Daxun is a 310S stainless steel sheet supplier from China

As China’s leading stainless steel plate supplier and exporter, Daxun provides 310S stainless steel plates to the world.

- Grade: AISI 310-310S-S31008

- Fabrico: chapa laminada a frio, chapa laminada a quente, chapa forjada

- Standard: ASTM, ASME, GB, DIN, JIS, ISO, EN, BS

- Tipo: chapa fina laminada a frio, chapa grossa laminada a quente

- Superfície: 2B, NO.1, NO.4, HL, BA, 8K, etc.

- Comprimento: 2438mm3048mm6000mm pode ser personalizado

- Origin: TISCO, Baosteel, Pohang, Tsingshan, Delong

The global leader in stainless steel sheet fabrication services

S31008 (310S) Sheet and Plate, Austenitic stainless steel alloy 310S (UNS S31008) is designed for applications requiring high-temperature corrosion resistance. The alloy resists oxidation up to 2010°F (1100°C) with room temperature cycling. Alloy 310 can be used in moderate carburizing environments and is resistant to sulfidation due to its high chromium content and moderate nickel content. More severe carburizing environments in heat-treating equipment typically require a nickel alloy such as 330 (UNS N08330). Alloy 310S can be used in bonding, nitriding, mild oxidation, and thermal cycling processes; however, a reduced maximum service temperature is required. Alloy 310 can also be used in cryogenic applications because it has low magnetic permeability and remains strong down to -450°F (-268°C). When heated to 1202–1742, the alloy precipitates the sigma phase (650–950°C). Hardness is partially restored by solution annealing at 2012–2102°F (1100–1150°C). This alloy is also available as a low-carbon alloy, 310S (UNS S31008). It is easily fabricated. A high carbon modification, 310H (UNS S31009), is designed to improve creep resistance. In most cases, the grain size and carbon content of the plate can meet both 310S and 310H standards. Standard shop fabrication procedures can be used to easily weld and process alloy 310.

Stainless Steel 310S Plate has trace amounts of silicon, sulfur, phosphorus, manganese, and up to 24% chromium, 19% nickel, and up to 0.08% carbon. Heat resistance, corrosion resistance, strength, and even high-temperature oxidation resistance are just a few of the many benefits of this popular stainless steel alloy. It can be utilized in many different applications, including burners, oil burners, and evaporator pipes and tubes. Because of its affordability, it’s perfect for a range of applications requiring low-cost maintenance supplies.

Because of its exceptional resilience to high temperatures, the 310S stainless steel plate is a great option for a wide range of industries, including petrochemical and chemical production, food processing, power plants, dairy farms, sugar mills, breweries, and energy generation. 310S Stainless Steel Plate is capable of withstanding oxidizing environments up to 2100°F (1149°C) due to its high chromium concentration. Its ductility, toughness, and weldability are all excellent. Its exceptional low-temperature performance, even down to -20°F (-29°C), combined with its resistance to heat and corrosion make it the perfect material for cryogenic applications. In conclusion, it is an excellent option for high-temperature industrial applications due to its strong resistance to oxidation and ability to prevent scaling at temperatures as high as 2000°F (1093°C).

Dados técnicos

- Parâmetro

- Elemento

- Propriedades mecânicas

- Padrão

| Product Parameters: 310(UNS S31008) Stainless Steel Sheet/Plate | |||

| Largura | 10mm~2500mm | ||

| Espessura | 0.2mm~100mm | Thickness tolerance | +/-0.03mm |

| Padrão | ASTM/ASME 240/480,JIS 4305,DIN EN 10088-2 | ||

| Superfície | 2B,BA,8K,NO.1,NO.4,NO.3,hairline,checkered,gold ,black ,rose gold,etc | ||

| specification | 1000*2000/L,1219*2438/L,1250*2500/L,1500*3000/L1500*6000/L,1800*6000/L,2000*6000/L2200*6000L | ||

| Mill Origin | TISCO, ZPSS, BAOSTEEL, JISCO, ZSESS, ATI, SMC, HAYNES, VDM, ArcelorMittal, Outokumpu, etc. | ||

