Our heat treatment – your solution

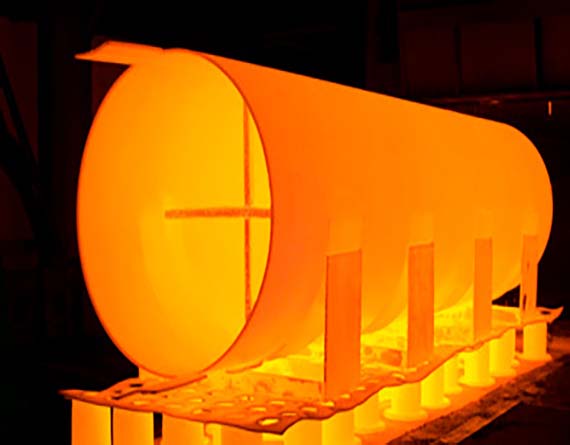

에서 Daxun 합금, you will find comprehensive solutions to meet all your heat treatment needs. Regardless of the project size or complexity, we are here to provide professional support. Whether it is alloy plates, equipment components, pipes, profiles, or slabs, our expertise and advanced processes ensure the right heat treatment solutions tailored to your requirements.

Heat treatment processes

당사가 제공하는 열처리 프로세스:

-

스트레스 릴리프 아네일링

-

Normalizing

-

Hardening

-

Tempering

-

Soft Annealing

-

Pearlitizing

-

Ferritizing

-

공기 또는 물 담금질을 통한 용액 어닐링

-

솔루션 트리트먼트 + 에이징(STA)

-

요청 시 다른 프로세스 이용 가능

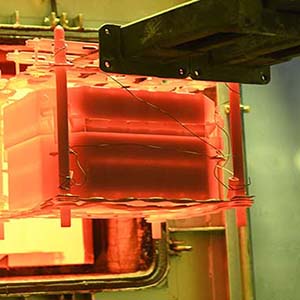

We professionally carry out and document all heat treatment operations around the clock, using the latest technology. Our highly qualified team can handle orders from all areas of the metalworking industry. We combine in-depth knowledge of all heat treatment processes with the flexibility of a medium-sized company.

Of course, we also have a quality assurance system in accordance with ISO 9001: 2008. Reason enough to let us heat treat your products.

Temperature:

Control and regulation range: Room temperature to 1,250°C

Maximum furnace dimensions:

19 meters long, 6 meters wide, 5 meters high

Maximum furnace load:

350 tons

Crane capacity:

100 tons

Water Quenching Tank:

8,000 x 3,000 x 3,600, with an immersion capacity of up to 12 tons, an integrated circulation system, water temperature recording, and a charging time of less than one minute.

Forced Air Annealing (with fan):

During the heat treatment process, the warm furnace atmosphere is passed through a series of tube bundles (e.g., heat exchangers) to achieve uniform heating.

Unsere Dimensionen - Ihre Wahl

bogie hearth kiln with 20 burners / 100 kW each

- 5,500 x 3,800 x 3,600mm (LxWxH)

- Temperature up to 1,100°C

- 2 bogies / 80,000 kg load capacity each

bogie hearth kiln with 40 burners / 120 kW each

- 19,000 x 5,000 x 5,000mm (LxWxH)

- Temperature up to 750°C

- 1 bogie / 200,000 kg load capacity

bogie hearth kiln with 30 burners / 120 kW each

- 12,000 x 4,300 x 2,500 mm (LxWxH)

- Temperature up to 1,100°C

- 1 bogie / 60,000 kg load capacity

bogie hearth kiln with 12 burners / 230 kW each

- 7,000 x 2,000 x 1,850 mm (LxWxH)

- Temperature up to 1,250°C

- 2 bogies / each 30,000 kg load capacity

- 2 water basins with charging facilities

- 8,000 x 3,000 x 3,600 (LxWxH)

- Continuous circulation of water

- Submersible device up to 12,000 kg

hood furnace with 3 burners / 150 kW each

- 1,450 x 1,450 x 1,200 mm (LxWxH)

- Temperature up to 1,100°C

- Loading capacity max. 1,000 kg

hood furnace with 2 annealing stations with 10 burners each / 350 kW each

- 6,300 x 4,350 x 4,000 mm (LxWxH)

- Temperature up to 1,100°C

- Loading capacity up to 150,000 kg

chamber furnace electrically heated

- 600 x 400 x 300 mm (LxWxH)

- Temperature up to 1,000°C

Shuttle furnace with 20 burners / 300 kW each

- and 2 annealing stations 16,900 x 6,000 x 5,500 mm (LxWxH)

