Grade 23 Ti 6Al-4V ELI Titanium Alloy Pipe Manufacturer

As a leading supplier of titanium and titanium alloy tubes in China, Daxun provides high-performance titanium tubes to the world.

- Titanium tube Grade:Grade 23 – UNS R56401

- Titanium tube types:Seamless Ti tube, Ti welded tube, forged Ti tube

- Titanium tube density The density of grade 23 titanium is 4.51 g/cm3

- Standards:ASTM B338/ASME SB338、ASTM B337/ASME SB337、ASTM B861/ASME SB861、ASTM B862/ASME SB862、AMS4911、AMS4928

- Softest Ti,High ductility, Very corrosion resistant, good cold formability

————Daxun produces titanium tubes in China to meet the diverse and ——demanding needs of customers!

Provide High Quality Grade 23 Titanium Pipe to Customers Around The World

Grade 23 titanium tubing, also known as Ti-6Al-4V ELI, is a high-strength, lightweight alloy composed of titanium with 6% aluminum and 4% vanadium in an extra-low interstitial (ELI) form.It is an improved alloy based on the classic Ti-6Al-4V (grade 5) by further reducing the content of interstitial elements such as oxygen, iron, and nitrogen (such as oxygen content ≤ 0.13%).Its extra-low interstitial (ELI) composition significantly enhances fracture toughness and fatigue resistance compared to standard titanium alloys, allowing it to perform reliably under cyclic loading conditions. The alloy maintains its impressive strength-to-weight ratio even at cryogenic temperatures, unlike many metals that become brittle in extreme cold. Additionally, Grade 23 exhibits superior corrosion resistance in both acidic and chloride environments, outperforming many stainless steels and other titanium grades in aggressive chemical settings.

Where is Grade 23 titanium pipe used?

Grade 23 titanium tubing has unique applications in cutting-edge medical devices, particularly orthopedic implants such as spinal fusion cages and joint replacement components, which require lifelong biocompatibility and fatigue resistance. It is particularly well-suited for dental implant systems, where osseointegration (a direct structural connection between bone and implant) is crucial to the long-term success of the system. In aerospace, it is the material of choice for hydraulic and fuel lines in commercial and military aircraft, which must balance weight reduction with extreme pressure requirements. The material’s properties also make it an ideal choice for high-performance bicycle frames used by professional cyclists, where its vibration-absorbing properties and fatigue resistance provide a competitive advantage.

Key Notes:

ELI (Extra Low Interstitial): Grade 23 has stricter limits on oxygen, nitrogen, hydrogen, and carbon compared to standard Grade 5 (Ti-6Al-4V) to enhance ductility and biocompatibility.

Primary alloying elements: Aluminum (Al) and vanadium (V) contribute to strength and phase stability.

Impurity control: Low iron, carbon, nitrogen, and hydrogen ensure superior corrosion resistance and fatigue performance.

Key performance:

High strength + high toughness: tensile strength can reach 895-930 MPa (annealed state), elongation ≥10%, better than ordinary Grade 5, suitable for scenes with dynamic loads.

Excellent corrosion resistance: acid resistance (such as hydrochloric acid, sulfuric acid), alkali resistance, seawater resistance, outstanding performance in medical implants and chemical equipment.

Biocompatibility: non-magnetic, non-toxic, excellent compatibility with human tissue, is the preferred material for orthopedic implants.

Processability: can be formed by forging, rolling, machining, welding performance is better than ordinary titanium alloy.

Dados

- Parâmetro

- Propriedades mecânicas

- Propriedades físicas

| Elemento | Ti | Al | V | O | Fe | C | N | H | Other elements |

| Gama de composição (wt.%) | >89% | 5.50 – 6.75% | 3.50 – 4.50% | ≤ 0.13% | ≤ 0.25% | ≤ 0.08% | ≤ 0.05% | ≤ 0.0125% | ≤ 0.4% |

| Imóveis | Valor |

|---|---|

| Ultimate Tensile Strength | 860-950 MPa |

| Yield Strength | 795-860 MPa |

| Alongamento | 10-15% |

| Resistência à fadiga | ~500 MPa (at 10⁷ cycles) |

| Resistência à fratura | 70-90 MPa√m |

| Dureza | 320-350 HV |

| Módulo de elasticidade | 90-110 GPa |

| Imóveis | Valor |

|---|---|

| Densidade | 4,43 g/cm³ |

| Ponto de fusão | 1660-1680°C |

| Condutividade térmica | 7.2 W/m·K |

| Coeficiente de expansão térmica | 8.6 × 10⁻⁶ /°C |

| Resistividade eléctrica | 1.78 μΩ·m |

| Capacidade térmica específica | 560 J/kg·K |

Escolha a Daxun para ajudar o seu projeto a arrancar.

