Daxun is a 321 stainless steel coil China supplier

As a leading stainless steel coil supplier and exporter in China, Daxun supplies stainless steel coils to all over the world.

- Coil grade: S32100-321

- Coil features: corrosion resistant, acid and alkali resistant,High temperature resistance

- Coil thickness: 0.4 mm to 12.00 mm

- Coil width: 1000 mm, 1250 mm, 1500 mm and 2000 mm.

- Coil surface: 2B, BA, matte, polished, 8k mirror.

If necessary, stainless steel coils will come with a protective film to protect the metal surface from unnecessary damage.

Global leader in stainless steel Coil fabrication services

Type 321 is a titanium-stabilized chromium nickel austenitic stainless steel that has corrosion resistance comparable to 304/304L. This grade is commonly utilized in the 800-1500˚F temperature range and is stabilized against chromium carbide precipitation by adding titanium, resulting in the precipitation of titanium carbides. Type 321 exhibits superior intergranular corrosion resistance, oxidation resistance up to 1500˚F, and stronger creep and stress rupture qualities than 304/304L. It is also strong at low temperatures and non-magnetic when annealed.

Shop Daxun’s extensive range of SS 321 Coil, AISI 321 Coil, SUS 321 Coil, 2B Finish 321 Stainless Steel Coil, BA Finish 321 Stainless Steel Coil, 2b Finish 321 Grade Stainless Steel Coil, ASTM A240 321 BA Stainless Steel Coil, SS 321 Coil Manufacturer, NO.1 Finish 321 Stainless Steel Coil, SS 321 Cold Rolled Stainless Steel Coil.

Dah Hsun is an ISO 9001:2008 certified firm that is a major supplier and exporter of ASTM A240 Stainless Steel Coils. Stainless steel coils can be cut to your requirements and include a full set of mill test results. Custom lengths and widths are available up to 2000mm. Exporting is our specialty! We can obtain several hard-to-find grades and/or non-standard sizes to satisfy our customers’ specific needs. We have vast experience processing steel coil goods and can divide all stainless steel coils to the desired sizes. Introducing our extensive line of Dah Hsun Stainless Steel goods – the pinnacle of dependability, durability, and performance. We are glad to provide a wide selection of grades and varieties to fulfill the diverse needs of industrial and architectural applications.

Our stainless steel coil goods, which range from the Austenitic series to the Ferritic series and other special categories, are well-known for their high performance and extensive requirements. The austenitic series includes 304/304L/304J1, 321 and 316/316L/317L/316Ti/310/309, which can fulfill varied thickness requirements and give a variety of surface treatments, including 2B, BA, NO.4, 8K, SB, HL, NO.1, and so on.

Our ferrite line, which includes 430, ultra-pure ferrite 443, and 436L/439/444/441, caters to customers looking for unique qualities and applications. These materials can accommodate thicknesses ranging from 0.4mm to 3.0mm and offer a variety of surface treatment options such as 2B, BA, NO.4, 8K, SB, HL, and so on.

By selecting our stainless steel coils, you are investing in a material that ensures long service life, great reliability, and exceptional performance. Don’t compromise on quality; choose our stainless steel solutions and see the impact they can make in your project. Contact Daxun today for additional information or to place an order for the stainless steel coil specs and quantities that you require.

Dados

- Parâmetro

- Elemento

- Propriedades mecânicas

- PROPRIEDADES FÍSICAS

- Todos os equivalentes

- 304 coil stock

| SS321 Stainless Steel Coil Specification | ASTM A240 / ASME SA240 |

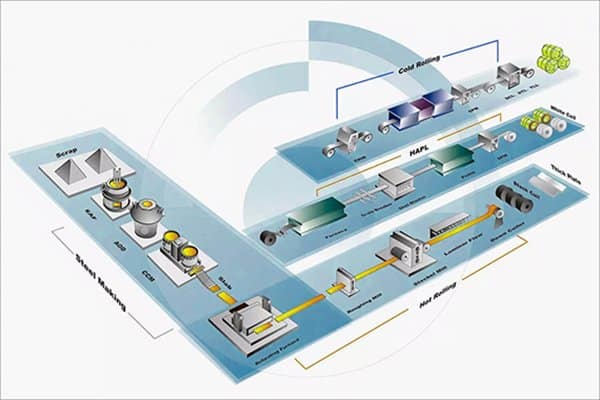

| SS321 Stainless Steel Coil Manufacturing Process | Hot Rolled (HR) / Cold Rolled (CR) |

