Grade 7 (Ti-0.15Pd) Titanium Alloy Plate Manufacturer - Daxun Alloy

Como um dos principais fornecedores de titânio na China, a Daxun fornece placas de titânio de alto desempenho para o mundo.

- Plate Grade:Grau 7 UNS R52400

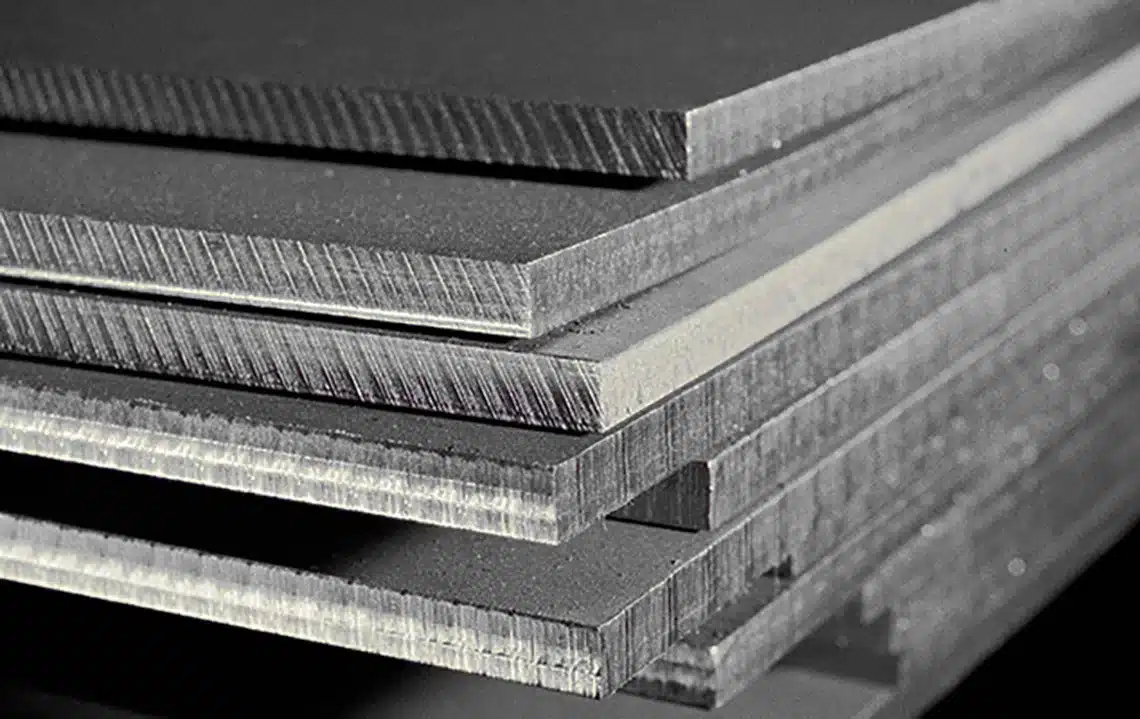

- Plate Production type:cold rolling, hot rolling, forging.

- Padrão:ASTM B 265,ASME SB265,AMS491 etc

- Features:High strength, Lightweight, High-temperature resistance

- Surface:bright, polished, pickled, sandblasted, etc.

- Size:0.3mm ≤ 1000mm ≤ 2500mm or as your request

————A Daxun produz chapas de titânio na China para satisfazer as diversas necessidades de ——necessidades exigentes dos clientes!

Providing High-quality Grade 7 Titanium Plate to Serve Customers Worldwide

Grade 7 titanium plate (Ti Grade 7 / UNS R52400) is a palladium-enhanced, commercially pure (CP) titanium alloy specifically engineered for supreme corrosion resistance in aggressive environments. It consists of titanium (≥99%) with a critical addition of 0.12–0.25% palladium (Pd), which fundamentally alters its electrochemical behavior. This palladium modification dramatically improves resistance to reducing acids (e.g., sulfuric, hydrochloric, phosphoric), chloride solutions (including seawater and brines), and crevice/pitting corrosion—scenarios where standard CP grades like Grade 2 would rapidly degrade. While retaining the inherent advantages of titanium—low density (~4.5 g/cm³), high strength-to-weight ratio, excellent weldability, and biocompatibility—Grade 7 exhibits superior performance at elevated temperatures (up to ~400°C/750°F) and in highly oxidizing or acidic conditions. Its passive oxide layer, stabilized by palladium, provides unparalleled protection against chemical attack, making it one of the most corrosion-resistant metallic materials available.

Where is Grade 7 titanium plate used?

Grade 7 titanium plate is extensively used in chemical processing for critical components like reactor vessels, heat exchangers, piping systems, and agitators handling acids, chlorides, or organic solvents. In marine and offshore engineering, it serves in seawater desalination plants, heat rejection systems, and subsea equipment exposed to high-salinity environments. The alloy also excels in pollution control systems (e.g., flue-gas desulfurization scrubbers), pharmaceutical manufacturing, and medical implants (e.g., orthopedic devices) due to its inertness and longevity. Despite its higher initial cost—driven by palladium content—Grade 7 delivers exceptional lifecycle value by minimizing downtime, maintenance, and replacement costs in corrosive service. Its reliability in preventing catastrophic failures ensures safety and efficiency in applications ranging from nuclear waste containment to aerospace fluid systems, justifying its selection as a premium solution for the most demanding corrosion challenges.

