Daxun is an experienced Ti 6Al 4V Grade 5 Titanium Plate manufacturer

As a leading supplier of titanium in China, Daxun provides high-performance 6-4 titanium plates to the world.

- Plate Grade: Grade 5-Ti-6Al-4V-USN 56400-TC4

- Plate Production type: cold rolling, hot rolling, forging.

- Standard: ASTM B265 AMS 4911、AMS-T-9046、ASTM F1472 etc

- Features: High strength, Lightweight, High-temperature resistance

- The density of grade 5 titanium plate is 4.51 g/cm3

- α-β titanium alloy, aluminum stabilizes the α phase, vanadium stabilizes the beta phase

————A Daxun produz chapas de titânio na China para satisfazer as diversas necessidades de ——necessidades exigentes dos clientes!

A global leader in high performance Ti-6Al-4V alloy titanium plate manufacturing services

DAXUN, based in China, is a prominent manufacturer and supplier of Ti 6AL 4V (Grade 5, UNS R56400) titanium plates. We are dedicated to providing high-performance, world-class titanium plates, ensuring timely global delivery of ASTM B265 Grade 2 and Grade 5 titanium plates.

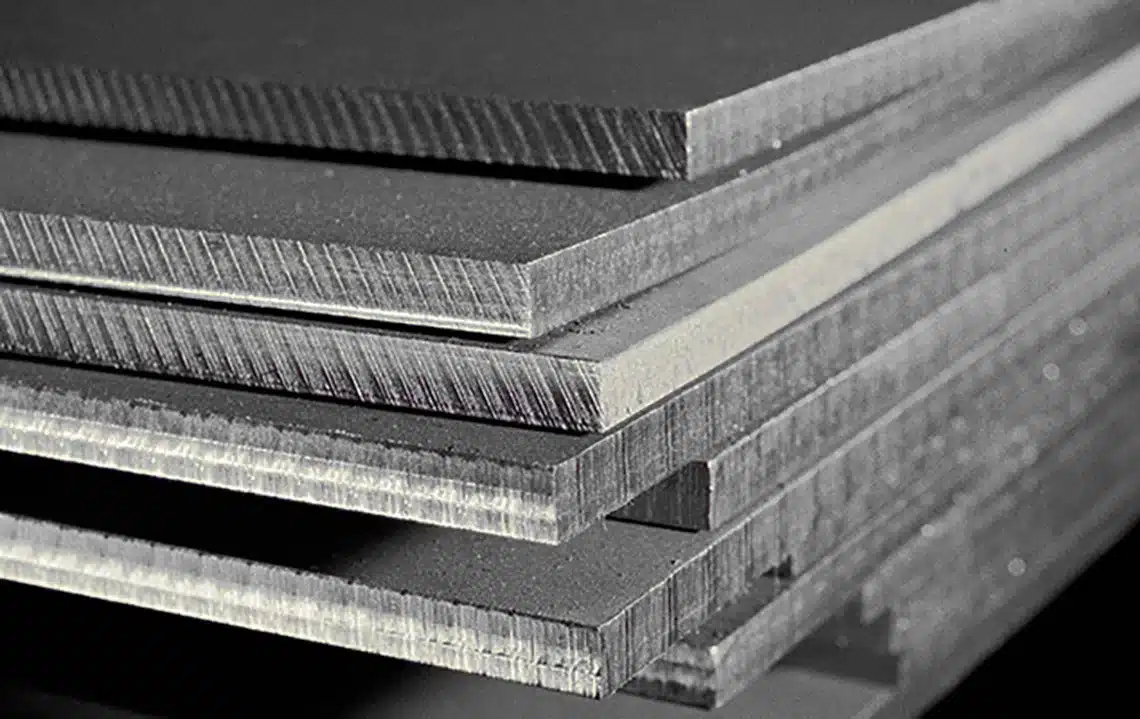

We produce Grade 5 titanium plates (UNS R56400) in thicknesses from 0.5mm to 300mm, with specifications for cold rolling (0.5 mm-6.0 mm), hot rolling (6.0–50 mm), and forging (over 50 mm). Grade 5 (Ti-6Al-4V), often referred to as the “workhorse” of titanium alloys, is renowned for its exceptional strength, ductility, and resistance to both corrosion and high temperatures. These qualities make it a top choice for numerous general and military applications. Our products meet various standards such as ASTM, ASME, AMS, GB, GJB, MIL, JIS, and EN.

