CP Grade 4 Titanium Pipe Manufacturer

Grade 4 titanium pipe is recognized as the strongest among commercially pure titanium grades, delivering exceptional mechanical performance combined with superior corrosion resistance. Its high tensile strength and excellent ductility allow it to endure demanding operational environments, making it an ideal solution for industries where reliability and durability are critical. Unlike lower grades, Grade 4 titanium pipe provides a higher strength-to-weight ratio without sacrificing formability, ensuring versatility in both fabrication and end-use applications.

The advantages of grade 4 titanium pipe

In industrial settings, Grade 4 titanium pipe is widely used in chemical processing, marine engineering, and aerospace sectors due to its outstanding resistance to aggressive media, including chlorides and acids. Its ability to withstand high pressure and extreme temperatures makes it suitable for critical fluid transport, heat exchangers, and hydraulic systems. Additionally, its biocompatibility extends its utility to medical applications where long-term structural integrity and resistance to bodily fluids are essential.

The technical advantages of Grade 4 titanium pipe are further highlighted by its low maintenance requirements and extended service life, even under cyclic loading and exposure to corrosive environments. This translates to reduced downtime and lifecycle costs for operators, reinforcing its value as a premium material choice. For projects demanding uncompromised performance and resilience, Grade 4 titanium pipe stands out as a benchmark in high-performance piping solutions.

Grade 4 titanium pipe is the strongest among commercially pure titanium grades, offering an impressive combination of high tensile strength, excellent ductility, and superior corrosion resistance. With a minimum yield strength of 480 MPa and ultimate tensile strength exceeding 550 MPa, it outperforms Grades 1-3 in load-bearing applications while maintaining the renowned resistance to chloride-induced pitting and crevice corrosion. Its chemical composition, primarily titanium with trace amounts of oxygen, iron, and carbon, contributes to its robustness and biocompatibility, making it suitable for both industrial and medical environments.

When compared to other materials, Grade 4 titanium pipe surpasses stainless steel in corrosion resistance and offers a better strength-to-weight ratio than many nickel-based alloys. Although its initial cost is higher, its extended service life, reduced maintenance, and reliability in harsh environments often result in lower lifecycle costs. For projects requiring uncompromised performance—such as offshore oil rigs, chemical reactors, or high-performance aerospace systems—Grade 4 titanium pipe represents the optimal choice.

データ

- 化学組成

- 物理的性質

- 機械的特性

| エレメント |

Maximum Content (%)

|

| 窒素(N) | 0.05 |

| Carbon © | 0.08 |

| Hydrogen (H) | 0.015 |

| 鉄(Fe) | 0.5 |

| Oxygen (O) | 0.4 |

| チタン (Ti) | バランス |

| プロパティ | 価値 |

| 密度 |

4.51 g/cm³ (0.163 lb/in³)

|

| 融点 |

1660°C (3020°F)

|

| 熱伝導率 |

~16.4 W/m·K (114 BTU·in/hr·ft²·°F)

|

| 電気抵抗率 |

5.4 × 10⁻⁵ Ω·cm

|

| 熱膨張係数(20~100℃) | 8.6 µm/m·°C |

| プロパティ | 価値 |

| 引張強さ、極限 |

550 MPa (80,000 psi) min

|

| 引張強さ、降伏点 |

480 MPa (70,000 psi) min

|

| 破断伸び | 15–25% |

| 弾性係数 |

~104 GPa (15,100 ksi)

|

| 硬度、ヴィッカース | ~280 HV |

Daxunを選んで、あなたのプロジェクトを成功に導きましょう。.

