Daxun is a 409 stainless steel sheet supplier in China

As China’s leading stainless steel plate supplier and exporter, Daxun provides 409 stainless steel plates to the world.

- Grade: AISI 409

- Fabrico: chapa laminada a frio, chapa laminada a quente, chapa forjada

- Standard: ASTM, ASME, GB, DIN, JIS, ISO, EN, BS

- Tipo: chapa fina laminada a frio, chapa grossa laminada a quente

- Superfície: 2B, NO.1, NO.4, HL, BA, 8K, etc.

- Comprimento: 2438mm3048mm6000mm pode ser personalizado

- Origin: TISCO, Baosteel, Pohang, Tsingshan, Delong

410 Global leader in stainless steel sheet fabrication services

Daxun’s Grade 409 stainless steel plate has good corrosion resistance and is typically one of the least expensive varieties of stainless steel. It has a high tensile strength, is easily welded using arc welding, and is suited for resistance spot and seam welding. It is worth noting that welding type 409 does not reduce its corrosion resistance. It can be utilised in a variety of applications, including vehicle and truck exhaust systems, heat exchangers, agricultural spreaders, fuel filters, gas turbine exhaust mufflers, and others that demand precise shaping, toughness, and better weldability. One of this stainless steel grade’s primary advantages is improved weldability.

Grade 409 is a stabilised ferritic general-purpose stainless steel sheet with 11% chromium. It is especially well-suited for applications that require oxidation or corrosion resistance that carbon steel and some coated steels cannot provide. 409 has strong oxidation resistance and formability, but poor corrosion resistance because to its low chromium concentration. 409 has lower corrosion resistance than grades 304, 430, or 439, but it outperforms mild steels. Roll forming, stretch bending, deep drawing, and press forming are all options for shaping 409. When 409 is annealed, it will not harden when cold treated with mild roll forming processes such as press or stretch bending. Weldability for grade 409 is fair. This stainless material should not be utilised in shock-loaded structures because the grain structure grows in the heat-affected zone, which can have a direct impact on mechanical qualities. 409 is commonly used for tubing and stampings in automotive exhaust system applications. The mechanical qualities of this stainless steel sheet grade provide significant benefits in the automotive and agricultural industries. This offers good protection from exhaust gas and high-temperature ambient corrosion. However, the mechanical properties outweigh the stainless steel’s look. It is not advised for use in decorative purposes.

Dados técnicos

- Parâmetro

- Composições químicas

- Propriedades mecânicas

- PROPRIEDADES FÍSICAS

- Padrão

| Product Parameters: Stainless Steel Sheet/Plate | |||

| Largura | 10mm~2500mm | ||

| Espessura | 0.2mm~100mm | Thickness tolerance | +/-0.03mm |

| Padrão | ASTM/ASME 240/480,JIS 4305,DIN EN 10088-2 | ||

| Superfície | 2B,BA,8K,NO.1,NO.4,NO.3,hairline,checkered,gold ,black ,rose gold,etc | ||

| specification | 1000*2000/L,1219*2438/L,1250*2500/L,1500*3000/L1500*6000/L,1800*6000/L,2000*6000/L2200*6000L | ||

| Mill Origin | TISCO, ZPSS, BAOSTEEL, JISCO, ZSESS, ATI, SMC, HAYNES, VDM, ArcelorMittal, Outokumpu, etc. | ||

| Certification | ISO, SGS, BV, TUV,CE etc | ||

| Elemento | % Present (in product form) |

| Carbono (C) | 0.03 |

| Silício (Si) | 1 |

| Manganês (Mn) | 1 |

| Fósforo (P) | 0.04 |

| Enxofre (S) | 0.015 |

| Crómio (Cr) | 10.50 – 12.50 |

| Molibdénio (Mo) | 6 x (C+N) to 0.65 |

| Ferro (Fe) | Equilíbrio |

| Product Form | ||||

| C | H | |||

| Thickness (mm) Max | 8 | 13.5 | ||

| Yield Strength Rp0.2 N/mm2 | Longitudinal | 210 | ||

| Transverse | 220 | |||

| Resistência à tração | Rm N/mm2 | 380 – 560 | ||

| Elongation min. in % | A80mm1) <3mm (longitudunal + transverse) | 25 | ||

| A2) ≥3mm (longitudinal + transverse) | ||||

| Densidade | Condutividade térmica | Electrical | Modulus of | Coefficient of | Specific Heat | Derretimento |