| SS321 Stainless Steel Coil Grades | 202 / SS321 / SS321L / SS321H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. |

| UNS No. – UNS SSS32100, UNS SSS32103, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| EN No. – 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| SS321 Stainless Steel Coil Thickness | 0.6 MM TO 80 MM THICKNESS |

| SS321 Stainless Steel Coil Width | 1250 MM / 1500 MM / 2000 MM / 04 Feet / 05 Feet and Custom Cut Width as Per Requirement |

| SS321 Stainless Steel Coil Length | 2400 MM / 2420 MM / 6000 MM / 08 Feet / 10 Feet / Coil Cut and Custom Cut Length as Per Requirement |

| SS321 Stainless Steel Coil Surface Finish | 2B, 2D, BA, MATT, MATT PVC, No.4, No.5, SB, HR, No.8, Mirror, Hairline, Brush, Textured, Oil base wet Polished, Both sides Polished available. |

| SS321 Stainless Steel Coil Coating | PVC coating Normal / Laser, Film: 100 micrometer, Color: black/white. |

| SS321 Stainless Steel Coil Other Testing | NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, etc. |

| SS321 Stainless Steel CoilValue Added Services | Gas Cutting / CNC Plasma Cutting / Profiling / Rolling / Bending / Sheet Metal Fabrication / Drill / Punch / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| SS321 Stainless Steel Coil Packaging | Loose / Carrate / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps |

| SS321 Stainless Steel Coil Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| SS321 Stainless Steel Coil Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC |

| Manufacturer | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO,Arcelor Mittal, VDM,Nippon Metal, Outokumpu,Qingshan,Delong. |

| Shipping Port | Shanghai/Ningbo port/Tianjin/Qindao |

| Elemento | Type 321 | Elemento | Type 322 | Elemento | Type 323 | Elemento | Type 324 |

| Carbono | 0.08 max. | Carbono | 0.09 max. | Carbono | 0.10 max. | Carbono | 0.11 max. |

| Manganese | 2.00 max. | Manganese | 2.01 max. | Manganese | 2.02 max. | Manganese | 2.03 max. |

| Sulfur | 0.030 max. | Sulfur | 0.031 max. | Sulfur | 0.032 max. | Sulfur | 0.033 max. |

| Phosphorus | 0.045 max. | Phosphorus | 0.046 max. | Phosphorus | 0.047 max. | Phosphorus | 0.048 max. |

| Silicon | 0.75 max. | Silicon | 0.76 max. | Silicon | 0.77 max. | Silicon | 0.78 max. |

| Chromium | 17.00 – 19.00 | Chromium | 17.00 – 19.01 | Chromium | 17.00 – 19.02 | Chromium | 17.00 – 19.03 |

| Nickel | 9.00 – 12.00 | Nickel | 9.00 – 12.01 | Nickel | 9.00 – 12.02 | Nickel | 9.00 – 12.03 |

| Titânio | 5x(C+N) min. – 0.70 max. | Titânio | 5x(C+N) min. – 0.71 max. | Titânio | 5x(C+N) min. – 0.72 max. | Titânio | 5x(C+N) min. – 0.73 max. |

| Nitrogénio | 0.10 max. | Nitrogénio | 0.11 max. | Nitrogénio | 0.12 max. | Nitrogénio | 0.13 max. |

| Tipo | Resistência ao escoamento 0.2% offset (KSI) | Resistência à tração (KSI) | % Elongation (2″ Gauge length) |