Titanium Grade 5, also known as Ti-6Al-4V, is composed of 90% titanium, 6% aluminum, and 4% vanadium, making it an α-β titanium alloy. In this alloy, aluminum stabilizes the α phase, while vanadium stabilizes the β phase. Key characteristics of Ti-6Al-4V plates include exceptional overall performance, excellent processability, and outstanding strength at both ambient and elevated temperatures. They also demonstrate excellent creep resistance, thermal stability, fatigue performance in seawater, crack growth resistance, and strong fracture toughness under hot salt stress corrosion. Furthermore, these plates exhibit remarkable plasticity and superplasticity, making them versatile for various processing methods, welding, and machining.

DAXUN is a metal expert focused on small and large pure titanium plate and 6-4 titanium alloy plate projects. DAXUN is your reference point and long-term partner, ready to provide you and your business with grade 5 titanium plates and any technical assistance you may need. You can think of DAXUN not only as your industrial pure titanium plate and titanium alloy plate supplier, but also as your strategic partner to help you meet any challenges and needs you may encounter, ultimately allowing you to achieve your project goals.

DAXUN’s service center in China has 6al 4v titanium plate products in stock and can quickly process orders. Through basic processing, water jet cutting and plate nesting products, we provide added value to our customers, saving them time and costs.

Continuous investment in DAXUN’s production facilities and capacity agreements with partners ensure that DAXUN is at the forefront of titanium plate quality now and in the future.

Dados

- Parâmetro

- Ingrediente

- Propriedades mecânicas

| Ti 6Al-4V Titanium Plate and sheet Type | Plate, Sheet, Strip, Coils, Foils, Flats, Clad Plate, Plain Sheet, Rolling Sheet, Rolling Plate, Flat Shim, Flat Sheet, Shim Sheet, Rolls, Blank (Circle), sheared, annealed, soft annealed, descaled, tread plate, Checker Plate |

| Grau | ASME SB265、AMS 4911、AMS 4919、AMS 4914、ASTM F67、ASTM F136, MSRR, AMS, BS |

| Titanium Alloy Gr 5 Plate Length | 1000mm-13000mm or as required |

| Gr 5 Titanium Plate Width | 1000mm-1219mm-1500mm-1800mm-2000mm-2500mm or as required |

| UNS R56400 Plate Thickness | 0.3 to 120mm or as required |

| ASTM B265 Titanium Alloy Gr 5 Plate Process | Hot/ Cold Rolled/forging |

| UNS R56400 Plate surface | No.1, No. 2D, No. 2B, BA, No.3, No.4, No.6, No.7, 2B, 2D, BA NO(8), Cold rolled sheet (CR), Hot rolled plate (HR), SATIN (Met with Plastic Coated), No.1 finish hot rolled ASTM B265 Titanium Alloy Gr 5 Plate, 1D, 2B, No.4, BA, 8K, satin, hairline, brush, mirror etc. |

| ASTM B265 Titanium Alloy Gr 5 Plate, Sheet and Strip | JIS: N0, N2, N1, NW2200, NW2201, NW4400, NW5500, NW6002, etc |

| Titanium Grade 5 Sheet ASTM | ASTM B265 |

| Titanium Grade 5 Sheet AMS | AMS 4902 |

| Tolerances of width and thickness | EN 10258 (formerly DIN 59381),EN 10151 ASTM B265 Titanium Alloy Gr 5 strip for springs,EN 10088 ASTM B265 Titanium Alloy Gr 5 strip (general) |

| Ti 6Al 4v Grade 5 Titanium Plate standards and approvals | EN ISO 18286 EN 10051 EN 10088-1 ISO 15510 EN ISO 9445 ASTM A 480 ASTM A 959 ASME IID |

| Standard Ti-6Al-4V ALLOY Plate & Sheet Sizes | 1000 x 2000 mm, 1220 x 2440 mm, 1500 x 3000 mm, 2000 x 2000 mm, 2000 x 4000 mm |

| Cold rolled Gr 5 Titanium Plate 0.5-6.4 mm | |

| Hot rolled Gr 5 Titanium Plate 3.0–60.0 mm | |

| UNS R56400 Plate Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard ASTM B265 Titanium Alloy Gr 5 Sheet suppliers |

| Availability of Titanium Alloy Gr 5 Foil sizes | Thickness : 8-100 microns (0.00031-0.004 in) |