| Certification | ISO, SGS, BV, TUV,CE etc | ||

| Elemento | % Present (in product form) | |

| C, H, P, L | TW* / TS* | |

| Carbono (C) | ≤0.10 | ≤0.15 |

| Silício (Si) | ≤1.50 | ≤0.75 |

| Manganês (Mn) | ≤2.00 | ≤2.00 |

| Fósforo (P) | ≤0.045 | ≤0.045 |

| Enxofre (S) | ≤0.015 | ≤0.030 |

| Crómio (Cr) | 24.00 – 26.00 | 24.00 – 26.00 |

| Níquel (Ni) | 19.00 – 22.00 | 19.00 – 22.00 |

| Azoto (N) | ≤0.11 | - |

| Ferro (Fe) | Equilíbrio | Equilíbrio |

| Product Form | |||||

| C, H, P | L | TW* / TS* | |||

| Thickness a or diamter d (mm) | a ≤ 12 | d ≤ 25 | - | ||

| Hardness HB max. 1) 2) 3) | 192 | 192 | - | ||

| Proof Strength3) | Rp0.2 N/mm2 | 210 | 210 | 230 | |

| Rp1.0 N/mm2 | 230 | 230 | 270 | ||

| Resistência à tração | Rm N/mm2 | 500 – 700 | 500 – 700 | min. 500 | |

| Elongation min. in % | Long Products | 351) | 351) | 334) / 355) | |

| Produtos planos | 0.5 ≤ a/d < 3 | 334)5) | 334)5) | 354)5)6) | |

| 3 ≤ a/d | 354)5) | 354)5) | 354)5)6) | ||

| 310 | 310S | 310H |

|---|---|---|

| UNS S31000 | UNS S31008 | UNS S31009 |

| ASTM A240 | ASTM A240 | ASTM A240 |

| ASTM A480 | ASTM A480 | ASTM A480 |

| ASME SA240 | ASME SA240 | ASME SA240 |

| AMS 5521 | AMS 5521 | AMS 5521 |

Escolha a Daxun e deixe os seus clientes satisfeitos.

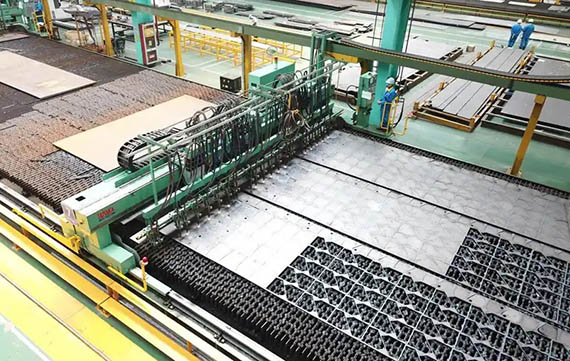

Entrega rápida

We provide timely and fast delivery of 310S stainless steel plate products for customers with urgent needs. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real-time, and the data is seamlessly connected; in terms of logistics, the processing center is close to highways and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on time.

Benefits of Stainless Steel 310S Plates :

- Corrosion resistance: The main benefit of 310S stainless steel plates is their excellent corrosion resistance. They resist corrosion from a wide range of environments, including acidic and alkaline solutions, making them suitable for a wide range of applications.

- High-temperature strength: 310S stainless steel plates exhibit excellent strength at elevated temperatures. This property is critical in applications that are frequently exposed to high temperatures, ensuring structural integrity and performance in demanding conditions.

- Durability and lifespan: The durability of 310S stainless steel plates gives them a long service life, making them an affordable choice for many applications. The material is resistant to wear and tear, minimizing the need for frequent replacement.

Benefits of Stainless Steel 310S Plates :

310S/2520 Plate Features:

- High-temperature resistance

- Excelente resistência à oxidação

- Improved creep/rupture properties

- Excelente resistência à corrosão

- Not susceptible to thermal fatigue and cyclic heating

- Good strength at temperatures up to 2100°F

Qualidade, entrega, inspeção

- Daxun controla rigorosamente a qualidade do produto. Antes de efetuar uma encomenda, enviar-lhe-emos a garantia do produto ou, se necessitar de amostras para teste, também podemos enviar amostras gratuitamente.

- During the production process, we carefully measure the diameter, thickness, and surface quality of each product to ensure it meets exacting standards. Our standard delivery time is typically 7 to 15 days. However, for special-sized products, the delivery time may be extended to 20 days to accommodate the additional customization and processing required.

O nosso prazo de entrega está estritamente de acordo com o contrato. - Apoio a agências terceiras do cliente para se deslocarem à fábrica para inspeção

- Apoio a amostras gratuitas aos clientes para testes

- Apoio à inspeção de fábrica no local ou por vídeo

Aplicações

- Cryogenic Components: Designed to withstand extremely low temperatures, ensuring optimal performance in critical applications.

- Food Processing: Reliable materials and components tailored for hygienic and efficient food production systems.

