Grade 9 (Ti-3Al-2.5V) Titanium Alloy Plate Manufacturer - Daxun Alloy

As a leading supplier of titanium in China, Daxun provides high-performance titanium plates to the world.

- Plate Grade:Grade 9 UNS R56320

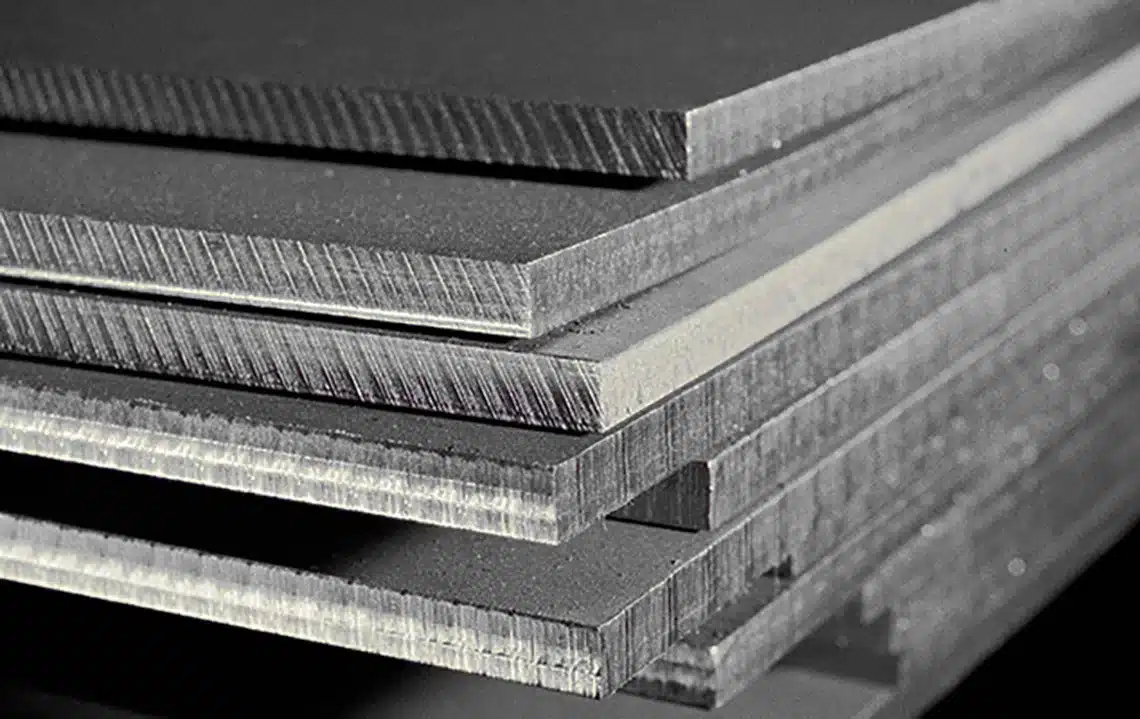

- Plate Production type:cold rolling, hot rolling, forging.

- Standard:ASTM B 265,ASME SB265,AMS491 etc

- Features:High strength, Lightweight, High-temperature resistance

- Surface:bright, polished, pickled, sandblasted, etc.

- Size:0.3mm ≤ 1000mm ≤ 2500mm or as your request

————Daxun produces titanium sheets in China to meet the diverse and ——الاحتياجات المتطلبة للعملاء!

Providing High-quality Grade 9 Titanium Plate to Serve Customers Worldwide

Grade 9 titanium plate is a high-performance near-alpha titanium alloy with a nominal composition of Ti-3Al-2.5V. It is based on pure titanium (Grades 1-4) reinforced with appropriate amounts of aluminum and vanadium, achieving an excellent balance of strength and toughness. Compared to pure titanium, Grade 9 boasts significantly higher strength and yield strength while maintaining good ductility and toughness. It is particularly renowned for its excellent weldability and cold formability. This material also offers lightweight, excellent corrosion resistance (especially in chloride environments), and good biocompatibility. It is both strong and durable, yet can withstand a variety of harsh operating conditions, making it an ideal choice for applications requiring high performance and reliability.

Where is Grade 9 titanium plate used?

In the aerospace industry, Grade 9 titanium plate is widely used in the manufacture of aircraft structures, fasteners, hydraulic systems, and engine components. Its combination of high strength and low density effectively reduces aircraft weight and improves fuel efficiency. In marine engineering and shipbuilding, its exceptional resistance to seawater corrosion makes it the material of choice for ship hull structures, desalination equipment, heat exchangers, and offshore platform components, ensuring long-term reliability in harsh marine environments. In the medical industry, Grade 9 titanium plate, due to its excellent biocompatibility and moderate strength, is widely used in the manufacture of orthopedic implants (such as plates and screws), dental implants, and surgical instruments. Furthermore, Grade 9 titanium plate demonstrates its unique value and adaptability in high-end sports equipment (such as bicycle frames and golf club heads), chemical equipment (corrosion-resistant reactors and heat exchangers), and precision mechanical components requiring lightweight and high strength.