Dados

- Parâmetro

- Propriedades físicas

- Propriedades mecânicas

| Elemento | Símbolo | Gama de composição (wt.%) |

|---|---|---|

| Titânio | Ti | Balance (>99%) |

| Palladium | Pd | 0.12–0.25% |

| Ferro | Fe | ≤0.30% |

| Oxigénio | O | ≤0,25% |

| Carbono | C | ≤0,08% |

| Nitrogénio | N | ≤0,03% |

| Hidrogénio | H | ≤0,015% |

| Outros elementos | Each | ≤0.40% (single element) |

Caraterísticas principais

- Strength-to-Weight Ratio: Comparable to pure titanium (Grades 1–4) but lower than Ti-6Al-4V (Grade 5) or Ti-3Al-2.5V (Grade 9). Optimized for corrosion resistance over mechanical strength.

- Corrosion Resistance: Unmatched in reducing acids (e.g., HCl, H₂SO₄), chlorides, and crevice corrosion environments. Outperforms all commercially pure grades (1–4) and Grade 5/9 in aggressive chemical media due to palladium (Pd) stabilization.

- Biocompatibility: Fully non-toxic and MRI-compatible. Suitable for surgical instruments and chemical processing equipment, though not used for permanent implants (Grade 23 preferred).

- Formability: Retains excellent cold formability, weldability, and machinability of pure titanium. Significantly easier to fabricate than Grade 5/9, enabling complex geometries without specialized tooling.

| Imóveis | Valor (Imperial) | Valor (métrica) |

|---|---|---|

| Densidade | 0.163 lb/in³ | 4.51 g/cm³ |

| Ponto de fusão | 3,000-3,050°F | 1,650-1,680°C |

| Condutividade térmica | 9.5 Btu/(hr·ft·°F) | 16.4 W/(m·K) |

| Coeficiente de expansão térmica | 4.8 × 10⁻⁶/°F | 8.6 × 10⁻⁶/K |

| Resistividade eléctrica | 1.78 × 10⁻⁶ Ω·cm | 1.78 μΩ·m |

| Imóveis | Valor (Imperial) | Valor (métrica) |

|---|---|---|

| Resistência à tração | 50,000–65,000 psi | 345–450 MPa |

| Yield Strength | 30,000–45,000 psi | 207–310 MPa |

| Alongamento | 20–30% | 20–30% |

| Dureza (Brinell) | 120–160 HB | 120–160 HB |

| Módulo de elasticidade | 14.9–16.0 × 10⁶ psi | 103–110 GPa |

Escolha a Daxun para ajudar o seu projeto a arrancar.

Aplicações comuns

Grade 7 titanium plates and sheets are primarily utilized in applications requiring exceptional corrosion resistance, particularly in aggressive chemical environments, combined with moderate strength and excellent weldability.

- Applications include chemical processing equipment such as heat exchangers, reactor vessels, and piping systems that handle chlorides, acids, and other corrosive substances.

- Industrial applications include marine components, offshore oil and gas equipment, and desalination plants where exposure to saltwater and harsh chemicals is common.

- Pharmaceutical and food processing equipment that demands high purity standards and resistance to corrosive cleaning agents.

- Laboratory equipment and analytical instruments that require superior chemical resistance for accurate testing and processing.

- Pollution control systems, including scrubbers and ductwork in power plants and industrial facilities that handle corrosive exhaust gases.

Entrega rápida

Daxun provides customers with timely and fast delivery of grade 7 titanium plate products. Behind the speed is the system support from professional production capacity, and information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real-time, and the data is seamlessly connected.

Corte à medida

A Daxun Alloy fornece aos clientes soluções de corte personalizadas de vários tamanhos para o ajudar a controlar a perda de tamanho das placas de titânio, poupando assim os seus custos e tempo de processamento. Nossos métodos de corte incluem:

- Corte por jato de água

- Corte a laser

- Corte a plasma

- Corte de fios

- Dobragem

- Corte longitudinal

- Serrar

Embalagem

Prestamos especial atenção à embalagem. Embalamos os nossos produtos de várias formas, consoante o produto. Embalamos os nossos produtos de várias formas, tais como:

- Caixas e caixotes

- Embalagem retrátil

- Paletes de madeira

- Caixas de madeira

Apoio técnico

Se necessitar de qualquer assistência técnica adicional, o nosso metalúrgico residente e a nossa equipa experiente terão todo o prazer em ajudar. Além disso, a Daxun possui um laboratório de testes certificado - o primeiro na indústria de inventário de multi-metal e plástico.