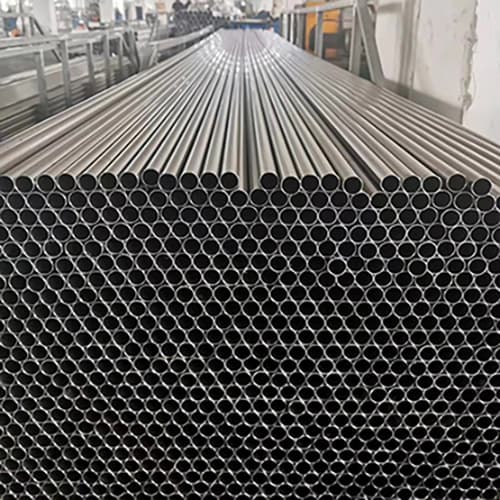

高度な生産:チタン無縫鋼管

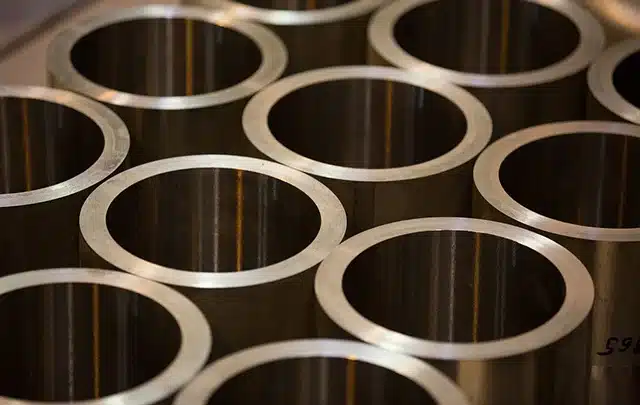

- CP Grade 4 titanium pipes are typically manufactured according to major international standards such as ASTM B338, ASME SB338, ASTM B861 (for seamless pipes), and ASTM B862 (for welded pipes). They are readily available in a variety of sizes, with diameters ranging from 3.35mm to 152mm and wall thicknesses from 0.020″ to 0.220″, accommodating diverse project requirements.

CP Grade 4 Titanium Tube Features

- Balanced Properties: As a commercially pure titanium, it offers a great balance of moderate strength and excellent corrosion resistance, stronger than Grade 1 and 2.

- Superior Corrosion Resistance: Exceptionally resistant to chloride and seawater environments, making it ideal for marine and chemical processing applications.

- Good Fabricability: It is well-suited for forming, welding, and machining, allowing for easy manufacturing of complex components.

- Biocompatible: Safe for use in medical implants and food processing equipment due to its non-toxic and hypoallergenic nature.

- Cost-Effective: Provides better performance than lower grades without the high cost of titanium alloys, offering a practical solution for many industrial uses.

高度な製造:チタン溶接管

チタン溶接管:直径範囲は6.0mm~1219mm、肉厚範囲は0.3mm~30mm(直径による)、長さ最大25000mm、Gr1チタン管から製造。溶接管は、電気管溶接機において自動タングステン不活性ガス(アルゴン)溶接法を用い、平らな圧延ビレット(管ブランク)から製造され、製造ライン上で熱処理されます。機械的試験、幾何学的測定、100%超音波検査および渦電流検査、空気圧または静水圧試験を実施後、完成したチタン溶接管は顧客仕様に基づき梱包されます。製造技術ならびに検査・試験設備により、薄肉溶接管がASTM B 338およびASME SB 338規格を満たすことが保証されます。

試験報告書

The test reports we provide include: Factory test certificate for CP Grade 4 titanium welded pipe and CP Grade 4 titanium seamless pipe, EN 10204 3.1, Chemical report, Mechanical report, PMI test report, Visual inspection report, Third-party inspection report, NABL approved laboratory report, Destructive test report, Non-destructive test report. (Daxun will provide according to customer’s requirements)

アプリケーションと標準

CP Grade 4 Pipes and Tubing are extensively applied in extremely corrosive conditions in the below Industries:

- 熱交換器、反応容器、蒸発器、輸送パイプラインなどの化学処理部品、自動車排気システム、石油・ガス産業、石油化学プラント、化学プラント、産業機械、電力産業、製紙・パルプ産業、食品加工産業、製油所、医薬品・食品加工設備など。

- 規格:ASTM B861、B862、B338 / ASME SB861、SB862、SB338

Standard : ASTM, ASME and API

品質、納期、検査

Daxun performs several quality assurance tests, these tests include flattening test, flaring test, ultrasonic flaw detection test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the Titanium Welded Pipe and Titanium Seamless Pipe materials are suitable for the required application. During the production process, we measure the diameter, thickness and surface of the products. Our standard delivery time is 5-7 days and the delivery time for special size products is 15-20 days.