- Temperature up to 700°C

- Loading capacity up to 300,000 kg per loading station

00,000kg, 50,000kg, 40,000kg, 32,000kg

Here are common heat-treatable metal products, organized by category, including the more common alloys and typical heat treatment methods:

1. Heat-Treatable Steels

1.1 Carbon Steels (Medium and High Carbon)

| 등급 | 열처리 | 일반적인 애플리케이션 |

|---|---|---|

| 45, 50, 55 (e.g., SAE 1045) | Quenching + Tempering | Shafts, bolts, gears |

| T8, T10 (High carbon tool steel) | Quenching + Low-Temp Tempering | Knives, molds, gauges |

1.2 Alloy Structural Steels

| 등급 | Key Alloying Elements | 열처리 | 애플리케이션 |

|---|---|---|---|

| 20Cr, 20CrMnTi | Cr, Ti | Carburizing + Quenching + Tempering | Gears, bushings |

| 40Cr, 42CrMo | Cr, Mo | Quenching + Tempering | Crankshafts, couplings |

| 35CrMo, 30CrMnSiA | Cr, Mo, Si | Quenching + Tempering | High-strength bolts, axles |

1.3 Spring Steels

| 등급 | 열처리 | 애플리케이션 |

|---|---|---|

| 65Mn, 60Si2Mn | Quenching + Medium-Temp Tempering | Auto springs, shock absorber wires |

| 55CrSi, 50CrVA | Quenching + Tempering | High-grade springs, clutches |

1.4 Tool Steels

| 유형 | Common Grades | Characteristics |

|---|---|---|

| Cold Work | Cr12MoV, GCr15 | High wear resistance |

| Hot Work | H13 (4Cr5MoSiV1) | Excellent thermal fatigue resistance |

| High-Speed Steel | W18Cr4V, M2 | Excellent red hardness for cutting tools |

1.5 Heat-Treatable Stainless Steels

| 유형 | 등급 | 열처리 | 애플리케이션 |

|---|---|---|---|

| Martensitic SS | 410, 420, 440C | Quenching + Tempering | Knives, bearings |

| Precipitation-Hardening SS | 17-4PH (SUS630), 15-5PH | Solution + Aging | High-strength, corrosion-resistant components |

2. Heat-Treatable Non-Ferrous Alloys

2.1 Aluminum Alloys (Heat-Treatable Series)

| Series | 등급 | 열처리 | 애플리케이션 |

|---|---|---|---|

| 2xxx (Al-Cu) | 2024, 2618 | Solution + Artificial Aging | Aerospace structures |

| 6xxx (Al-Mg-Si) | 6061, 6082, 6005, 6106 | Solution + Aging | Construction, structural components |

| 7xxx (Al-Zn-Mg-Cu) | 7075, 7475, 7050, 7010 | Solution + Double Aging | Aerospace, sports equipment |

2.2 Titanium Alloys

| 유형 | Grades | 열처리 | 애플리케이션 |

|---|---|---|---|

| α+β titanium | Ti-6Al-4V (Grade 5), Ti-6Al-6V-2Sn | Solution + Aging | Aerospace, medical rods |

| β titanium | Ti-10V-2Fe-3Al, Ti-15V-3Cr-3Al-3Sn | Solution + Aging | High-strength, formable parts |

| Commercially Pure Titanium | TA1, TA2 (Grade 1, 2) | Annealing only | Pipes, heat exchangers (non-strengthened) |

2.3 Magnesium Alloys

| Series | 등급 | 열처리 | 애플리케이션 |

|---|---|---|---|

| AZ Series | AZ91D, AZ80A | Solution + Aging | Lightweight housings, auto parts |

| ZK Series | ZK60, ZK21 | Solution + Aging | Aerospace, bicycle parts |

2.4 Copper Alloys (Precipitation-Hardened)

| 등급 | 열처리 | 애플리케이션 |

|---|---|---|

| Beryllium Copper (C17200) | Solution + Aging | Precision springs, injection mold inserts |

| Chromium Zirconium Copper (C18150) | Solution + Aging | Welding electrodes, conductive parts |

| Nickel-Silicon Bronze (C7025) | Aging Treatment | High-speed electronic connectors |

3. Purpose of Heat Treatment

| Method | Purpose |

|---|---|

| 어닐링 | Softening, improved ductility |

| Quenching | Increasing hardness and strength |

| Tempering | Reducing brittleness, improving toughness |

| Solution Treatment | Homogenize alloying elements |

| Aging (Natural/Artificial) | Precipitation hardening to enhance strength |