| 321 | 30 min. | 75 min. | 40 min. |

| Densidade (lb./in^2) @ RT | 0.29 | |

| Módulo de elasticidade em tensão (psi x 10^6) | 28 | |

| Calor específico (BTU/o F/lb.) | 32 a 212 oF | 0.12 |

| Condutividade térmica (BTU/hr/ft^2/ft) | 212oF | 9.3 |

| 932oF | 12.8 | |

| Coeficiente médio de expansão térmica (pol. x 10^-6 por o F) | 32 a 212oF | 9.2 |

| 32 a 600oF | 9.5 | |

| 32 a 1.000oF | 10.3 | |

| 32 a 1.200oF | 10.7 | |

| Resistividade eléctrica (micro ohms - cm) | a 70oF | 28.4 |

| Gama de pontos de fusão (oF) | 2500 – 2550 |

| PADRÃO | WERKSTOFF NR. | UNS | JIS | CHINA | BS | GOST | PT |

| SS 321 | 1.4541 | S32100 | SUS 321 | 06Cr18Ni11Ti | - | - | - |

| Tisco Stainless Steel 321 coil | • 321 Stainless Steel B. Q. Profile coil |

| • SS 321 Perforated coil | • Best selling 4’x8′ mirror finished ss 321 coil |

| • Stainless Steel 321 UNS S31635 coil | • Decorative hairline inox cold rolled ss 321 coil |

| • A 240 Chequered 321 coil | • Hair Line Finish SS 321 coil |

| • Aperam Stainless Steel 321 coil | • Laser cutting ss 321 coil |

| • Stainless Steel 321 coil | • Tisco Supplier 3mm Thickness Stainless Steel 321 coil |

| • A 240 321 coil | • Decorative Stainless Steel 321 coil |

| • SS 321 Embossed coil | • Scotch Brite SS 321 coil |

| • Outokumpu SS 321 coil | • Baosteel Stainless Steel 321 coil |

| • SA 240 321 stainless steel coil | • Stainless Steel Cladding 321 coil |

| • Bright Hammered Pattern Decorative SS 321 coil | • Black SS 321 coil 4mm Thick |

| • Stainless Steel 321 coil | • Bright-pickled Stainless Steel 321 coil |

| • SS DIN 1.4571 coil | • Cold rolled, heat treated 321 coil |

| • ThyssenKrupp Stainless Steel 321 coil | • 3mm Cold Rolled AISI SS 321 coil |

| • ASTM A240 Stainless Steel 321 coil | • Mill Supply SS 321 coil |

| • Surface Polishing SS 321 coil | • Grade Prime SS 321 coil |

| • 321 Stainless Steel HR coil | • Carpenter Custom 450 Stainless Steel 321 coil |

| • 321 Stainless Steel Chequered coil | • Cut to Size Stainless Steel 321 coil |

| • 321 Stainless Steel Golden Laser Pattern coil | • Non Magnetic Polishing Stainless Steel 321 coil |

| • Super thin-Mirror surface BA ss 321 coil | • ASME SA240 321 coil |

| • Super Austenitic SS 321 coil | • 321 Stainless Steel Blank coil |

| • ASTM A240 321 coil | • 321 Stainless Steel Perforated coil |

| • JMSS cold rolled ss 321 coil | • Embossed ss 321 coil |

| • Cold Rolled No.1 Finish SS 321 coil | • Cheap cold rolled ss 321 coil with best price |

| • SEW 400 Stainless Steel 321 coil | • Brush finish ss 321 coil price list |

| • Hot Rolled Stainless Steel 321 coil | • SS URANUS B6 321 coil |

| • Sales Promotion SS 321 coil | • 2B SUS SS 321 coil |

| • Cr Stainless Steel 321 coil | • Food Grade Stainless Steel 321 coil |

| • SS 321 Mill Test Certificate coil | • No. 4 PVC Coated SS 321 coil |

| • ASTM A240 321 coil | • SS 321 coil Blasted Tin-Gold Rose |

| • Cold rolled, bright annealed 321 coil | • 2mm ASTM SS 321 coil |

| • Ground Stainless Steel 321 coil | • Stainless Steel Corrugated 321 coil |

| • Hot Selling AISI SS 321 coil | • ASTM B625 321 coil |

| • SS 321 Rose Golden coil | • Brushed or dull polished Stainless Steel 321 coil |