| lbm/in^3 | (BTU/h ft. °F) | Resistividade | Elasticity | Thermal Expansion | (BTU/lb/ | Range |

| (in x 10^-6) | (psi x 10^6) | (in/in)/ | °F) | (°F) | ||

| °F x 10^-6 | ||||||

| 12.4 at 932 °F | 39.4 at 752°F | 6.60 at 32 – 1000°F | ||||

| 49.6 at 1652 °F | 6.86 at 32 – 1500°F | |||||

| at 68°F: 0.280 | 9.4 at 212°F | 28.3 at 68°F | 29 | 5.84 at 32 – 212°F | 0.114 at 68°F to 212°F | 2500 to 2590 |

| UNS 409 | 1.4512 | 409L |

| ASTM A240 | ASTM A240 | ASTM A240 |

| ASTM A480 | ASTM A480 | ASTM A480 |

| ASME SA240 | ASME SA240 | ASME SA240 |

| AMS 5521 | AMS 5521 | AMS 5521 |

Escolha a Daxun e deixe os seus clientes satisfeitos.

Entrega rápida

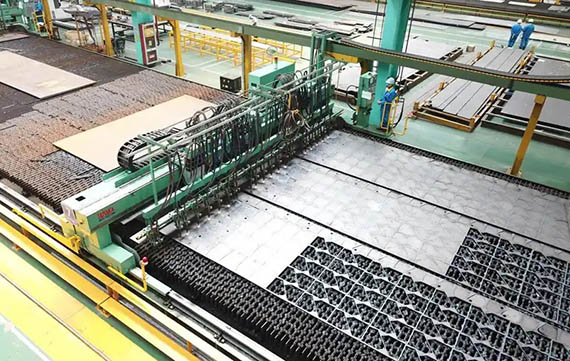

We provide timely and fast delivery of stainless steel products for customers with urgent needs. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real time, and the data is seamlessly connected; in terms of logistics, the processing center is close to highways and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on schedule.

Advantages/Disadvantages

This stainless steel grade has mechanical qualities that provide significant benefits in the automotive and agricultural industries. This offers enhanced protection from exhaust gas and air corrosion at high temperatures. However, the mechanical characteristics of this stainless steel outweigh its visual look. It is not advised for use in decorative purposes.

Stainless Steel 409 Applications

- 409 stainless steel plate for agricultural machinery

- 409 stainless steel plate for automotive panels

- 409 stainless steel plate for stamping products

- 409 stainless steel plate for cookware

- 409 stainless steel plate for home appliances

- 409 stainless steel plate for kitchens

- 409 stainless steel plate for food service equipment

- 409 stainless steel plate for sinks

- 409 stainless steel plate for railway vehicles

- 409 stainless steel plate for exhaust

Qualidade, entrega, inspeção

- Daxun also conducts several quality assurance tests. These tests include flattening test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the material is suitable for the required application.

- During the production process, we measure the diameter, thickness, and surface of the product. Our standard delivery time is 7-15 days, except for some special size products, our delivery time will increase to 20 days.

O nosso prazo de entrega está estritamente de acordo com o contrato. - Apoio a agências terceiras do cliente para se deslocarem à fábrica para inspeção

- Apoio a amostras gratuitas aos clientes para testes

- Apoio à inspeção de fábrica no local ou por vídeo

Apoio técnico

Se necessitar de qualquer assistência técnica adicional, o nosso metalúrgico residente e a nossa equipa experiente terão todo o prazer em ajudar. Além disso, a Daxun possui um laboratório de testes certificado - o primeiro na indústria de inventário de multi-metal e plástico. Isto, na nossa opinião, demonstra a nossa dedicação inabalável à qualidade e a nossa filosofia como um fornecedor de serviço completo.