Advanced Production

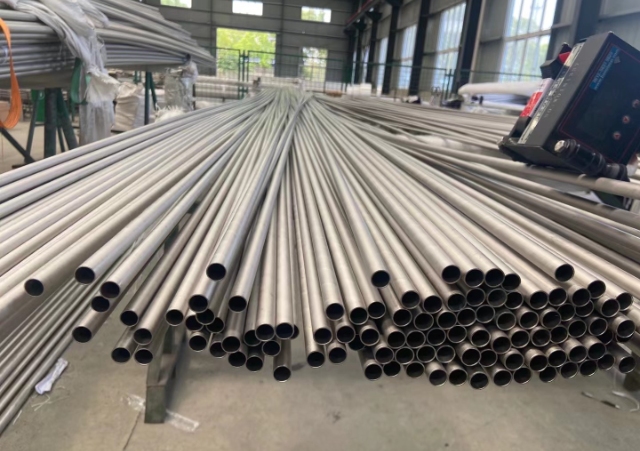

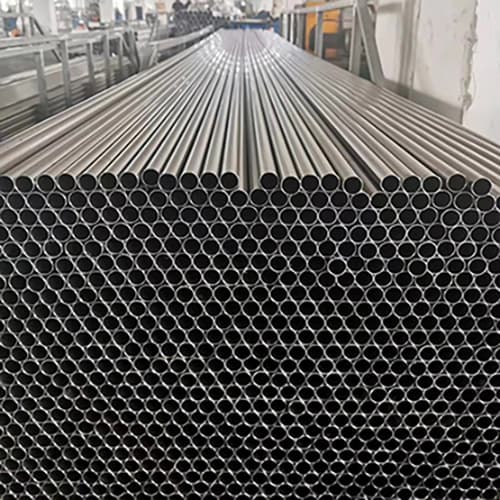

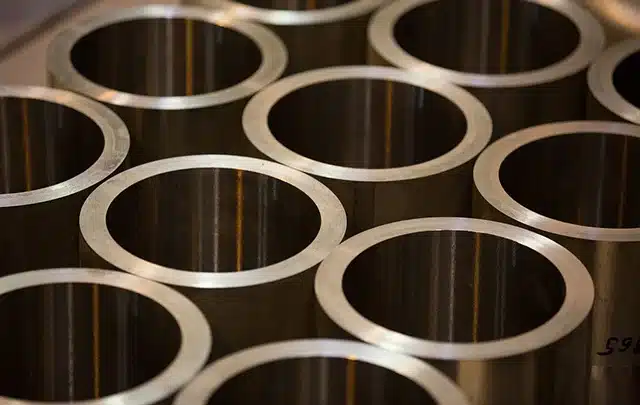

We offer a comprehensive selection of Grade 23 titanium tubing solutions, including both welded and seamless options to meet diverse industrial requirements. Our inventory features precision-engineered tubes manufactured to the highest quality standards, ensuring optimal performance in demanding applications. Whether you need welded tubes for cost-effective solutions or seamless tubes for superior pressure capabilities, our Grade 23 titanium products deliver exceptional strength-to-weight ratios, outstanding corrosion resistance, and biocompatibility for aerospace, medical, marine, and chemical processing industries.

Relatórios de ensaio

We provide comprehensive documentation and certification reports for all our Grade 23 titanium tubing, ensuring complete transparency and compliance with industry standards. Our documentation package includes material test reports (MTRs), chemical analysis certificates, mechanical property verification, and non-destructive testing results. Each batch of our Grade 23 titanium tubes comes with full traceability records, detailing the manufacturing process, heat treatment information, and quality assurance protocols.

Qualidade, entrega, inspeção

Daxun performs several quality assurance tests, these tests include flattening test, flaring test, ultrasonic flaw detection test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the Grade 23 Titanium Welded Pipe and Grade 23 Titanium Seamless Pipe materials are suitable for the required application. During the production process, we measure the diameter, thickness and surface of the products. Our standard delivery time is 5-7 days and the delivery time for special size products is 15-20 days.

- O nosso prazo de entrega está estritamente de acordo com o contrato.

- Apoio a agências terceiras do cliente para se deslocarem à fábrica para inspeção

- Apoio a amostras gratuitas para teste do cliente

- Apoio à inspeção de fábrica no local ou por vídeo

Apoio técnico

Se necessitar de qualquer assistência técnica adicional, o nosso metalúrgico residente e a nossa equipa experiente terão todo o prazer em ajudar. Além disso, a Daxun possui um laboratório de testes certificado - o primeiro na indústria de inventário de multi-metal e plástico. Isto, na nossa opinião, demonstra a nossa dedicação inabalável à qualidade e a nossa filosofia como um fornecedor de serviço completo.