| • Surface coated Stainless Steel 321 coil | • Cold rolled, heat treated, pickled 321 coil |

| • Satin finish Stainless Steel 321 coil | • 10K Mirror Finish Surface SS 321 coil |

| • AISI stainless steel 321 armor coil | • Gold Etched SS 321 coil |

| • Satin finish Stainless Steel 321 coil | • 18 Gauge SS 321 coil |

| • Mirror Finish SS 321 coil | • Patterned Stainless Steel 321 coil |

| • SS 321 coil Gold Brush Finish | • #4 Finish Stainless Steel 321 coil |

| • 321 Stainless Steel CR coil | • Patterned Stainless Steel 321 coil |

| • 321 Stainless Steel 2B coil | • Passenger Elevator Cabin SS 321 coil |

Escolha a Daxun e deixe os seus clientes satisfeitos.

Resposta rápida

Fornecemos entrega atempada e rápida de produtos de aço inoxidável para clientes com necessidades urgentes. Por detrás da velocidade está o sistema de apoio, desde o fluxo de informação até à logística e ao fluxo de capital. Por exemplo, em termos de fluxo de informação, os dados das encomendas da Daxun são enviados para o sistema de logística em tempo real, e os dados estão perfeitamente ligados; em termos de logística, o centro de processamento está perto de auto-estradas, rios e mares, com uma programação razoável, resposta rápida, armazenamento e ligação de transporte, e carregamento eficiente, garantindo que a tarefa é concluída dentro do prazo.

Vantagens da Daxun

Quality is belief, and integrity is a business card. Daxun pioneered the concept of “performance excellence management” and implemented the “PDCA+Lean” management model. The company’s business card says “Daxun = assured quality”. Daxun Stainless Steel achieves full traceability of each steel coil from the ERP system, including variety, specification, and origin, and advocates and encourages industry anti-counterfeiting. Daxun Stainless Steel relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strict monitoring during sales, and provides worry-free service guarantees after sales.

Stainless steel coil packaging

A Daxun Alloy assegura a melhor qualidade de embalagem, uma vez que esta desempenha um papel importante no transporte internacional de mercadorias, onde as mercadorias passam por vários canais para chegar ao destino final, pelo que prestamos especial atenção à embalagem. Embalamos os nossos produtos de várias formas, consoante o produto. Embalamos os nossos produtos de várias formas, tais como:

- Caixas e caixotes

- Película retrátil

- Paletes de madeira

- Caixas de madeira

Qualidade, entrega, inspeção

- Daxun also conducts several quality assurance tests. These tests include flattening test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the material is suitable for the required application.

- During the production process, we measure the diameter, thickness, and surface of the product. Our standard delivery time is 7-15 days, except for some special size products, our delivery time will increase to 20 days.

O nosso prazo de entrega está estritamente de acordo com o contrato. - Apoio a agências terceiras do cliente para se deslocarem à fábrica para inspeção

- Apoio a amostras gratuitas aos clientes para testes

- Apoio à inspeção de fábrica no local ou por vídeo

Informações para encomenda

As ordens de compra devem incluir quantidade, grau, tipo ou categoria, referência API5L, espessura, largura, comprimento e quaisquer anexos aplicáveis ou requisitos adicionais relacionados com a composição química, propriedades mecânicas, tratamento térmico, testes adicionais, processo de fabrico, revestimento de superfície ou acabamento final. Contacte Daxun agora, nós responderemos ao seu e-mail o mais rápido possível.

Apoio técnico

Se necessitar de qualquer assistência técnica adicional, o nosso metalúrgico residente e a nossa equipa experiente terão todo o prazer em ajudar. Além disso, a Daxun possui um laboratório de testes certificado - o primeiro na indústria de inventário de multi-metal e plástico. Isto, na nossa opinião, demonstra a nossa dedicação inabalável à qualidade e a nossa filosofia como um fornecedor de serviço completo.