- Furnaces: Durable solutions for burners, doors, fans, ducting, and liners, supporting high-temperature industrial processes.

- Fluidized Bed Furnaces: Robust components including coal burners, grates, ducting, and bellows for enhanced operational efficiency.

- Ore Processing and Steel Mills: High-performance equipment for smelting, steelmaking, and continuous casting operations.

- Petroleum Refining: Specialized systems such as catalytic recovery units, flares, heat exchangers, and tube hangers for maximum efficiency in refining processes.

- Power Generation: Precision-engineered components like gas furnace internals, pulverized coal burners, and tube hangers to support energy production.

- Sintering and Cement Plants: Reliable burners, burner hoods, feed and discharge systems, and bellows for seamless operation in harsh environments.

- Heat Treating: Advanced solutions, including annealing covers and boxes, burner grates, doors, fans, muffle furnaces, retorts, heat exchangers, and walking beams for consistent performance in thermal processing.

SS 310S Plate Surface Treatment

1D: The surface is matte with a discontinuous particle shape.

2D: Branco com um tom prateado.

2B: Silver gray with better gloss and flatness than the 2D surface.

Ba: Superfície próxima do espelho com excelente brilho e refletividade.

N.º 3: Bom brilho e superfície rugosa.

N.º 4: A superfície tem linhas finas e bom brilho.

HL: Cinzento prateado com cabelo dourado.

8K: Superfície espelhada.

310 plate stainless steel Features

Daxun Deixe a sua marca melhorar rapidamente

- Galeria

- Tolerância

- Estado de entrega

- Outras séries de produtos

| Tolerância para chapa 2B | |||

| Tamanho | Classificação de tolerância | ||

| Grupo 1 | Grupo 2 | Grupo 3 | |

| 0.4 | 0.3 ~ 0.32 | 0.33 ~ 0.37 | 0.37 ~ 0.39 |

| 0.5 | 0.4 ~ 0.42 | 0.43 ~ 0.47 | 0.47 ~ 0.49 |

| 0.6 | 0.5 ~ 0.52 | 0.53 ~ 0.56 | 0.57 ~ 0.59 |

| 0.7 | 0.6 ~ 0.62 | 0.63 ~ 0.67 | 0.67 ~ 0.69 |

| 0.8 | 0.7 ~ 0.72 | 0.73 ~ 0.77 | 0.74 ~ 0.79 |

| 0.9 | 0.8 ~ 0.82 | 0.83 ~ 0.87 | 0.87 ~ 0.89 |

| 1 | 0.89 ~ 0.9 | 0.91 ~ 0.94 | 0.94 ~ 0.99 |

| 1.2 | 1.02 ~ 1.08 | 1.09 ~ 1.15 | 1.16 ~ 1.18 |

| 1.5 | 1.32 ~ 1.38 | 1.39 ~ 1.45 | 1.46 ~ 1.48 |

| 2 | 1.72 ~ 1.79 | 1.8 ~ 1.86 | 1.87 ~ 1.9 |

| 2.5 | 2.23 ~ 2.36 | 2.32 ~ 2.42 | 1.42 ~ 1.47 |

| 3 | 2.7 ~ 2.77 | 2.78 ~ 2.82 | 2.85 ~ 2.9 |

| Tolerância para chapa laminada a quente n.º 1 | |||

| Tamanho | Classificação de tolerância | ||

| Grupo 1 | Grupo 2 | Grupo 3 | |

| 3 | 2.6 ~ 2.75 | 2.75 ~ 2.85 | 2.86 ~ 2.9 |

| 4 | 3.5 ~ 3.6 | 3.6 ~ 3.75 | 3.76 ~ 3.95 |

| 5 | 4.5 ~ 4.6 | 4.6 ~ 4.75 | 4.75 ~ 4.95 |

| 6 | 5.4 ~ 5.6 | 5.6 ~ 5.75 | 5.75 ~ 5.85 |

| 8 | 7.3 ~ 7.5 | 7.5 ~ 7.65 | 7.65 ~ 7.85 |

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9.6 ~ 9.85 |

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11.6 ~ 11.85 |

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13.6 ~ 13.85 |

| 16 | 15.2~ 15.5 | 15.5~ 15.7 | 15.7~ 16.1 |

| 18 | 17.2~ 17.5 | 17.5~ 17.7 | 17.7~ 18.1 |

| 20 | 19.2~ 19.5 | 19.5~ 19.7 | 19.7~ 20.1 |

| 30 | 29.2~ 29.5 | 29.5~ 29.7 | 29.7-30.1 |

| 40 | 39.2~ 39.5 | 39.5~ 39.7 | 39.7~ 40.1 |

| 50 | 49.2~ 49.5 | 49.5~ 49.7 | 49.7~ 50.1 |

| 60 | 59.2~ 59.5 | 59.5~ 59.7 | 59.7~ 60.1 |

| Entrega Estado Escolha | Estado da superfície |

| Laminados a frio | 2B |

| 2D | |

| BA | |

| Fio de cabelo | |

| N.º 3 | |

| N.º 4 | |

| 6K | |

| 8K | |

| Nota: | |

| 1. Se necessitar de um estado de entrega diferente do acima indicado, por favor confirme connosco. | |