409 plate stainless steel Features

Daxun Deixe a sua marca melhorar rapidamente

- Galeria

- Tolerância

- Estado de entrega

- Outras séries de produtos

| Tolerância para chapa 2B | |||

| Tamanho | Classificação de tolerância | ||

| Grupo 1 | Grupo 2 | Grupo 3 | |

| 0.4 | 0.3 ~ 0.32 | 0.33 ~ 0.37 | 0.37 ~ 0.39 |

| 0.5 | 0.4 ~ 0.42 | 0.43 ~ 0.47 | 0.47 ~ 0.49 |

| 0.6 | 0.5 ~ 0.52 | 0.53 ~ 0.56 | 0.57 ~ 0.59 |

| 0.7 | 0.6 ~ 0.62 | 0.63 ~ 0.67 | 0.67 ~ 0.69 |

| 0.8 | 0.7 ~ 0.72 | 0.73 ~ 0.77 | 0.74 ~ 0.79 |

| 0.9 | 0.8 ~ 0.82 | 0.83 ~ 0.87 | 0.87 ~ 0.89 |

| 1 | 0.89 ~ 0.9 | 0.91 ~ 0.94 | 0.94 ~ 0.99 |

| 1.2 | 1.02 ~ 1.08 | 1.09 ~ 1.15 | 1.16 ~ 1.18 |

| 1.5 | 1.32 ~ 1.38 | 1.39 ~ 1.45 | 1.46 ~ 1.48 |

| 2 | 1.72 ~ 1.79 | 1.8 ~ 1.86 | 1.87 ~ 1.9 |

| 2.5 | 2.23 ~ 2.36 | 2.32 ~ 2.42 | 1.42 ~ 1.47 |

| 3 | 2.7 ~ 2.77 | 2.78 ~ 2.82 | 2.85 ~ 2.9 |

| Tolerância para chapa laminada a quente n.º 1 | |||

| Tamanho | Classificação de tolerância | ||

| Grupo 1 | Grupo 2 | Grupo 3 | |

| 3 | 2.6 ~ 2.75 | 2.75 ~ 2.85 | 2.86 ~ 2.9 |

| 4 | 3.5 ~ 3.6 | 3.6 ~ 3.75 | 3.76 ~ 3.95 |

| 5 | 4.5 ~ 4.6 | 4.6 ~ 4.75 | 4.75 ~ 4.95 |

| 6 | 5.4 ~ 5.6 | 5.6 ~ 5.75 | 5.75 ~ 5.85 |

| 8 | 7.3 ~ 7.5 | 7.5 ~ 7.65 | 7.65 ~ 7.85 |

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9.6 ~ 9.85 |

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11.6 ~ 11.85 |

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13.6 ~ 13.85 |

| 16 | 15.2~ 15.5 | 15.5~ 15.7 | 15.7~ 16.1 |

| 18 | 17.2~ 17.5 | 17.5~ 17.7 | 17.7~ 18.1 |

| 20 | 19.2~ 19.5 | 19.5~ 19.7 | 19.7~ 20.1 |

| 30 | 29.2~ 29.5 | 29.5~ 29.7 | 29.7-30.1 |

| 40 | 39.2~ 39.5 | 39.5~ 39.7 | 39.7~ 40.1 |

| 50 | 49.2~ 49.5 | 49.5~ 49.7 | 49.7~ 50.1 |

| 60 | 59.2~ 59.5 | 59.5~ 59.7 | 59.7~ 60.1 |

| Entrega Estado Escolha | Estado da superfície |

| Laminados a frio | 2B |

| 2D | |

| BA | |

| Fio de cabelo | |

| N.º 3 | |

| N.º 4 | |

| 6K | |

| 8K | |

| Nota: | |

| 1. Se necessitar de um estado de entrega diferente do acima indicado, por favor confirme connosco. | |