SS 321 Stainless Steel Coil Features

Daxun Alloy Deixe a sua marca melhorar rapidamente

- Galeria

- Product Series

- Main Equipment

| Grau | Tipo | Espessura | Superfície |

| Austenítico | 304/304H/304L/304J1 | 0,25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0,3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferrite | 430 | 0,4-3,0 mm | 2B/BA/NO.4/8K/SB/HL |

| Ferrite ultra-puro | 443 | 0,4-2,0 mm | 2B |

| 436L/439/444/441 | 0,5-3,0 mm | 2B、2D | |

| 409L | 0,4-2,5 mm | 2B、2D | |

| Aço superaustenítico | N08904 | 0,6-50mm | SWE / JPN / CHN |

| S31254 | 0,5-50mm | SWE / JPN / CHN | |

| N08926 | 0,5-50mm | SWE / JPN / CHN | |

| N08367 | 0,5-50mm | SWE / JPN / CHN | |

| Liga à base de níquel | N08031 | 1.0-50mm | EUA / JPN / GER |

| N08810/N08800 | 0,8-50mm | EUA / JPN / CHN | |

| N08028 | 1,0-20mm | EUA / GER / JPN | |

| N08020 | 1,0-20mm | EUA / GER / JPN | |

| N08825 | 0,8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50mm | EUA / GER / JPN | |

| N06022 | 1.0-50mm | EUA / GER / JPN | |

| N06625 | 0,8-20mm | EUA / GER / CHN | |

| N04400 | 1,0-20mm | EUA / GER / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20mm | EUA / JPN | |

| Titânio | TA1/Gr1 | 0,5-50mm | JPN / CHN |

| TA2/Gr2 | 0,5-50mm | JPN / CHN | |

| Material de soldadura | ERNiCrMo-13 | 1.2、2.4mm | ALEMANHA |

| ERNiCrMo-3 | 2,4 mm | ALEMANHA | |

| ERNiCrMo-4 | 2,4 mm | EUA |

| Subsidiary | Main Equipments | Qty | Annual Capacity |

| Daxun Stainless steel co.(JiangSu) | Slitting Machine | 1 | Decorative Sheet:60,000 tons |

| Cutting Machine | 1 | ||

| No.4 And Hairline Sheet To Sheet Polishing Machine | 1 | ||

| No.4/Hairline Coil To Coil Polishing Machines | 1 | ||

| 8K/Super Mirror Sheet To Sheet Polishing Machines | 2 | ||

| 8K/Super Mirror Coil To Coil Polishing Machines | 3 | ||

| PVD Color Coating Machines | 4 | ||

| Liquid Chemical Coating Machines | 2 | ||

| Anti Finger Printing Machines | 2 | ||

| Auto Pick and Place machines | 16 | ||

| coil Washing Machine | 1 | ||

| Daxun Stainless steel co.(Shanghai) | Cold Rolling Machine | 3 | 2B Coils:100,000 tons |

| Annealing & Pickling Line | 2 | Decorative Sheet;30,000 tons | |

| Slitting Machine | 1 | ||

| Cut to Length Machine | 1 | ||

| No.4/HL Polishing Machine(Sheet to Sheet) | 3 | ||

| 8K Polishing Machine(Sheet to Sheet) | 13 | ||

| PVD Titanium Coating Machine | 4 | ||

| Liquid Chemical Coating Machines | 1 | ||

| Daxun Stainless steel co.(Shandong) | Cold Rolling Machine | 3 | 2B & BA Coil:220,000 tons |