| 2. Em caso de pedido de informação ou de encomenda, agradecemos que nos informe de qualquer requisito adicional não indicado aqui. | |

| Estado de entrega | |

| Entrega Estado Escolha | Estado da superfície |

| Laminados a quente | N.º 1 |

| N.º 3 | |

| N.º 4 | |

| 6K | |

| 8K | |

| Em conserva | |

| Nota: | |

| 1. Se necessitar de um estado de entrega diferente do acima indicado, por favor confirme connosco. | |

| 2. Em caso de pedido de informação ou de encomenda, agradecemos que nos informe de qualquer requisito adicional não indicado aqui. | |

| Grau | Tipo | Espessura | Superfície |

| Austenítico | 304/304H/304L/304J1 | 0,25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0,4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0,3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferrite | 430 | 0,4-3,0 mm | 2B/BA/NO.4/8K/SB/HL |

| Ferrite ultra-puro | 443 | 0,4-2,0 mm | 2B |

| 436L/439/444/441 | 0,5-3,0 mm | 2B、2D | |

| 409L | 0,4-2,5 mm | 2B、2D | |

| Grau | Tipo | Espessura | Original |

| Aço resistente ao calor | 309S | 0,5-40mm | CHN |

| 310S | 0,5-40mm | CHN | |

| Aço duplex | 2101 | 1,5-50 mm | CHN |

| 2304 | 3.0-50mm | CHN | |

| 2205 | 0,5-60mm | CHN | |

| 2507 | 1.0-60mm | SWE / JPN / CHN | |

| Aço superaustenítico | N08904 | 0,6-50mm | SWE / JPN / CHN |

| S31254 | 0,5-50mm | SWE / JPN / CHN | |

| N08926 | 0,5-50mm | SWE / JPN / CHN | |

| N08367 | 0,5-50mm | SWE / JPN / CHN | |

| Liga à base de níquel | N08031 | 1.0-50mm | EUA / JPN / GER |

| N08810/N08800 | 0,8-50mm | EUA / JPN / CHN | |

| N08028 | 1,0-20mm | EUA / GER / JPN | |

| N08020 | 1,0-20mm | EUA / GER / JPN | |

| N08825 | 0,8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0,5-50mm | EUA / GER / JPN | |

| N06022 | 1.0-50mm | EUA / GER / JPN | |

| N06625 | 0,8-20mm | EUA / GER / CHN | |

| N04400 | 1,0-20mm | EUA / GER / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0,5-20mm | EUA / JPN | |

| Titânio | TA1/Gr1 | 0,5-50mm | JPN / CHN |

| TA2/Gr2 | 0,5-50mm | JPN / CHN | |

| Material de soldadura | ERNiCrMo-13 | 1.2、2.4mm | ALEMANHA |

| ERNiCrMo-3 | 2,4 mm | ALEMANHA | |

| ERNiCrMo-4 | 2,4 mm | EUA |

The surface and shape of 310S stainless steel plate (7)

Informações disponíveis para consulta e descarregamento

Daxun é um fabricante confiável de chapa de aço inoxidável

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless steel plates are certified by ISO9001, SGS, CE, OQC and more international quality standards.We also have strict quality control to ensure that the stainless steel plates have less defects. At Daxun, rest assured that all products are durable, high quality and high performance.

Produtos e projectos recentes de casos quentes

Produtos relacionados (13)

Podemos fornecer amostras de chapas de aço inoxidável para que possa verificar a qualidade. A amostra é grátis e o cliente só paga o frete.

Exportámos para mais de 42 países, como o Canadá, Chile, Kuwait, Alemanha, Coreia do Sul, Arábia Saudita, Singapura, etc.

O nosso MOQ é de 1 tonelada para chapas de aço inoxidável.

As encomendas de teste podem ser entregues no prazo de uma semana. Para as encomendas normais, são necessárias cerca de duas semanas.