| Width: Up to 500 mm (19.5 in) | |

| Weight (in rolls) : Up to 50 kg (110 lb); e.g. approxi- mately 1400 m at 8 microns and ap- proximately 112 m at 100 microns. | |

| Corte | To provide a comprehensive service, we use a variety of cutting methods, including: |

| Laser Plate Cutting,Plasma Plate Cutting,Oxy-propane Flame Cutting | |

| Perfis plasmáticos | De acordo com os desenhos do cliente |

| Value added services for Cp Grade 5 Titanium Plate | Laser cutting, Waterjet cutting, Plasma cutting, Bending and mechanical processing, edge preparation, welding, sawing and shearing. |

| China Grade 5 Titanium Plate Manufacturer | ASTM B265 Titanium Alloy Gr 5 Plate: material 3/16″ [5.00 mm] and over in thickness and over 10″ [250 mm] in width;Gr 5 Titanium Sheet: material under 3/16″ [5.00 mm] in thickness and 24″ [600 mm] and over in width;Alloy Titanium Grade 5 Clad plate: Alloy Titanium Grade 5 Clad plate is a composite steel plate made by bonding UNS R56400 Titanium Grade 5 Plate, etc.ASTM B265 Titanium Alloy Gr 5 Strip: cold-rolled material under 3/16″ [5.00 mm] in thickness and under 24″ [600 mm] in width. |

| UNS R56400 Plate Origin | CHINA |

| Packing of Ti-6Al-4V plate | Bundles with waterproof cloth outside or plywood box |

| Test | UT, SGS testing, TUV etc |

| Why buy UNS R56400 Sheet from DAXUN? | Free quote、Free sample、EN 10204 3.1、Mill Test Certificate is supplied with shipment.、NABL Approved Lab Reports、Any third party inspection is accepted.、Tested to ASTM A923 Method “C” or ASTM G48 Method “A”.Minimum Nitrogen content and Ferrite Count Test |

| Composição química: | |||

| Símbolo | Elemento | Mínimo % | Máximo % |

| Al | Alumínio | 5.50% | 6.75% |

| V | Vanádio | 3.50% | 4.50% |

| Fe | Ferro | 0.30% | |

| O | Oxigénio | 0.20% | |

| C | Carbono | 0.08% | |

| N | Nitrogénio | 0.05% | |

| H | Hidrogénio | 0.01% | |

| Y | Ítrio | 0.01% | |

| Outros, cada | 0.10% | ||

| Outros, total | 0.40% | ||

| Ti | Titânio | Resto | |

| Propriedades físicas | Métrica | Inglês | Comentários |

| Densidade | 4,43 g/cc | 0,16 lb/in³ | |

| Propriedades mecânicas | |||

| Dureza, Brinell | 334 | 334 | Estimado por Rockwell C. |

| Dureza, Knoop | 363 | 363 | Estimado por Rockwell C. |

| Dureza, Rockwell C | 36 | 36 | |

| Dureza, Vickers | 349 | 349 | Estimado por Rockwell C. |

| Resistência à tração | min. 895MPa | 129810 psi | |

| Resistência ao escoamento | min. 828MPa | 120090 psi | |

| Alongamento na rutura | min.10 % | 10 % | |

| Redução da área | min.25 % | 25 % | |

| Módulo de elasticidade | 113,8 GPa | 16500 ksi | |

| Resistência ao escoamento por compressão | 970 MPa | 141000 psi | |

| Resistência à tração entalhada | 1450 MPa | 210000 psi | Kt (fator de concentração de tensões) = 6,7 |

| Resistência máxima do rolamento | 1860 MPa | 270000 psi | e/D = 2 |

| Resistência ao escoamento do rolamento | 1480 MPa | 215000 psi | e/D = 2 |

| Poisson’s Ratio | 0.342 | 0.342 | |

| Impacto Charpy | 17 J | 12,5 pés-lb | Ranhura em V |

| Resistência à fadiga | 240 MPa | 34800 psi | a 1E+7 ciclos. Kt (fator de concentração de tensões) = 3,3 |

| Resistência à fadiga | 510 MPa | 74000 psi | Não anotado 10.000.000 ciclos |

| Resistência à fratura | 75 MPa-m½ | 68,3 ksi-in½ | |

| Módulo de cisalhamento | 44 GPa | 6380 ksi | |

| Resistência ao cisalhamento | 550 MPa | 79800 psi | Resistência ao cisalhamento final |