| Annealing & Pickling Line(2B & BA) | 2 | Decorative Sheet:60,000 tons | |

| Tension Levering & Skin Pass | 1 | ||

| Slitting Machine | 1 | ||

| Cut to Length Machine | 1 | ||

| No.4/HL Polishing Machine(Sheet to Sheet) | 1 | ||

| 8K Polishing Machine(Sheet to Sheet) | 11 | ||

| Automatic Copper Coating Machine | 1 | ||

| Digital Printing Machine | 1 | ||

| PVD Titanium Coating Machine | 3 | ||

| Liquid Chemical Coating Machines | 1 | ||

| Anti-finger Machine | 1 | ||

| Daxun Stainless steel co.(Sichuan) | Slitting Machine | 1 | 2B & BA Coil:180,000 tons |

| Cutting Machine | 1 | Decorative Sheet:50,000 tons | |

| No.4 And Hairline Sheet To Sheet Polishing Machine | 1 | ||

| No.4/Hairline Coil To Coil Polishing Machines | 1 | ||

| 8K/Super Mirror Sheet To Sheet Polishing Machines | 1 | ||

| 8K/Super Mirror Coil To Coil Polishing Machines | 1 | ||

| PVD Color Coating Machines | 1 | ||

| Liquid Chemical Coating Machines | 1 | ||

| Anti Finger Printing Machines | 1 |

SS 321 Surface Types of Stainless Steel Coils (6)

Informações disponíveis para consulta e descarregamento

Daxun is a trustworthy stainless steel coil manufacturer

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless steels are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the stainless steel coils have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

Produtos e projectos recentes de casos quentes

Produtos relacionados (10)

Leading stainless steel coil Suppliers in China

Daxun has been engaged in international business for more than ten years. In 2023, its export revenue exceeded US$100 million, and its export volume ranked among the top Chinese stainless steel manufacturers. Daxun continues to improve its service skills. In order to serve the global market, we have established three export service facilities in China and cooperated with engineering enterprises, steel mills and international trading companies. Daxun provides stainless steel chain services and has established long-term cooperative relationships with dozens of well-known steel mills around the world. Its inventory includes 50,000 tons of conventional stainless steel coils and 20,000 tons of duplex steel, nickel-based alloys, heat-resistant steel and other metals. Daxun’s stainless steel materials are of consistent quality. Types, specifications and delivery weights strictly comply with standards.

What are 321 stainless steel coils?

- 321 stainless steel coil is a low-carbon austenitic stainless steel that is resistant to a wide range of corrosive conditions. 321 has great weldability, acceptable machinability, and exceptional manufacturing qualities.

- 321 stainless steel coil is widely utilized in the chemical, pulp & paper, marine, and offshore engineering sectors, as well as the food and beverage industries.

- 321 stainless steel coil is also very resistant to chloride stress corrosion, cracking, and pitting. It is also resistant to hydrochloric acid at temperatures as high as 250°C (480° F).

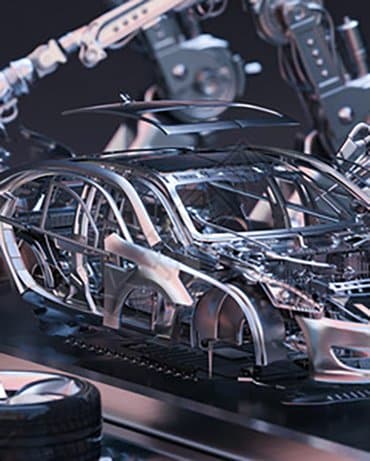

What applications can 321 stainless steel coils be used in?

- 1. Pipeline for burning of petroleum waste gas.

2. Engine Exhaust Pipe

3. Boiler shell, heat exchanger, and heating furnace components

4. Silencer components for diesel engines.

5. Boiler Pressure Vessel

6. Chemical transfer truck.

7. Expansion Joint

8. Spiral-welded pipes for furnaces and dryers

Features of 321 Stainless Steel Coils

- Good Corrosion Resistance: 321 stainless steel coil offers higher corrosion resistance than 304 and 316 stainless steels, making it perfect for usage in corrosive settings.

- Excellent Weldability: 321 stainless steel coil may be welded using any method, including arc welding (TIG/GTAW), electron beam welding (EBW/EFW), submerged arc welding (SAW), and laser beam welding (LBIW).

