで、適切な解決策をご提案できます。

お問い合わせ “ページのフォームにご記入いただくか、”+86 13382898899 “までお電話ください。WhatsAppはオンライン、Eメール([email protected])は6時間以内に確認いたします。すべてのお問い合わせやメッセージに迅速に対応させていただきます。また、毎週お客様と市場情報を共有しています。

We can provide titanium rod samples for you to check the quality. Sample is free and you just pay the freight.

カナダ、チリ、クウェート、ドイツ、韓国、サウジアラビア、シンガポールなど42カ国以上に輸出しています。.

Our MOQ is 300 Kg for titanium rod.

トライアル・オーダーは1週間以内にお届けできます。通常のご注文の場合、おおよそ2週間かかります。.