| Propriedades eléctricas | |||

| Resistividade eléctrica | 0,000178 ohm-cm | 0,000178 ohm-cm | |

| Permeabilidade magnética | 1.00005 | 1.00005 | a 1,6kA/m |

| Suscetibilidade magnética | 3.30E-06 | 3.30E-06 | cgs/g |

| Propriedades térmicas | |||

| CTE, linear 20°C | 8,6 µm/m-°C | 4,78 µin/in-°F | 20-100ºC |

| CTE, linear 250°C | 9,2 µm/m-°C | 5,11 µin/in-°F | Média no intervalo 20-315ºC |

| CTE, linear 500°C | 9,7 µm/m-°C | 5,39 µin/in-°F | Média no intervalo 20-650ºC |

| Capacidade térmica específica | 0,5263 J/g-°C | 0,126 BTU/lb-°F | |

| Condutividade térmica | 6,7 W/m-K | 46,5 BTU-in/hr-ft²-°F | |

| Ponto de fusão | 1604 – 1660 °C | 2920 – 3020 °F | |

| Solidus | 1604 °C | 2920 °F | |

| Liquidus | 1660 °C | 3020 °F | |

| Beta Transus | 980 °C | 1800 °F | |

Escolha a Daxun para ajudar o seu projeto a arrancar.

Entrega rápida

Daxun provides customers with timely and fast delivery of grade 5 titanium plate products. Behind the speed is the system support from professional production capacity, and information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real-time, and the data is seamlessly connected.

Key Features

Grade 5 titanium alloy plate is the most commercially available of all titanium alloys. It combines high strength and toughness. Grade 5 can be cold drawn and extruded, but this process is generally limited to smaller industrial facilities and is more commonly applied to commercially pure grades.

Ti-6Al-4V Grade 5 titanium alloy has good comprehensive properties:

- Alta resistência

- Creep resistance

- Fatigue resistance

- Heat treatable

- Good ductility

- Good plasticity

- Good weldability

- Suitable for service temperatures -196°C-450°C

Aplicações comuns

Ti-6AL-4V titanium plates and sheets are primarily used for components that demand superior corrosion resistance, high strength at elevated temperatures (400-450°C), as well as good ductility and lateral strength.

1. Applications include jet engine compressor blades, disks, and rings, fuselage components like wings and doors, turbine disks, bulkheads, military aircraft parts, engine nozzles, landing gear doors, and fuselage superplastic forming components.

2. Military applications include armor, guidance, shell casings, etc.

3. Spacecraft components, including rocket engines and heat shields, etc.

4. Medical and surgical instruments.

5. Sports equipment, including bicycle frames and golf clubs.

Corte à medida

A Daxun Alloy fornece aos clientes soluções de corte personalizadas de vários tamanhos para o ajudar a controlar a perda de tamanho das placas de titânio, poupando assim os seus custos e tempo de processamento. Nossos métodos de corte incluem:

- Corte por jato de água

- Corte a laser

- Corte a plasma

- Corte de fios

- Dobragem

- Corte longitudinal

- Serrar

Embalagem

Prestamos especial atenção à embalagem. Embalamos os nossos produtos de várias formas, consoante o produto. Embalamos os nossos produtos de várias formas, tais como:

- Caixas e caixotes

- Embalagem retrátil

- Paletes de madeira

- Caixas de madeira

Apoio técnico

Se necessitar de qualquer assistência técnica adicional, o nosso metalúrgico residente e a nossa equipa experiente terão todo o prazer em ajudar. Além disso, a Daxun possui um laboratório de testes certificado - o primeiro na indústria de inventário de multi-metal e plástico.

Grade 5 Titanium Plate Features

Daxun Grade 5 Titanium sheet Let your brand improve rapidly

- Outros graus de chapa de titânio

| Para além dos produtos listados abaixo, outros produtos metálicos disponíveis não estão listados aqui. Outros produtos metálicos que a DAXUN pode fabricar e fornecer incluem Tântalo, Nióbio, Zircónio, Háfnio, Níquel, Cobre, etc., que se apresentam principalmente sob a forma de Placa, Barra e Tubo. | |

| Norma de produtos/transformação | Grau/tamanho |

| Placa de titânio, folha, bobina- ASME SB265, AMS 4911, AMS 4919, AMS 4914, ASTM F67, ASTM F136 | GR1, GR2, GR3, GR4, GR5, GR7,GR9, GR12, GR16, GR17, GR23,Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3(Espessura: (0,0197”-6”)Largura máxima: 12 pés,Comprimento máximo: 50 pés) |