- 当社の納期は、契約に厳密に従います。.

- 顧客の第三者機関が工場に検査に行くのをサポートする。

- 顧客テストのための無料サンプルをサポート

- 現場検査またはビデオ工場検査をサポート

パッケージング

国際貨物は様々な経路を経て最終目的地に到着するため、梱包は重要な役割を担っています。商品によって、様々な方法で梱包しています。当社では、以下のような様々な方法で商品を梱包しています:

- 箱と木箱

- シュリンクラップ

- 木製パレット

- 木製ボックス

テクニカルサポート

さらに技術的なサポートが必要な場合は、常駐の冶金学者と知識豊富なスタッフが喜んでお手伝いいたします。さらに、Daxunは、マルチメタルおよびプラスチック在庫業界初の認定試験所を誇っています。これは、当社の品質への揺るぎないこだわりと、フルサービスサプライヤーとしての理念を示すものだと考えています。.

Daxun CP Grade 4 Titanium TUBE Let your brand improve rapidly

- ギャラリー

CP Grade 4 titanium tube form (4)

関連商品 (3)

Grade 4 titanium pipe is the strongest of the commercially pure titanium grades. Its key characteristics include high tensile strength, excellent ductility, and superior corrosion resistance, especially against chlorides and acids. It offers an outstanding strength-to-weight ratio, making it both durable and lightweight.

The primary difference is strength. Grade 4 titanium has a significantly higher minimum yield strength (480 MPa) compared to Grade 2 (275 MPa). While Grade 2 is more formable and often used for general corrosion resistance, Grade 4 is chosen for applications requiring higher mechanical strength and pressure resistance, such as in aerospace or demanding chemical processing components.

Due to its robust properties, Grade 4 titanium pipe is commonly used in the aerospace industry for hydraulic and fuel lines, in chemical processing for heat exchangers and pressure vessels, and in marine engineering for desalination plants and offshore platforms. It is also found in medical implants where high strength and biocompatibility are essential.

Absolutely. Laser cutting is an excellent method for fabricating Grade 4 titanium pipe, offering high precision, clean cuts, and a minimal heat-affected zone. This is particularly beneficial for creating complex shapes or preparing pipe ends for welding. It’s crucial to use optimized cutting parameters and an assist gas like argon or nitrogen to prevent oxidation and maintain the material’s corrosion resistance.

The higher initial cost is due to the complex extraction and refining processes required for titanium. However, Grade 4 titanium pipe often provides a lower total cost of ownership. Its exceptional corrosion resistance leads to a much longer service life and significantly reduced maintenance and replacement costs, especially in harsh environments where stainless steel would fail quickly.

チタンのグレードはコストをわずかに増加させますが、総コストは主に必要なチタンの形状と形態によって決定されます。

大迅では、チューブ、パイプ、コイル、棒材など、幅広いチタン製品を取り扱っております。お客様がご指定される各製品の長さ、幅、数量により、お支払い金額が変動いたします。

残念ながら、プロジェクトの詳細やチタニウムの使用目的がわからないと、オンラインで価格をお見積もりするのは難しいです。

幸いなことに、当社の専門家チームが常に皆様のチタンに関するご要望にお応えし、アドバイスを提供いたします。[email protected] までメールをお送りいただければ、アドバイスと正確な見積もりをご案内いたします。

ご要望のチタニウムのグレード、形状、数量について、可能な限り詳細な情報をご提供ください。これにより、お客様のニーズをより正確に把握できます。

お問い合わせ “ページのフォームにご記入いただくか、”+86 13382898899 “までお電話ください。WhatsAppはオンライン、Eメール([email protected])は6時間以内に確認いたします。すべてのお問い合わせやメッセージに迅速に対応させていただきます。また、毎週お客様と市場情報を共有しています。

私達は質を点検するためにあなたのためのステンレス鋼板のサンプルを提供してもいいです。サンプルは無料で、お客様は運賃を支払うだけです。.

カナダ、チリ、クウェート、ドイツ、韓国、サウジアラビア、シンガポールなど42カ国以上に輸出しています。.

トライアル・オーダーは1週間以内にお届けできます。通常のご注文の場合、おおよそ2週間かかります。.