البيانات

- المعلمة

- الخصائص الفيزيائية

- الخواص الميكانيكية

| العنصر | نطاق التركيب (بالوزن %) |

|---|---|

| تي | الرصيد (>90%) |

| آل | 2.50-2.50-3.50% |

| V | 2.00.00-3.00% |

| في | ≤0.25% |

| O | ≤0.13% |

| C | ≤0.08% |

| N | ≤0.03% |

| H | ≤0.015% |

| أخرى | ≤0.4% (عنصر واحد) |

Key Characteristics

- نسبة القوة إلى الوزن: Higher than pure titanium (Grades 1–4) but lower than Ti-6Al-4V (Grade 5).

- مقاومة التآكل: Excellent in marine, chemical, and chloride environments.

- التوافق الحيوي: Non-toxic and MRI-compatible, but less commonly used in implants than Grade 23.

- Formability: Superior to Grade 5; suitable for complex forming, welding, and machining.

التطبيقات النموذجية

- الطيران والفضاء: Hydraulic tubing, aircraft fittings, fasteners.

- Marine: Heat exchangers, seawater components, propeller shafts.

- Medical: Surgical instruments, non-implantable devices.

- Industrial: Chemical processing equipment, pressure vessels.

| الممتلكات | القيمة (إمبراطوري) | القيمة (متري) |

|---|---|---|

| الكثافة | 0.160 رطل/بوصة³ | 4.43 جم/سم مكعب |

| نقطة الانصهار | 3,000-3,050°F | 1,650-1,680°C |

| التوصيل الحراري | 6.5 وحدة حرارية بريطانية/(ساعة-قدم-فهرنهايت) | 11.2 واط/(م-ك) |

| معامل التمدد الحراري | 5.3 × 10-⁶/°F | 9.5 × 10-⁶/K |

| المقاوماتية الكهربائية | 120 ميكرومتر مكعب | 120 ن أوم-م |

Room Temperature Properties (Annealed Condition)

| الممتلكات | القيمة (إمبراطوري) | القيمة (متري) |

|---|---|---|

| قوة الشد | 130-140 كسي | 895-965 ميجا باسكال |

| قوة الخضوع (إزاحة 0.2%) | 120-125 كسي | 825-860 ميجا باسكال |

| الاستطالة | 10-15% | 10-15% |

| تقليل المساحة | 25-30% | 25-30% |

| الصلابة (برينل) | 280-320 هكتار | 290-330 HBW |

| معامل المرونة | 16.5 × 10⁶ رطل لكل بوصة مربعة | 114 جيجا باسكال |

الأداء في درجات الحرارة العالية

| درجة الحرارة (درجة فهرنهايت) | قوة الشد (ksi) | قوة الخضوع (ksi) |

|---|---|---|

| 400 درجة فهرنهايت (200 درجة مئوية) | 115-125 | 105-110 |

| 600 درجة فهرنهايت (315 درجة مئوية) | 100-110 | 90-95 |

| 800 درجة فهرنهايت (425 درجة مئوية) | 85-95 | 75-80 |

اختر Daxun لمساعدة مشروعك على الانطلاق.

Common applications

Grade 9 titanium plates and sheets are primarily used for components that require an excellent balance of strength, ductility, and corrosion resistance, offering superior weldability and formability compared to other titanium alloys.

- Applications include aerospace components such as airframe structures, pressure vessels, and engine components that require moderate strength but exceptional corrosion resistance.

- Industrial applications include chemical processing equipment, heat exchangers, and marine components due to their outstanding resistance to corrosive environments.

- Oil and gas industry components, including downhole drilling equipment and subsea systems, where both strength and corrosion resistance are critical.

- Medical implants and surgical instruments, particularly where biocompatibility and moderate strength are required.

- Performance automotive components, including exhaust systems, suspension parts, and high-performance vehicle frames that benefit from titanium’s strength-to-weight ratio.

توصيل سريع

Daxun provides customers with timely and fast delivery of grade 9 titanium plate products. Behind the speed is the system support from professional production capacity, and information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real-time, and the data is seamlessly connected.

Custom Cutting

Daxun Alloy provides customers with customized cutting solutions of various sizes to help you control the size loss of titanium plates, thereby saving your processing costs and time. Our cutting methods include:

- Water jet cutting

- Laser cutting

- Plasma cutting

- Wire cutting

- Bending

- Slitting

- Sawing

التعبئة والتغليف

We pay special attention to packaging. We pack our goods in many ways depending on the product. We pack our products in many ways such as:

- الصناديق والصناديق

• Shrinkwrap

- منصات خشبية

- صناديق خشبية

الدعم الفني

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry.