| AMS-T-9046 | |

| Chapas e folhas de titânio e de ligas de titânio | |

| Titânio comercialmente puro (CP) | |

| Designação do código | Resistência ao escoamento |

| mínimo, ksi 1 / | |

| CP-1 Gr1 | 70 |

| CP-2 Gr2 | 55 |

| CP-3 Gr3 | 40 |

| CP-4 Gr4 | 25 |

| Ligas alfa de titânio(A) | |

| Designação do código | Composição |

| A-1 | 5A1-2.5Sn |

| A-2 | 5A1-2.5Sn(ELI) 2 / |

| A-3 | 6A1-2Cb-1Ta-0.8Mo |

| A-4 | 8A1-1Mo-1V |

| Ligas de titânio alfa-beta (AB) | |

| Designação do código | Composição |

| AB-1 Gr5 | 6A1-4V |

| AB-2 Gr5 | 6A1-4V(ELI) |

| AB-3 | 6A1-6V-2Sn |

| AB-4 | 6A1-2Sn-4Zr-2Mo |

| AB-5 | 3A1-2,5V |

| AB-6 | 8Mn |

| Ligas de titânio beta(B) | |

| Designação do código | Composição |

| B-1 | 13V-11Cr-3A1 |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3A1-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3A1 |

| Processamento: | |

| Laminagem a quente | Laminagem a frio |

| Graus disponíveis: | |

| PC Grau 1 | Grau 6Al-2Sn-4Zr-2Mo (6-2-4-2) |

| PC Grau 2 | Grau 6Al-4V ELI (antigo Grau 23) |

| Grau 7 | Grau 6Al-6V-2Sn (6-62) |

| Grau 19 | Grau 8Al-1Mo-1V (8-1-1) |

| Grau 5 (6Al-4V) | Grau 9 (3Al-2,5V) |

| Grau 6 (5Al-2.5Sn) | PC Grau 3 |

| Aplicação | |

| Indústria química | Dessalinização da água do mar |

| Indústria petroquímica | Aeroespacial |

| Domínio da maquinagem, domínio automóvel | Componente de telemóvel Campo. |

Common Surfaces of Grade 5 Titanium Plates (4)

Informações disponíveis para consulta e descarregamento

Daxun is a trustworthy titanium plate manufacturer

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all titanium plates are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the titanium plates have fewer defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

Produtos e projectos recentes de casos quentes

Produtos relacionados (7)

Titanium plate and sheet Grade 5

- Our expertise includes the provision of products in the form of titanium sheets for industrial and aerospace applications, whereby we make sure our customers trust us to meet their product specifications. We are flexible to change over to meet the specifications, or requirements, of each project—planning and budgeting the process down to the preparation of raw materials, inspection, and delivery of the finished product. Ever since the very beginning of DAXUN’s history, we have established excellent relations with consumers from other parts of the world and forged very important relationships with key international partners in the world market of titanium.

- Our technological strengths guarantee high-level material provision for tightly fulfilling the needs of your project. We also nurture robust company chains, research facilities, and subsidiaries to see that each order meets top-tier standards of production and delivery. Customer service is one of the cornerstones at DAXUN.

- We provide clear communication, and detailed pricing that covers the whole process of production. Besides, we answer technical questions related to our products. When you work with us, you get nothing but high-quality raw materials supplied with great service and professional technical support.

Description

- DAXUN ALLOYS is a global supplier and manufacturer of metal titanium to the aerospace, oilfield, biomedical, military, and other critical industries in China. With an inventory of comprehensive titanium mill products, we are able to offer quick delivery requirements through an advanced mill capability.

- At DAXUN, we have quality, customer outstanding service, and overall customer satisfaction. With a large stock of titanium ingots and billets, DAXUN produces Ti-6AL-4V plates, sheets, forged titanium plates, and 6-4 titanium plate forgings. Our product price is competitive, with no requirement for a factory minimum quantity, thus delivery times are faster than ordering directly from a factory.

- Third-party inspection reports can also be provided, in which the key items such as mechanical properties and chemical composition are called out to ensure compliance with the material standards for both room temperature and high-temperature performance.

- The added value services extended by DAXUN also include heat treatment, hole drilling, water jet cutting, ultrasonic inspection, and mechanical testing.