- High Strength: Because of their enhanced carbon content and austenite grain size, 321 stainless steel coils have strength levels that are up to 50% greater than 304 stainless steels and up to 80% higher than 316 stainless steels.

PROCESSING:

- Type 321 cannot be hardened through heat treatment. Annealing: Heat to 1750-2050°F, then cool with water or air. Forming: Type 321 is easily created and drawn. Like other austenitic stainless steels, Type 321 work hardens and may necessitate annealing after harsh shaping.

WELDING:

- This alloy welds similarly to Types 304 and 304L. A significant distinction is the titanium additive, which minimizes or eliminates carbide precipitation during welding. When a filler is required, either AWS E/ER 347 or E/ER 321 is most commonly specified.

CORROSION:

- Type 321 is highly resistant to organic chemicals, dyes, and inorganic compounds. It is resistant to nitric acid and sulfur acids to varying degrees. Long-term exposure in the 900-1500°F range may reduce its overall corrosion resistance, but the grade remains more resistant to intergranular corrosion than unstabilized grades.

What are the commonly used surfaces of stainless steel coils?

The surface finish of 201 stainless steel coil might vary depending on the cold rolling processing methods used and the surface treatment used after rolling. Surface treatments for stainless steel coils include NO.1, 2B, 4, HL, 6, 8, BA, TR hard, heavy rolling bright 2H, polished bright, and other surface treatments:

- NO.1: The surface obtained after hot rolling, heat treatment and pickling of stainless steel strip. It is used to remove the black oxide scale formed by pickling or similar processes during hot rolling and heat treatment. It ranks first in surface treatment. The No. 1 surface is silvery white and matte. It is generally used in heat-resistant and corrosion-resistant industries that do not require high surface gloss, such as the alcohol industry, chemical industry, large containers, etc.

- 2B: Unlike the 2D surface, the 2B surface is smoothed by a light roller, and the surface is brighter. The surface roughness Ra value measured by the equipment ranges from 0.1 to 0.5μm, which is a typical value for most processing types. This stainless steel strip surface has the strongest adaptability and is suitable for industries such as chemical, papermaking, petroleum, medical, and a wide range of fields such as building curtain walls.

- TR hard surface: TR stainless steel is also called hard steel. Its characteristic steel grades include 304 and 301, which are used for items that require high strength and hardness, such as railway vehicles, conveyor belts, springs and washers. The idea is to use the work hardening characteristics of austenitic stainless steel to improve the strength and hardness of steel coils through cold working methods such as rolling. In order to replace the gentle flatness of the 2B base surface, the hard material is gently rolled by a few percent to tens of percent, and no annealing is performed after rolling. Therefore, the TR hard surface of the hard material is the rolled surface after the cold rolling process.

- Re-rolled bright 2H: After the rolling operation, the stainless steel strip will be bright annealed. A continuous annealing line can be used to quickly cool the strip. The stainless steel strip travels along the line at a speed of 60-80m/min. After this process, the surface finish will be 2H re-rolled bright.

- No. 4: The No. 4 surface has a good polishing effect and is brighter than No. 3. It can also be obtained by polishing the cold-rolled stainless steel coil with a 2D or 2B surface, and then polishing the processed surface with a sanding belt with a particle size of 150-180#. The tool measures the surface roughness (Ra) between 0.2 and 1.5μm. The No. 4 surface is widely used in restaurants and cooking equipment, medical equipment, architectural decoration, containers and other applications.

- HL: The HL surface is often called a hairline finish. The Japanese JIS standard specifies a continuous hairline abrasive surface obtained by polishing with a 150-240# abrasive belt. The restrictions under the Chinese GB3280 standard are unclear. HL surface finish is commonly used for architectural decoration, such as elevators, escalators, and exterior walls.

- No. 6: The No. 6 surface is further polished on the basis of No. 4 with a Tampico brush or a W63 grit abrasive material specified in the GB2477 standard. The surface has good metallic luster, softness, weak reflection, and no imaging. Due to its good performance, it is very suitable for curtain walls, tassel decoration, and cooking supplies.