Daxun Grade 9 Titanium sheet Let your brand improve rapidly

- Other Titanium Plate Grades

| Apart from the products listed below, other available metal products are not listed here. Other metal products DAXUN can manufacture and supply include Tantalum, Niobium, Zirconium, Hafnium, Nickel, Copper etc., which are mainly in the form of Plate, Bar and Tube. | |

| Products/Processing Standard | Grade/Size |

| Titanium Plate, Sheet, Coil— ASME SB265, AMS 4911, AMS 4919, AMS 4914,ASTM F67, ASTM F136 | GR1, GR2, GR3, GR4, GR5, GR7,GR9, GR12, GR16, GR17, GR23,Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3(Thickness:( 0.0197”-6”)Max Width: 12 feet,Max Length: 50 feet) |

| AMS-T-9046 | |

| Titanium and Titanium alloy sheet, plate | |

| Commercially pure titanium (CP) | |

| Code designation | Yield strength |

| minimum, ksi 1 / | |

| CP-1 Gr1 | 70 |

| CP-2 Gr2 | 55 |

| CP-3 Gr3 | 40 |

| CP-4 Gr4 | 25 |

| Alpha titanium alloys(A) | |

| Code designation | Composition |

| A-1 | 5A1-2.5Sn |

| A-2 | 5A1-2.5Sn(ELI) 2 / |

| A-3 | 6A1-2Cb-1Ta-0.8Mo |

| A-4 | 8A1-1Mo-1V |

| Alpha-beta titanium alloys(AB) | |

| Code designation | Composition |

| AB-1 Gr5 | 6A1-4V |

| AB-2 Gr5 | 6A1-4V(ELI) |

| AB-3 | 6A1-6V-2Sn |

| AB-4 | 6A1-2Sn-4Zr-2Mo |

| AB-5 | 3A1-2.5V |

| AB-6 | 8Mn |

| Beta titanium alloys(B) | |

| Code designation | Composition |

| B-1 | 13V-11Cr-3A1 |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3A1-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3A1 |

| Processing: | |

| الدرفلة على الساخن | الدرفلة على البارد |

| Available Grades: | |

| الصف الأول الابتدائي | Grade 6Al-2Sn-4Zr-2Mo (6-2-4-2) |

| الصف الثاني الابتدائي | Grade 6Al-4V ELI (Formerly Grade 23) |

| Grade 7 | Grade 6Al-6V-2Sn (6-62) |

| Grade 19 | Grade 8Al-1Mo-1V (8-1-1) |

| Grade 5 (6Al-4V) | Grade 9 (3Al-2.5V) |

| Grade 6 (5Al-2.5Sn) | الصف الثالث الابتدائي |

| Application | |

| الصناعة الكيميائية | Desalination Of Sea Water |

| Petrochemical Industry | الطيران والفضاء |

| Machining Field, Automobile Field | Mobile Phone Component Field. |

أحدث مشاريع ومنتجات الحالة الساخنة

المنتجات ذات الصلة (7)

Grade 9 titanium (Ti-3Al-2.5V) offers an optimal balance between strength, ductility, and corrosion resistance. It contains 3% aluminum and 2.5% vanadium, which gives it approximately 20-30% higher strength than pure titanium (Grade 1-4) while maintaining excellent formability and weldability that surpasses many other titanium alloys.

Grade 9 titanium plates provide exceptional corrosion resistance, high strength-to-weight ratio, excellent weldability, and good formability. These properties make them ideal for applications requiring durability in harsh environments while reducing overall weight, which can lead to improved fuel efficiency in transportation applications.

Machining Grade 9 titanium requires slower speeds, lower feed rates, and ample coolant compared to steel or aluminum. Using sharp, high-quality carbide tools with rigid setups is essential. The material has a tendency to work-harden, so maintaining positive cutting action and avoiding dwell times is important for successful machining.

Grade 9 titanium excels in marine environments, offering outstanding resistance to seawater corrosion, crevice corrosion, and stress corrosion cracking. Unlike many stainless steels that may require regular maintenance or replacement in marine applications, Grade 9 titanium can provide decades of service with minimal degradation, making it cost-effective despite higher initial material costs.

Yes, Grade 9 titanium is highly suitable for welding and fabrication. It can be welded using TIG, MIG, plasma arc, and electron beam welding processes. The alloy requires proper shielding from atmospheric contamination during welding, but generally offers excellent weldability without the need for post-weld heat treatment in most applications.

يُرجى ملء النموذج الموجود في صفحة “اتصل بنا”، أو الاتصال بمدير المبيعات لدينا على “+86 13382898899”، وسوف نتصل بك في أقرب وقت ممكن. واتسابنا على الإنترنت، وسيتم التحقق من البريد الإلكتروني ([email protected]) في غضون 6 ساعات. سيتم الرد على كل استفسار أو رسالة على الفور. بالإضافة إلى ذلك، نشارك معلومات السوق مع عملائنا كل أسبوع

We can provide titanium sheet samples for you to check the quality. Sample is free and you just pay the freight.

لقد قمنا بالتصدير إلى أكثر من 42 دولة، مثل كندا، وتشيلي، والكويت، وألمانيا، وكوريا الجنوبية، والمملكة العربية السعودية، وسنغافورة، وغيرها.

Our MOQ is 1 ton for titanium sheet.

يمكن تسليم الطلبات التجريبية في غضون أسبوع. بالنسبة للطلبات العادية، يستغرق الأمر أسبوعين تقريباً.