| 2. Em caso de pedido de informação ou de encomenda, agradecemos que nos informe de qualquer requisito adicional não indicado aqui. | |

| Estado de entrega | |

| Entrega Estado Escolha | Estado da superfície |

| Laminados a quente | N.º 1 |

| N.º 3 | |

| N.º 4 | |

| 6K | |

| 8K | |

| Em conserva | |

| Nota: | |

| 1. Se necessitar de um estado de entrega diferente do acima indicado, por favor confirme connosco. | |

| 2. Em caso de pedido de informação ou de encomenda, agradecemos que nos informe de qualquer requisito adicional não indicado aqui. | |

| Grau | Tipo | Espessura | Superfície |

| Austenítico | 304/304H/304L/304J1 | 0,25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0,3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferrite | 430 | 0,4-3,0 mm | 2B/BA/NO.4/8K/SB/HL |

| Ferrite ultra-puro | 443 | 0,4-2,0 mm | 2B |

| 436L/439/444/441 | 0,5-3,0 mm | 2B、2D | |

| 409L | 0,4-2,5 mm | 2B、2D | |

| Grau | Tipo | Espessura | Original |

| Aço resistente ao calor | 309S | 0,5-40mm | CHN |

| 310S | 0,5-40mm | CHN | |

| Aço duplex | 2101 | 1,5-50 mm | CHN |

| 2304 | 3.0-50mm | CHN | |

| 2205 | 0,5-60mm | CHN | |

| 2507 | 1.0-60mm | SWE / JPN / CHN | |

| Aço superaustenítico | N08904 | 0,6-50mm | SWE / JPN / CHN |

| S31254 | 0,5-50mm | SWE / JPN / CHN | |

| N08926 | 0,5-50mm | SWE / JPN / CHN | |

| N08367 | 0,5-50mm | SWE / JPN / CHN | |

| Liga à base de níquel | N08031 | 1.0-50mm | EUA / JPN / GER |

| N08810/N08800 | 0,8-50mm | EUA / JPN / CHN | |

| N08028 | 1,0-20mm | EUA / GER / JPN | |

| N08020 | 1,0-20mm | EUA / GER / JPN | |

| N08825 | 0,8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50mm | EUA / GER / JPN | |

| N06022 | 1.0-50mm | EUA / GER / JPN | |

| N06625 | 0,8-20mm | EUA / GER / CHN | |

| N04400 | 1,0-20mm | EUA / GER / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20mm | EUA / JPN | |

| Titânio | TA1/Gr1 | 0,5-50mm | JPN / CHN |

| TA2/Gr2 | 0,5-50mm | JPN / CHN | |

| Material de soldadura | ERNiCrMo-13 | 1.2、2.4mm | ALEMANHA |

| ERNiCrMo-3 | 2,4 mm | ALEMANHA | |

| ERNiCrMo-4 | 2,4 mm | EUA |

The surface and shape of 409 stainless steel plate (7)

Informações disponíveis para consulta e descarregamento

Daxun é um fabricante confiável de chapa de aço inoxidável

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless steel plates are certified by ISO9001, SGS, CE, OQC and more international quality standards.We also have strict quality control to ensure that the stainless steel plates have less defects. At Daxun, rest assured that all products are durable, high quality and high performance.

Produtos e projectos recentes de casos quentes

Produtos relacionados (13)

Podemos fornecer amostras de chapas de aço inoxidável para que possa verificar a qualidade. A amostra é grátis e o cliente só paga o frete.

Exportámos para mais de 42 países, como o Canadá, Chile, Kuwait, Alemanha, Coreia do Sul, Arábia Saudita, Singapura, etc.

O nosso MOQ é de 1 tonelada para chapas de aço inoxidável.

As encomendas de teste podem ser entregues no prazo de uma semana. Para as encomendas normais, são necessárias cerca de duas semanas.