Properties of Grade 5 titanium alloy

Titanium 6al-4v has a density of 4.43 g/cc.

- Propriedades térmicasMelting Point: 1604 – 1660 °C Solidus: 1604 °C Liquidus: 1660 °C Beta Transus: 980 °C

- Propriedades mecânicasTensile Strength, Ultimate: 1170 Mpa Tensile Strength, Yield: 1100 Mpa Elongation at Break: 10% Modulus of Elasticity: 114 Gpa

- DurezaBrinell: 334 Rockwell: C 363 Vickers: 36

-

Dureza

Brinell: 334

Rockwell: C 363

Vickers: 36

Heat Treatment

- Ti 6Al 4V alloy titanium plate is commonly heat treated to increase its characteristics. Usually, rolling annealing, solution treatment, or aging treatment are widely used. Stress relief is utilized for shaping and welding pieces, whereas beta annealing is used to increase the strength of an alloy.

Excellent Corrosion resistance

- The Ti 6Al 4V Plate quickly forms a ceramic oxide layer on its surface, safeguarding it against degradation in all but the toughest situations. Because of this, the Grade 5 Titanium Plate is extensively utilized in saltwater and humid conditions. It also has a modest tolerance to very acidic conditions, but titanium alloys incorporating palladium are superior.

Thermal processing

- Ti 6Al 4V Plate is usually hot worked using a recrystallization process to obtain the proper microstructure. This allows the alloy’s yield strength and hardness to remain low while maintaining its ductility. In Grade 5, this process is performed at temperatures between 870°C and 980°C to prevent excessive alpha phase growth.

Cold Working

- Ti 6AL 4V Titanium Plate is not easily cold-worked due to its low elastic modulus, which causes it to return to its original shape. Grade 5 can be cold drawn and extruded, but this is generally limited to small industrial processing facilities using commercially pure titanium grades.

Weldability of Ti-6Al-4V Titanium Alloy Plate

- Ti 6Al-4V can be welded with filler metal. The metal must be shielded with an inert gas to avoid oxygen absorption in the weld area, which can cause embrittlement and failure. Gas tungsten arc welding is the most popular welding method for the alloy, but gas metal arc welding can be widely used to weld larger components.

- Ti 6Al-4V can be successfully welded by plasma arc welding, spot welding, electron beam, laser beam, resistance welding, and diffusion welding.

Machinability of Ti-6Al4V Grade 5 Plate

- Unlike other metals, the Ti6Al4V parts are easy to machine and can be used as standard parts. The following elements contribute to the efficient machining of Ti6Al4V parts: low cutting speeds, high feed rates, suitable cutting fluids, sharp tools, and a solid setup. Learn more on Daxun’s machining page.

Equivalent Grade

- 6-4 Titanium

- Ti 6-4

- 6Al4V Titanium

- Alpha Beta Titanium

- Titânio de grau 5

- Ti-Grade 5

- 6%Al-4%V Titanium

- Titan Grade 5 (6Al-4V) EN Designation

- TC4

- Ti64

- ASTM Grade 5

- DIN 3.7165

Get in touch with your preferred grade 5 titanium plate supplier

- Contact Daxun for the latest prices on Grade 2 Titanium Plates. It couldn’t be easier to buy the Titanium Plates you need, as well as all our other products, through our website. Alternatively, you can call our China sales team at +86 13382898899 to place your order and they will be happy to process your order. If you have any questions, you can even send an email to [email protected] and our team will get back to you as soon as possible. If you have any technical questions about Titanium Plates, you can also submit your details using the Contact Us form.

Preencha o formulário na página “Contacte-nos” ou ligue para o nosso gestor de vendas através do número “+86 13382898899” e entraremos em contacto consigo o mais rapidamente possível. O nosso WhatsApp está online e o e-mail ([email protected]) será verificado no prazo de 6 horas. Todas as perguntas ou mensagens serão respondidas prontamente. Além disso, todas as semanas partilhamos informações de mercado com os nossos clientes

Nós podemos fornecer amostras de folha de titânio para você verificar a qualidade. A amostra é grátis e você só paga o frete.

Exportámos para mais de 42 países, como o Canadá, Chile, Kuwait, Alemanha, Coreia do Sul, Arábia Saudita, Singapura, etc.

Nosso MOQ é de 1 tonelada para chapas de titânio.

As encomendas de teste podem ser entregues no prazo de uma semana. Para as encomendas normais, são necessárias cerca de duas semanas.