Daxun Grade 7 Titanium sheet Let your brand improve rapidly

- Outros graus de chapa de titânio

| Para além dos produtos listados abaixo, outros produtos metálicos disponíveis não estão listados aqui. Outros produtos metálicos que a DAXUN pode fabricar e fornecer incluem Tântalo, Nióbio, Zircónio, Háfnio, Níquel, Cobre, etc., que se apresentam principalmente sob a forma de Placa, Barra e Tubo. | |

| Norma de produtos/transformação | Grau/tamanho |

| Placa de titânio, folha, bobina- ASME SB265, AMS 4911, AMS 4919, AMS 4914, ASTM F67, ASTM F136 | GR1, GR2, GR3, GR4, GR5, GR7,GR9, GR12, GR16, GR17, GR23,Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3(Espessura: (0,0197”-6”)Largura máxima: 12 pés,Comprimento máximo: 50 pés) |

| AMS-T-9046 | |

| Chapas e folhas de titânio e de ligas de titânio | |

| Titânio comercialmente puro (CP) | |

| Designação do código | Resistência ao escoamento |

| mínimo, ksi 1 / | |

| CP-1 Gr1 | 70 |

| CP-2 Gr2 | 55 |

| CP-3 Gr3 | 40 |

| CP-4 Gr4 | 25 |

| Ligas alfa de titânio(A) | |

| Designação do código | Composição |

| A-1 | 5A1-2.5Sn |

| A-2 | 5A1-2.5Sn(ELI) 2 / |

| A-3 | 6A1-2Cb-1Ta-0.8Mo |

| A-4 | 8A1-1Mo-1V |

| Ligas de titânio alfa-beta (AB) | |

| Designação do código | Composição |

| AB-1 Gr5 | 6A1-4V |

| AB-2 Gr5 | 6A1-4V(ELI) |

| AB-3 | 6A1-6V-2Sn |

| AB-4 | 6A1-2Sn-4Zr-2Mo |

| AB-5 | 3A1-2,5V |

| AB-6 | 8Mn |

| Ligas de titânio beta(B) | |

| Designação do código | Composição |

| B-1 | 13V-11Cr-3A1 |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3A1-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3A1 |

| Processamento: | |

| Laminagem a quente | Laminagem a frio |

| Graus disponíveis: | |

| PC Grau 1 | Grau 6Al-2Sn-4Zr-2Mo (6-2-4-2) |

| PC Grau 2 | Grau 6Al-4V ELI (antigo Grau 23) |

| Grau 7 | Grau 6Al-6V-2Sn (6-62) |

| Grau 19 | Grau 8Al-1Mo-1V (8-1-1) |

| Grau 5 (6Al-4V) | Grau 9 (3Al-2,5V) |

| Grau 6 (5Al-2.5Sn) | PC Grau 3 |

| Aplicação | |

| Indústria química | Dessalinização da água do mar |

| Indústria petroquímica | Aeroespacial |

| Domínio da maquinagem, domínio automóvel | Componente de telemóvel Campo. |

Produtos e projectos recentes de casos quentes

Produtos relacionados (7)

Grade 7 titanium plate is a commercially pure titanium alloy with the addition of 0.12-0.25% palladium, which significantly enhances its corrosion resistance. This combination maintains the excellent formability and weldability of pure titanium while providing superior resistance to reducing acids and other highly corrosive environments.

Grade 7 titanium plates offer good strength with a minimum yield strength of 275 MPa and minimum tensile strength of 485 MPa. They maintain excellent ductility with approximately 20% elongation, allowing for good formability during fabrication processes.

Yes, Grade 7 titanium plates can be welded using standard titanium welding procedures including TIG, MIG, and plasma arc welding. However, proper shielding with inert gas is essential to prevent contamination during welding. The palladium addition does not significantly affect weldability compared to other commercially pure titanium grades.

We offer Grade 7 titanium plates in various surface finishes including hot-rolled, pickled, sandblasted, and polished finishes. Custom surface treatments can also be provided based on specific application requirements.

Our Grade 7 titanium plates undergo strict quality control including chemical composition analysis, mechanical property testing, and ultrasonic inspection. We provide full material traceability and certification with each order, ensuring compliance with applicable standards such as ASTM B265 and AMS 4902.

Standard lead times for Grade 7 titanium plates typically range from 2-4 weeks depending on size, thickness, and quantity requirements. We also maintain a stock of commonly used dimensions for immediate delivery and can accommodate urgent requests when possible.

Preencha o formulário na página “Contacte-nos” ou ligue para o nosso gestor de vendas através do número “+86 13382898899” e entraremos em contacto consigo o mais rapidamente possível. O nosso WhatsApp está online e o e-mail ([email protected]) será verificado no prazo de 6 horas. Todas as perguntas ou mensagens serão respondidas prontamente. Além disso, todas as semanas partilhamos informações de mercado com os nossos clientes

Nós podemos fornecer amostras de folha de titânio para você verificar a qualidade. A amostra é grátis e você só paga o frete.

Exportámos para mais de 42 países, como o Canadá, Chile, Kuwait, Alemanha, Coreia do Sul, Arábia Saudita, Singapura, etc.