- BA: BA is a surface that is brightly heat treated after cold rolling. Bright heat treatment is annealing in a protective atmosphere to ensure that the surface is not oxidized and retain the gloss of the cold-rolled surface, and then it is polished with a high-precision smooth roller to improve the surface brightness. The instrument evaluates the surface roughness to be 0.05-0.1μm, indicating that the surface is close to a mirror surface. BA surfaces can be used in a variety of applications, including food utensils, household appliances, medical equipment, automotive parts, and decorations.

- No. 8: Mirror surface, maximum reflectivity, no abrasive particles. The stainless steel deep processing industry also refers to 8K board. BA material is often used as raw material for mirror processing. It only needs to be polished. The surface is beautiful after mirror processing and is often used in building entrances and interior decoration.

What is the standard sea packaging stainless steel coil?

- Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

Eye to wall and eye to sky are both available; - By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air, sea or land;

- Shipping Port: Shanghai, Ningbo, Qingdao, Tianjin or as your request.

Why choose Daxun’s stainless steel coils?

Reliable Stainless Steel Coils and Sheets Inventory Guarantee

- Have you ever been in a situation where you required a significant quantity of stainless steel coils right away, only to discover that the supplier was running low on stock? This condition may impair your workflow and plans.

- Our Advantages: With us, this situation will be a thing of the past. Our inventory is always ample, guaranteeing that even the largest orders are fulfilled quickly and in accordance with your business schedule.

Custom Stainless Steel Material Processing

- You may have experienced a circumstance in which bespoke processing is required, but locating the correct supplier to match your exact requirements might be difficult.

- Our Advantages: We have great processing capabilities to satisfy any of your specific needs. Whether it is size, stainless steel surface treatment, or other unique requirements, we offer expert one-stop service.

Competitive Stainless Steel Prices

- When looking for a stainless steel coil provider, price is typically a major factor. You may have to make a compromise with your chosen supplier due to excessive costs.

- Our Advantages: We keep pricing low by implementing excellent cost control and improved sourcing methods. This implies that by choosing us, you will not only receive high-quality products but also outstanding value for money.

Various Specifications of Stainless Steel Coils in Stock

- Finding stainless steel coils with exact specifications might be a challenge. It is critical to select a supplier who understands and serves these specific needs.

- Our Advantages: Our portfolio demonstrates versatility, with a wide choice of materials, thicknesses, and widths. We take pleasure in our ability to satisfy your project’s exact specifications.

Precision Stainless Steel Shearing Service.

- Precision shearing is required for the usage of stainless steel coils, but not all vendors offer this precise service.

- Our Advantages: Our shearing service is both professional and efficient, delivering precise cuts that fit your exact demands.

Contact your stainless steel coil suppliers

- You can easily order stainless steel coils in any size and quantity online.

Alternatively, our friendly sales team will be happy to take your order. Simply call +86 13382898899 or email Daxunhejin@gmail and we will get back to you as soon as possible.

Please fill in the form on the “Contact Us” page, or call our sales manager at “+86 13382898899”, we will contact you as soon as possible. Our WhatsApp is online, and email ([email protected]) will be checked within 6 hours. Every inquiry or message will be responded to promptly. In addition, we share market information with our customers every week

As amostras podem ser fornecidas gratuitamente, mas o frete é suportado pelo cliente e será reembolsado após cooperação.

Exportámos para mais de 42 países, como o Canadá, Chile, Kuwait, Alemanha, Coreia do Sul, Arábia Saudita, Singapura, etc.

Our MOQ is 1 ton for stainless steel coil.

We have a complete organization from raw material purchasing to processing and shipment arranging. In the whole chain, the documentary people ad QC will look for and check it by precise requirements.The third party inspection is welcomed.

As encomendas de teste podem ser entregues no prazo de uma semana. Para as encomendas normais, são necessárias cerca de duas semanas.