Daxun Grade 23 Titanium TUBE Let your brand improve rapidly

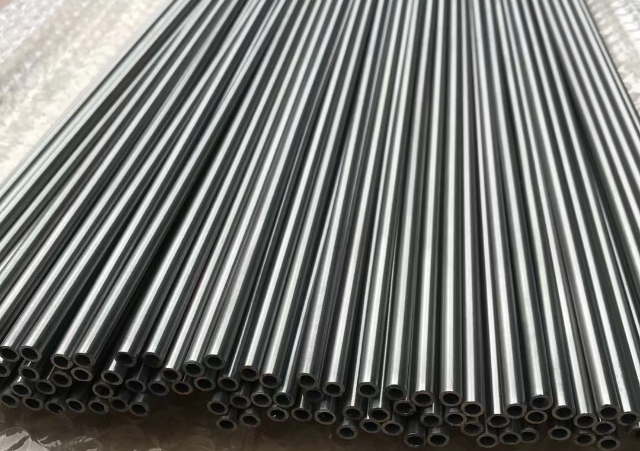

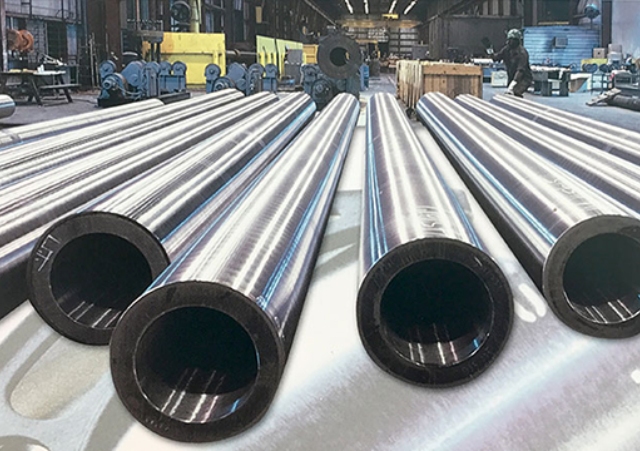

- Galeria

Grade 23 titanium tube form (4)

Produtos e projectos recentes de casos quentes

Produtos relacionados (5)

Grade 23 titanium pipe (Ti-6Al-4V ELI) is an extra low interstitial version of the popular Grade 5 titanium alloy. It contains reduced levels of oxygen, iron, and other interstitial elements, which results in improved fracture toughness, better fatigue resistance, and enhanced biocompatibility while maintaining high strength-to-weight ratio.

Grade 23 titanium tubes offer excellent biocompatibility, reducing the risk of adverse reactions when implanted in the human body. They have a modulus of elasticity closer to bone than many other metals, which helps reduce stress shielding. Additionally, their superior fatigue resistance ensures long-term performance in load-bearing medical applications.

Grade 23 titanium tubes exhibit outstanding corrosion resistance in most environments, including seawater, chlorides, and acidic conditions. The protective oxide layer that forms on the surface provides exceptional resistance to pitting and crevice corrosion, making them suitable for marine and chemical processing applications.

We offer Grade 23 titanium tubes in a comprehensive range of sizes, with outer diameters from 6mm to 120mm and wall thicknesses from 0.5mm to 10mm. We can also provide custom dimensions and special tolerances to meet specific project requirements.

Yes, we can supply Grade 23 titanium tubes with various surface treatments including anodizing, passivation, polishing, and coating options. These treatments can enhance specific properties such as wear resistance, friction characteristics, or aesthetic appearance depending on your application needs.

All our Grade 23 titanium tubes undergo rigorous quality control including ultrasonic testing, eddy current inspection, and dimensional verification. We provide full material traceability and complete documentation including chemical analysis, mechanical properties, and non-destructive testing reports with every order.

Embora o grau de titânio aumente ligeiramente o custo, o custo total é determinado principalmente pela forma e pelo formato do titânio que pretende.

At DAXUN, we offer a wide range of titanium products, including tubes, tubes, coils and bars. The length, width and quantity of each item you require will affect the amount you pay at checkout.

Infelizmente, é difícil apresentar um preço online sem saber muito sobre o seu projeto e para que será utilizado o titânio.

Felizmente, a nossa equipa de especialistas está sempre aqui para o ajudar e aconselhar nas suas necessidades de titânio. Ao enviar um e-mail para [email protected], poderemos responder-lhe com alguns conselhos e um orçamento exato.

Certifique-se de que inclui o máximo de informação possível sobre o grau, a forma e a quantidade de titânio de que necessita para compreender melhor as suas necessidades.

Preencha o formulário na página “Contacte-nos” ou ligue para o nosso gestor de vendas através do número “+86 13382898899” e entraremos em contacto consigo o mais rapidamente possível. O nosso WhatsApp está online e o e-mail ([email protected]) será verificado no prazo de 6 horas. Todas as perguntas ou mensagens serão respondidas prontamente. Além disso, todas as semanas partilhamos informações de mercado com os nossos clientes

Podemos fornecer amostras de chapas de aço inoxidável para que possa verificar a qualidade. A amostra é grátis e o cliente só paga o frete.

As encomendas de teste podem ser entregues no prazo de uma semana. Para as encomendas normais, são necessárias cerca de duas semanas.